-

Posts

14,713 -

Joined

-

Last visited

-

Days Won

10

Everything posted by Raizer

-

Rope worked better than air in my shitty old 4g63 when I did the stem seals. Was just lucky I had the piston at TDC and it caught the valve that wanted to drop lol

-

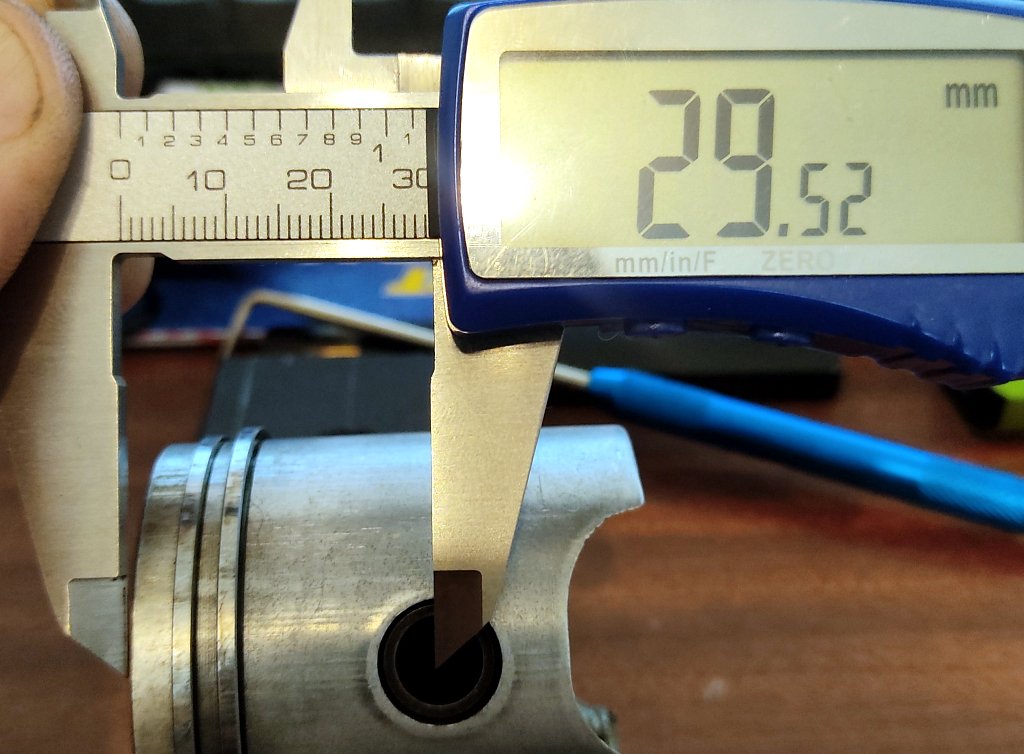

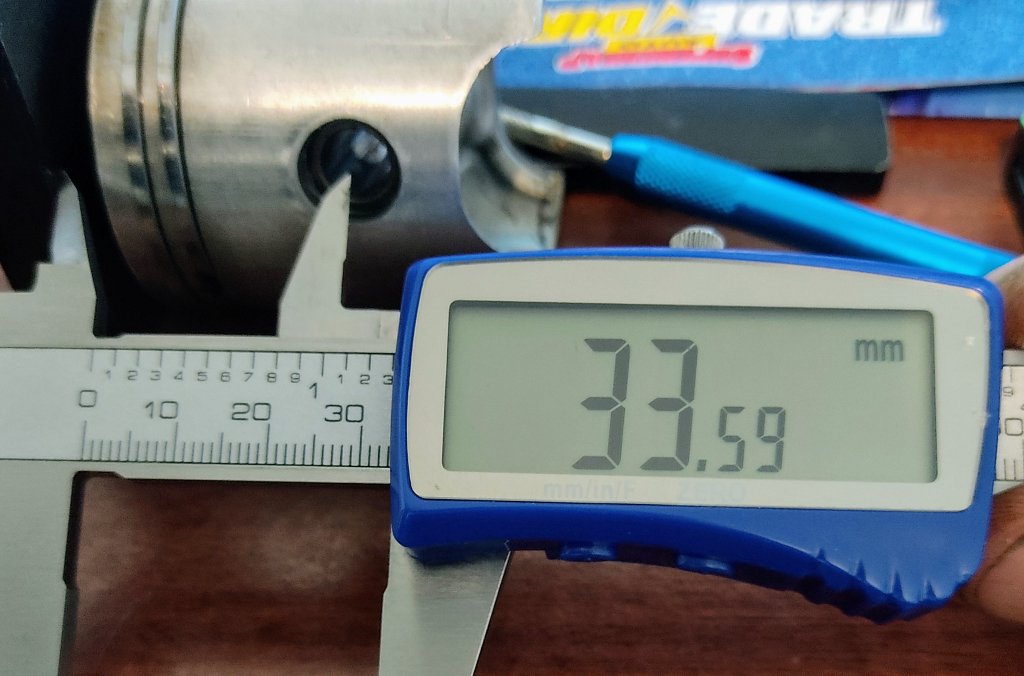

Toshihiko at TKRJ pistons got back to me informing me that they don't have stock of the 1.75 or 2.00 over options, but they have the 1.50 I've already got available. Ended up asking him for exact measurements of the piston, they are between 48.450 to 48.470. My current 1.50 measured up at 48.305 and the cylinder at 48.495. Worst case fitment is 48.495 - 48.450 = 0.045 clearance in the cylinder! So it would actually need a slight hone to fit!! Also if I ever order another Chinese/Taiwanese kit I'm granting permission for everyone to give me an ass kicking!

-

I was even contemplating pistons for weird rotary hoes and eastern European chainsaws thanks to some of @ESKIN8R's scouring of Meteor Piston catalogs haha It still bugged me that my original piston that is meant to be a +1.50 from an old TS75 doesn't match up to what's listed for TS/TM/RV75 or A80 models which are all meant to have pretty much the same piston. So I pulled my top end off yet again, quadruple checked the measurements and spent the couple of hours reading piston catalogs again, and well it's paid off as I have found only one piston from TKRJ that matches almost every measurement!!* I give you the piston from a Yamaha YG-80! Even better news is that I seem to be able to order them in both 1.75 and 2.00 oversize. Another couple giveaways are that all the TKRJ pistons for Suzuki have notches for getting the pin clips in/out, none of the Yamaha ones do and also the ring locator pins are around the 4 and 8 positions, Yamaha are at about 2 and 10. *The only measurement that doesn't match up is the overall length, mine is 2.2mm shorter and has some kinda obvious file marks where it has had clearance added to clear the crank webs at BDC ha

-

Looking at going to 49mm bore I think Looking at Lifan 110 and Honda CT90's as potential liner donors

-

Haven't really kept up to date with Alex's videos lately, will give that a watch soon though! Used to chat with him a bit on another forum, but all the noobs with China scooters got to him I think and he stopped posting haha. Lol so this: "plan to attempt removing the liner, adding the extra ports like my current one and seeing if I can make a head on the lathe and get it to run" ain't going to work out. Casting isn't too bad, not great but a bit of file work and a coat of paint and it'll be mint. Major giveaway it's not genuine, Suzuki kits are 72CM3 and that font is very China spec too lol Piston is junk IMO And the reason I can't just port the shit out of this liner as I'd planned is this is at BDC: Blue marks are to show the ring pin locations And well below BDC: Anyone got some thick wall ductile iron tube kicking about??

-

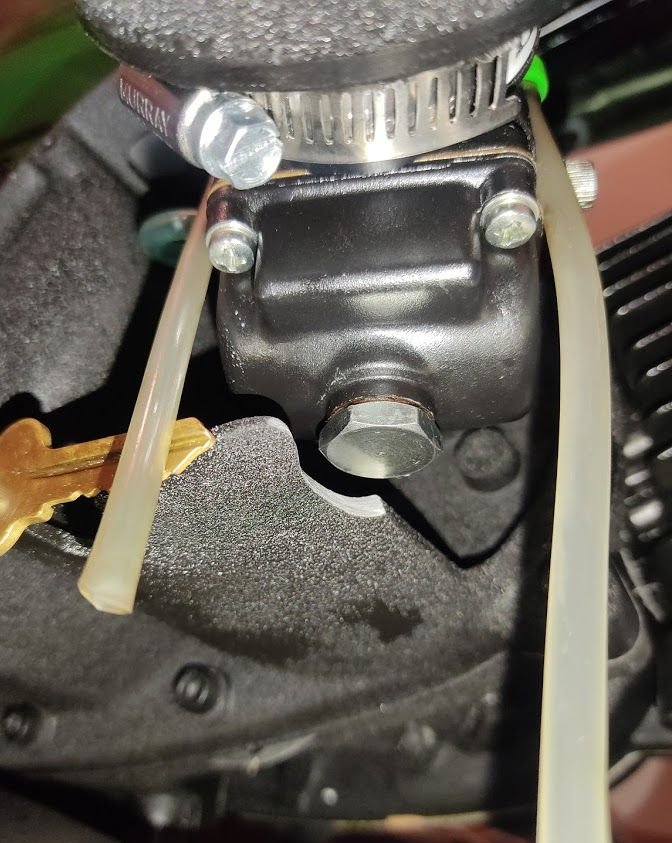

Gave it a good amount of hard nang this morning, didn't feel like it was trying to lock up once, so I think it's safe to say the new rod kit is good lol I paid for a carb with the quick change jetting cap, I'm going to use the quick change cap!! Also think I've sound a solution to my piston slap woes, have come across a few NOS Taiwanese kits here in NZ! Have put my hand up for 2 for now, one is going to just be a bit of an experiment test bed, plan to attempt removing the liner, adding the extra ports like my current one and seeing if I can make a head on the lathe and get it to run. I know with the Taiwanese kits that I shouldn't expect great things from the piston and to keep the compression and RPM on the lower side of fun, but if the liner is decent enough there is factory size (47mm), +0.50 and +1.00 TKRJ pistons in stock with a supplier here in NZ which I know will take the abuse I have planned for it. IF I manage to pull that off then the second one will be getting a new Wiseco or Melling cylinder sleeve and 49mm Wiseco piston from a late model 80cc and another new head, that should give quality oversize piston options for years to come.

-

-

Spent most of yesterday and last night scrolling through more piston catalogues than I care to think about trying to find a match, zero luck though. Emailed TKRJ and IKYP in Japan as well as Wiseco, J.E and Pro-X about +1.75 or +2.0 TS75 pistons, TKRJ said they used to make them but I'm 20 years too late, IKYP don't deal with the public. Wiseco said no problem at all, but it'd come under "custom piston" so minimum order is 12 and $$$. No one else got back to me. @GuyWithAviators likely has a worn out PW80 piston for mock up/experimentation as they look close. DS80 and JR80 use the same piston and are damn close, but the "compression height" is around 3mm lower which would fuck my port timing completely. So current plan is put it back together with the current piston and ride it while I try to track down a U70/TS75/RV75/A80 cylinder to use as a donor and build it around a 49mm DS/JR80 piston.

-

Have got 0.10 to 0.12 clearance up the top of the bore, should be more like .05 to .06 really. Looked at FR80 and A80 pistons, but the compression heights and lengths rule them right out. I'm already running a +1.50 TM75 or TS75 piston, looks like TKRJ used to also do +1.75 and + 2.00 kits but I'm having absolutely zero luck finding even a part number for either of them. Yamaha Beluga 80cc looks to be the closest I can find, would need 3.2mm taken off the skirt and the head would need about .3 less gasket, but they aren't the most common piston either and it'd put the bore right at the max that I'd be comfortable with.

-

Te Urewera Undertaking, 2020 Nov 27th, 28th, 29th.

Raizer replied to johnnyfive's topic in Upper North Island Region

Even those cheap TM ones need oil, otherwise they are pretty much only stopping rocks and cats from being sucked in. Chainsaw bar oil is a cheap/half assed alternative to proper filter oil, it's got additives to make it sticky etc. -

And proof it does actually move Jetted way too rich currently so it just 4 strokes instead of coming on pipe lol

-

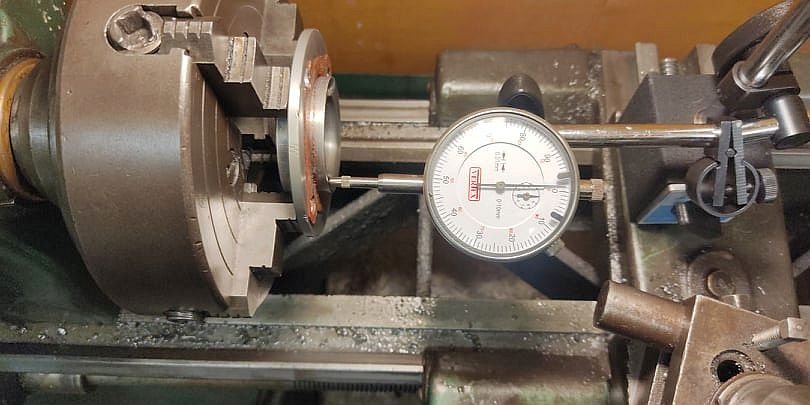

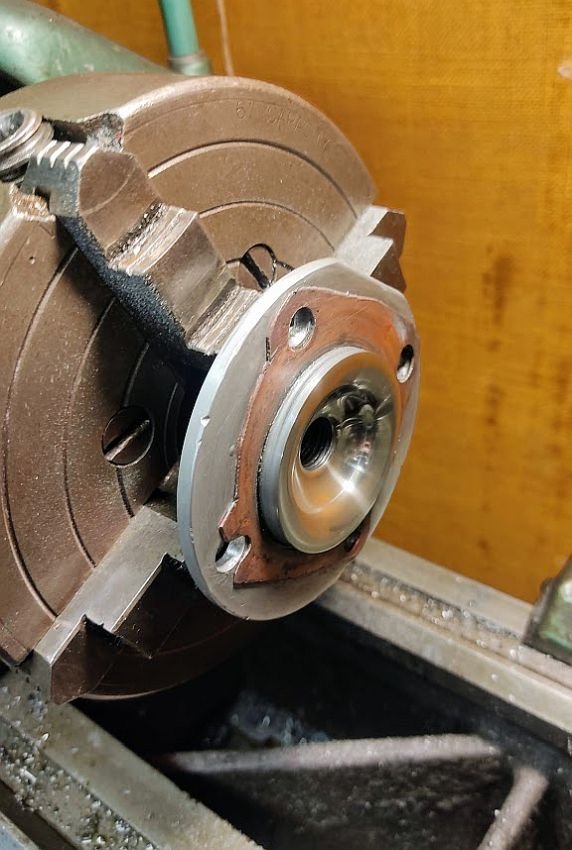

Let me preface this by saying I have next to zero idea WTF I'm doing with a lathe!!! Got it to about .05 run out, after about 45minutes fucking about! Did mange to get the face dead on though in much less time Took a bit of a guess at the angle/did a fair few dry runs just eyeballing the tool path. Couldn't get anything close to a clean cut though, the carbide tip wanted to leave gouges, so yeah spent a while with a file then different grits of paper Have ended up with a squishband starting at 1.09mm tapering to 1.16mm, in the correct direction this time haha! If I had more confidence I'd be attempting a 0.34 skim off the flange to drop that down to .75 squish, but for now I'm going to see how it goes as is. Fingers crossed this actually helps ha

-

Yeah squish angle is backwards I reckon. Checked several points around the bore multiple times to confirm and keep getting the same results

-

Re-measured the squish before and dunno why, but I measured a few points of the squashed solder and it gets tighter towards the centre rather than looser, that could have an effect! Jonny had a different piston in it at one stage, guessing he set the combustion chamber up to match an earlier piston. So I'm thinking of attempting to cut a new squish angle to match the piston I'm using and also skim the mounting flange to gain a touch of compression while I'm at it.

-

It was high temp paint not oil/shush! So that rules out the too much compression theory then. Guess it's just a case of just send it and fix what breaks.

-

Lol fuck, been talking with Jonny, sounds like the squish etc I set it up to was pretty much where he found the knock limit of avgas, that'll do it! Guess making a couple combustion chamber inserts with lower compression will be a great first project to learn how to use my new lathe. /Who's got a hook up on drums of methanol?

-

Lol you weren't supposed to notice that! /Na, clutch cover is just sitting in place with only one of the 4 screws holding it still, that one was just sitting in it's hole.

-

In answer to my earlier post, cry then put it away to think about what it's done was the reaction. Cunt of a thing!! Sound is 100% right in the top of the stroke like I always thought, just now it's easier to pin point as the new big end has 100% made a huge difference to bearing and knocking sound. Too much compression maybe?

-

She even gave me my own chopping board just for engines haha

-

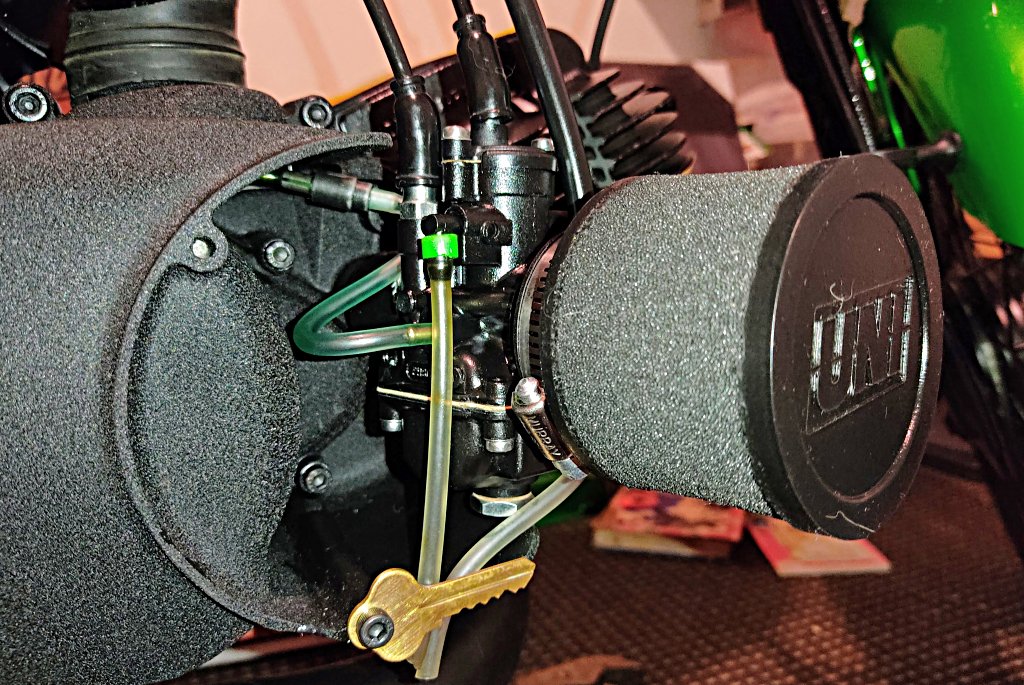

New carb got completely stripped, squirted with CRC's finest satin black with more enthusiasm than @MopedNZ playing with a bum gun after a night of S.E.A's dodgiest street food and cheap beer. It also went for a bit of a spin in the lathe so it'll actually fit in it's spigot. Reassembled and refitted with fresh mounting o-rings Along with the digital clock with bonus tachometer function I also treated myself to a rather nice RK X-ring chain finished in jet black with gold accents So now it's ready to add gearbox oil and attempt yet another "first" start. If the noises are gone then I should really finally machine the new flywheel for it then it'll be ready for summer pesting!!* A summer later than planned but hey Ha If it's still tapping I'll likely cry/push it outside and forget it exists. *Keep an eye out for an Auckland City 2T pest and succulent Chinese meal fest event in the upper north island events section*

- 191 replies

-

- 15

-

-

Te Urewera Undertaking, 2020 Nov 27th, 28th, 29th.

Raizer replied to johnnyfive's topic in Upper North Island Region

Did you happen to be following @Shakotom at the time? -

Couple idle heat cycles, retourqe head, send it. /I easy for a bit if I've got a new clutch to bed in.

-

Yeah you have to do that, it's the only way to get enough oil flow to wash out the large amount of swarf they come packed with for shipping.

-

Te Urewera Undertaking, 2020 Nov 27th, 28th, 29th.

Raizer replied to johnnyfive's topic in Upper North Island Region

Covid shipping has fucked a lot of things.