-

Posts

7,233 -

Joined

-

Last visited

-

Days Won

39

Content Type

Forums

Downloads

Events

Gallery

Posts posted by Roman

-

-

The c56 1nz bellhousing is 1nz specific, so theres no direct bolt on for a t50

-

1

1

-

-

The sump on these are a lot more complicated, because the cut line is up around the centerline of the crank, rather than having the block extend down past everything.

So you'd definitely be modding one, rather than remaking one.

But another thing is, with the motor being so small you could possibly just have the whole thing sitting up above crossmember anyway and would be sweet.

It's hilarious to see how short that motor looks when sitting on top of that crossmember, haha. -

Yeah, just the difference from iron block to alloy I guess!

This engine would be way lighter and more compact if it was designed from the start to be 2.5 litre.

But, part of the reason it's good for this application is because its bodged down to 2500cc from a bigger design.

It's also amazing how much you can win or lose based on accessories as well.

Like some of the engine brackets on factory engines are absolutely massive cast iron things!-

4

4

-

-

- Popular Post

- Popular Post

Pulled the motor back out to do firewall activities.

Borrowed more of Nathan's stuff, so I could hang it all off the scales and see how we're looking weight wise now that most of the stuff is finalized.

This is with motor, flywheel, clutch, engine mounts, clutch slave&master, gearbox, alternator, exhaust manifolds.

And a pair of extra exhaust flanges which I'm hanging the motor from.

So 209kg all up isnt too bad. For reference @Hyperblade had the full beams 3SGE setup sitting at around 199kg when using ITB kit and 1NZ alternator.

Or for some other context, people list the weight of a 1JZGE alone at around 200-210kg.

So by switching from lead acid battery to a lithium one I've as good as neutralized the weight gain.

Then there are some other currently podgy parts like the factory seats still in there.

So, this should still be a sub 1000kg car with most of the interior in, I'd imagine.

-

31

31

-

1

1

-

- Popular Post

- Popular Post

Toyota legend Mark Roads has a Spare Celica/Carina GT-T spec brake booster.

Which is a little smaller than the Soarer one, and will bolt up.

So will go pick that up some time next week.

Back to the firewall problem, I borrowed a laser projector tool from @flyingbrick that is a cool piece of gear.

It can draw a 360 degree line, all on the same plane.

So I'm going to mark where this line lands everywhere, Then I can either cut the metal back to this line so it's all straight.

Or, is use it as a reference point for knowing how far a piece needs to bend back or whatever.

Makes the problem seem easier in my brain, having some sort of reference point to work to.

I'll need to pull the motor back out to do this properly, so will dig out all of my engine crane parts out of storage and make a start on that.

Slowly making progress on a few different fronts which is good.

-

26

26

-

- Popular Post

- Popular Post

The cable that links the banks of throttles together was made from a motorcycle cable repair kit, so one end had a little screw in type fitting.

However problem is that you need to push the cable all of the way through and out the other side to tighten it properly. Which I cant do, because of how it slots in.

So I just left some cable hanging out the other side, then buzzed it with the tig and now it's sweet.

I could lift up my bench vice using that connection so think it will be fine for pulling some throttles open.

Burning the midnight oil some more, now that I can. I drained the brake fluid and got the Soarer booster and master cyl out.

I was hoping to fit this KE70 booster, which is much smaller diameter so gives me a bit more room to get bolts in.

But unfortunately the bolt pattern through the firewall is different.

The Soarer is 100x70mm, the KE70 is 80xsomething I think.

It's tempting to redrill the firewall holes but the bracket on the other side has spacers/dowel type things on it, which make it more effort to redo properly.

So will keep on the lookout for a slightly smaller booster with a 100x70 pattern.

It's looking as though a Hilux Surf has the same pattern, and hopefully a smaller booster. So will try find one of these, unless anyone has something similar lying around they could measure?

There's one on Trademe so I've asked the guy if he can measure it up. Otherwise looks like there are some Surfs at pickapart, so will have a look next time I'm in Auckland.

-

17

17

-

Hahaha its all good fun aye!

I think part of the issue was just the way the article presented it.

By which I mean, when I posted the trackday video first somewhere, it gets a really positive reception.

Then people ask what's in it, and cant believe it.

But then if you tell it by the numbers first, no one wants to watch a trackday video that validates the fact that it did indeed go quite good.

Then another issue was that the article sort of made it sound like it was making 150hp at the engine.

Which on an American or UK dyno means about 30whp.-

4

4

-

-

I've already got one ball busting project thats proving difficult, I didnt need two. haha!

If I was doing a K swap or 2ZZ swap, this car probably wouldnt even be going yet.

But I learned so much from it during that short time span, it was awesome.-

8

8

-

-

- Popular Post

- Popular Post

I am so absolutely stoked to have some garage space again. Feels like I've been let out of jail or something!

So I have been burning the midnight oil a bit.

I got the passenger side manifold all finished, filled it all up with water and no leaks.

So hopefully it's good haha.

I started on the rest of the exhaust a while back, but will chop it back up and redo it. As I was kinda thinking I'd make the extractors to suit the pipe locations, but it's worked out the other way around.

I am so absolutely over the moon to be able to spend nights or rainy days working on things now.

The collector doesnt look so tiny/weird now that the rest of the pipe is on it.

Just need to add the rear part after the collector onto the other side too, then I can make a start on the 2-1 section and rest of exhaust.

-

40

40

-

1

1

-

- Popular Post

- Popular Post

I think I might have mentioned it before, but its honestly one of my best trackday memories.

Two uni students came to a Taupo trackday, back when it was the old small track.

One was in a 3 cyl NA diahatsu Mira, and the other was in a 1500cc Ford Fiesta canvas top.

These cars were super closely matched in speed etc, and they were out there all day just absoluting wailing on their cars chasing each other around.

They came back into the pits with hugest grins, and everyone spectating was just loving watching these cars go 20 out of 10. So good.

While other people grumbling that their semi slicks were getting hot or something. Zero fucks given and max enjoyment.

It was like a mini Best Motoring video or something. haha.-

14

14

-

2

2

-

13 hours ago, anglia4 said:

This thread still occupies so much space in my brain. I find myself constantly adding Echo's and Vitz'z to my trademe watchlist...

One thing that has definitely changed, is vitz peoples perceptions of C56 boxes.

It used to be that if I didnt go grab one out of the car from pickapart, it would stay in there and be crushed with the car.

The most recent manual vitz RS to land at pickapart, was not even off the forks and someone was there to grab the box. haha.

Although, not so many coming through these days, think I was right on the tail end of the bulk of NCP13s lifecycle through pickapart.-

4

4

-

-

12 hours ago, 440bbm said:

So what actually happened to this, all i've seen was all the shenanigans here and then it went BOOM and has it just dissapeared or just got parked for now somewhere for more funds/rainy days/carina finished?

I parted it out, and no one wanted the shell so it got towed away by the wrecker.

Done and dusted!

Carina will be cool though

maybe-

6

6

-

1

1

-

-

- Popular Post

- Popular Post

10 hours ago, GARDRB said:Parted out, now he's just the 1NZ influencer and spends all his time replying to fans on his OnlyFans... I mean Instagram

Thanks, I hate it

-

4

4

-

15

15

-

6

6

-

Hey I was talking to an Imp guy, and mentioned that you'd added some weight in the back with the reflectors.

He said no worries, just pop an extra brick in the front and you'll be right.

Hope that helps-

2

2

-

1

1

-

5

5

-

-

- Popular Post

- Popular Post

What's been happening with the carina in the 5 weeks since last update?

Absolutely fuck all

I've been busy putting the garage up, and have been away on some work trips. But then have also been off/on sick for nearly this whole time.

However I've finally reached a turning point.

The shed is up! and weather tight, or, close enough.

Still work left to do, but good enough to biff the carina in there. So now I can at least work on it at night time and on rainy days.

I've decided not to fire the motor up yet, because its fairly distracting from getting any other work done.

Instead I will work on all of the peripheral issues that prevent me from driving it.

So I took the front guards off, and all of the interior out so I've got a clear working space for a few things that need doing.

The people who replaced the roof on our house were kind enough to leave a pair of tin snips out somewhere. The guy didnt want them back, as they'd started to rust.

Some CRC later and they're pretty good again. It turns out these are pretty good at cutting firewall metal without any of the aggro that a grinder causes spraying metal and dust everywhere.

So I trimmed the firewall hole a bit bigger so it's a little more all on the same plane, and back far enough that there's still an okay amount of room behind the motor.

The main thing here, is that there is a rear water outlet on the motor that connects both of the heads to a coolant return pipe that runs back up the vee to the front.

It needs to slide backwards a fair bit, to remove it. If you cant remove it, then you cant get the heads off.

So I've been thinking about whether or not I care about this.

Since so much of the motor has to come apart to remove the heads anyway (sump off, front cover off)

I'd rather do that out of the car anyway. It's not much work to remove the motor, and I'll always opt for that over trying to work on something in a confined space.

It's not like I'll ever be in a situation at a track day, where pulling the heads off is a solution to a problem that can be fixed same day.

So I think I'll just make sure I can do all of the nuts and bolts up, reach the coolant hoses but not worry about being able to get that coolant outlet off.I got the fuel rails all connected up, and tested them with some fuel pressure.

The rear fittings were hosing some fuel out, and needed to have the faces sanded flat. After that they sealed fine.

Everything is now holding pressure with no leaks.

Main things to do at the moment are try sort the firewall, and swap over the brake MC and booster to the smaller KE70 units.

Realistically I'm at the point of pushing shit uphill to try get everything sorted by drag day.

As I need a few more trips out of town for work between now and then.

But I will do my best.-

32

32

-

1

1

-

Shit yeah! Thats awesome to be WOF'd.

Are there any enrichment settings in ECU you can play with?

Might need a tad more on throttle stab -

I guess an intetesting datapoint is that if you look at almost any motor that transitions from cable to ethrottle. They end up with bigger throttle(s)

As you can just reshape the opening rate to get around drivability issues at low rpm. Where 30% throttle might give you 90% of airflow.

-

2

2

-

-

More displacement will just turn your drivetrain into a noodle by loading it up with low rpm torque.

Maybe a little bigger cam, bit more boost will acheive same thing easier?

There's so many headaches associated with engine machining work, that can often go wrong even if you get the best people involved.

I reckon there's bound to be a sweet spot for you with factoryish block and the right bolt on stuff.

Do you have any guesstimates for drag day time / MPH / etc?

I think I'll be somewhere in the 14s on first shakedown and with standard cams. (assuming I make it)

-

4

4

-

-

Matching the pedal and throttle body doesnt matter, as they both communicate to the ECU completely separately.

So find a pedal that best fits rather than what matches the motor.

Some good options for e-throttle pedals from commonish cars.

Prius/Aqua/etc has a pedal that's easy to get. RX8 pedal is a nice unit if it fits.

The prius/350z/etc sensor is like a TPS with a little lever arm on it, so you might be able to weld something up to just adapt this to your factory pedal.

-

1

1

-

1

1

-

-

A lot of the expensive looking aftermarket options that do the same thing as you're suggesting (Jenvey, EFI hardware etc)

Look to just be a Bosch ethrottle unit with the guts put into a CNC'd housing.

I think the chopped up factory throttle body is a good plan, might need to retain something to support the far end of the throttle shaft though.

This is only 2 wire which would suggest it's just a regular DC motor but not sure how it would work in reality.

Says 24 volt so not sure if it would work okay on a 12 system, guess so?

Might work too slowly though, dunno.

https://www.aliexpress.com/item/1005006106982472.html

EDIT:

This one might be good, good price too.

https://www.aliexpress.com/item/1005007988405812.html-

1

1

-

1

1

-

-

The bulldozer throttle setup wasnt suitable, I also bought a cheap cruise control cable unit.

However I found that it housed a stepper motor not a DC motor, so too much of a pain to get it working.

Would have been a nice solution if it was a regular DC motor.-

1

1

-

-

E-throttle is just an H bridge controlling a DC motor...

So you can literally use any DC motor that is within its torque and rpm range with the available juice (~14v and 2 amps or something like that?)

A lot of the ethrottle setups have a lot of internal gearing to step down the motor speed by roughly 10:1 - 20:1 kinda range.I'd definitely not reccomend removing any of the springs from the throttle bodies though, probably wont pass wof/cert/etc, and it's also very dangerous if your motor fails and there's nothing to bring them to home position.

-

5

5

-

1

1

-

-

It's quite common to see a step between the head and the flange, as there's no downside to it being slightly oversized.

Acts to reduce reversion a bit.

But unlikely to be worth the effort of the extra welding etc steps halfway down the pipes for a manufacturer.

-

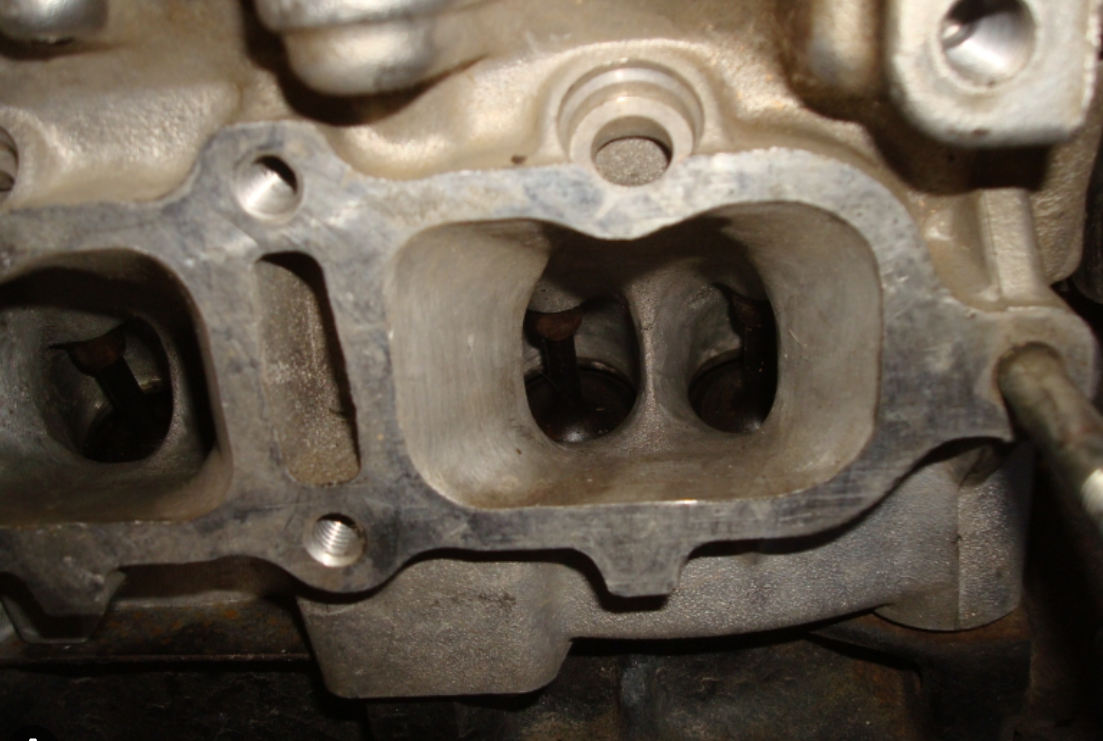

I cant find a beams motor comparison @Truenotch, you able to snap a pic of intake port for comparison?

As it's a really interesting before/after of a VVT motor.

Early 3SGTE port was wide to accomodate TVIS then absolutely pinched up like crazy.

Disgusting. haha.

Roman's 4GR V6 Carina discussion thread

in Project Discussion

Posted

Ohhh this looks good hahaha