-

Posts

7,238 -

Joined

-

Last visited

-

Days Won

39

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Roman

-

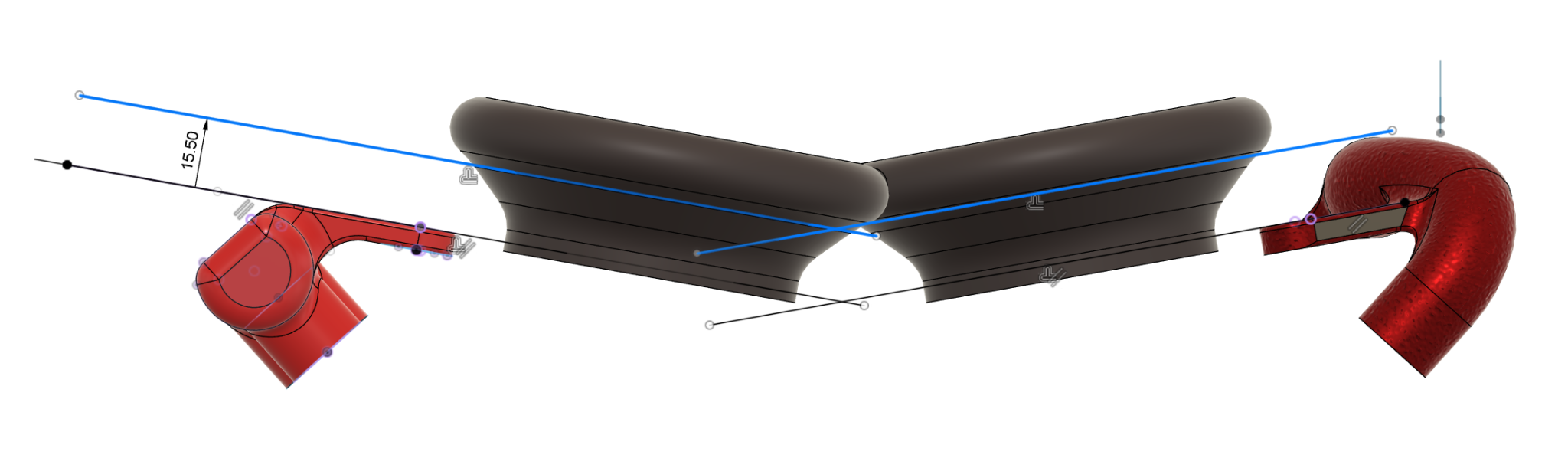

Yep 100%, can keep plodding along with this while also getting other things sorted. Still got a to-do list that's a mile long to get car sorted for cert. My metal printed linkages parts to hopefully finalize my ethrottle setup should be arriving in a few days hopefully. That's the main thing I need done, to carry on tuning the car. I've had a fairly bodgey way of mounting the e-throttle motors currently (cable ties were involved) and this means the PID isnt great. B theres a little bit of slop in everything, it tends to undershoot or overshoot by a bit. Once everything is solidly sorted, hopefully the bank to bank targets will be really good. I've also been thinking that may some of my wacky fuel results, like wanting 85% VE at 5% throttle at 800rpm. Is due to lack of a fuel damper. I originally designed the rails to accomodate these, but with the final version they slightly hit on the lip on the firewall. So might be a reason to redo the rails anyway. For the next iteration I'll put everything that needs to be machined on the same plane. Injector holes and the fuel hose fitting all facing the same way, and on the opposite side of a flat base. It will give a whole heap more space around the throttles.

-

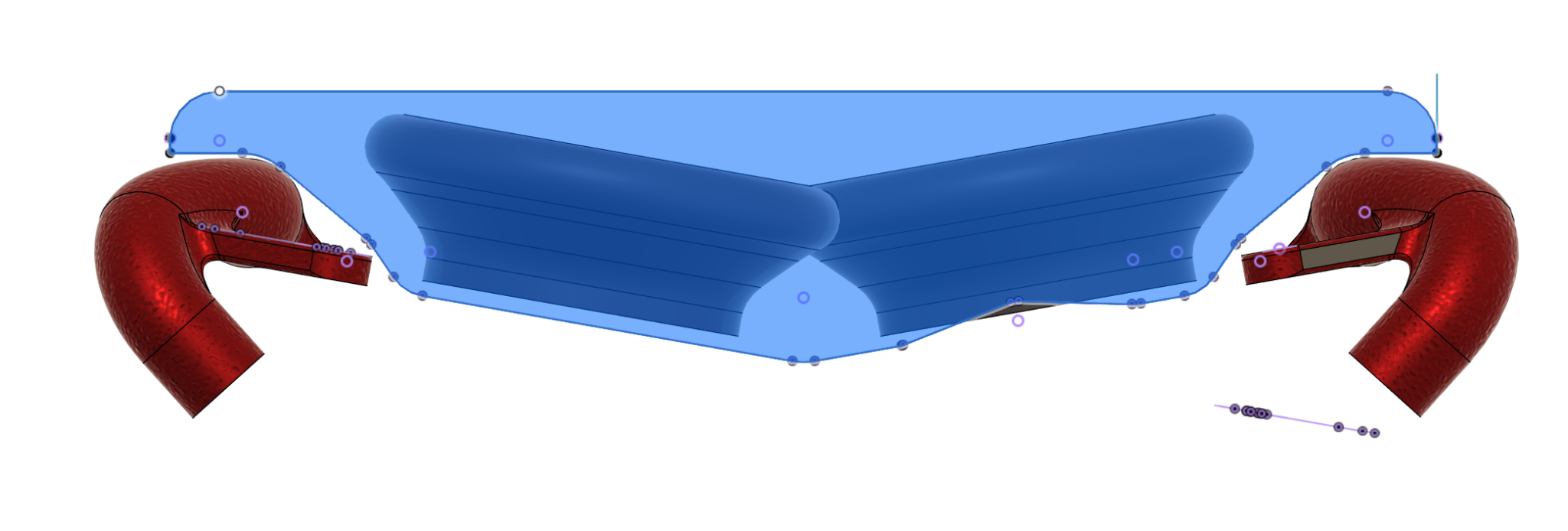

Yeah I can probably figure out something like that. Just having another look at the engine bay, there's another simple way to improve the situation whether it ends up front feed or side feed which will unshroud the throttles a bit. Which is redo the fuel rails. I thought they would look cool with the swoopy sort of design but they look a bit strange when on the motor. I could easily remake them so they are only as low as the flange that mounts them to the throttles. Then I can run a wider airbox all the way back. Then they will be hidden so wont matter what they look like. So will just make them easier to machine this time.

-

-

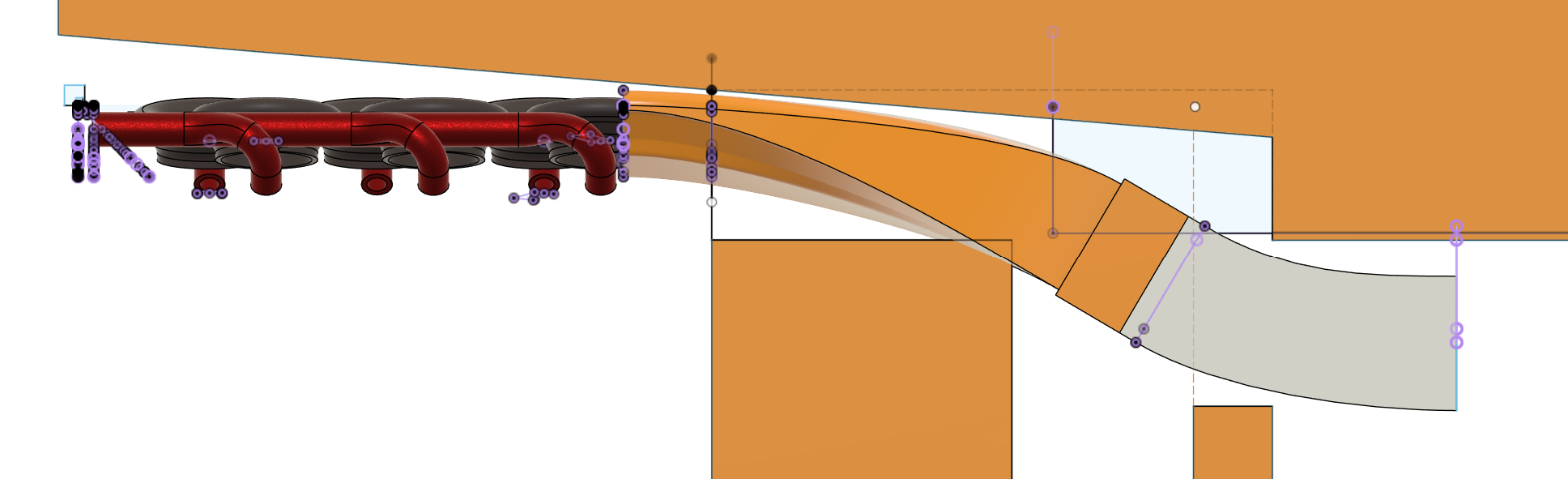

The longer filter is only 85mm tall instead of 100mm, so might be the better pick given the constraints.

-

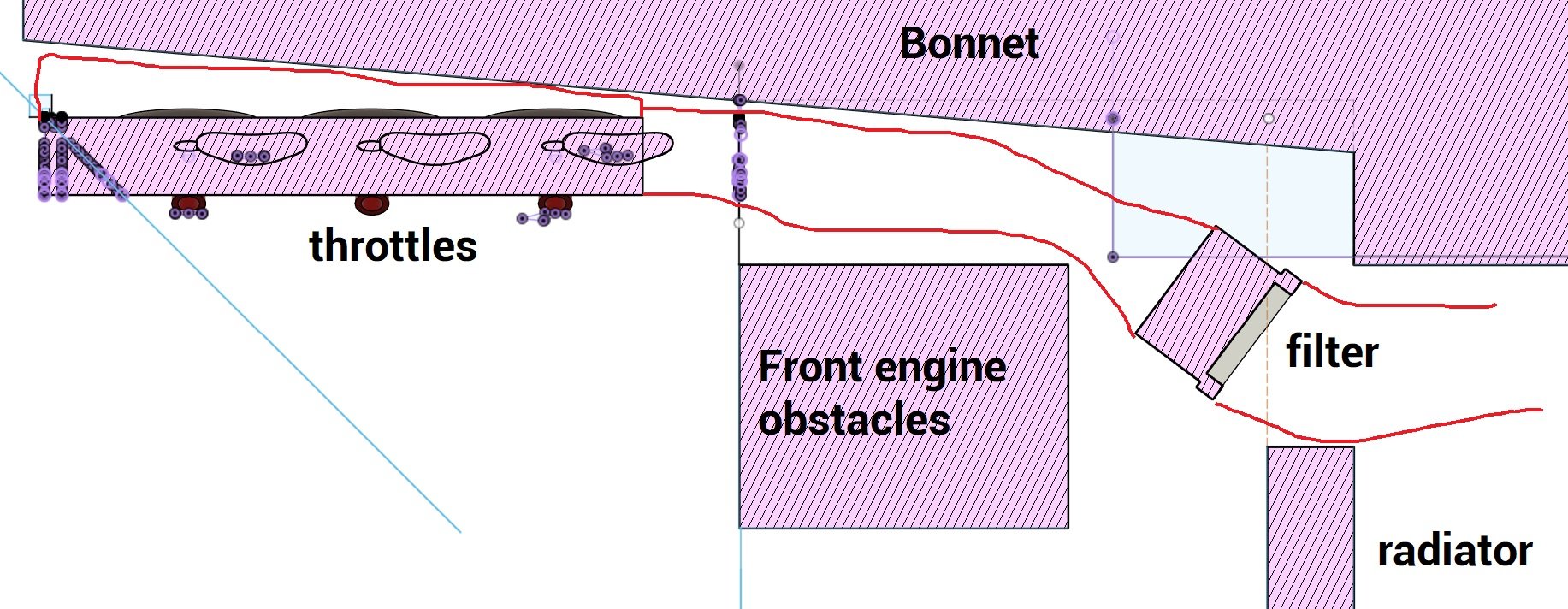

Yeah these filters are not a solid plastic housing, its like silicone rubber or something. So could definitely make it curved if that works better or whatever. It's easy to test though, even without a dyno - Two back to back runs, with the filter in or out. (and/or airbox off) It looks like I might need to rethink my plans anyway. I have just been doing some bonnet measurements and it's a lot worse than I would have hoped. I've just cut the center brace out of a spare bonnet, so max clearance possible. Even with that gone there's only about 20mm clearance from the top of my lower manifold part to the underside of bonnet at the worst point. So I might need to run some side feed inlets on it instead of coming straight out the front. Or make it a lot wider at the pinch point, so cross sectional area is still alright.

-

Stop being provocative, he clearly doesnt like having a painted floor. Although he hasnt told us what sort of carpet he's going to put down instead Great work Sheepers this car is going to be absolutely ace. I look forward to seeing it some time.

-

Whoa! Looks awesome

-

Yeah that's a fair point. Itt looks a decent size in person. But looking up the car's that it fits, it's all fairly sedentary Peugeot stuff. It's 330x100mm with 50mm deep pleats. So it's still considerably considerably more filter area than nearly any pod filter I guess.

-

Found an easier option I think. Rather than running the super long wide filter, and having it directly over radiator. I guess it's easier to put it a little close to the motor, and then any flexi join etc that's needed, isnt critical to sealing filtered air in. I found this other filter in my bucket, which looks like a good size and means everything fits within my printer's width: So now I'm printing the front part to hold it on and dip it down a little. It looks like I've got more room around the radiator cap than I first thought, so will un-scoop some of that area. Might add some ridges that run front to back to add rigidity to the whole thing. But for now, make sure it all fits. Then figure out how much of a roof I can put on it, and how to hold it all together. This has been fun to make some fairly quick progress on for once.

- 132 replies

-

- 38

-

-

Sounds good, cant wait to see it!

-

Cool, do they let you use the dyno at work for beams related activities?

-

Are there any more events coming up soon @Truenotch ?

-

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

-

I have / had an Earth-X battery. Chose that brand because it had extra protections in it for short circuiting / overcharging / etc compared to some other options. But that was a while ago, they might be all same same now.

-

There's an old story, perhaps it's a wive's tale, I dont even know what sort of era it's from. But anyway. Someone developed some aero doodads for the front of the car or something, and the car was going really fast. When they bought the car into the pits, the crew would quickly go throw a blanket over the rear of the car. Everyone was so fixated with trying to see what was under the blanket, that no one bothered to see what was hiding in plain sight. What I'm trying to say is, if you make something in the engine bay out of carbon fiber, and then draw some titties on it. No one's going to look anywhere else in your engine bay

-

Thats a good way to approach it! So easy to get distracted by something else going on, and forget you havent finished doing something.

-

Another thing, and you'll have to excuse my hypocrisy because I've currently got a big lead acid battery sitting behind the passenger seat. Ha. But, when I had the battery mounted in the boot of the carina. When I switched to a lithium battery, which happily can crank over the V6. The battery weighed less than just the cable that I had removed to remote mount the battery. My lithium battery broke the terminal part from me doing stupid things with it, but plan is to buy another one and put it back in the bay. As it makes everything so much simpler, and its a lot lighter. Not that I'm guessing your tooooo fussed about weight given 4WD stuff added etc. But its also incredibly simpler with a lot fewer points of failure. Appreciate if you want the look of a clean engine bay though and want the battery out of there.

-

Main thing about voltage fluctuating is to make sure that your injectors and coilpacks are getting power from same-ish supply as the ECU. So if the ECU dips to 12.0v, your injectors are also seeing 12.0v so your deadtimes are correct. and to a lesser extent dwell time for coilpacks.

-

Sealing to bonnet: Have thought about that, but nah dont like that idea. As I doubt it actually seals very well. Like if I'm going to have an air filter, I want it to work 100% properly. So I can be confident of driving it on gravel etc. But it does make me think that I might mount the filter a little close towards the engine, hard mounted to the airbox. Then the front section over the radiator can be flexible without the flexi section risking ingress of debris if it has an issue. Alex - I cant use ramflo filters, because the extra torque would twist my chassis off the line

-

I guess probably easier to just buy those hood pins that are visibly "up" when not locked. Ahh well all good in hindsight. Bet that was scary having bonnet up like that!

-

Damn, sucks about the bonnet! I guess having some sort of "is bonnet shut" sensor or switch doesnt really help, because pins could still be out while the bonnet is sitting in its normal position. Seems inevitable to make this easy mistake eventually. Good work on the filter, I will award you max irony points if some swarf from making an air filter is what damages your motor finally. haha! Did you manage to do any testing on other trumpet lengths?

-

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

Maybe some wool tuft testing inside and outside -

Wow, that's cool as! Sounds sweet. Yeah I am basically going to bin nearly the whole exhaust except for extractors and try some other stuff. Hoping to keep the noise down a bit.

-

Airbox activities. I wasnt sure how to start on this or what might fit with bonnet yet. So just start with making a base plate that clears the rails etc. Then the goal is to have a filter, or at least the air inlet. Running over radiator. Dipping into my bucket-o-filters i found this one which fills the gap pretty well. A few more top part tests then printed one with a flange on the front. So i can test the shape and start dipping it down. Mainly just need to work around the radiator cap area. It looks like i will have a pinch point to the bonnet about where the flange is. So decided to start making it wider as soon as the fuel rails finish. This is current scheme thats just started on the printer. Im not sure what the lid will look like yet, but will try use as much head height as possible. Im not 100% sure how I will make the final version yet. Possibly thin nylon print with carbon smooshed over the top.

- 132 replies

-

- 40

-

-

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

You did it!