-

Posts

2,350 -

Joined

-

Last visited

-

Days Won

2

Everything posted by Kimjon

-

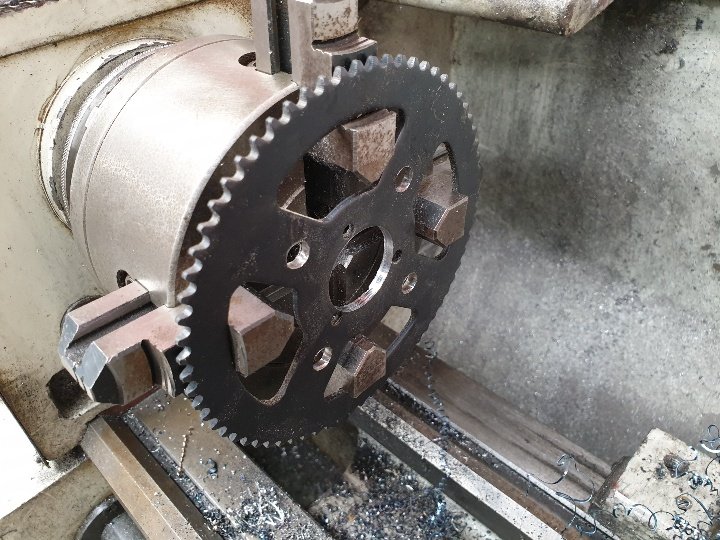

I've re geared the rear end, from 68 to 78 rear sprocket now. Too late at night to annoy my neighbors...so untested. But should be like once trying to start a car off in third gear...to now putting it in first. Hopefully this is the last step in making it awesome!

-

Maybe just run a wasted spark type system, should be easy enough to set up by using parts off a wrecked bike or car.

-

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

Tachometer on a drift trike anyone? Why sure...here we go. 1990's cool. Now I can see just how slow I'm going:) -

Got more power out of it with the different carburetor...way better.Also keeping the tank full helps a lot, as it was starving for fuel when low, due to side to side sloshing in the tank affecting the fuel supply.I'm pretty happy with it now. Just a sprocket swap to 78 and I'll call it done. The lower gearing will bring it to where I want it. I still haven't hit powerband yet...need long straight to get up there.

-

Well, it goes. But it sucks down low! To be honest its not quite what I was expecting??? I was hoping for a bit more out of it. Theres not enough room on my drive to get into power band, and that's when it should liven up. I've ordered new sprockets to change the gearing. This will certainly help. And then I'll run in somewhere with more space to hit powerband. However...it goes, it moves, it's got fuck loads of potential....

-

Fuck yeah...got it sorted!!! So loud, seriously think I've damaged my hearing. Ear plugs a must!

-

Drum roll...and finished it! Fuck yeah...stoked!!! Need to pick up fluids for it tomorrow and fire this bad boy up. 16,500rpm of 2-stroke awesome about to wake the dead!

-

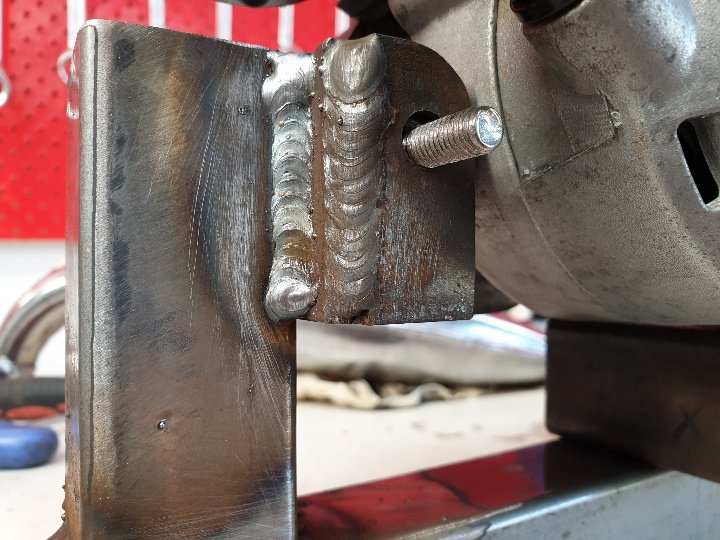

And solution for the chain landing on a half link: Pretty happy with this. Also some cunt designed an asymmetric clutch on this. The chain goes rearward on a pocket bike...but about 120° the other way on this project. I have no idea why they made it fit only one way(?), it would have created more work for the design team, tool makers etc, etc...however it is what it is. So I redrilled and tapped a hole elsewhere after much head scratching. Now the 3rd bearing support can go back on and do its job, but facing the way I need it to.

-

Turned my attention towards the motor again, while I'm waiting on this to dry: The motor drives it's own internal water pump via an o-ring as a drive belt. Over time, these stretch and your going to lose tension on the drive pulleys. As a precaution I replaced it, and side by side it had stretched quite a lot...so possibly a lucky save there! Said o-ring above. You can see the water pump pulley here (smaller one on right). And o-ring installed on water pump pulley and to the pulley that is behind the flywheel. Job done!

-

-

I'm confident it should actually just start up right now if I put fluids in it. Any excuse to use this awesome tool! Nutsert in place, holes step drilled for various purposes. Fuel tank mounts welded in place. All the plumbing done, fuel lines, tap, filter, throttle cable, hydraulic brake lines...all seam to fit and be right length. Next, take it all apart and paint it. Then final assembly.

-

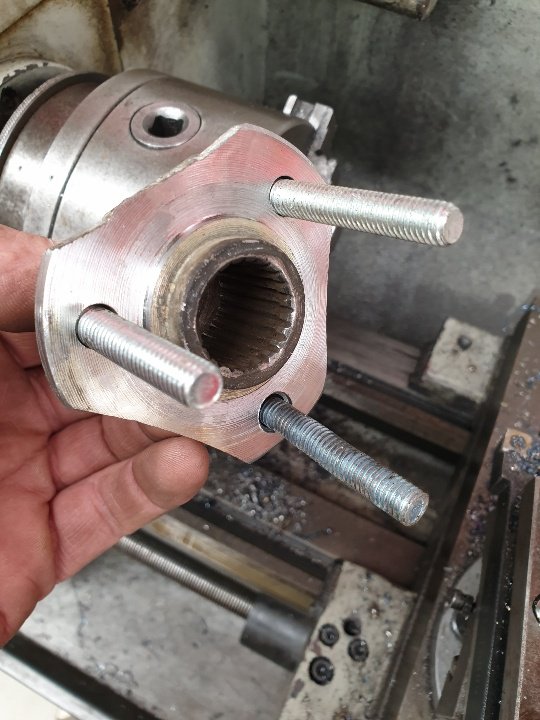

Okay, got to step away from this thing and actually do some real work. But I did manage to plumb it all up this morning- using some creative thinking and the smallest pipes I had. Made these joiners up on the lathe. Needed a total of 6 to make it all work. This is the bottom hose. As you can see there's a lot of joins in it. Not the best practice...but it's a matter of necessity. It's not like I can go to Repco and give the disinterested teenager behind the counter my number plate and expect him to have one in stock. And all done. Pretty happy all things considered.

-

And winding up my mate ("Handmaids Tail", reference those without Netflix). Two more tabs to weld on to mount fuel tank and done. Only problem is I haven't received the fuel tank yet... so boredom has kicked in and I'm making funny cardboard plates to occupy my ADHD.

-

Chain guard and reservoir bottle brackets made and then welded in place. About all I can do until the postman comes with all the shit I ordered off trademe last night.

-

-

That's my offroad gokart. Its rough as...but such fun! My mate nicknamed it "the Somali battle wagon" It's got no working brakes, but engine compression works good enough to slow you down. In that video I was been a pussy, as I'd just fixed it and was testing my fix. Its solid as now.

-

-

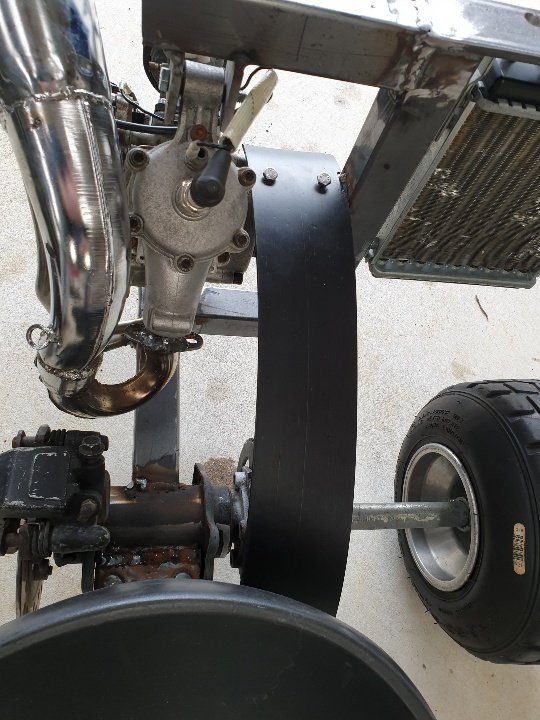

Put 4hrs work into this today, picture time: Exhaust all sorted. Hubs cut down, latched, re-drilled new pcd. So much work in these...its the hardest part of the build and the least fun to do. Got stance? Stretched tyres onto much wider rims. Sprocket: new pcd drilled, centre bored out, old sprocket cut down and used as a spacer. Engine mounts. Only solved half the problem so far. Need to fit other stuff before finding a solution for the next bit. But happy with progress so far.

-

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

@HighLUX out of interest, what's the ID of that pipe? I currently drive past 2 civil projects where they're using this stuff. If it's the right ID I'll approach them with a box of beer. -

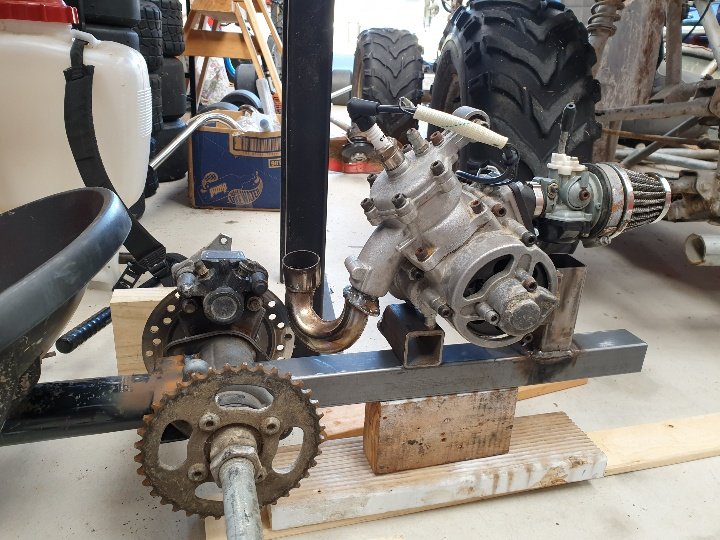

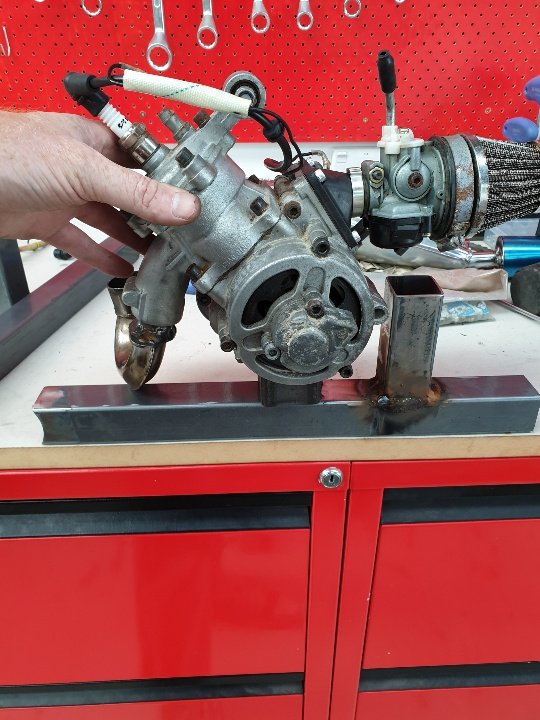

Out of the parts I got, I made the best out of what I had and put this together today. I squirted some engine start into it and it fired straight up... so I know it'll work. This is likely the direction I'll go.

-

I was seriously considering doing this. What's cooler than 1 motor, obviously 2 motors! But it would be gokart fast and even I wouldn't want to ride something like this at 130kph! These liquid cooled motors start at the bottom end around 8hp, and go upward of 15hp for the top of the line European motors. Very impressive for such small capacity. That's my attraction towards these motors - stupid power from such a small motor...

-

So, I picked this lot up... all water cooled 39cc ~8hp motors. Yes, approximately 8hp! So many parts, enough to make a 4th working bike....and another spare engine for ummm, yeah...maybe, hmmmm???

-

Don't know...but I'd be keen to ride in any class if it's on again.

-

This was my ride for dropping kids off duties. The kids were young enough not to be embarrassed. The pretentious soccer mum's however were another story, as they looked down at me from their Audi 4x4's... I'm sure they felt compelled to report me to chyfs...

-

Here's a clip of us fucking around warming the trikes up. For some it's the first time they've ridden one. We then went on to a structured knockout system of elimination. Though towards the end the system went out the window and we just made shit up.