-

Posts

4,153 -

Joined

-

Last visited

Everything posted by Evan

-

Those go carts are the Hamilton Boys High year 13 metal work project, trademe it littered with them

-

This is a real long term fuck around type hobby and I haven't thought much about the engine management side of things - I've spent more time dreaming about stroking it to a 7.5 litre than anything else. In saying that it will probably end up with a Link batch firing in pairs, so 6 drivers needed. It really is dumb in my opinion that aftermarket ECU manufacturers don't have a model with 12 injector drivers.

-

Barra cylinder heads

-

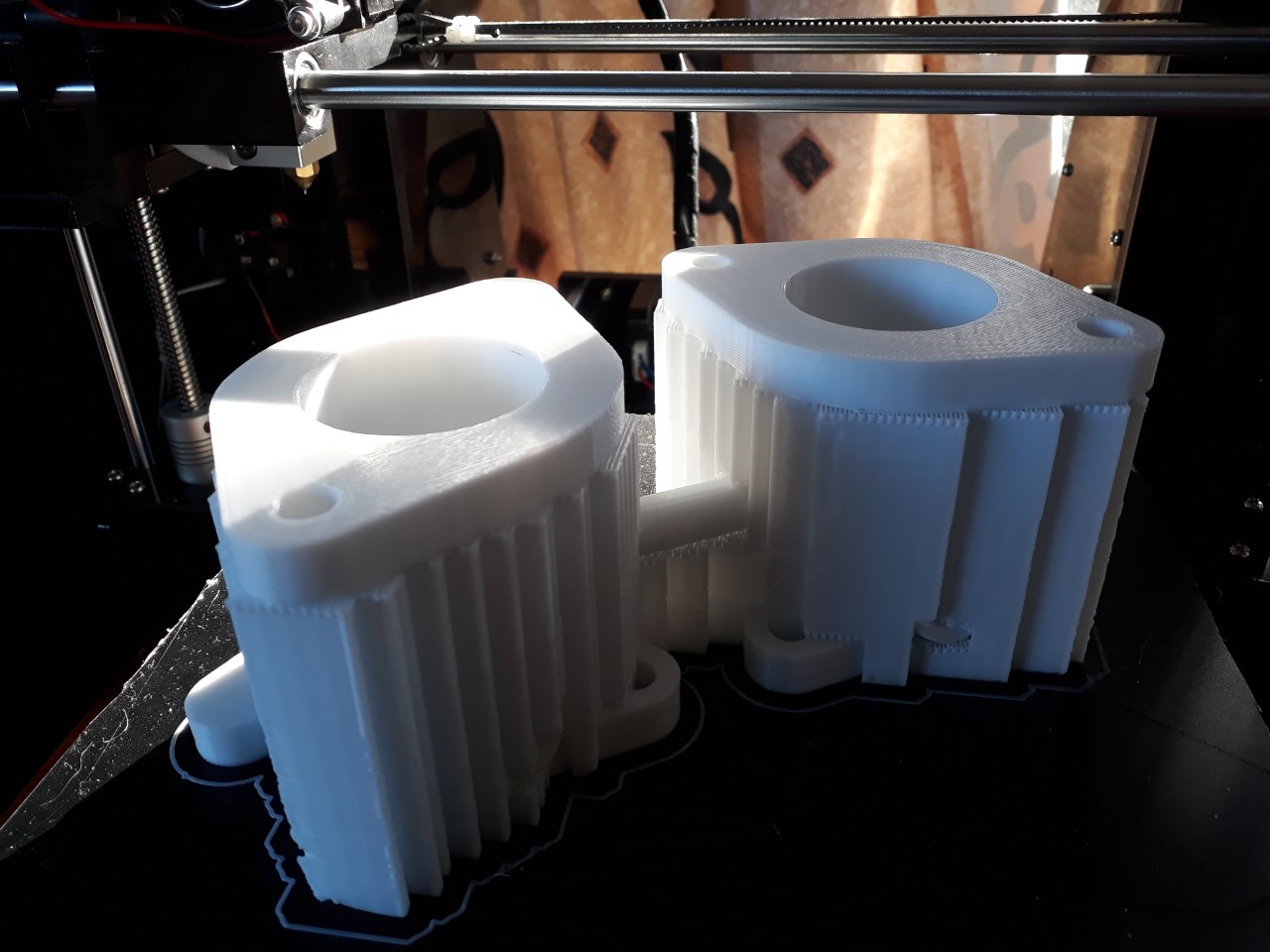

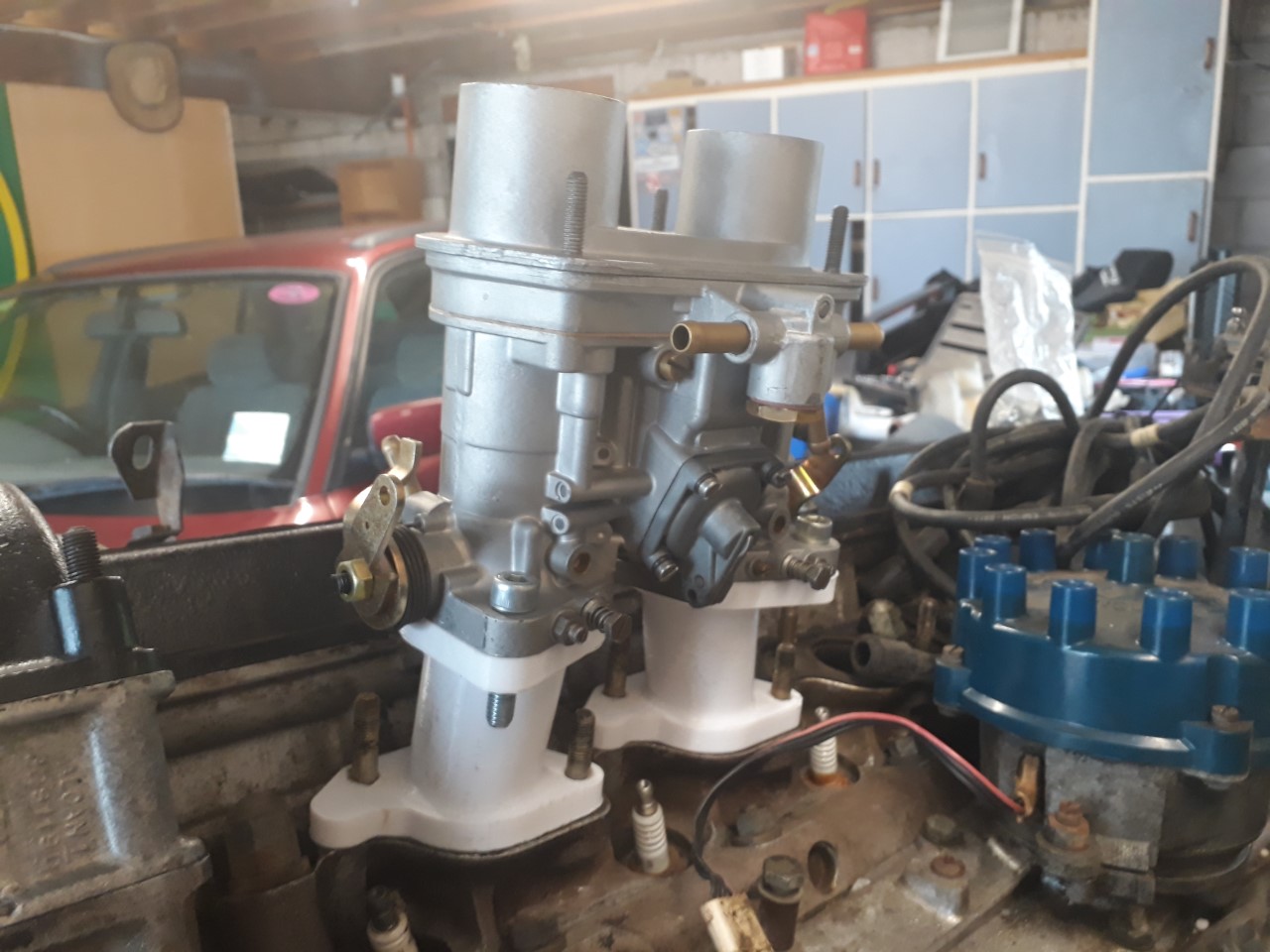

Been fairly busy recently so progress on this has been slow but I have a couple of photos of some things to share with everyone. What seems like an eternity ago Ned talked me into buying a 3D printer off Aliexpress, so that is exactly what I did, I ordered and paid for one Anet A6 3D printer and for some reason two arrived in the mail.... WHOOP. I then set about having a crash course on how to make it make things as I wanted to be able to print the above intakes myself rather than chew up someone elses recreational time. The above model showed one entire bank all joined as one piece, I broke that model into 3 so that it is actually printable given the size/speed of the printer, basically now they are paired so it is one manifold per carb. Because Ned had already printed the earlier version of the intakes for the front two cylinders on the right hand bank I decided to have a go at printing the middle two cylinders, this time as a single joined unit, hoping that my measurements were right. What you see in the next photo took NINE AND A HALF HOURS. I've since learnt that if I print the models upside down from what you see above it takes approx 2 hours off the print time, I think mainly from the need for less support structure. Good to know seeing as there are 5 more to go.... Anyway, chopped all the support structure off (what a prick of a job) and was left with this Now, the big question was, will it fit? is that joining bar the right length???? Hoorah! Next I put the earlier prints on the front 2 cylinders and chucked some carbs on with some appropriately sized bolts to locate the holes to get a feel for where it's going Next I want to print the other 5 'paired' intakes which, after knocking 2 hours off the print time for each one and having 2 printers running simultaneously should only take about 22 hours...fun and games.

- 82 replies

-

- 26

-

-

Think I broke the forum, try that?

-

Also get a load of this for some Carburetor foam. I put up a wanted ad on here for some more 40mm Weber IDF type 13/15s. Someone said there was one on trademe, it's mine now. When I saw the ad I thought it was weird that it had all the caps on the fuel line pipes and on top plate, no matter it's the right type so I brought it. When it showed up I set about pulling it apart so that I can get it vapour blasted like the other 3 I have, the remarkable thing about this one, is that is appears to be brand new, although it is dull and a bit dirty on the outside I don't think this thing has ever had fuel though it. Remarkable for something that is 40 years old, Once I get around to getting it blasted I'll slap it back together and put it next to the other 3. Still on the hunt for another 2 if anyone knows of any.

-

So Mr Vapour let the cat out of the bag earlier on about having the Webers act as throttle bodies with the injectors sitting in the manifolds underneath. Hopefully this gives an illusion of running on carbs when really it isn't. Buying 6 of the Heritage setup shown above would be cheaper (maybe) but where's the fun in that? Also I don't think they do an IDF/IDA style - only a DCOE rep - might be wrong on that one though. So I picked up a lone 'short' injector from NZEFI to get some basic dimensions off and see if things are going to fit. I have concerns about the amount of real estate between the two banks of intake manifolds and whether or not there is enough space to fit 2 rows of injectors and fuel rails, at this stage I think things are going to be ok. That injector is a Siemens 600 and something cc job that should be more than plenty, it's 42mm front to back. Originally I then drew up some injector bosses on the model shown a page or 2 back with the injectors put in at a 90 degree angle to the intake runner, so they are spraying perpendicular to the airflow. not Ideal but at the time I was too scared to try and draw them on an angle because I don't know what I'm doing/ learning as I go. 872463 people said that was dumb so I watched some more youtube videos and redrew it with the injectors pointing down, can't get too carried away with the angle because the wiring plug is going to clash with flange the Weber bolts to So picked a number of 20 degrees from horizontal and called that good enough, also added a bar to tie all the pieces together and give the fuel rail something to bolt to. Have ended up with:

-

I might have to buy a new screw driver for the occasion

-

^ yeah those Heritage injection set ups are the business

-

Barra

-

It's hard to tell in the pics how bad it is. Are you in Auckland? Pull it to pieces and have @Mr Vapour Vapour blast it for you so it looks A+, get a new throttle shaft and bearing set from somewhere on the internet (Ebay, chances are that throttle shaft isn't straight which is making the situation worse). slap it all back together and see how bad it is then - it might be usable as is.

-

- 138 replies

-

- 6

-

-

Can you PM me a $ of what you would charge to cast 12 of these things if I sent you some files of what I want the end result to be?

-

KK, I'm going to refer you to post 1, paragraph 1.

-

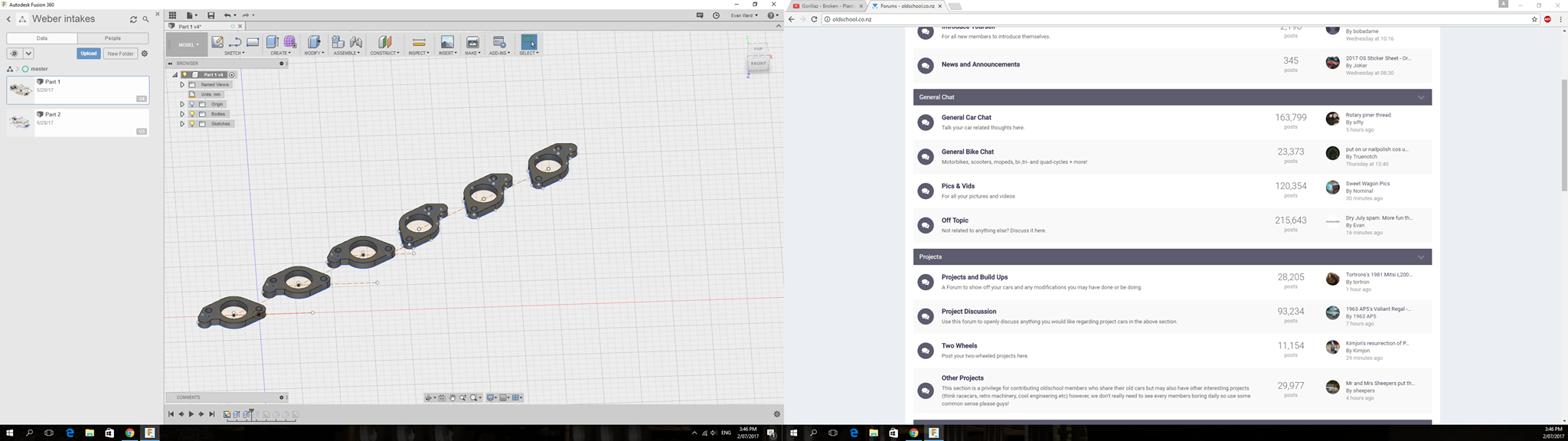

So my problem is that because I havent got any prior knowledge of CAD things I don't know what is officially considered 3D modelling. Like those intakes are just a push/pull extrusion of a 2D sketch right, so is that considered 3D modelling? Fusion does allow you to do animations and join components together and stuff so I'm going to say yes it does.... Not sure re file types. One of it's biggest assets and biggest drawbacks is fusion 360 is cloud based, everything saves to the cloud, however you can export files, haven't looked into what formats though.

-

So, I live with Brocklee Dave, who's good buddies with Rob (I assume it's the same Rob, there can't be that many in the casting world). As far as I know Rob knows about the project from Dave talking to him, however I haven't spoken to Rob directly

-

Now, Will it fit? Well, by crikey, it might just work... Of course it's all good having one side line up, the real test is when #2 is made and whether or not it will simultaneously line up. On the desk it looks plausible. And with some minor filing of the holes on the cylinder head flanges (I haven't fixed the spacing issue with the stud holes) they even fit on the head, with the ID on the intake runner being on the money with the intake port on the cylinder head. It all looks plausible, but just to be sure I drop some bolts of conveniently the right diameter through the holes to see if they line up. Magic, The butterflies open like they should and it appears the intake runner and bottom of the carb line up as they should, not bad for a rookie if I do say so myself.

- 82 replies

-

- 22

-

-

Anyway, back to CAD. When you don't know what you are doing and someone tells you that you need to 'loft' the two holes in the flanges together to make it one part and provide the intake runner, you wonder to yourself, What the fuck is a loft? Google tells you that it is the button that joins 2 shapes on 2 different planes pretty much, cool....where's that button? Found it! (there was a bit of trail and error during this bit while I worked out what the fuck was going on but got there in the end) I then managed, after a couple of hours, to turn two into six. Each one of these is different, no two are the same. Then, again thanks to Ned and his 3D printer, six digital things turned into one real life thing.

- 82 replies

-

- 10

-

-

Bead blasting things yourself is all well and good, but you need an air compressor that can keep up and it can take a bit of time. I saw a guy (Brent) advertising his vapour blasting business on here and thought I'd give that a go. and I tell you what, it's the way to go, paying someone to clean up your mess is just so easy. So the two shitty carbs got his treatment, you can see the before and after here. This has presented a problem though, as the Carb I originally bead blasted myself has a slightly duller finish than the Vapour basted ones, so it will be coming apart tomorrow to get vapour basted, hopefully it comes out looking similar. Kind of hard to tell the differnet in the photo of all 3 lined up, the one on the right being #1, It is duller than the other 2 in person Anyway, If you have grubby stuff that you don't want grubby anymore, I 100% recommend throwing it at Brent http://vapourblastingnz.co.nz/

-

cool, I'll carry on then. So CAD is a prick of a thing if you are a hobbyist, everyone wants $4.2 million for a licence for a legitimate copy of some software. I was watching a youtube video by ICON 4x4 (go check them out, they build some fancy FJ40s) where he mentioned a free CAD software called Fusion 360, I did a google then downloaded it. Since then I've started to dabble in working out how to use it, which for someone who has no prior knowledge in design work is a bit of a learning curve, Youtube videos to the rescue. After much mincing about I managed to draw a thing, well, a series of things, taking the measurements off one of the intake port gaskets. This is where I need to make honorary mention of Ned, he has the ability to make your drawing turn into an actual thing. I send him a copy of the file and the next day I get a text saying he has some things for me. 3D Printed out of PLA, whatever that is, some kind of plastic. If that isn't amazing enough, lo and behold, the things fit. The stud holes aren't quite in the right place, they're a couple of mm to close to each other, nothing a quick file can't fix though. The other flange shown above lined up perfectly with the bottom of the Weber. At this point I think I am the bees knees.

-

Photos working?

-

Try that

-

Hmmmm, they not loading? trying to host them on the forum, gimme a minute.

-

While that is going on, a couple of months back another weirdo (I say weirdo because you have to be to own one of these things) lists a V12 Jaguar engine for sale here on Oldschool. On this particular night I'm 3 or 4 Coronas deep, which to me is the perfect amount to assist in making rash decisions without worrying about the consequences. So I message the guy and say I'll take it, and fire some money away. Oh man, It's in Dannevirke. How is this going to work, luckily a buddy was going to a wedding down Wellington ways and picked it up for me on the way back, I then picked it up from his place in the Waikato. It is a Pre HE motor, out of a Series 2 XJ12 sedan according to the block number, The internet led me to believe the Pre HE motors are the ones to get when it comes to these motors, which was it's big selling point. I made a day trip to pick it up and got it back to Auckland and on an engine stand, I swear it was the worlds longest day

- 82 replies

-

- 12

-