-

Posts

8,221 -

Joined

-

Last visited

-

Days Won

10

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Unclejake

-

I (of course) have the advantage of seeing at least some of the circuit in real life (impossible to photograph)and I suspect the cooler has been installed to cool 100% of the system (apart from the 24V pump). @rusty360's idea of pushing the spool (I didn't know that was a spool) by hand will be awesome tomorrow. Above the big hose to the PTO is a black steel tank that seems very robust. I wonder if it's designed to hold pressure?. I guess not, but I'm not sure. That black steel tank doesn't appear to have a filler.... but the Hiab does have a filler and an orange tank, and it looks like the orange Hiab tank has a gravity fed hose that feeds the black tank. The orange tank is empty. I dunno what's in the black tank. Unfortunately the hydraulic hoses in and out of the 24v pump are smaller than all the other hoses, and evidently this complicated system worked two years ago before one hose 'blew' (read: It wore out from dragging onto the gravel roads) so I figure I'll get a guy in with another Hiab to tilt the deck up, replace the 'blown' hydraulic hose, fly in some hydraulic-oil, repair the wiring as best as I can.... and then use @Hemi's "start the engine with the PTO engaged" approach. If it's all a disaster I'll have wasted my money and time and will tow the truck to my property, dig a big hole and bury it. Seriously I will. But if the deck goes up and down I'll sort out all the brake lines etc. and drive around the island tipping shit wherever I like. LOL!

-

Thanks a million team. I just got into wifi range so photos from this afternoon have suddenly appeared in the thread. One photo is less obvious than the others. It's the top of the hydraulic-oil tank and shows what I assume must be the electric over hydraulic valves mentioned by others. No sign of air in this truck. Red lever is attached to a morse style cable that runs to the PTO. If I lift the lever when the engine is running there's a graunch noise (makes sense now). The gearbox feels OK. Wiring has been damaged by rats and from sitting for two years. Additionally, some local chaps were trying to 'fix' the wiring for the previous owners in 2022. I have removed a little of that wiring which has now made the engine run. Yay! Incredibly; The engine didn't even make a full rotation under the starter before it burst into life and went straight to a steady idle. The engine and chassis are very sound I'll try Hemi's diagnostic plan ASAP. I will need someone else with me to crank the engine whilst I watch for things happening SERIOUSLY appreciate all your input. Amazing information for a numpty like me. Thank you EDIT: Freight alone to get a truck this size to the island would be about $8k, so it's worth making a bit of effort on. I reckon replacing the brake, clutch, and fuel fluid lines could take two full days, but bundy tube is pretty cheap

-

-

-

That would explain a few things. Thank you. At risk of sounding stupid: Can I pull up the red lever with the engine off, start the engine and then expect to see hydraulic-oil pissing out of the fitting where I removed the blown tipper ram feed hose?

-

-

I can't get the 24v pump to do anything unfortunately. Wet as hell here so I haven't been under the truck this afternoon. Fuck resizing images on an Android phone is a ballache. I'll have to sort out the photos from the laptop tonight. With the ignition on but the engine stationary I can get something to make a thud noise when I turn the broom raise knob, but impossible to know what's thudding by myself. I need an assistant. Still very keen to know if any of this effort is useful without a clutch though

-

Should I be seeing an electrical switch on the dash to let the tray down then? I'm heading back to the truck in about an hour so can get more photos Also: Can I test any of the PTO hydraulic circuit without using the clutch?

-

Shit. Thanks Hemi. I think I need to get someone with a working Hiab to pull the tray up. It's a rats nest of hoses and valves that are bloody hard to see with the tray down.

-

Folks, I'm a bit out of my depth here. I bought a half fucked 2003 Isuzu NQR truck and don't know how to test the tipper. The clutch line is blown, so although I can start the truck in gear and drive it around in that gear (only) I can't disengage the clutch at this time. A new clutch line is two weeks away All the brake lines and fuel lines have rusted through, but that's probably not relevant right now. At one point the truck had a rotary broom on the front. That has been removed and the hydraulic hoses simply joined together behind the front bumper. From what I can see the broom worked on a 24v hydraulic pump mounted to the side of the chassis. You can see the white plastic reservoir behind the Hiab i the below photo There's another pair of hydraulic hoses coming from the Hiab and the steel undertray hydraulic tank that I THINK are also joined together behind the front bumper (it's really hard to see) The truck currently has most of a Hiab fitted, but the Hiab is missing the boom and is very rusty. I don't care about the Hiab and want it removed I care about the tipper. The ram is under the deck and is a single action(?) ram. The ram only has one hydraulic hose that goes from from the top of under-tray hydraulic tank to the ram... but that hose has burst. There's a big hose that goes from the bottom of the tank to the PTO. The pressure hose on the PTO goes to some kind of valve arrangement that I am struggling to see with the tray down. It's a mystery at this point. There's a red lever inside the cab that operates a cable that seems to engage or de-engage the PTO The hydraulic system includes the PTO, a hydraulic cooler, numerous electric solenoids, an electric switch bank in the cab to divert oil to either the hoist or the broom There's an under tray hydraulic tank with numerous hoses coming out of the top of it via electric solenoids. There is no filler cap on the tank (and I can't tip up the deck for a better look) It looks like the under-tray tank gets filled via the Hiab hydraulic tank, which will be a problem when I delete the Hiab So... what I'm hoping to do is throw away the Hiab, delete all the spare hoses and solenoids, delete the 24v pump, cooler etc. etc.... and simply run a pressure hose from the PTO to the tipper ram. I figure that'll make the ram go up? What I don't understand (and I've got no clutch at the moment so can't experiment) is how the deck would come down again. Is it as simple as slipping the clutch? Finally: I'd like to be about to spread 'metal, along the driveway as I drive. Am I about to make that impossible? FML I know NOTHING about tipper trucks. I've never used one. LOL

-

It's interesting that the noise is present under both reverse and forward load. It could be as simple as a broken exhaust mount. Probably worth someone under the vehicle when it's running and in gear before you pull too much apart. In related news: I have spent weeks (off and on) trying to find a knocking exhaust over bumps in one of my Land Cruisers. I could have sworn the exhaust was hitting the gearbox. The sound was absolutely coming up from the transmission tunnel.... but strangely stopped when I cleaned the inside of the windscreen last week..... and it fell out onto the bonnet.

-

Oh dear. At least that eliminates everything behind the output shaft.. If there's an inspection plate on the bellhousing I'd check for a loose flexplate/tourqe convertor (if the gearbox mounts seem OK)... but apart from that I am out of ideas. Best of luck Flash. Hopefully it's nothing too serious

-

Do you hear the sound when in gear but stationary, or only when moving?

-

There's a reasonable chance this vehicle was once sold by The Checkered Flag motor company in Pt. Chev, Auckland. Google suggests they're no longer in business but I guess it's possible some records still exist if you could get in touch with whomever owned the business. A long shot I know, but IIRC they had a thing for Panteras. I came very, very close to buying a Ford Sierra RS Cosworth from them a long time ago but pulled out due to concerns wrt the valve guides. That was a very brutal car to drive, but quite good fun

-

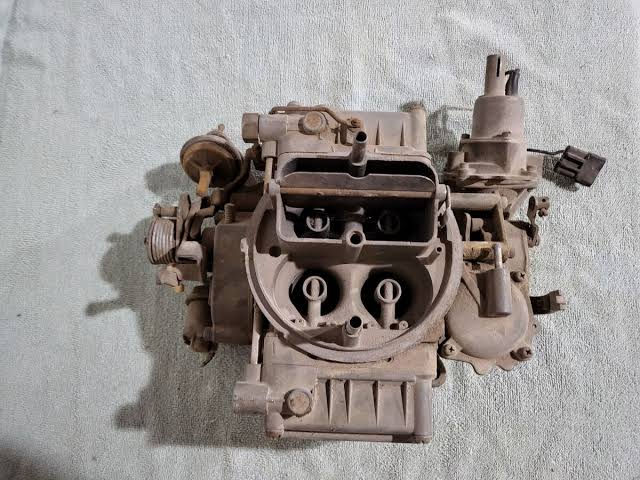

Not exactly the same I know, but the four flutes on the casting closest to the bottom of the photo and the single tube just above that casting says Holley... and not Edelbrock

-

Nominal is right. It's Holley. There's a few on eBay. Search vintange Holley for a few more photos

-

It's a very, very long time since I looked at one... but it immediately looked like an Edlebrock. Google will probably prove that wrong though

-

I don't know exactly - but I'd guess at 6 metres below the orchard. The property boundary is ocean to the north and a large lagoon to the south. The orchard is roughly 6m above sea level and lagoon level. The lagoon was up a metre or so above sea level last year, but is now more or less the same as the ocean so I figure the ground water will be about sea level. I've dug down about 3 metres (for a toilet) and no sign of water there, but the previous owner installed a water bore (unknown depth) with a surface mounted pump and I don't think the pump can suck up more than about 8 metres

-

Today I learned what eight people filleting blue cod can do in a day. Fishing is Chatham's primary industry (followed by farming and tourism) and the fishery is largely in incredibly good shape. My plan is to plant around 30 fruit trees this year. The soil is largely sand so it makes sense to add affordable fertiliser... which in this case is cod skins and guts. The plastic bins are known as a dolav. There was 1.2 tonnes of skins and gut in the pair of them (no fish frames)... all waste product from just eight people cutting fish yesterday. Impressive.... and don't worry about cod being decimated. It's a great table fish and quotas are really well managed. The future looks good. Hopefully my avocados don't stink.

- 34 replies

-

- 25

-

-

I'd remove the gearbox and pay VERY careful attention to the gearbox input shaft nose and how much fore and aft clearance it has to the crankshaft when the bellhousing is bolted up tight to the engine block.

-

Non-functional as in he can't get the clutch to release, or non-functional as no drive is transmitting from the engine to the road wheels?

-

I'm guessing most everyone is bored with this by now, but it turns out the Skellerup Master Blaster hose nozzle is 'taxing' the system by 19 litres a minute. There's nothing wrong with the nozzle. It's just designed for more pressure than I'm delivering it. I've settled on a smallish, lightish, petrol powered pump to alleviate the symptom. A bigger bore (140lm long) underground pipe would have made all the difference... but I didn't do my research properly before buying pipe and TBH the cost of a petrol pump is less than replacing the pipe... so that's the plan. Tomorrow I'll start back-filling all the trenches. After that it's too late to turn back... and I'm OK with that. Thanks everyone for the advice. Now onto the next drama! EDIT: I looked at lots of minor brand ~$450 pumps and decided a new Honda from a reputable supplier (who's experienced in sending stuff to Chatham Island) was worth double the money. Consequently the Christchurch Stihl shop got an order for a really light-weight Honda WX15 tonight. The dudes from that store come over here annually to shake hands and peddle their wares so it'll be easier to sort spare parts etc. when things go bad. I'm also guessing the Honda will be quieter than the Xlyongikin/Vellisuckymota equivalents, and at only 10kgs the Honda should cost less than $60 in freight and may be here on Thursday. TBC https://www.hondaoutdoors.co.nz/wx15-portable-pump

- 23 replies

-

- 10

-

-

The first of 42 rafters came off the mill today. The plan had been to mill these in February.... but nah. They'll just have to go up a bit wet. I have a plan for that. It might even work! Ha.

- 34 replies

-

- 12

-

-

The 20m of 25mm hose wasn't installed when I did the visual checks on Tuesday, so you didn't miss a thing. Your advice has been spot on. I'll have a look into 50mm hose (thank you, I hadn't thought of that), but a 50mm hose would be a heck of a weight to be dragging around a building site, and unfortunately I need it 20m long to get to all four corners so I'll have to make a compromise somewhere. I just need to decide if it's expense/noise/flow/pressure or convenience that I want least. Edit: I'll do some additional flow checks without the nozzle, then without the hose, hose tail etc. Both the upper 'tap' and lower tap will be identical setups. I.e. 40mm LDPE>40mm ball valve>25mm hose tail>20lm 25mm PVC washdown hose>25mm hose tail>Skellerup Master Blaster nozzle

-

Howdy gents, it's a beautiful day here so I abandoned paid work very early. In reference to my first drawing: The lowest tap delivers 120 litres per minute without the washdown hose attached The troublesome tap delivers 67lpm without the washdown hose, but 37lpm through the 20 metre long 25mm i/d PVC washdown hose and nozzle. Ergo: I reckon I need a spray/stream nozzle better suited to low pressure than the Skellerup Master Blaster I was sent. Should be an easy fix. Yay!

- 23 replies

-

- 11

-