-

Posts

14225 -

Joined

-

Last visited

-

Days Won

10

Posts posted by Raizer

-

-

On the subject of Chassis Tech, any feedback on their drop spindles?

-

1 hour ago, Adoom said:

Jeez, this thing turned up in 11 days! I wasn't expecting it until the end of July.

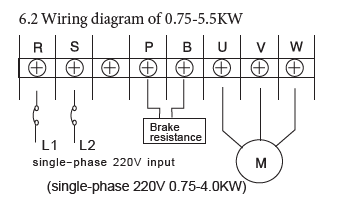

But unlike the 7.5KW model I have, this 4KW one has no ground terminal. The manual doesn't show a ground connection in the circuit diagram for the smaller models.

Do I connect the heat sink to ground? Does it not need to be grounded?!?

I was wondering the same thing (have got a 2.2kw on the way), guys on hobby machine forums say just run the earth to your mill/lathe/whatever.

-

12 minutes ago, MaxPower said:

anyone done any mods to their round column mill?

Only DRO and 3ph conversion so far.

Going to make a stabiliser to stop the head rotating soon though + a gas strut to make lifting it easier.

-

6 hours ago, tortron said:

I believe that's going from matawai to gisborne

That's this one, Otoko hill

-

1

1

-

1

1

-

-

Or aluminium flanges and decent straight joiners could be the go too

-

1

1

-

-

1 hour ago, HumberSS said:

Might have a rotary table lurking around that you can have for fuck all. From memory it needed some love. Where are you based?

Very interested, I'm in Gisborne.

Lol I now know all about the lack of torque when you run a 400v 3ph motor off a 220v 3ph output VFD.

My ancient old mill motor can't be swapped to star/220v so it's looking like I'm going to be joining everyone else on here with AliExpress VFDs.

-

1

1

-

1

1

-

-

Just be prepared to refresh all the bearings or at least clean out and regrease them along with just generally cleaning up and oiling all the moving parts, that's been the only actual issue as such I've had with mine is the bearings.

Otherwise just the normal round column mill limitations, plan your work around the longest tool you'll need for whatever you're doing so you can avoid having to raise or lower the head and losing it's position etc.

Speaking of bearings, I found a source of sealed angular contact bearings in the UK, made in China by a German owned company, they are no FAG or SKF but are the factory spindle bearings used in Sieg, Optimum and several other Chinese mills and mini lathes so worth a go imo.

-

3

3

-

-

If you ever need to change the belt, rather than pulling everything out just cut it, pretty much anywhere that deals with conveyer belts will be able to supply a joiner.

I had one in my old lathe, you just get a slight clink noise when it passes over the pulleys lol

-

6

6

-

-

Yeap fan switch or temp sender in some models.

-

- Popular Post

- Popular Post

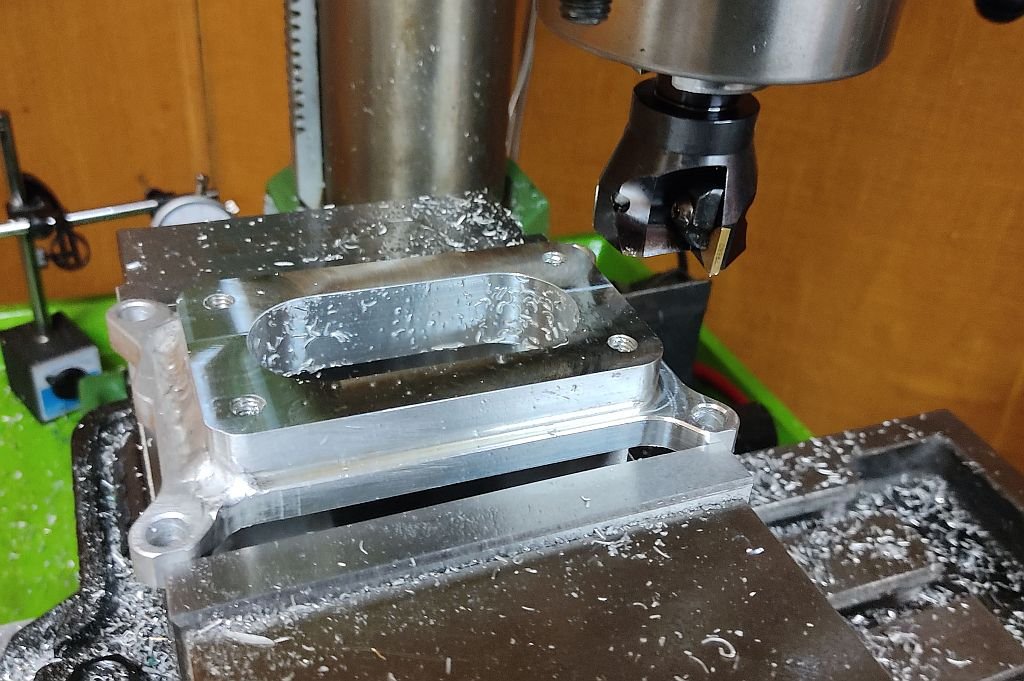

Loving TouchDRO still, just starting to learn a bit more about it's features like hole patterns etc.

That's just a screenshot of it running on my phone, it's way better on the tablet in landscape display.

Made an adaptor for @chris r and it nailed the hole positions etc.

Still got so much to learn with the TouchDRO and machining in general, but even a somewhat basic project like this has shown me a few things I'd do different to get improvements and also extended my tooling wishlist a lot haha.

Keeping an eye out for a decent deal on a boring head, rotary table and a few other things.

-

13

13

-

- Popular Post

- Popular Post

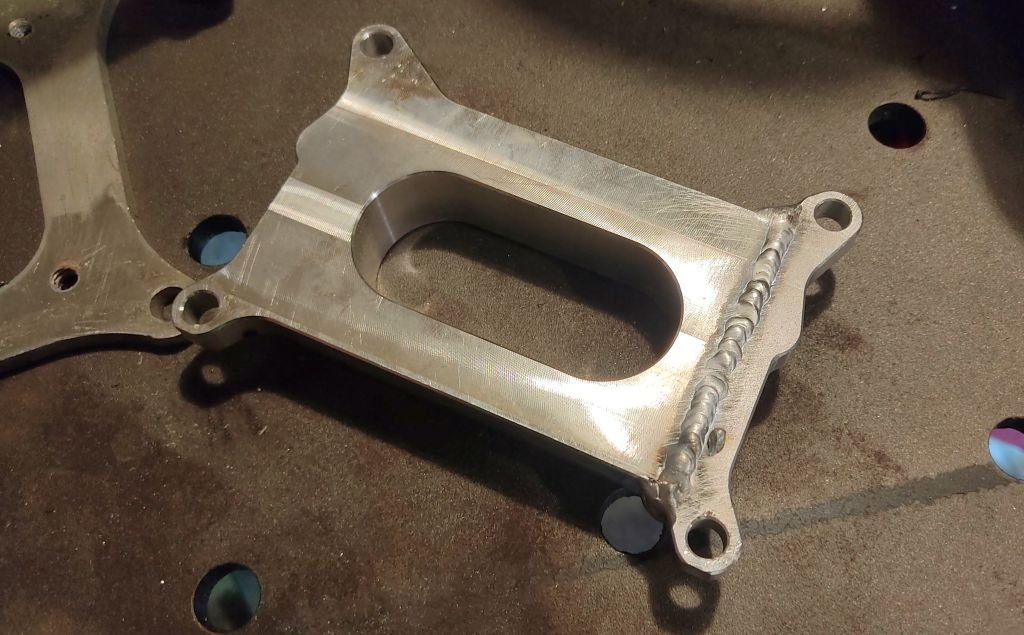

Even less pretty, but still hopefully functional.

TBI to Holley adapter made from a couple scrap bits of 12mm alloy plate.

-

10

10

-

13 minutes ago, Tiger Tamer said:

So the Imp engine is out of the rear and you have louvers in the boot which you call a bonnet, so it must mean you are going front engine ?. Front wheel drive ?.

Front radiator conversion, have to let the hot air out somewhere etc.

-

3

3

-

-

@chris r had a fancy Weber adapter CNC machined, but somewhere along the way it gained an extra 10mm in the base.

So I made it a lot less fancy but a lot more functional.

I haven't welded alloy in way too long/needed to preheat more, but it's solid!

-

8

8

-

1

1

-

-

1 minute ago, SOHC said:

Is that a west lake mechine?

It's a Rong Fu, Westlake depending on age is either a rebadged Rong Fu or a clone.

-

1

1

-

-

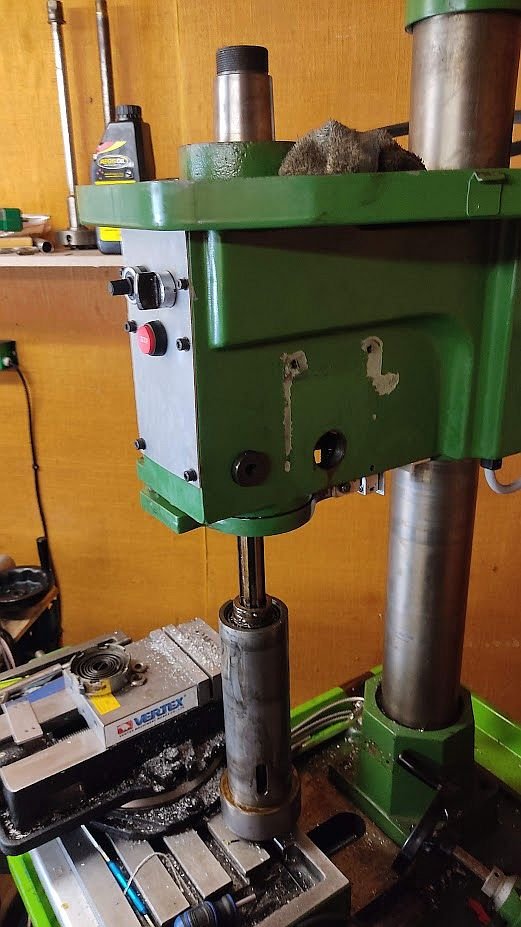

While working on the VFD/motor install I noticed the middle pulley was super stiff to turn and made some interesting noises.

While the mill is "new", 40odd years of sitting unused really hasn't been good for the grease in the bearings at all, it's gone rock hard.

Spindle came out without too much drama

The driver gets pushed out the top of the head

And pulled back down, all the splines in it were caked up with hard dark dried out oil/grease/shipping protection gunge

Took a sec to realize these are LH thread lol

And all cleaned up ready for the new spindle bearings to arrive in the morning.

I know a few of you on here have RF30 and RF30 clones, so it might be useful to post the bearing specs

Spindle: 7206 and 7207 both 2RS - That's changing from open tapered roller bearings to sealed angular contact ball.

EDIT: It appears sealed options are VERY hard to find in NZ, so 30206J and 30207J it is for now

Bit more research makes it look like for sealed it's either FAG or dirt cheap generic Chinese bearings, no SKF/NTN/Nachi etc options.

FAG 7206-B-XL-2RS-TVP and FAG 7207-B-XL-2RS-TVP are what I really want, but are around $300 for the 2 shipped from Europe.6009 x2 for the top driver

6204 x2 for the middle pulley

-

9

9

-

-

@chris r hooked me up with some buttons and cable etc, so made up a new front panel.

The motor from the first mill looked pretty much perfect inside, so it got a couple new bearings and rattle can rebuild.

Little bit of wiring and it should be good to go!

Still after a 80 or 90 frame, .75kw to 1.5kw 4 pole 3 phase motor for my lathe too, had planned to at least temporarily swap the new mill motor into the lathe but yeah it's a lot bigger.

-

5

5

-

-

- Popular Post

- Popular Post

Y axis took a little more head scratching, but again having bought the slim scales paid off.

Popped the main spindle pulley off

And added an inset magnet to the bottom

$6 Jaycar Arduino Hall effect sensor

Just needed to come up a bit higher, so using a chunk of what I think was green acetal I came up with this

It's held in place with 4x 8mmx3mm magnets inset in the under side, means I didn't have to drill any more holes in my mill and also makes alignment with the spinning magnet super easy.

10" Android tablet for the display gives so many more features than most off the shelf DROs and the app is constantly being updated etc.

Just need to clean all the chips off the mill, terminate some wires for the tach and do a bit of cable management now.

Oh and swap in the 3ph motor + VFD.-

19

19

-

- Popular Post

- Popular Post

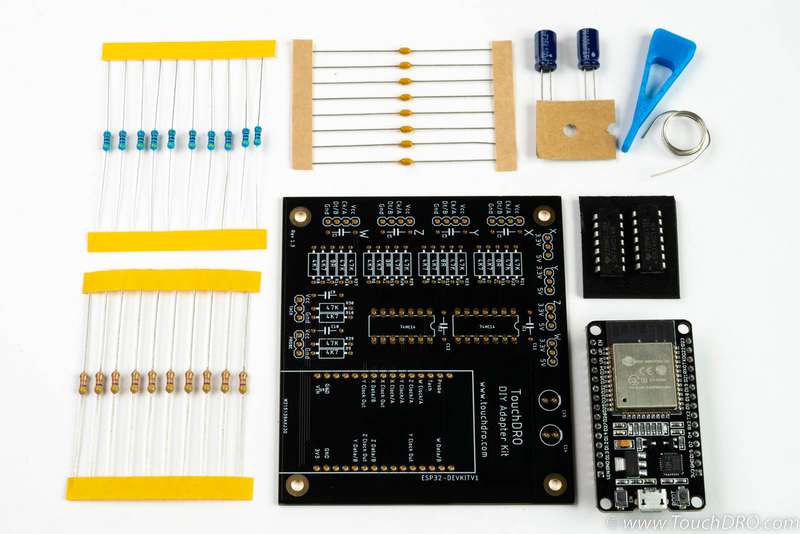

On 03/04/2023 at 21:44, Raizer said:Got a electronic jigsaw puzzle sent from the states.

And some slim series SINO scales also from the states via Amazon.

@flyingbrick modded some .STL files for the case and @mo999 printed them out for me (Cheers guys!)

It even glows in the dark!!

X axis was super easy to mount, just replaced the stops with the scales and modified the included read head bracket a tiny bit to line up with the existing holes in the mill.

Many people seem to modify digital calipers for the Z axis, but not me...

The TouchDRO has the ability to blend 2 scales for one axis, so once I get around to making a guide to stop the head swiveling when being raised or lowered I can add a second scale to have head height taken into account with the spindle etc.

Getting a bit pic heavy-

14

14

-

1

1

-

No Bunnings near you?

/or did you get a discount on D-plan?

-

1 hour ago, smokin'joe said:

so if the lad fits new sparkbungs to his LN130 manual Surf/4Runner, will is fix the excess smoke and give him more than 15WHP ??

Need to pull the little hose off the front of the turbo for those.

-

Set of 180° headers and 3" pipe. Sorted.

-

4

4

-

2

2

-

-

1 hour ago, Roman said:

Ideal starting point is the 5GR motor.

Its 2500cc with 2GR sized bore and a crazy tiny stroke. But this motor was only available in China for whatever reason.

$5200 inc DHL shipping from AliExpress haha

-

5

5

-

2

2

-

1

1

-

-

4 minutes ago, johnnyfive said:

Here's hoping, I reckon DX ones will be in their fleet till they're 100% ruined hah.

Pretty sure I've seen NZpost with a couple though.

NZ post 100% has some, there's a few kicking about around here.

-

2 hours ago, Bling said:

Belts need to be gone too, but they may be attached to seats anyway so no biggie. Just FYI.

Never had that mentioned, your mileage may vary though.

/All my rear buckles are attached to the seats, but I've still got at least some of the rear belts.

For Questions Regarding WOFs/CERTs/NUMBER PLATEs

in Tech Talk

Posted

And coming via an Aussie eBay reseller I'm guessing it'd likely be even worse for me to attempt to get proof too.

Was actually your B2000 that's got me looking at possibly running drop spindles, I've recently picked up a 90 B2000 I'm wanting to tidy up a bit and drop a fair bit.