-

Posts

11652 -

Joined

-

Last visited

-

Days Won

2

Posts posted by flyingbrick

-

-

Now I'm trawling the net for vids of this mad dog doing 8's

-

Nah I need bigger balls and practice. There's people in the world that could do 8's on my bike in it's current state

-

2

2

-

-

I think I included pics and maybe info on the Racebox Mini unit that I purchased on indigogo a few months ago. I have only just started using it.

Great piece of kit, you can use it for recording any speed and distance measurements that you'd like.

I have been practicing 0-100 and 60ft - Both are relatively embarrassing but it is super bloody fun stopping in the middle of a rural road (while on the way to work) and thrashing it off the line.

I was initially measuring 0-100 only and was doing the bulk of it with the front off the ground for a best time of 3.6 seconds (no rollout correction). Recording 60 ft time showed that I'm simply not getting the clutch out and to full throttle fast enough so that has to be the focus now.

Hopefully in the future I'll be confident enough to maybe run some 13's with @Roman at an OS drag day!

-

3

3

-

-

-

Yeah I have the right groove in use. Never thought to check alignment though!

-

19 hours ago, tortron said:

That's probably your rollers needing tension sorted

Pisses me right off. Even with a new liner it struggles. Yes probably need to drop roller tension so it just skids. Actually maybe I cranked the tension prior to new liner and then didn't drop tension again.. oooohhhhhh

-

On 25/09/2022 at 10:49, Jusepy82 said:

ok awsome thanks lads , 0.6mm wire it is !

Only bugger i have found is that it birdsnests easy, but that could be more user error than anything

-

1

1

-

-

57 minutes ago, Mattwho? said:

Looking at getting my first welder and am looking at this kit from Machinery Warehouse. https://www.machineryhouse.co.nz/k1103

I have no idea what im doing yet so will need something fairly foolproof to get me started. Is this a decent kit/welder? All of my welding will be car related so don't need anything too heavy.

That's pretty good, but budget in a big regulator to take normal bottles. Those small ones are not cost effective

-

4

4

-

-

Oooh, it's actually an es, owned by @64valiant

Quite a special bike and I hope when the times right he starts a project thread for it

-

4

4

-

-

-

Any and all swarf in our garage ends up in our house. They are still the same thing. Fml.

Love the updates tho man.

Edit. It's damn cool how you are able to successfully use many different methods of doing stuff and you know when to use each one and when not to.

I admit, my first thought when I saw the scalloping of that tube was OMG ITS GOING TO BANANA WHEN HE WELDS IT HOWS HE GOING TO STOP THIS and then you bust out the silver solder and I'm like "argh, genius"

-

3

3

-

-

- Popular Post

- Popular Post

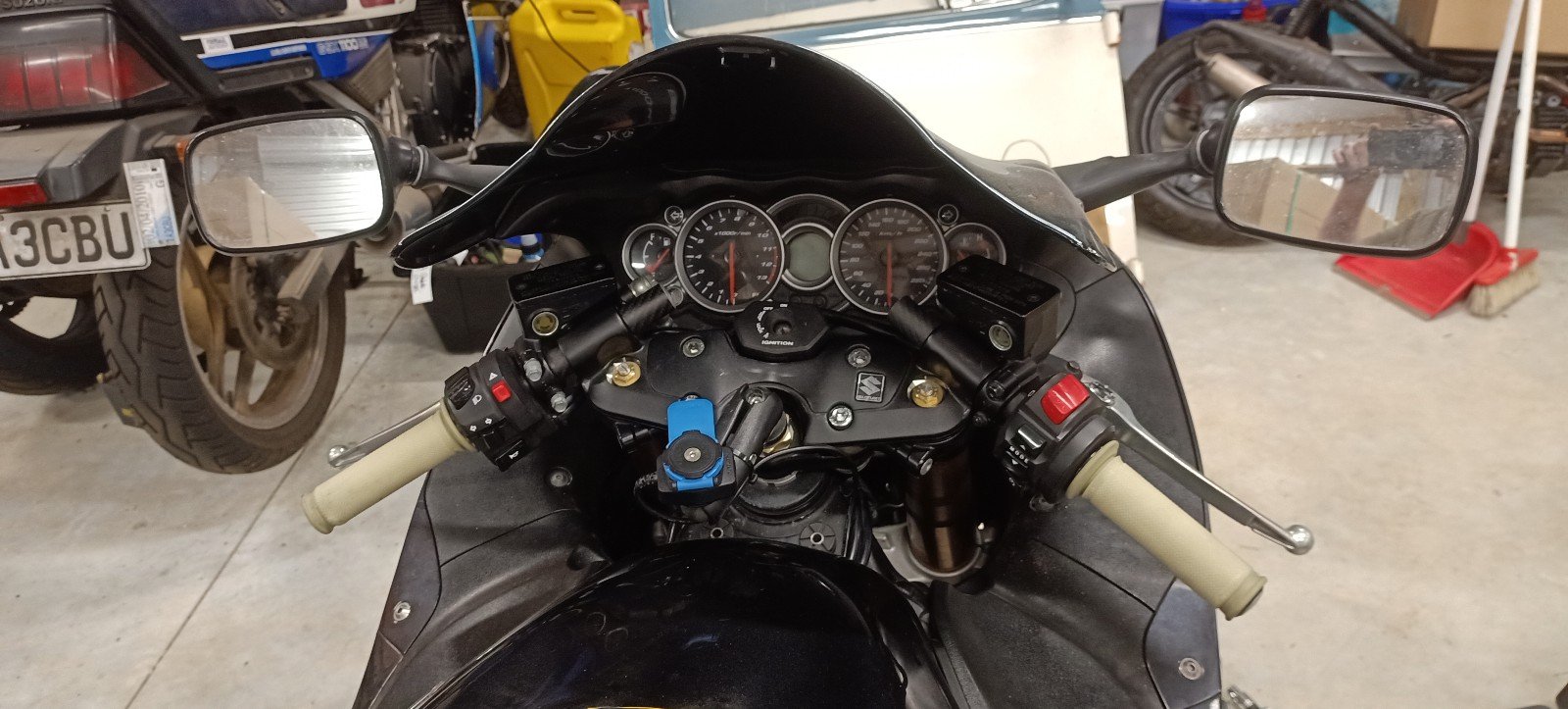

Took this out for about four hours yesterday for a really good shakedown run. It couldn't have gone better, I'm REALLY happy with how these mods have gone so far.

-The carbon fibre pegs didn't fall off. They felt rock solid the entire time, and unless I tactually thought about the new rearsets (at one stage I thought, hey, these aren't slippery, that's good)- they felt 100% like the old ones, which is perfect. No additional vibration either (which was a minor concern as the factory ones have rubber isolator bushes plus big rubber foot pads.

-The carbon bars are amazing. Holy shit was I worried about these. I bought some bloody expensive raised clipons but ended up having to stick with the factory's rubber isolated top yoke to hold them. The CF bars saved over 1kg over the original bars and end weights. I was told that CF is naturally good at dampening vibration but that doesn't work with my brain because to me CF is "springy". Maybe its the rubber isolators doing their job, maybe its the CF, but regardless- have had the bike to some good speeds and the bars remain totally DEAD, zero vibration at all. Infact there might even be less vibration or hum than there was previously with the solid aluminum bars and end weights- but this may have been caused by the heated grips which lack squish. I went with 32mm diameter renthal kevlar grips which look unusual (pale yellow) but feel farking great for my hands (my right wrist is a problem)

-I changed to an early 200's R1 throttle tube. This was a factory part and at 45$ was a real bargain- It reduces throttle movement from 1/4 to 1/5th turn. This is a HUGE deal as it means you don't have to take a second bite with your hand prior to overtaking. Again, I was a bit worried that it might make things twitchy but in reality not a concern in the least. I did not even think about the change in throttle response until after the ride when i thought " hey I didn't need to consciously move my wrist once!"

-The EBC sintered metalic front pads and gen2 (metalman brand from australia) zx10r discs have got a lot more initial bite than my old discs, this caught be a bit off guard a few times when I squeezed on a bit more front brake than expected, but overall thats awesome. Everything works, no vibrations or other problems.

-The weight loss. The half KG off the front wheel by going zx10 plus the other 13KG lost since last ride (I had those pipes on before i pulled it to bits) has made an absolutely huge difference to how it rides. Far far far more than people would assume. I don't know if its because that half KG is rotating mass up front, or if its because a large portion of that weight was up quite high on the bike, but shits incredibly responsive compared to before. I was worried that there was going to be some placebo effect, or maybe i wouldn't notice because I hadn't been on it for a few months, but the first time did a bit of a zig-zag up the road I was like "oh my god". Its extreme enough that for the first hour (and occasionally after that) I was pushing a bit too deep into some corners and was having to straighten back up a little mid corner.

I sat round with a workmate and compared weights yesterday-One source had my year bike at 225kg (lighter than the other gen2's as I don't have ABS). Weight loss would put mine about 200kg, or 20kg more than most of the 1 liter superbikes around (like his big dollar aprilia). So I've I've managed to halve the difference, that's a long way toward making it not a "whale" and really puts things into perspective.

I can't really do much more to chop out any additional weight except fit the ZX rear wheel (might be a job for next winter)...or I could shell out for CF fairings or lose 5kg front and 5kg rear by going with some billet magnesium wheels (shit would be amazing) but right now I'm 10/10 happy.

Cold kiwi this weekend hence the lame roof rack on the rear

-

13

13

-

1

1

-

I don't know if that system is usual. The ones I have seen have a lever and screw that operates on the same piston as the fluid.

-

2

2

-

-

2 hours ago, cletus said:

Have seen someone use an oem rear caliper off some sort of car with handbrake mechanism built in as a handbrake caliper

They just sealed up the brake hose port and filled it with brake fluid and used the mechanical handbrake part

My brain can't figure out how the piston moves If it's hydrolocked

-

Wilwood does cable and electronic parking brake calipers.

-

Lots of cars have cable hand brakes- there should be a huge number of choices.

-

- Popular Post

- Popular Post

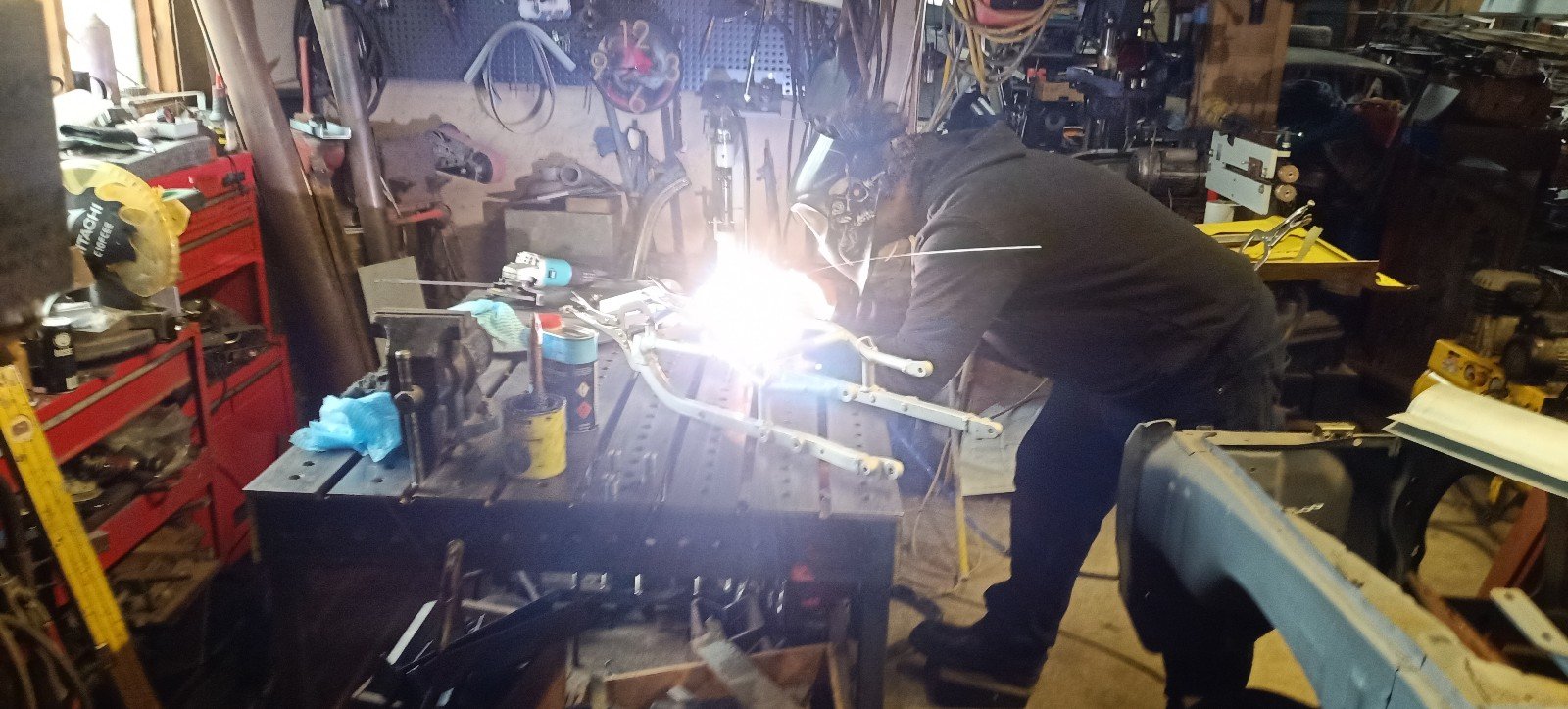

Had a guy weld some new machined bosses onto the aluminium subframe. This is the final step needed to convert it to gen2 plastics (the light weight subframe is from a gen1). This saves 2.9kg over the steel subframe from the gen2 but shouldn't be used for touring with luggage and pillion (not a problem here as A, I don't know anyone I'd like to have on the back, and B, I didn't bother with the hardware to attach the pillion seat.

So now it's all back together (aside from bars) and it pretty much looks just the same as it did before- which is fine by me.

-

10

10

-

-

1 hour ago, zep said:

I looked into flocking. Not my thing, it looks cheap to me.

Where can I look for the "recover in vinyl, for a few hundy" option?

Can nearly guarantee you'll wish you had done something else.

No chance of finding a mint dash in australia and having it sent over?

-

I know I worked with a relatively small sample size, but I saw Lincoln welders fail and be sent out for repair more than any other brand. They must be alright because people swear by them....but it left a bad taste in my mouth

-

1

1

-

-

2 hours ago, vk327 said:

I recently brought the weldskill 205 acdc and really like it, TGA abrasives https://tgaabrasives.co.nz/shop/welding-plasma/welding-equipment-welding-plasma/tig-machines-welding-equipment-welding-plasma/cigweld-weldskill-205-ac-dc-tig-welder/ were a bit cheaper than blackwoods too, the 8m tig torch is handy for some jobs but a bit of a pain for others so iv got a 4mt flex head wp17 setup for it now as well. really rate the ease of use, great upgrade over my old china acdc tig

I need to pull finger and get set up to tig here. That's a damn nice option. 8m lead is long!

-

Okay.. last post about these rear sets. Finally all installed with torqued and loctited Ti hardware (cheaper to buy it in silver and just dip them yourself and it's only a few seconds, plus the color matches)

The left side with Ti hoop was a BASTARD to color because the act of heating the Ti to do the riveting creates a layer of oxide that must first be removed. It's a patchy gold/red/purple now which doesn't match the other side, but for now it will do. (Occured to me this morning that I might need to visit @Kimjon for a Hoon on his sand blaster then immediately anodise to fix the problem)

Extremely happy with how it's all come out ☺️.

-

7

7

-

-

7 hours ago, Willdat? said:

Seems reasonable to me, I always think, 'how long would it take me make it by hand?' $200 doesn't seem bad for a part you know will fit first time.

Definately. Plus the material itself is pricy.

I justify it because I know if I don't pay someone else to do the hard stuff-i'll just never do it.

-

3

3

-

-

Got my little aluminium spacers for the front discs (washers) and my titanium hardware, then had a new tire put on the zx10 wheel and the old tire pulled off the busa one.

580g of unsprung and rotational weight- damn happy with that!!

I then drilled some holes in the left side rear set plate and used gas and a form to bend some 6mm titanium rod to shape. I hammered it through the holes(was a right fit) then heated the ends with more gas and hammered/riveted the back side. Super happy with how that's turned out too!!!

Will clean up and re-anodise the whole lot, then final assembly :-D.

Oh and the black guard is a glass one for a gsxr1000. It saves 370g

-

5

5

-

1

1

-

Nathan's motorcycles.....

in Two Wheels

Posted