-

Posts

3264 -

Joined

-

Last visited

-

Days Won

2

Everything posted by kpr

-

Ol mate @Dudley not quite gettin them shots on the camera

-

Managed a new pb yesterday, at least in na spec anyway 13.25 @ 105mph done a bunch of 13.6's. started at 3800rpm launch. kept putting it up as was bogging off the line. much different than with the 195/45 r14's, which would basically have to drive it off the line, but since the gearing was so low would pick up rpm fast enough to get an ok 60ft. with the 185/55r15's china tyres was super lazy, but surprising amount of grip. once got launch up to 5000rpm , 60ft started to drop. done a 13.4. next and last run put it up to 5500rpm. spun a little, went 13.25. with still pretty rubbish 2.10 60ft. 13.1 probably would have been doable with few more runs, but pretty happy with 13.2 . Should easily do a 12 with better tyres. but little clutch and t50 would be in a world of hurt.

- 216 replies

-

- 22

-

-

Ah yes, that was the part i wasn't sure on. out of link manual, should have scrolled down further. kinda makes more sense, kinda doesn't

-

little street pull/ sound check at start of this vid:

- 216 replies

-

- 22

-

-

-

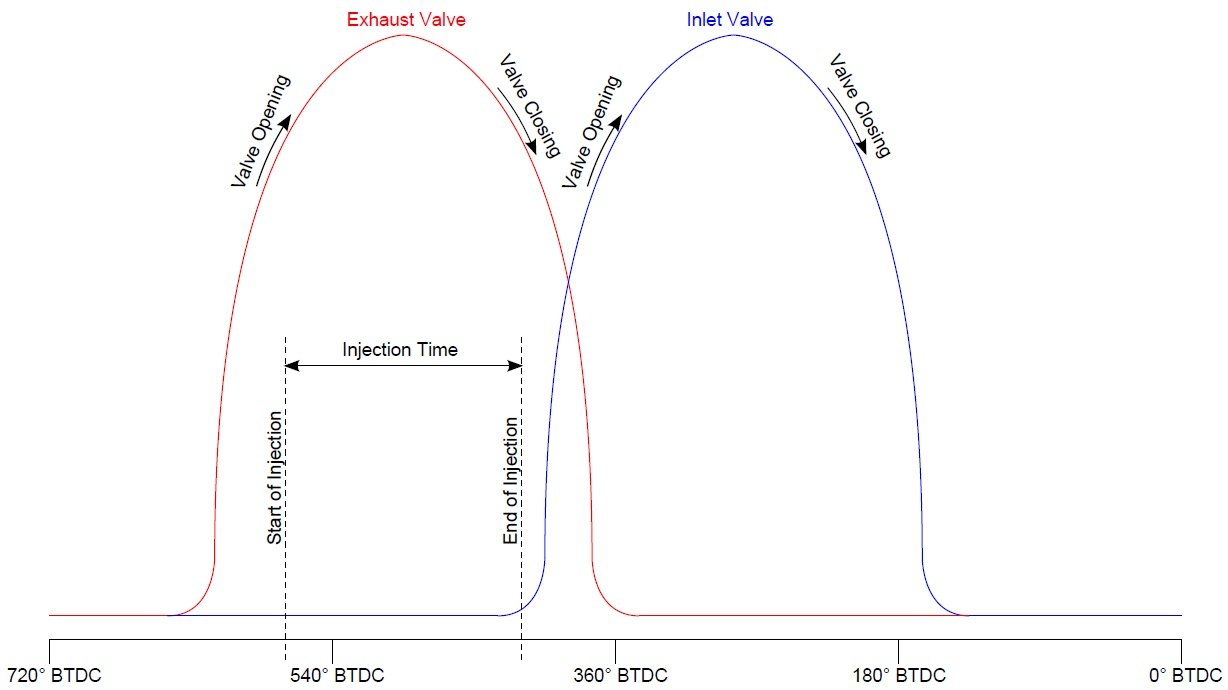

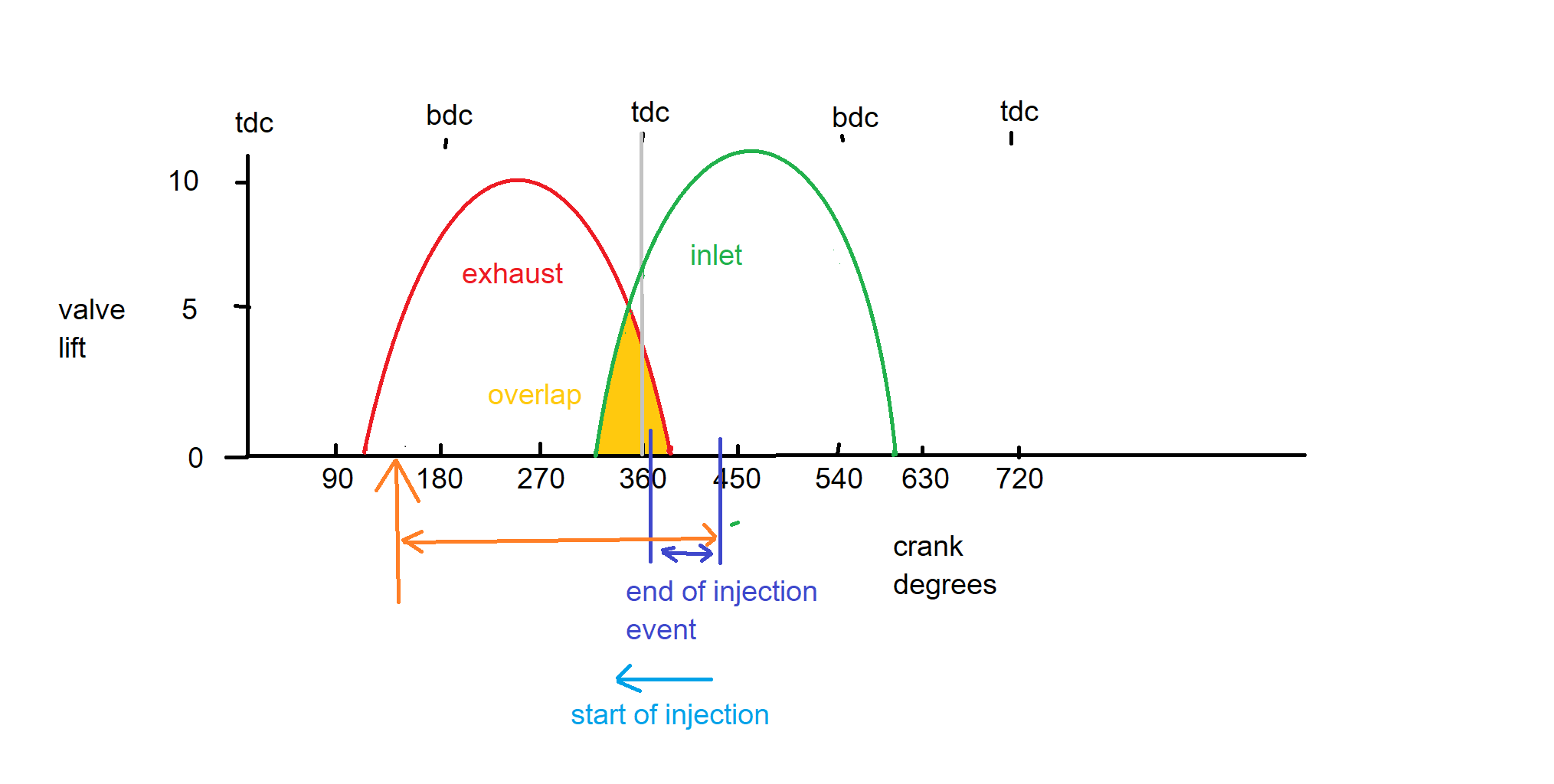

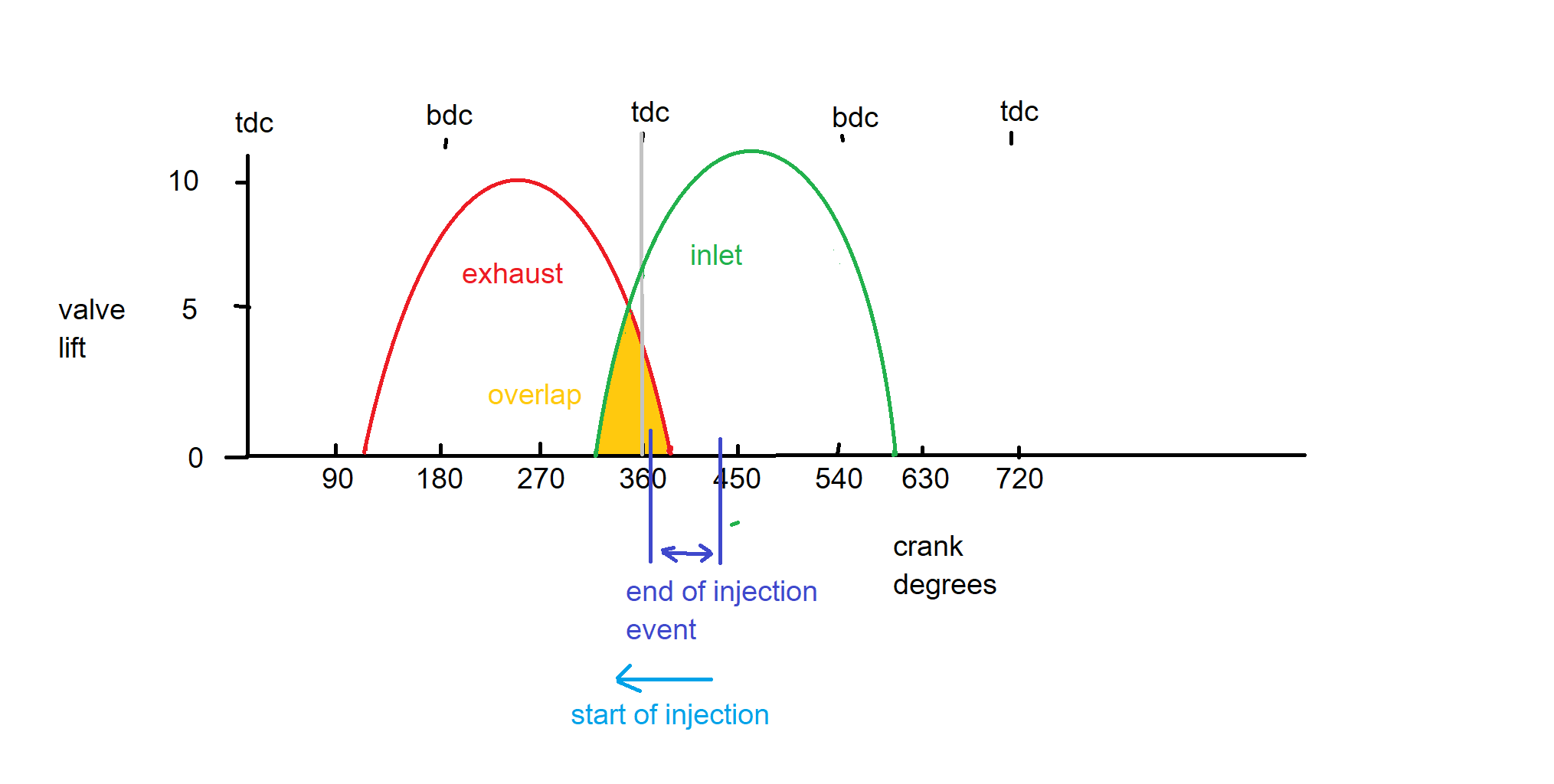

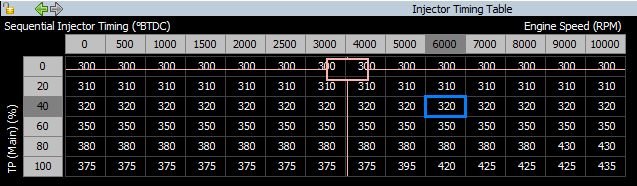

maybe plausible its avoiding fuel going out the exhaust. orange is rough injection window at 9500rpm. around 4ms. some guesstimation and poor math says would take almost 1ms more to get to intake valve. but that doesn't take into account the intake valve would be shut at the time. and making it out the exhaust valve for that matter It did have a bad day when running at 300 but mostly through the low/midrange. lost all the power. possibly didn't like the fuel hanging around in the intake port, rather than going out exhaust. who knows, maybe majority of the fuel is going through on the overlap and mixes better. Interesting there is something in it though. have tried in the past with smaller cams and didn't do shit so left it locked to 400.

-

If my drawing is correct. this is pretty close to whats happening in my engine. end of injection being when the ecu closes the injectors. start is calculated by ecu depending on fuel requirements. so the more fuel needed, the start moves to left. also more fuel required i'm moving the window to the right. so is it loosing fuel out the exhuast on overlap? or some other wizardry? as can see there is a pretty big opportunity when both the valves are open at 5mm, for air fuel to go which ever way it pleases haha. I haven't done the math, but would assume start of injection would be well before the overlap. but then there is also the time it takes to make it from the injector to the exhaust valve before it shuts. injectors are 980cc running at 40% duty right up top. approx 100mm back from intake valve

-

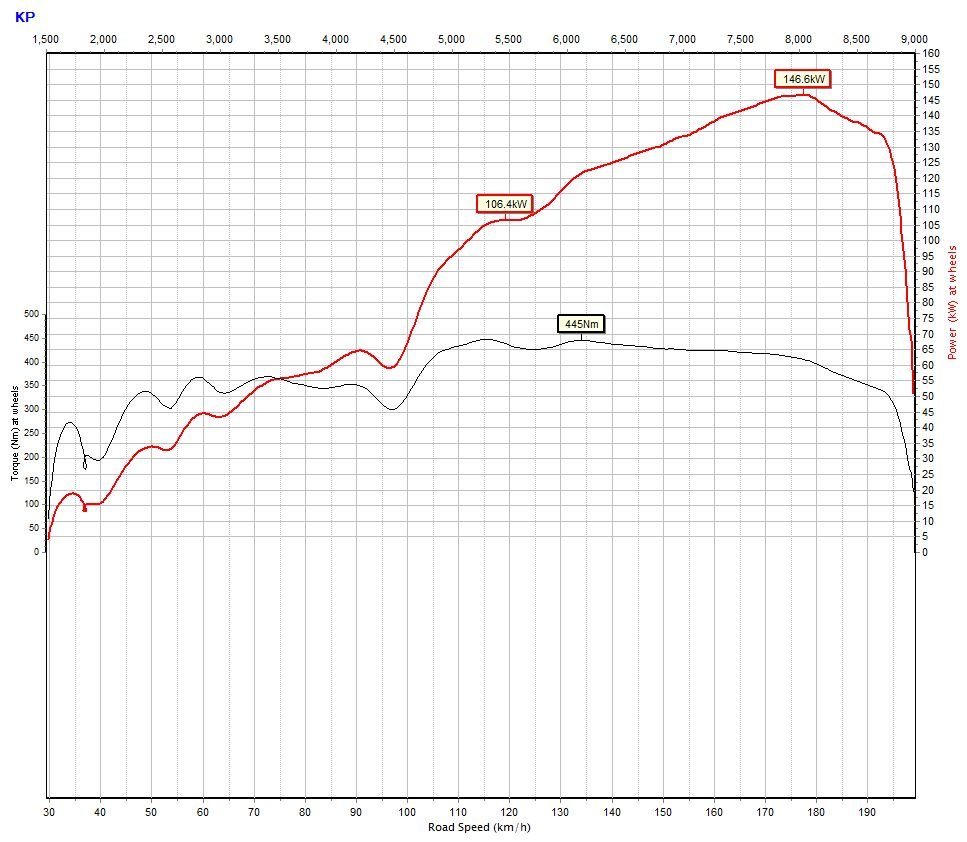

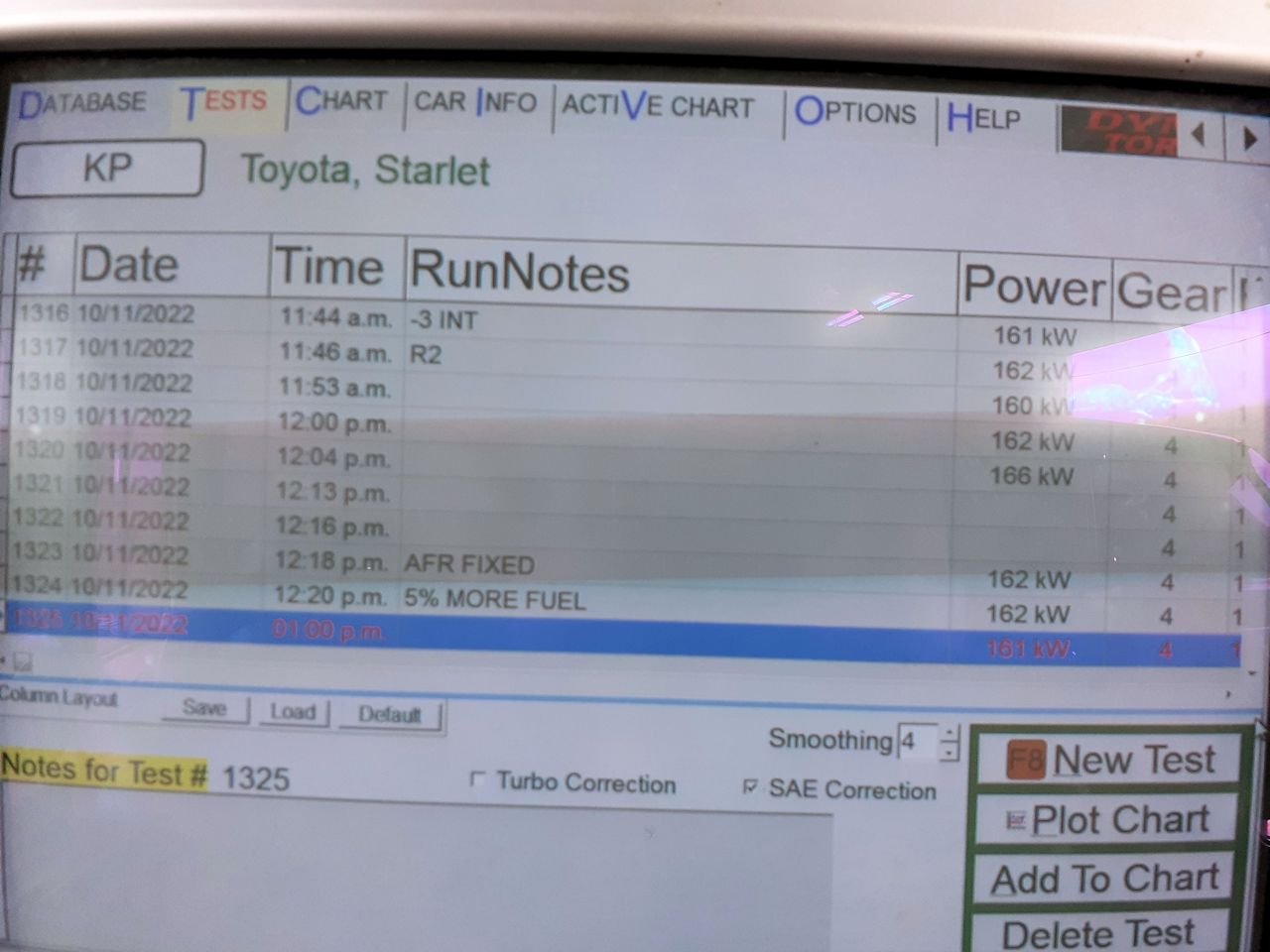

So going back a few pages, I found what looks to be the dyno graph, just before last time took it to the drags so yeah should do stuff, maybe

- 216 replies

-

- 21

-

-

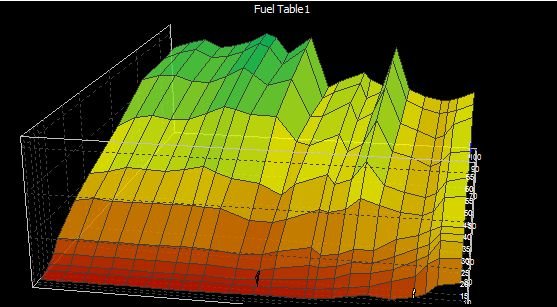

Done a few more tweaks and got a touch more out of it. fixed some stuff in the fuel system that was causing a few afr spikes. played with the injector timing, which seemed to give some small gains here and there, mostly noticeable right up top 9500+ Pretty much lined up with when afr richest = best. I had been running fixed 400 end of injection which worked pretty good for fixed number. heading towards 300 would result in massive loss in bottom end. but it did like a little less than 400 down there. right up top it liked over 400. So yeah running this engine with the big 980cc injectors is actually a benefit. Seems to be a touch of power in it. Even if there wasn't/isn't, would be wasting fuel, going to a smaller injector. since the injector would be open for so long, part of it wouldn't be burnt Bottom line is what it likes at wide open, ignore the rest of map haven't fill it out properly yet. Injector timing made some of the changes in fuel map slightly less aggressive, but yeah big cam itb tune always going to be all over the shop contrary to popular belief, something like this is harder to tune than a turbo engine making way more power. gains from last time in red the atlantic engine in dark green. I should probably try the big headers at some stage. think it will be really close to the atlantic curve. at least lose the power below 6k haha

- 216 replies

-

- 17

-

-

-

Its actually made it off the dyno and onto the road. amazing I stole @Roman clutch sensor idea. spans 0-5v over clutch range. so can pick engagement point in ecu software, rather than mucking around trying trying to adjust a switch to right spot. So yeah set up launch control. On my shitty old concrete tyres i use on the dyno,would only take 2200rpm launch. then would cut loose again a 5k. I set up an ignition retard map, based on time after the lauch control switched off, so will pull timing and come on power less aggressive in 1st gear. then back to full timing by the time hit 2nd, which worked ok but pretty weak sauce acceleration> Found some slightly softer springs and did some shock adjustments which helped a little bit. but still ended it tyre fire Before swapping to some slightly better condition 195/45 14's. thought would try some other junk got hanging around Enter the 185/55 15 linglings first attempt = tyre fire. but after zinging the crust off them and running them at 15psi. got it to hook up at 3800rpm and able to get rid of the timing retard map. aint no drag car but seems to take off fairly decent for what it is

- 216 replies

-

- 44

-

-

-

Had bit of a setback with making the new vvti parts for this engine. So have shelved it for a bit, as wanting to get this thing to the os drags. soo put the big cams back in. Tried the big toda 320deg in the intake and the 318deg kelford in the exhaust. it didn't like. no more peak, just lost everywhere else. almost zero usable cam timing adjustment, due to piston to valve clearance. only did a few pulls then swapped the HVC 318/304 set back in. Its real sensitive to small changes with 318/304, both cam timing and intake lengths. Tired a bunch of different intake lengths and cam timing, to attempt to put a peak on the top of the graph, rather than it flat lining. usually can shuffle the intake tuning to where it wants to make peak power, so will make even more. Didn't really want to have it, would result in a dip just before it flat lined or make it fall off earlier. Almost like its running out of airflow. but the Atlantic engine does the same thing. maybe long rpd bottom end will help. Ended up with intake length only 10mm shorter than what i normally run. Little bit of a compromise here and there but overall happy with the numbers and shape of graph. I can pull the dip out at 5500rpm to a point, advancing the inlet, but it loses power up top and piston to valve is pretty spicy. around the 160kw mark for 1500rpm is pretty good. was spitting out over 160kw constantly on "normal day" (corrected and uncorrected numbers the same) with air filter setup on. vs stockish engine for a laugh. rpm scale bit off

- 216 replies

-

- 31

-

-

-

-

yeh pretty interesting how its pretty much bang on the same, then exact point where is a restriction.

-

Edit; ol mate dave quicker on the trigger in the graph game found some stuff turd engine 100% vs 70% 52mm throttles a 20v i tuned awhile 100% vs 70% 45mm throttles good engine from sometime ago. 100% 70% 20% ! Im just going by the notes i wrote in the run. plus i dunno how good i was holding the throttle bang on those numbers couldn't find any closer to 100% but i recall doing it in the past on 45's or 47's, to see what it would do and was still a small loss at 95% Also the fuel and timing probably a little different. but looking like a pretty solid no. just hold it tapped one other thing thats interesting the good engine still makes the same power as the turd at 70% throttle with same throttles.

-

I often do runs around the 70% mark when tuning itb stuff. if i recall correct, once have a few rpm on the engine, usually just makes the same power till throttle plate becomes a restriction. I'll see if i can find some runs on the dyno. there might be something in it, at low rpm where you should probably just change down a gear. can be a vast difference in the fueling between high and low load at low rpm, on an engine with aggressive cams. throttle plate tends to "filter" out the big peaks and dips down there.

-

Just had something super cool on the dyno, well if your a 4age foamer at least Yep an actual formula atlantic 4age. in a formula atlantic car where it should be. not just some guy with atlantic covers bolted to a stock bluetop engine originally built by and made 254hp (189kw) on loynings usa engine dyno. The car even had the original efi setup and ecu from late 80's ! uncorrected numbers again; 170kw. so showing about 10-11% drive line loss, compared to engine dyno numbers. seems about right. This is it overlayed onto the kp's dyno graph, with the HVC cams, same run as the green in previous post. only 4-5kw off the peak and 20kw more at 5k, not bad!

- 216 replies

-

- 44

-

-

-

keen, if can make it work fitment wise

-

Yes i need to redeem myself and all 4age's for that matter, after @Roman beat my NA pb .01 seconds or something silly blue jelly bean time: 13.49 @ 99.5mph and 2.09 60ft. Its great grand fathers time: wow 2018, didn't realize it was that long ago. Should have another 15kw or so than what was running on that pass. As for the gearbox, It seems to be working good now, with the new parts and angle grinder machine work. but yeah would probably go j160 for the next move if had to. rather stick with the t50 though. lighter and dont have to mess around with new clutch combo, driveshaft and making it fit in the tunnel. Engine uses rpm to make the power, so doesn't make gearbox breaking torque. but im still hesitant to put a lot of grip into it, to get it down the 1/4 mile quicker.

-

Should hopefully make it this year!

-

Tried shortening the intake a touch. 20mm to be exact, it did some stuff and made a little more peak power as expected. It also liked about 5degrees intake advance without losing peak power, which bumped up the midrange a bit. probably would make a little bit more peak if made some other changes. but would start hurting the low end / midrange even more. so im calling it here for the dick swinging number. 166kw uncorrected. green is after the runner length and cam timing change I actually took it off the dyno and took it for a spin down the road after this. feels like a weapon in the top end and actually changes gears now! Have also been testing a few cam combo's to run with vvti. as the 318 degree HVC intake cam is a little big to be swinging around, due to piston to valve clearance. and the fact that it only works in a smallish window. with duration being so long. green line as above with the hvc cams red is running the new smaller cam combo through a few cam timing settings, to simulate what vvti will do. only down 3kw up top and nicely fills the hole at 4500. along with a bit through the midrange and still holding power till almost 10k. seems like the winner to me.

- 216 replies

-

- 29

-

-

-

doesn't matter so much on inline 6 cylinder or 4 cylinder for that matter (unless oddball setup) . long as crank itself is balanced, and all the pistons and rods are the same weight as each other. which is easy enough to do yourself. aftermarket pistons should be pretty much bang on. but worth weighing them anyway. along with the pin and ring set going on them. mix and match pins/ pistons. zing a bit off pistons if needed factory toyota rods, at least all the 4age one ive weighed can be a bit off. i would assume jz would be no different. so probably worth doing more so than the pistons. you can end weight them. or at least make them weigh the same if cant be assed making a jig.

-

still got awhile to go before make those numbers uce

-

should be about 12.6:1 . but have never measured super accurate. Its running 11.3:1 pistons, with head skim and thin gasket to up compression and tighten squish. not a fan of the pointy dome pistons available for them. it'll make those numbers on 95 pump gas. because "street car"

-

Put some 193hvc kelfold cams in it. 318/304 deg 11mm/10.1mm lift. bit of a sack down low and not going to work with my plan. but good to see theres a bit left in it! i may have a little play with intake runner lengths to push the tuning up to 9k. see what it will do, before move onto next cam combo Thats 161.9kw if you cant see it..

- 216 replies

-

- 24

-

-

-

Yeah the bit your after is part of the oil pump. They usually stuck in there pretty good, not something that would just come out. hole maybe flogged out and may need to look into other options, if just falls out. rather than the factory part