-

Posts

14,314 -

Joined

-

Last visited

-

Days Won

88

Content Type

Forums

Downloads

Events

Gallery

Everything posted by cletus

-

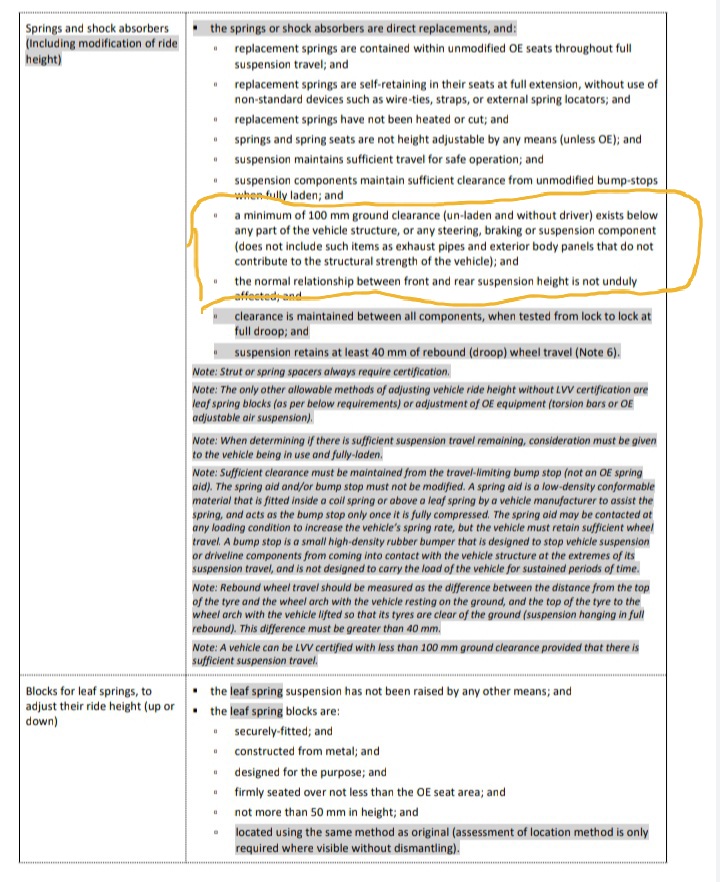

I had a read and cant find any exclusion for that so I'd say yes it does include those parts in the 100mm minimum

-

Wof emissions requirements https://vehicleinspection.nzta.govt.nz/virms/in-service-wof-and-cof/general/exhaust/exhaust-emissions Cert emission requirements (note these are only applied when an engine swap is certified or a scratch built vehicle is certified- a vehicle with it's original engine , even if modified, just has to comply with the wof virm) https://lvvta.org.nz/documents/standards/LVVTA_STD_Exhaust_Gas_Emissions.pdf

-

What about a custom made vvti solenoid with a bigger piston, instead of making heaps of oil pressure?

-

Got wheels powdercoated, 235/60/15 front, 245/60/15 rear. Looks ridiculous now, lowering is required sooner than later. I think its actually got lifted springs in the front, they have eibach branding on them and its higher than other stock ones I've seen pics of I might go up a tyre size all round, if it doesnt rub when slammed

- 528 replies

-

- 12

-

-

-

In some cases in the land of freedom, that's the repair, lol I have a customer with a first gen camaro that didnt quite look right, he had it blasted and it had double rear panels, the original rusty ones were still there

-

Ecom on pertol? No. Unsurprisingly. Checked its fuel consumption just as a matter of interest pre mods- 15.9L/100 around town and a bit of motorway Went to rotorua today with cruise control set at 100 most of the time, 14.35L/100 It came with a set of headers, so I'll put those on, should try a new thermostat because it seems to run a bit cool, and I should probably fit an electric fan as the engine driven viscous one takes a while to 'unlock' when it's cold Stay tuned for riveting updates on the subject

-

Theres a form we fill out that they take to vtnz/vinz Usually check the ID of the vehicle first and if theres any obvious issues tell the owner to go sort that out before the cert goes any further I've only ever had one dodgy one come back with the correct paperwork. The rest have dissapeared or NZTA has got involved I spoke to a cop about it once, he said if its had all the original identifiers removed, it is very unlikely that they would ever be able to return it to its rightful owner

-

Yeah has to be braided if its inside the car. Use ptfe braided hose if it's going inside the car, unless you like the stench of fuel in the car 24-7 , the rubber braided hose leaches out fuel smells

-

Have had a few really dodgy ones over the years, a "mitsubishi lancer 1500cc" that had "been converted to a makkinen evo replica" And a "V6 commodore with a LS swap" that had really low kms and lots of weird rust almost like it had been hidden in a damp shed for 10 years and you could see where the SS stickers on the doors were and the engine number had been attacked with a chisel and the date tag on the belts didnt match the year on the rego and the vin tag under the glass had heaps of weird scratches on it Or the VE commodore that had a different vin on the bit under the carpet on the floor to under the glass and in the engine bay because whoever the crackhead that stole it didnt realise there was a chassis number in the floor

-

A certifier has to send it to a TSDA to sort out any discrepancies in the ID of the vehicle. With old stuff it can be tricky because a lot dont have a stamped in number so swapping tags is very hard to pick up unless there is a difference in the body, ie if someone put VK commodore plates on a VH you'd notice because the body is different. Ive had quite a few cars that have never come back after being asked to sort out ID issues but most of them have been cars where it's been obvious, ie the stamped in number in the firewall had been cut out and another one welded in The last old car I had with chassis number problems, was one that the owner had lost the tag when it got painted, i failed it, next time i saw it hed "found the number under some bog" but had obviously got a punch set and diy'd the number into the front panel, he painted the front so it looked semi legit but forgot about the back side and the primer and paint had cracked where hed punched the numbers in It went to a TSDA to get a new vin, a bit of paperwork and a month or so of waiting and it got a new vin number on a proper tag

-

Relevant VIRM page for anyone interested https://vehicleinspection.nzta.govt.nz/virms/in-service-wof-and-cof/general/vehicle-identification/vin-and-chassis-number

-

95% of the time it will never get picked up. Lvv certifiers have been told to look for it specifically, it's in the wof virm but I'd say most wof inspectors wouldn't fail until theres a training update and then there will be a million cars that fail all of a sudden I got a bollocking from someone at NZTA once for looking at a vehicle that didnt have a vin number on it because it had been removed and lost when it was painted, Not even a proper cert inspection, it was a pre check

-

Its risky if you ask me. A 2 year rebuild on a car could mean a bunch of different employees come and go, things go missing, inspection sites lose their authority and throw everything away, etc I find, in practice, nobody knows about this requirement, removes tags for paint, then come in for cert with them re attached with new rivets and new engine bay paint Then we have to send them to vinz or vtnz to confirm that the id tag matches the car . Sometimes they return with a letter from the TSDA saying yep its sweet, some come back with a new 17 digit vin number attached No special rivets, it's pretty obvious when the tag has been removed for paint and refitted

-

Correct procedure is to take it to a vtnz or vinz that deals with re registering cars, tell them what you are doing, they will remove the tag, and store it while it's being painted then refit when it's done.

-

I'll find out what exactly was done, but the trans in my chev was rebuilt recently before I got it, it had a few things done to it because it was mostly used for towing It shifts quite hard, and had a few upgraded parts. It wasn't cheap

-

-

Most of the time that sort of thing has to be welded. You might be able to get an exemption from lvvta if you followed the right process but it might be more hassle than its worth. You would probably need to modify parts of it anyway for it to comply so may as well just weld it in Like tortron said its probably to do with the skill level of the installer in its home market, like many other things, the fact that something bolts in/on in america is a big selling point

-

Unfortunately once you have been stickered for exhaust noise, you need an exhaust noise cert regardless of if you put a standard exhaust back on

-

There has only been 1 update to the engine and driveline chapter since 2010 in the CCM Frontal impact standard is on the LVVTA website https://lvvta.org.nz/documents/standards/LVVTA_STD_Frontal_Impact.pdf

-

If they meet the requirements for not having upper anchorages , yes

-

Theres nothing in the lvvta rules that mentions the date on a harness Scratch built vehicle 100% must have upper anchorages There are other requirements when you use harness belts which may affect your decision to use them, if it's just a cost thing CCM is available free to download now , that and the frontal impact standard on lvvta.org.nz should have all the info you need

-

From memory I've only bothered to bench bleed once or twice ever, regular old "pump it up hold it down " bleeding has always worked for me

-

Probably easiest to grab 2 pipes off a master cyl at pap, just snip them off long enough that you can bend them up and over into the reservoir If it was me I'd try the vac bleeder first just to avoid getting brake fluid all over the place if you can worst case you can still do the pipes into the reservoir method once it's in the car

-

Usual bench bleed method is to make some short pipes that screw into the outlets and go into the reservoir below the fluid level so you pump fluid around and around until you get air bubbles out of the cylinder

-

Are you talking about just using the lap part only? Not the shoulder belts/ball squasher? That wouldn't be legal either as a belt has to be used as a set. I had a quick look for lever latch style belts if that's the look you are after but couldnt find any with a standard marking Your other potential problem is there is a rule to do with lap belts in the front of cars, post 55 should be lap and diagonal, apart from the vehicles that meet the requirements for not having to have an upper anchorage . One of those exemptions is, in some cases, a car can retain it's original lap belts if they are in good condition, but as soon as you fit a replacement belt then it has to be lap and diagonal. Have had that come up a few times where someone with a mustang or camaro thinks they are doing the right thing by fitting nice new lap belts but that tips it into needing upper anchorages fitting and cert