-

Posts

7,236 -

Joined

-

Last visited

-

Days Won

39

Content Type

Forums

Downloads

Events

Gallery

Posts posted by Roman

-

-

It's quite common to see a step between the head and the flange, as there's no downside to it being slightly oversized.

Acts to reduce reversion a bit.

But unlikely to be worth the effort of the extra welding etc steps halfway down the pipes for a manufacturer.

-

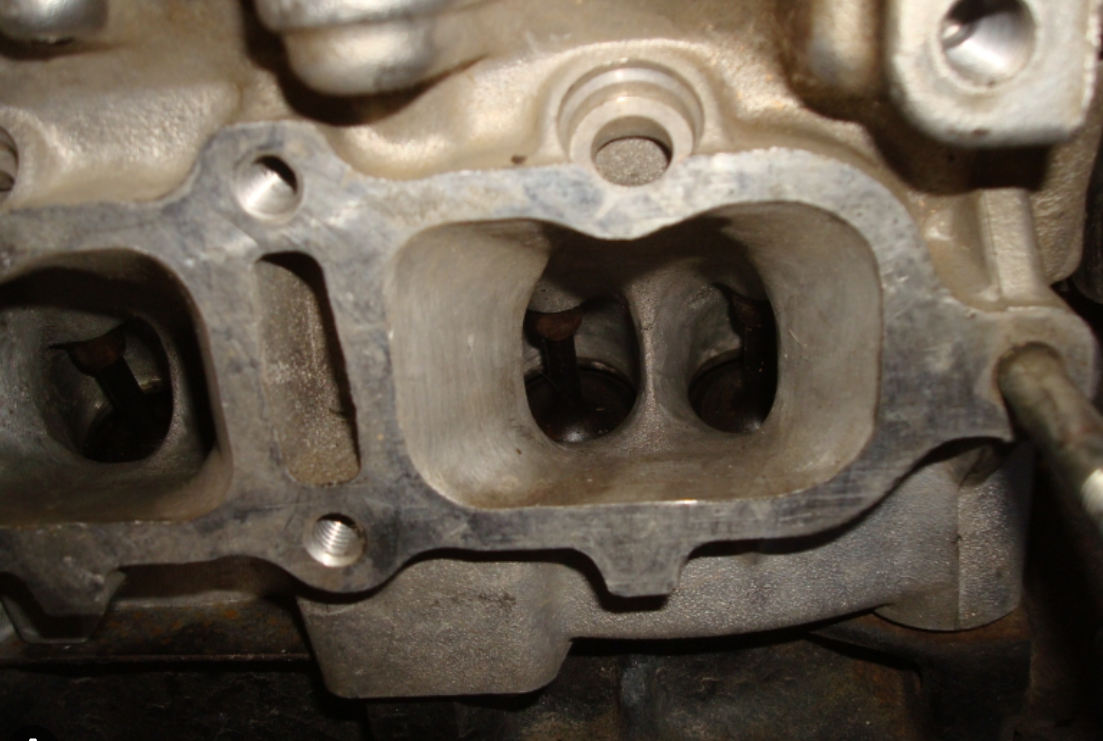

I cant find a beams motor comparison @Truenotch, you able to snap a pic of intake port for comparison?

As it's a really interesting before/after of a VVT motor.

Early 3SGTE port was wide to accomodate TVIS then absolutely pinched up like crazy.

Disgusting. haha.

-

5 hours ago, 440bbm said:

then you had the ability and development of alloy heads, casting possibilites and how to manufacture these repeatable. How much easier casting methodologies and more intricate shapes.. It's not just down to carbs or not. It was the time, where else can they save the money from in the cost of the car to the increase the cost of development and engine costs. there is so much more at play here.

Its a never ending loop. the more you think about of cause/effect and the times back then the deeper the hole gets.

Ahhh yeah I agree 100% !

The things that need to be taken into consideration at an OEM level are insane. And all of the constraints applied, and then trying to make it a sellable product with a warranty that lasts 100s of thousands of kilometers.

We're lucky as DIY tinkerers to have the freedom to do whatever the hell we want.

I guess the point I was trying to make, is that "old info" on the internet has a loooooonnnnggggggg lifespan.

And that generalizations about port size and so on, are only relevant metrics compared to other similar engines.

The graphs that @BiTurbo228 posted are really interesting because they show what a huge variation there is on what some people might consider to be a hard and fast rule.

For example, some testing that David Vizard might have done in the 70s or 80s, about optimizing a 2 valve carb motor.

Studied port sizes, ratios, runner lengths, and so on.

This information is absolutely 100% valid, in that context.

So for example, for that motor having good air speed is absolutely critical. Or you're getting fuel puddling in the engine.

But then on some EFI engines some dyno testing shows that runner diameter just isnt a critical factor anymore.

Going too big has virtually no downsides, and going too small absolutely kills it. (or whatever)

Yet some people will spend $$$$$ on an EFI motor and choke the hell out of it with tiny throttles or whatever.

Because they've applied irrelevant generalizations to their particular engine.

I've seen enough formulas, theories, etc absolutely fall on their face when it comes to emperical testing.

That apart from following some very loose rules about how things should be (no super sharp edges on inlet runners) I think it all just comes down to testing testing testing.

Some people pick a formula, decide that's the best possible thing, then test it and just accept the results good or bad. Rather than testing more iterations to validate their concepts.

So thats why I'm itching to get to that point, this current part sucks and I apologize to everyone who's been reading my drivel this long without seeing any interesting results for better or worse yet.

Hopefully though I'm close to thefinishstart line-

9

9

-

-

- Popular Post

- Popular Post

Here's my take on why we've seen wildly different sizes on things like exhausts, ports, valve size being "ideal" as tech has changed and we've progressed through the timeline.

Carb era

In the 60s or 70s when carburetors were common.

You've got a situation where the carb is mounted fairly far from the head, and suspending the fuel as it's transported to the combustion chamber is an absolutely critical aspect of the engine performance.

So you need small port sizes, small runner sizes in order to keep airspeed up. Even at low rpm.

Then your fuel pressure is really low. If there is only 3-4psi of fuel pressure, then having any sort of pressure wave in the intake manifold can hugely affect the fuel delivery.

If at some rpm point there is a harmonic wave that adds or removes 2psi of pressure, then you've just lost or gained 50% of your fuel pressure differential.

So as a general rule ports were small, valves were small, runners were small, and exhaust manifolds tried to avoid causing any massive peaks or troughs in the intake pressure.

Compression ratios were low, in order to avoid issues with knock as there was no computer control over ignition.

So very little cam duration, and tuned lengths somewhat avoided. Cast exhaust manifolds quite prominent.

2 valve heads common. Possibly because a 4 or 5 valve head, it was impossible to realize the benefits of the extra valve area when airspeed needed to be high all of the time.

Early EFI era

In say the 80s, EFI changed the game a bit by having a much higher fuel pressure and injectors mounted right by the head.

So now you didnt need super tiny intake runners to suspend the fuel with high airspeed.

The fuel is delivered straight down by the valves ready to go.

So now runners an get bigger, ports can get bigger, valves can get bigger.

You can realize the benefits of a 4 valve head, because you can have larger runners to match the higher valve area.

The higher base fuel pressure also means the motor is considerably less sensitive to differential fuel pressure changes from positive or negative tuned waves from intake or exhaust.

Having a tuned length exhaust manifold could be beneficial where it helps pull gas out, with comparatively little detriment when it's out of phase. As it's not disrupting the differential fuel pressure like with a carb.

So it's not going to cause stand off.

So now you could have a bit more cam overlap / duration without any downside.

Usually had fixed valve timing, basic ECU & injection, and still a reasonably low compression ratios on NA motors.

When you have a motor with a static compression ratio of say... 9:1 or 9.5:1 theres a still room in the head for residual exhaust gas to reside in the cylinder once the exhaust stroke is finished.

So these motors were really sensitive to the benefits of having good extractors, and EFI made them insensitive to the downsides.

So even really dunga motors like a 4AFE had a really nice 4-2-1 extractor setup. While the carb version of the same motor made in the same year, just has a cast manifold instead.

EFI was the change at this point that allowed the removal of a lot of constraints on design for things like tuned exhaust. That had a root cause of fuel delivery issues.

The Medium EFI era

Then we move to about the 90s. Still usually fixed cam timing. But it seems like manufacturers were trying to maximize the powerband a bit more, and ECUs can deal with knock etc a little better.

So we still see the decent 4-2-1 exhaust manifolds on everything, and more effort to try beef the powerband everywhere and improve economy.

So there's a range of different variable intake geometry coming out on motors.

Things like varaible plenum volume, variable runner designs, and so on all gave decent benefits.

Compression ratios generally getting a bit higher into the 10s.

Motors were making more power but also getting better fuel consumption without knock issues.

Port sizes, tuned lengths etc could now be based around what the variable geometry systems, with fewer downsides than before.

So everything could get a bit bigger. Power levels go up, as yet more of the design constraints of low rpm drivability were loosened.

VVT Era

Late 90s / early 2000s when variable cam phasers came in, it tipped the existing rule book on it's head again.

The cam phasers largely made any variable inlet geometry like TVIS obsolete. As it's diminishing gains having more than one variable system in place.

Cam phasers became the simplest and cheapest way to broaden a powerband, so the rest of the stuff got the boot.

It also seemed to allow engines to have port sizes and valve sizes to suit their peak power requirements, with even less detriment to mid range or low rpm.

A motor could now have heaps of overlap when it's beneficial, and not when it's not.

Cam duration and lift became more aggressive, ports and valves could get bigger with no downsides.

So looking at a beams 3SGE engine which has VVTI, for example. It has absolutely monstrous ports compared to earlier fixed timing heads.Crappy exhaust manifold Era

Move to the early/mid 2000s and we're in an era where ECUs control and knock strategies etc are so effective, that compression ratios can go even higher.

So ordinary to see 11:1 or more, even on economy engines.

When the compression ratio gets higher, and VVT is present. The motor is less sensitive to exhaust design (citation needed, just my observation)

So the motors can be made simpler and cheaper by putting a garbage manifold on, without any downside.

So we're kinda back to the carb era of exhaust stuff, where we're not relying on a tuned length system anymore.

Despite some absolutely disgusting exhausts, motors of this era are making better overall power/torque/economy/etc than earlier designs that were heavily reliant on a tuned 4-2-1 system.

Direct Injection Era

Then Direct Injection comes along, which was another technology that just tipped everything on it's head like VVT or EFI did.

D.I caused a renaissance for the long abandoned variable intake geometry designs.

As to get stratified charge working at low rpm, there needs to be lots of swirl in the chamber.

Which you cant do with a 4 valve head and the huge valve area.

Now the 80s style TVIS block off plates are back in vogue.

Total intake port area can be huge, because it gets cut back in half by the TVIS type systems when needed.

Based on the above I dont think there's any hard and fast rules around what works, because everythings works or does not work within the constraints of the surrounding tech level of the engine.

As a motor can be highly dependent on a tuned exhaust manifold, or, not. (carb era engines, or late high comp EFI engines)

Or highly dependent on airspeed, or not (carb era engines, or DI engines, but not anything else in between)

-

9

9

-

1

1

-

Things like bigport 4AGE and the early 3S engines had the huge port area, but then the TVIS system a little bit upstream that shuts off a runner to counteract it.

I guess if you looked at the "pinch point" when one of the runners is shut, it would go way to the other end of the graph.

The 4GR originally has this similar system as well, to make the DI stuff work at low rpm.

Also I think the 2.5 and 3 litre GR engines (3GR and 4GR) share the same intake manifold, so the 3 litre engine has the same entry shape but less taper down to the bigger valves.

So again, probably a shit way to design a 2.5 litre engine but just works out well for manufacturing reasons.

It seems that in the era of fixed cam timing, there was a trend back towards smaller ports.

But then as VVT emerged, it's back to having little downside to having a larger port again.

If you look at a 2ZZ the ports are absolutely huge, because I think the cam timing magic nulifies the major downsides of a bigger port.

I guess with a direct injection engine where there's no need to consider "wet flow" at all, there's potentially different constraints on port size/shape/etc.

Either way, hopefully not toooooooo long until I can quit the speculation, and move on to the excuse making stage.

Been too long off the road already.

Hoping to have garage weather tight by this coming weekend but have also had some miserable weather lately.-

6

6

-

-

I probably need to have an engine hold its guts in for more than 3 minutes at a time first. haha.

Hopefully I'm past the worst of it and can start getting to the good part... (drawing graphs and posting them on the internet)

He's got very different objectives to me, so I dont think a collaboration video would make much sense.

As he's running a business and looking for the cost/benefit point of making parts and so on.

So ultimately his videos are promotional material for his business which is cool.

I think it's awesome he's able to do that as a full time gig.

I dont really add any value to that equation.

One thing that I'm keen to test though, that he's pointed out as a flaw with factory cams.

Is that he says there is a bank to bank imbalance because of the way the rockers work.

I am thinking that this imbalance likely completely goes away once you have one bank's home position advanced slightly ahead of the other.

Rather than assuming that the zero degree "hard stop" is each cams zero point in relation to each other.

However that's just my theory and he's done a lot more testing than I have, so I could be totally wrong on that one.-

6

6

-

-

Kelford biggest are 242mm @ 1mm, 12.3mm lift

Vs 225mm and 11mm lift for the Frankenstein ones.

So Kelford still the best option for biggest possible cam at the moment.

Also considerably cheaper.QuoteNot sure if you've seen the latest update good info on factory injectors ie 4bar gives 15% more flow (good to confirm)

Also talks about his recommendation on aftermarket injectors.

I'm using the direct injection only motor, so factory injector information isnt relevant here as I'm using BMW ones mounted in the throttles.

I'm anticipating it'll have some fairly gross transient throttle response, as you always do when they're mounted high up.

When I do a version 2.0 motor I will drill the underside of the ports and run 2x injectors per cylinder, one into each port.

So then I can run some nicely small injectors and get a really good spray pattern from 32 nozzles total (or whatever)

and then less ugly shit up on top of my motor too.

QuoteHe's developing a billet oil pump gear

That will be cool! I mean it's not a known weakness at this stage, but probably a good idea.

I dont know why everyone with a 2GR is so shy about revving them. 86mm stroke engines (basically every 2 litre 4 cyl motor) have no problem doing 8500rpm all day long. Beams motor was happy doing that.

Only an 83mm stroke on a 2GR and I think they have a better rod ratio too.

To further throw a spanner into the works of my already stupidly compressed timeline to try get to the drags. I've been absolutely dead with the flu for about 2 weeks, only just getting better.

So I'm back on the mission to get my garage finished but its blowing a gale today so cant put any more cladding up for now.

Hopefully by next weekend the garage is all finished, which leaves me.... fuck all time to work on carina haha.-

2

2

-

-

20v Jokes aside this car has come together awesomely, great work.

Cant wait to see it / hear it!

Are you going to do anything further apart from fix the exhaust when someone gives your welder back

-

Here's a little song I've written in tribute to the 20v, set to the tune of What's my age again by Blink 182

Nightspeed drags, on a Friday night

Put helmet on to get the feelin' right

We started burning out, we started spinning cranks

But then the car it stalled on meAnd that's about the time VW walked away from me

Nobody likes you when you're twenty-vee

It's got too many valves and it shows

What the hell is 16V?

My friends say build 4age again

build 4age again?

build 4age again?Then later on, on the drive home

I called my mom from a payphone

I said my silvertop it handles like on rails

But I took a drag based sodomyAnd that's about the time that bitch hung up on me

-

1

1

-

1

1

-

5

5

-

-

When I was looking for a filter idea for echo (and future purposes)

I did a sort by price on the repco website, and did a click and collect on 1x of everything that cost less than $2 on clearance sale.

You're welcome to borrow the magic box if it's helpful hahaha

You might be able to fit two of the Mercedes ones on top of each other if you want a long/skinny.

https://www.repco.co.nz/parts-service/filtration/air-filters/k-n-performance-air-filter-33-2193/p/A1269832?rgfeed=true&cid=google-shopping&utm_source=google&utm_medium=cpc&gad_source=1&gclid=Cj0KCQjwsc24BhDPARIsAFXqAB1pM7TxCwegKJMgkEs4hOjCtq_VJ0QGd-1Uymoj8q0MXa8xR7-WTRMaAiFIEALw_wcB-

1

1

-

2

2

-

2

2

-

-

1 hour ago, BiTurbo228 said:

If there's anything the Germans have excelled themselves at it's marketing.

Yeah I remember this one guy had this real crazy idea and shit got wild

-

2

2

-

7

7

-

-

11 hours ago, BiTurbo228 said:

I think you mean tuning the handling Porsche style...

Worth noting that the gist of the article is that poor manufacturing tolerances were mostly to blame.

You cant compare what those notoriously sloppy and imprecise Germans are up to, to the finest Scottish craftsmanship!

It's only a rumour, but apparently some of the cars were actually assembled by people who were partially sober-

8

8

-

-

The only way I'll win is by firing all my pistons at his car.

Likewise, super keen to see your car again!

Has had a huge amount of development since last year, keen to see how it goes.

30% more trap speed this year? haha-

2

2

-

-

5 hours ago, BiTurbo228 said:

Garage looks good. I feel you about grit and crap getting everywhere. My old place was horrendous for that (only one real garage space, horribly cluttered so impossible to clean). Doing anything that required cleanliness like engine or diff builds was a nightmare. In my current garage build I'll end up with a clean garage and a dirty garage I can keep (mostly) separate which I'm very much looking forward to!

To-do list doesn't look too bad car-wise (though I didn't spot anything about wiring on it, is that all done?). 'Finish building garage' feels like one of those single list points that expand into a whole second list with lots of bits and pieces in it. I suppose it depends on how 'finished' you need to get it before it's functional enough to 'finish' the Carina. Technically I suppose you don't even need doors or interior cladding. Just a roof, walls and floor.

11,000rpm Cosworth KF 2.5l V6 on bodies as some motivation

Yeah I mainly just need a weather proof space. I can live without power lights etc for now.

As I just need to be able to take my motor out to work on the firewall etc without everything being exposed to the elements. (and animals)

So hopefully not too long to go.

All of the wiring is done, I need to test some things like lights and indicators and so on.

But the stuff needed for drags at least is pretty easy.

All of the engine wiring is sorted, all of the sensors have been tested and calibrated.

Alternator works, and all that.

That video you posted is interesting, because to me that KF motor sounds more like a high strung 4cyl.

I guess the thing with a V6 is that if you have even firing order separation on each bank. (So 60 deg V6, not 90 deg like DTM motor)

Then you have 240 deg of separation between each exhaust event on a bank. Compared to 180 degrees with a 4 cyl.

So the exhaust can sound a lot different because if you had a 6-1 (or effectively 6-1) you've got 120 degrees of separation so it will sound higher pitched.

But then if you ran totally isolated exhausts on each bank, or the pipes are really uneven.

It could also keep its "240deg" sound, and sound like a pair of 3 cyl motors driving in unison instead.

And then there's the effect of having an unequal length between each 3 pipes too on each side.

I guess a good comparison, is that a Subaru "boxer rumble" comes from only the pipe layout, not uneven firing order or anything.

Yet sounds wildly different to most other 4cyl motors. If you put an equal length manifold on it, they sound just like a normal 4 cyl.

Compared to a 4 cyl, there are lots of different ways you can affect the pipe interactions on a V6.

Can have a 6-1 manifold,

long primary, short secondary 6-2-1,

Short primary, long secondary 6-2-1,

Separate 3-1 with long or short primaries.

Then all of the ways that different mufflers can affect the sound... and what cams you have.

Then how much noise comes from the intake.

So it's probably a good thing that nothing is set in stone in terms of how the motor sounds.

As I'm not expecting it to sound particularly pleasant, or even go particularly well on first iteration.

But at least when the motor is going, and the car is driving. The fizz level ramps up, and doing the iterative changes and testing is the fun part for me.-

6

6

-

-

Damn I envy your clean tank, haha.

Surely a 4.3 final will be pretty good once the blower is on?

-

- Popular Post

- Popular Post

Honestly it could be anything ranging from really nice, to absolute dogshit depending on exhaust and so on.

Might take a few iterations of the exhaust to get it sounding nice.

It's hard to say because none of the (3500cc) 2GR people seem to run ITB or rev out very high, and I think thats what will define the sound on this.

Virtually everyone with the 2500cc version leaves them unmodified, because it's too hard to mod the direct injection engine.

Seems that equal length pipes is the key to nice exhaust sound though, so hopefully manifolds will help.

If the sound was hilariously out of place for a Carina, somewhat like below. That would be ideal.

(The Alfa 155 DTM has a 2500cc V6 that they run to 12k rpm)

However it might end up sounding like lil johhnys straight piped RB20DE swap

INB4 @xsspeed tells me that's a good thing

-

6

6

-

2

2

-

2

2

-

Exciting!

-

- Popular Post

- Popular Post

OS 2024 DRAG DAY QUEST!

I am running behind schedule of where I'd have hoped to be by now.

The last month has flown by without much progress. Due to concentrating on getting my new garage up and being away from home a lot for work.

Some other people have helped me though which I am very grateful for!

@flyingbrick helped me with getting the radiator patched up properly, many thanks! Now it will fit between the rails and hold water.

I'm not sure if he is a member on OS but Dan from Taupo helped me to machine the fuel rails.

Although I thought it was a cool idea at the time to make these a derpy shape since they are printed.

I guess I kinda forgot that it would be a total prick to hold them in place later on for machining.

Dan desinged some soft jaws which I printed. Then he drilled injector holes to correct size, and tapped the threads for the end fittings.

Thanks Dan! Much appreciated.

Hindsight: I should have added a hex shape or some flats onto the very end of the rail, so there's something to hold onto with a spanner when tightening the end fittings.

I've sourced one of the tiny dual diaphragm KE70 brake boosters and master cyls, this will give me a heap more clearance to the drivers side bank.

I wont fit this till later though.

As per usual my scheme for the extractors on passenger side didnt quite go to plan.

There just wasnt enough room for the 3rd runner to work nicely. without hitting the chassis rail.

So I have a bit of a dorky shape on 3rd runner but if it gets me going then thats cool. They're all fairly even lengths.

What's left to do, to get to the drags?

-Finish building garage

-Finish extractors

-make rest of exhaust fit

-fit mufflers

-hang exhaust

-make battery box / battery wiring

-wire up radiator fan

-redo fuel lines at back of the head

-add charcoal can and extend the line from under the car

-Make top and bottom radiator mounts

-Test start up?

-Test drive?

-Pull motor and box back out, crossmember out

-properly weld engine mounts and repaint crossmember

-Remake firewall

-Swap to KE70 booster and MC

-redo brake lines

I've got 8 1/2 weeks to get all of the above finished, put some miles on it, shake out any unforseen issues, and get a tech inspection.

So I'm kind of at the point where it's doable, but I need absolutely nothing to sideswipe me between now and then.

Which is highly possible. Kind of exciting. See how it goes!-

36

36

-

3

3

-

1

1

-

Yeah it's 6x9m and a 2.4m stud.

At my last place I had a 12x9m with 3m stud, and at first I loved the idea of having a huge open big single space.

But the problem is that if you want to do painting, or grinding or whatever... you have to cover up EVERYTHING.

So usually I just went outside anyway haha.

Then it all just ended up full of junk anyway.

So this time, on a rural section so I can have multiple things. So smaller workshop area but then have a big storage container, will build a little hut for the ride on mower, and so on.

Later on will hopefully have a little painting area or hot works area that you can just go get some work done without 100% admin time tacked on top.

But priority is to get this up, and get carina running for starters!

I've got a few issues at the moment though, all of the windows that were in it were a bit shit, and someone stood on the pile of glass and broke most of them.

I've patched up where the old side access door was (as goes out to nowhere)

So I'm a little short on cladding, and need some better windows. I drew a decent model of it for when I submitted my plans to the council for consent, it's been handy for checking dimensions of 2nd hand doors and windows to try come up with a plan for how they might fit.

Probably need a bunch of smaller ones rather than gigantic things.

-

8

8

-

-

- Popular Post

- Popular Post

Not great at the moment.

Have been away for a work a lot, and then have also started putting my garage up.

So although that's setting me back a bit on having time/energy doing car stuff.

I'm hoping that It'll let me catch up once I've got some extra covered space and so can start burning the midnight oil!

Hopefully get a few more trusses up today if it keeps clearing up.

-

25

25

-

I cant tell from your pics, but the most likely source of fuel problems will be conductive heat (metal fuel rail bolted directly to engine, transferring heat into fuel)

If there's a way to mount some plastic washers to isolate your fuel rails from touching the motor. This will likely make the biggest difference if fuel temp is your issue.

Is this car running a fuel surge tank? Generally EFI systems are less susceptible to fuel boiling as the pressure is so much higher.-

1

1

-

-

@Truenotch it sounds like you're going to be making some sort of cardboard based erotica?

...Subscribed-

8

8

-

-

Thanks for posting, god these type of multi day drag and drive events. Just so friggen cool.

I absolutely love that you're carrying your house around on the drag car hahaha.

The bit about taking the other guys driveshaft cracked me up, I can just imagine it

"Hey mate since you're totally fucked anyway..."-

3

3

-

2

2

-

-

Noodly Aspirated

-

3

3

-

5

5

-

Cheap diy DBW ideas for ITBs

in Tech Talk

Posted

E-throttle is just an H bridge controlling a DC motor...

So you can literally use any DC motor that is within its torque and rpm range with the available juice (~14v and 2 amps or something like that?)

A lot of the ethrottle setups have a lot of internal gearing to step down the motor speed by roughly 10:1 - 20:1 kinda range.

I'd definitely not reccomend removing any of the springs from the throttle bodies though, probably wont pass wof/cert/etc, and it's also very dangerous if your motor fails and there's nothing to bring them to home position.