-

Posts

442 -

Joined

-

Last visited

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Hyperblade

-

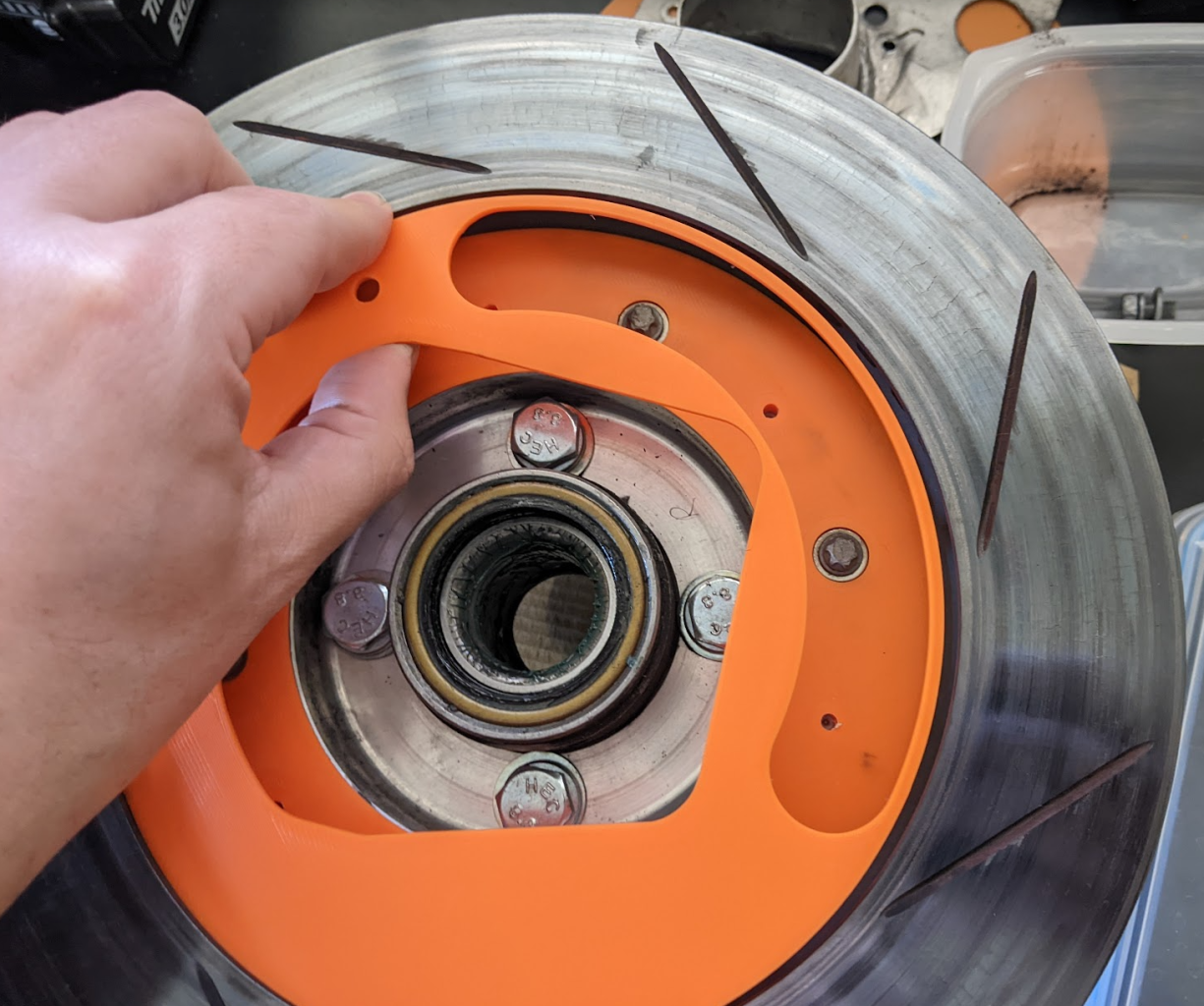

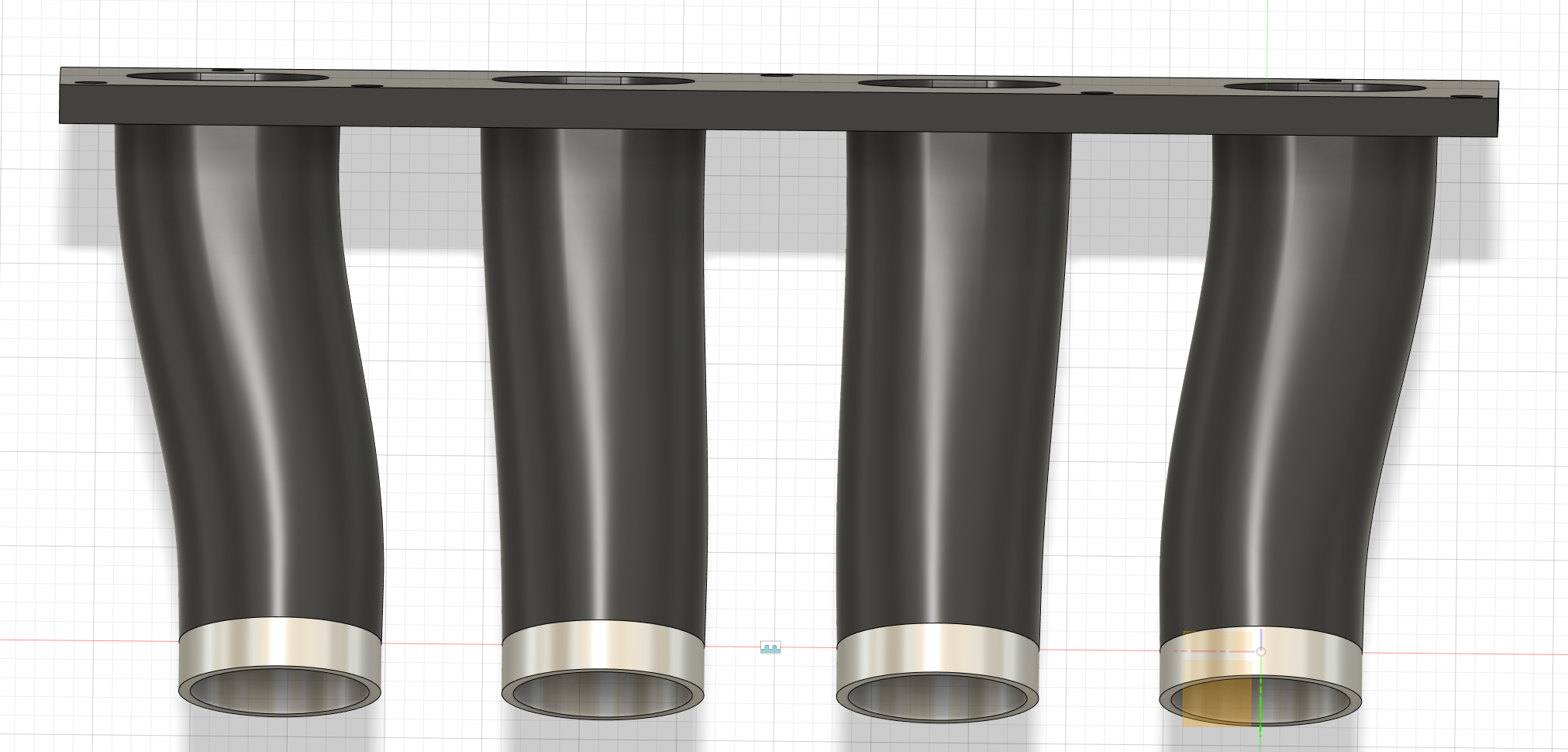

I need to go from this hole at a 45" angle up, right and inward towards engine bay and then adapt shape to to a 2.5" or 3" outlet to attach the hose on to, space is very tight. Orange plate will be 2mm ali, currently thinking of having it laser cut instead of doing it by hand. What options are there for achieving this relatively quickly and potentially at home? One I option i had thought of was to 3d print the inner and just hammer the aluminium around it, then get the seam welded (or try to do it in one piece), either way I would probably use a separate ali ring for the hose to clamp to. would end up being welded to the plate 2nd option might be the same inner but get someone to lay up carbon fibre around it (don't know anyone who does carbon fibre, or what that would cost me), but high temp area and not sure how specialised that is. I can't see fibreglass withstanding temperature? Any other thoughts on how to solve the problem?

-

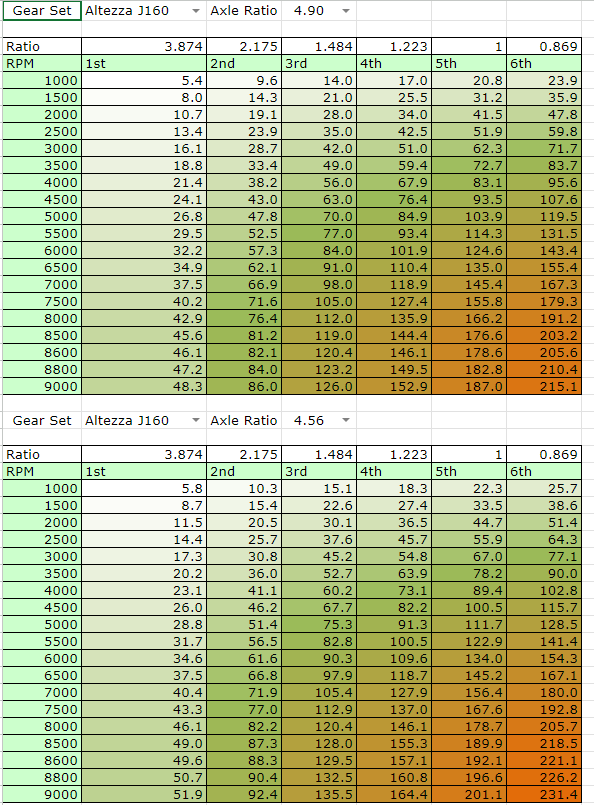

So the only TRS tyres you can still get secondhand from the series are the old rears, (now the new fronts) which need 10" wide rim, so most cars require substantial modification to run them. Those charts were based off the smaller TRS slicks that runs on 8" wide wheels. so you need to think carefully about what tyres your going to run, it may be that 15" might be the more economical option (even though I don't like the look of them on old cars) For grip, you will be wanting to aim for 185 - 200kph at the end of the straight which should be doable with your weight and power. I went with 2nd-6th gears which meant launching in 2nd and using 3rd for hairpin 4-5 everywhere else then 6th for straight. But the alternative (and much nicer if you street drive) is to use 1-5th which can be beneficial for N/A cars as not using overdrive 6th. Here's some diff/speeds (based on 54cm trs tyres) to give you an idea of where it would sit You have lots of revs available which gives you a few options (let me know if you want me to calculate any other options).

-

Tiger Tamers 1964 Hillman Minx Project

Hyperblade replied to Tiger Tamer's topic in Project Discussion

MSEL are great to deal with. Shipping is slightly more expensive but it's always next day delivery. Definitely can recommend them. -

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

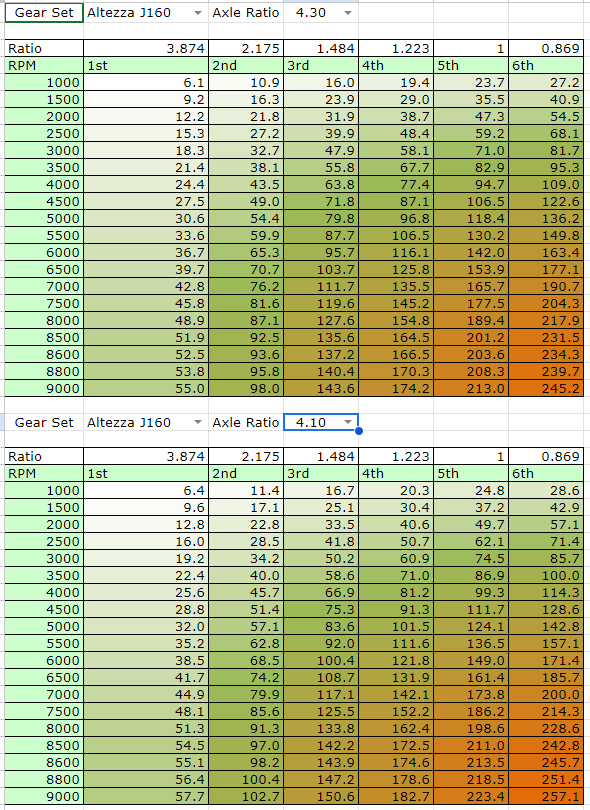

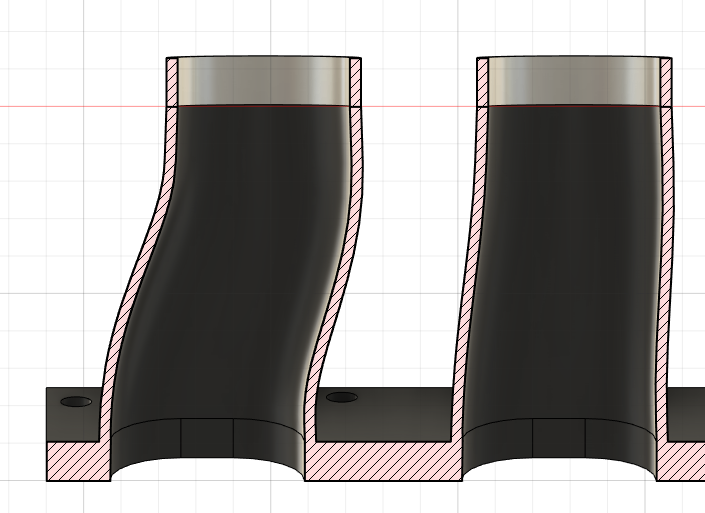

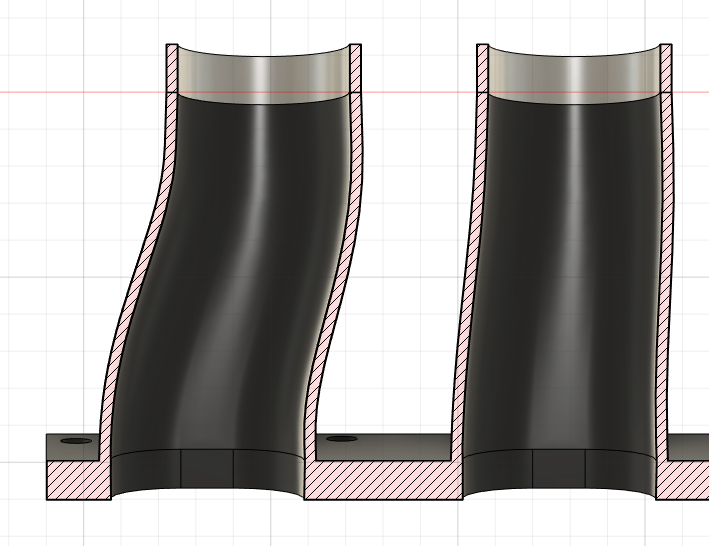

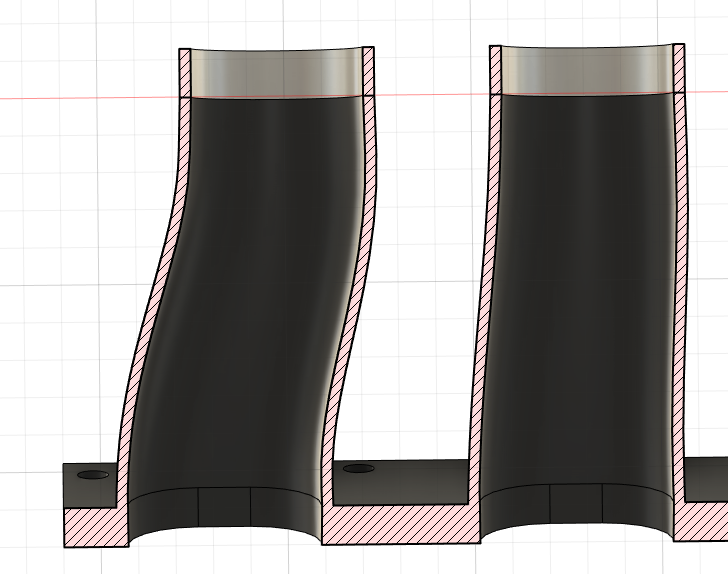

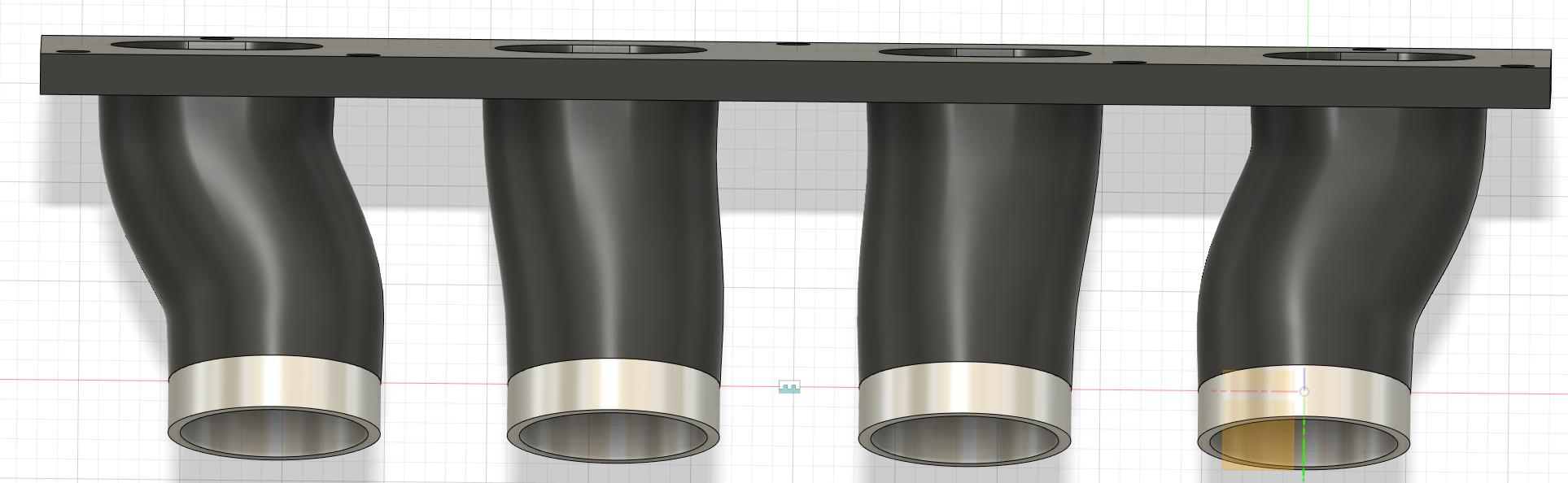

85mm long = To me that looks to sharp on the inside of the outer runner (middle runners look fine throughout). 100mm long = 110mm long 120mm long = Yeah haven't changed pulley so will be 50 degree one, interesting, might have to end up putting it back on the dyno after the ITB's to look at all that. I have been offered the use of one, just need to upskill in being able to tune. -

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

48mm throttle plate, 46mm (same size as port) outlet to runner. 53mm inlet to velocity stack. Are you going to remake the intake for it? Would be interesting to see another back to back but on k20. -

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

How important is getting the runner straightended up before the port? e.g. 150mm length vs 85mm Obviously the longer I make them the smoother it gets, but do need to take into account velocity stacks and potentially having to go 90 degrees with them to fit the total 320mm length in. -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

Small post to say a big thank you to @h4nd for coming round and getting an Oscilloscope trace of the Honda S2000 Speed Sensor (VSS) I've been having issues with (only taken me nearly 2 years to get round to it.) just waiting on Link to respond with their thoughts now, but have one potential solution we think should solve it. Traces are below if anyone else needs similar in the future -

Just Crank and Intake/Exhaust Cams. From what I have read on their forums what they advertise takes that into account, so you can actually go higher then stated normally as your not maxing them all out. Often people put a divider on the honda speed sensor, but the latest Link ECU's should be capable of handling it (and they do a plugin version now)

-

Yep Hall effect, it's positioned directly against one of the gears (nothing special I can see on the gear) I don't know the size of the gear it's against, so not sure how accurate it would be replicating it, I could 3d print something, but I assume you have to put some metal in it for it to work. I think it needs to be fairly high rpm to recreate the issue, I think outside the range of most drills/lathes. Have PM'ed you Thanks I'm in no rush so If h4nd and I can't work something out will give you a bell.

-

I need someone with an Oscilloscope and who knows how to use it to come round and help me diagnosis a speed sensor cutting out at 5000hz (120km/hr+) (according to the Link ECU). It's in a racecar so I can't drive it on the road, however I can recreate the issue on the jack stands, and I have a DTM connector (and know the pinout) in the engine bay to the sensor so will be relatively easy to intercept the signal? It's a Honda s2000 AP1 gearbox, and a Link G4X Xtreme X which has been double checked by link (capable of 10,000hz) I also have a spare speed sensor that can be bench tested if required. I can only do this during the day either during the week (I work from home most days) or weekends as the car is to noisy for the kids/neighbors... I'm located in Prebbleton and happy to pay for your time.

-

A friend races his RX7 with a 13B and a J160 and it's been pretty reliable for the most part (he's raced it since 2008). However last round he blew 4th gear, so the circlip mod may be worth looking into. The issue is a lot of the boxes for sale are all very high k's and it's not as easy as it used to be to find cheap good condition ones.

-

RE flywheel, I'm not up to speed on it all your issues, but could you run an insert like the K2F flywheels run (inserts can be bought separately)?

-

Yeah and for the price you don't even get a PDM built in. On the flip side at least g4x maps transfer over and plug a and b are same as g4x series so easy upgrade. But a bit underwhelming tbh.

-

Link have had one for a while G4+ Force GDI https://dealers.linkecu.com/force-gdi 4 Cylinder only though, ($3000+) And have their new G5 Voodoo Pro https://dealers.linkecu.com/G5-Voodoo-Pro ($5000+) Not a cheap exercise!

-

If using anywhere near the track then yep it's a big deal, if you make sure you have a good range available you will save yourself a lot of money in the long run. More choice means more competition so harder for the manufacturers to price gouge you. So calipers from MX5, GT86 etc are good choices as they are often tracked as standard. Generally though you are still limited to a smaller selection of compounds, my personal experience of bonded mintex was not a good one. But it's going to also depend on the use case, as proper track racing is quite different to say hill climb or street. Another option is picking a caliper that lets you water jet cut a pad down from another common pad size, this is what I did with my rear AE86 disk setup, I just had wilwood polymatrix pads cut down to suit, $25 to cut down per pad, and once they have template it's easy as. If your looking for long lasting brakes, bigger and thicker pads are what you want to go for, it helps them last a lot longer from the heat and just helps all the components around them.

-

Tiger Tamers 1964 Hillman Minx Project

Hyperblade replied to Tiger Tamer's topic in Project Discussion

That looks like a nice simple self contained approach definitely worth exploring further, when you add up all the fittings etc it really adds up quickly if doing a external setup. Good idea! And could fill the rest with foam to help stop it moving as well. -

Tiger Tamers 1964 Hillman Minx Project

Hyperblade replied to Tiger Tamer's topic in Project Discussion

Just for reference if you do decide to chop up the original tank (which is more then doable) Here's the starlet tank that was running the altezza pump (ignore all the other shit, it's mostly redundant). As long as you get the height of the pickup right e.g 2mm off bottom and run some baffling you would be fine. He ran basically what was like Icecream sized square at the bottom around the pump with a couple of holes (and return from regulator feeding into it), this was pretty good even on the track until the welds broke and it started rattling around. Granted he did blow it up in his face while welding it... but from what i've read if you purge a fuel tank correctly it's actually a straight forward job from that point of just standard welding. Yours has a relatively flat surface too, I would just cut it all out put a plate on top, grab a fuel pump setup from a modern car like a toyota/honda and do another fuel sender hole. -

Tiger Tamers 1964 Hillman Minx Project

Hyperblade replied to Tiger Tamer's topic in Project Discussion

Found a pic of the Altezza setup this was run in standard tank which had minor baffling added around it. This is a bodged version to move to a new tank setup but retain the regulator. -

Tiger Tamers 1964 Hillman Minx Project

Hyperblade replied to Tiger Tamer's topic in Project Discussion

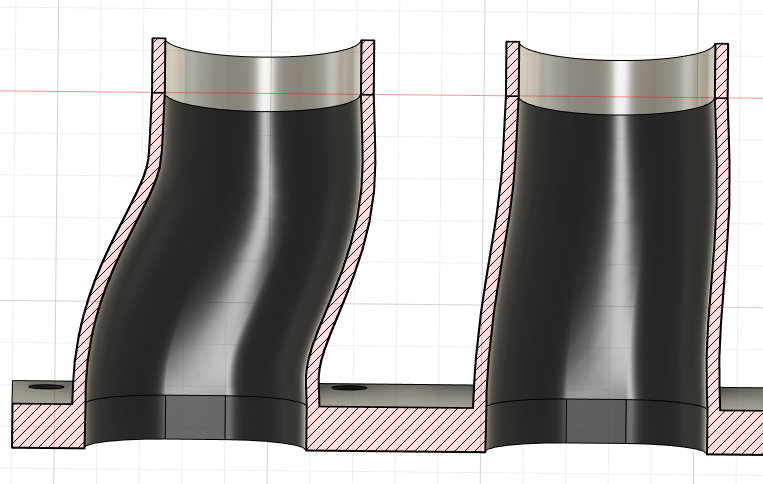

Most fuel pumps don't like sucking (they need to have a head of petrol above them), so the 2nd pump in a surge tank is for those cars that need a higher volume of fuel sent to the rail (or redundancy for race cars). I run a proper lift pump in the main tank so that it can run dry without killing it and it's not doing as much work as a high pressure fuel pump. In particular I run this one: https://msel.co.nz/fuel-pump-low-pressure-in-tank/ I ran returnless setup when I had the 3sge engine + altezza fuel pump in my car (it was retro fitted into the existing starlet tank), all you need is an in tank regulator which looks like this: (heaps of OEM options) it's just a fixed regulator. I would recommend a fuel dampener on the rail as well as we saw some interesting spikes with my k20 on the dyno when the injectors closed. The advantage with return style is that if you are running a supercharger/turbo you can have the regulator in the engine bay referenced to manifold pressure, so you can increase the pressure as boost goes up. If you plan to always stay NA then returnless will be perfectly fine. -

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

Ahh that would make logical sense. I'm not sure Skunk2 were aiming for any harmonic it looks more like it's designed for turbos. 320mm long looks close to a lot of things, may have to curve the velocity stacks to fit that in but that's all doable if being 3d printed. Will be another learning experience. Thanks for the feedback! -

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

Those are good points about dealing with the rev range. I've looked at the videos of how it works and it is a very clever design in it's simplicity. Still want to try it just to see the impact, I'm trying to get everything out of a stock K20 without opening it, so every little bit counts! Skunk 2 Ultra Street Manifold Runners Just measured the Skunk 2 Ultra street Manifold runners as a data point. These are all rough measurements as it's still on car and I'm not taking it off as it's a full days job (one of the reasons why I want to go to ITB's). Runner length 155mm from port face to velocity stack tip (estimated) Outer diameter where runner goes into manifold is 60.50mm, I think there is a fair bit of wall thickness assume 5mm which would make 50.50mm inside diameter. S65 ITB's S65 ITB's are out of my price range at the moment, plus the ones I have are a seriously nice bit of kit in terms of packaging and weight. I'm happy to use these ones to get experience with them, if they work better then what I have then that means I can sell the old skunk2 setup and look at other options. Will only cost me the ITB's and filament which is not a lot in comparison to off the shelf ITB's, plus i'm now sold on electronic ITB's since i've spent time and wired for them (obviously can still run cable if I need to), but not a chance I'm going with dbw module that's know to crap out... I had looked at the efi hardware ones back when i was first looking for options, but they add up quickly with all the linkage and accessories needed. Runner Length So in terms of runner length for the Jenvey ITB's (EP3 version BUT NOT the Tegiwa compromised version) they look to me Runner - ITB - Velocity Stacks = Total 85mm - 66mm(tapered) - 90mm(tapered) = 241mm So I was planning to match that with 85mm - 78mm(tapered) - 78mm(tapered) = 241mm But based on your suggestion it would be 85mm - 78mm(tapered) - 157mm = 320mm So it's interesting to see such a big difference between your suggestion and theirs! How does a tapered velocity stack affect things, my thinking is that as it's expanding it's slowing the pressure waves, so making it behave as if it's a longer velocity stack? How do you calculate that effect into it? -

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

You have to love the drivetrain loss going up just at the end of the graph to produce a nice curve, very convenient for them... To be fair the ambient temperature was different on the day. But yeah, people need to stop with BS made up figures. Yep, here's another brilliant one from them, I'm sure you've already looked at it. https://www.tegiwaimports.com/blog/?p=2443 I got caught out by this one when I brought my current ultra street manifold, i'm much more careful looking at these things now. Lecture away! (happy for anyone too), I always like considering all the possibilities and discussing this stuff with people who have actual real world experience. I agree slightly larger ITB's would be ideal so that you have a bit of wiggle room, but the feedback I've had is the normal Jenvey ITB's worked the best on a dyno(on built k20 in CRX) when comparing multiple different types, so if i match them in design I'm confident that it should perform at least better than the skunk2 intake I have currently. But I'm limited by what you can easily get off motorbikes due to the pricing, I had a look around at other options, but nothing stood out. However I do have a couple of other things planned to throw into the mix. Outboard injection. Variable velocity stacks (I'm on the hunt for a standard S1000RR airbox to get the mechanism) Intake will be using ram air to create pressure through filter and into air box. I have heaps of room to play around with lengths of stacks (which will be 3d printed so not expensive to make). Do you have any good calculators you use for working out lengths of intake runners? I also need to find the measurement of valve to intake flange to use in them. Just for reference car normally runs between 6000 to 9000rpm in a lap with lowest being 4700 rpm at hairpin. Being light and having the torque allows me to use more of the rev range, which helps with not overworking the tyres. -

Hyperblade's KP61R - Toyota Starlet with Honda K20a

Hyperblade replied to Hyperblade's topic in Projects and Build Ups

The last club day of the season (I was out in first round so not worried about points) was coming up and it was looking wet So I thought it would be a good opportunity to get the the car out for another shakedown of the new wiring, and get some experience in the wet (I've never driven in the wet). So first time out on a wet track in qualifying, i put it on pole... Race 1 Turns out it goes really good in the wet. Allowing me to take my first win by 30s over 2nd place (he sand bagged a bit after he accidently hit pit limiter and saw me race off into the distance). I managed a 1:42.5 which is I'm absolutely stoked with, that's only 7s off my dry time, and there was a little more in it (and that's with no changes from current dry setup). Also it confirmed that things like the wipers, lights and demisting (not running any, instead I'm using the heat from exhaust + radiator) all worked as expected. The wet's i ran are 4 year old ex Michelin TRS, and are absolutely amazing, it really was like driving in the dry, they are super soft and it shows as another competitor who is normally slightly faster in dry then me had older harder different brand wets and was 12s off my time. But also the weight of the car and it's handling characteristics show it's driveable/chuckable nature. Race 2 Race 2 was a handicap race and I was 60s behind first pack, unfortunately the guy who came 2nd place in 1st race was 15s in front of me, and he picked his pace up to match mine, i did manage to get within 9s of him on a damp track (rain had stopped). I came out of the day actually feeling excited to potentially race in the wet in the future, where as before I was very nervous, so that's also a massive win. ITBS Interestingly enough Tegiwa have just come out with some Jenvey ITB's to fit an EP3, they are very heavily compromised to fit in the engine bay, but do have some dyno charts. Check out the dyno results and see what you think about the results and claims... https://www.tegiwaimports.com/blog/?p=6297 Before: After: Let me know your thoughts in my discussion thread here: -

Loctite the bolts. I have a water blanking plate on my k20, and lost 1 bolt, and had 2 back out (out of 4), there is a lot of vibration with these engines (granted the blanking plate is also not designed great either), I was lucky as the blanking plate runs orings but it could have been a lot worse.

-

Hyperblade's KP61 Racecar "KP61R" Discussion

Hyperblade replied to Hyperblade's topic in Project Discussion

Yeah so all those thoughts crossed my mind when I did it. At the moment I have none of that. Each connector is numbered on the loom and the bulkhead plate is numbered, but that's obviously not a fool proof solution. Keying would be hard, you would have to machine the connectors down to put it in, and I'm not sure how much material is there to do that. I had thought of printing color coded wrappers for them then glueing them on. Can't use dummy pins as each connector doesn't have many to begin with. I have made each connector very similar, e.g. 12v always on pin 1, 5v on 2, sensor ground 3, so it limits the risk a little bit, and coils/injectors are all interchangeable with no risk. However my biggest concern is swapping the EWP with the ECU ground, if that happens then it's a straight path from fuse to ground. So no solid solution at present, but open to ideas.