- Popular Post

-

Posts

1101 -

Joined

-

Last visited

-

Days Won

1

Posts posted by Geophy

-

-

- Popular Post

- Popular Post

Would 10/10 reccomend the drive that @fletch installed, havent given it a hiding under load but the ability to make the most of the 3ph is awesome. Super variable speed seem to get around 80% of whatever rpm it is set on and forward and reverse controls is gonna be awesome for sketchy tapping situations. Is amazing how versatile one of these machines become once you can do cool motor things have a final drive rpm gauge to go on as well. Really struggled trying to find a drill/mill that goes slow enough I dont know how people run bigger drills and holesaws, my last 2 drill presses have been min speed 310 and 540rpm they basically spend there whole time going as slow as possible. With this bigger mill/drill having a factory minimum speed of 150rpm being able to go 80% slower is super versatile = 30rpm.

Excited to give it a hiding on the end of a 35mm morse taper bit make her really work for it.

@SOHC I understand its not going to last as long but for the versatility, price, availability and size you cant go wrong. If I get 2 years out of it and its awesome ill just buy another or upgrade. Phase converter has its place but its pretty mean just being able to use it like a normal tool without having to tutu around turning on and off different gear to make it run. Also makes the mill drill significantly more valuable if I was to sell it being plug and play at any address.

Only pic I have of it atm.

-

10

10

-

On 25/11/2021 at 21:19, datlow said:

didn’t you say you had high levels of metal in your blood or some such?

Tin arse

-

3

3

-

-

If you buy it Beaver ill give you a ride down and grab my stuffs.

-

1

1

-

-

Yeah just try a small bit, it will become obvious whether its working or not. Those rods go mean on the tig just scrape the flux off and wire wheel the rod. Use as your filler rod for all the dodgy repairs. Used them recently to weld up some holes between the vanes on a triumph 2000 water pump for old barry mate. Apparantly its still going mint, he refuses to replace it as reckons its a long term repair.

Was quite a good repair to do as was the gunkiest place to repair, super grot super shit casting but still welded good.

-

6

6

-

-

Making a bit of a shopping list, wondering if anyone has reccomendations for the following parts;

Boring head. Want to buy once and have it for the forseeable future within reason. Looking at just a 50mm one at this point.

Mill vice. After something basic but not chincey crap. Doesnt need to be hydraulic etc. Thinking something around the 125 to 150 width doesnt need to tilt but needs to roatate.

Cheers

-

On 18/10/2021 at 20:14, Muncie said:

Alright chaps I'm going to upgrade this year I want to sell everything I have now and go to a new multi process welder.

Lincoln 200M. Have been eyeing them up at around 2.1k+ gst. Seem to review well and being a lincoln its easy to get part.

-

6 hours ago, escorted said:

Spotted at the local scrappy

So how many beers is it gonna take for you to drop some hints on a location?

-

1

1

-

-

Wouldnt think so, the materials arent that dissimilar. Havent had one break on me yet and I use that trick alot.

-

1

1

-

-

Agree with KPR, 1.6 mild steel is the general rod

For stainless most of what I do is fine pipe work so I use a 1.2mm give a real tight weld.

Have 2.4mm mild steel as a back up for big gap craft jobs or things requiring filling up.

Stainless rod on mild steel is a good get out of jail card, its probably naughty but it welds yucky mild steel without going all poopy. Good if you are repairing old exhausts etc.

Really like the silicone bronze rods, makes pretty welds.

-

2

2

-

-

Yeah its under my bench, just need to finish off the new terminal connections. Will post updates once ive finished it.

-

1

1

-

-

Ohhh what a goodie. Good size bore and big toolholder, give you heaps of options. Have always cleaned older gear with wax and grease remover. Doesnt wreck the paint but actually cuts through it grime. Would reccomend giving it a quick hand polish and a wax, suprising how sharp they turn out.

For tooling Manu put me onto CarbideNZ in Palmy. Really good to deal with and pretty cheap. Wprth doing some learning on carbide tooling shapes such an easy solution. If anyone tells you it wont have enough grunt they are wrong, can get the equivilent geometry of HSS in carbide but doesnt loose its edge.

-

4

4

-

-

On 20/09/2021 at 17:43, Goat said:

Doesnt seem to support foot pedal. How often do you tig welders use a pedal.

I've only ever welded with a pedal, but i can imagine that it would be a right PITA for 90% of welding jobs.I can see why you would want one for more specialist jobs but have lived without it for the last 6 years. I think if you get to the point where you are wanting a pedal you would upgrade to a grunter machine as well.

-

1

1

-

-

Would like to bring 2 bikes, may I bring pitty pup if I hack it up into something exciting? 125cc hillclimb only.

-

1

1

-

-

-

On 13/09/2021 at 14:00, Flash said:

At $180 for the kit it seems like good value?

Tell us more about this? Where were you looking for these prices?

-

As more of a eastwood vs machinery house debate.

My old work had the original machinery house beadroller (eastwood style) which worked well but had alot of deflection. Did a trade with a mate so brought him the newer machinery house design and wow what a difference. So much stronger with almost not deflection at all and much beefier gears and adjusters etc. Definetly worth the $60 more. Have been giving it a hiding and wouldnt bother bracing the new one.

Something to consider in the future is you may want to convert it to powered, its amazing. The machinery house motor kit is $200 cheaper. Either way have a look at the other die kits available on there website may be something there that suits you.

We also made a small adapter amd put a steering wheel on, is a bit smoother then the handle as you can grab from the same spot everytime rather then having to reach through the handles arc.

-

6

6

-

1

1

-

-

-

On 02/09/2021 at 20:13, tortron said:

2-3 weeks for the stuff I have gotten recently. But might be better looking for a complete saw here

Is this the thinking that has lead you to own 10 Dr200s at once?

-

1

1

-

-

British racing green for me. Easy to make pop especially agains your pi badge. Also gloss green is reflective enough that is disguises welds you arent proud of.

Go you man looks great.

-

1

1

-

-

-

9 minutes ago, kyteler said:

Giz your slot mags Geophy.

Also. I may have videos that I took with me when I left that you will enjoy. I'll try remember to take them along to the next event I attend that you're also attending.

Unfortunately my stash of 4x100 tridens is all being used atm. Although here is a teaser for you, chucked them on a mates mx5 a few years ago. Would have looked much lovelier about 50mm lower. Other set is on my trailer.

But yes very keen to share factory sharns again maybe another wagnats?

-

3

3

-

-

- Popular Post

- Popular Post

3 hours ago, GuyWithAviators said:Yep pretty much. I haven’t looked too hard yet. @Geophyhas some 14” turbos for me on long term loan in the meantime however.

Close 13x6 Turbs. Same fitments as my corolla so will look good with more slam.

-

11

11

-

1

1

-

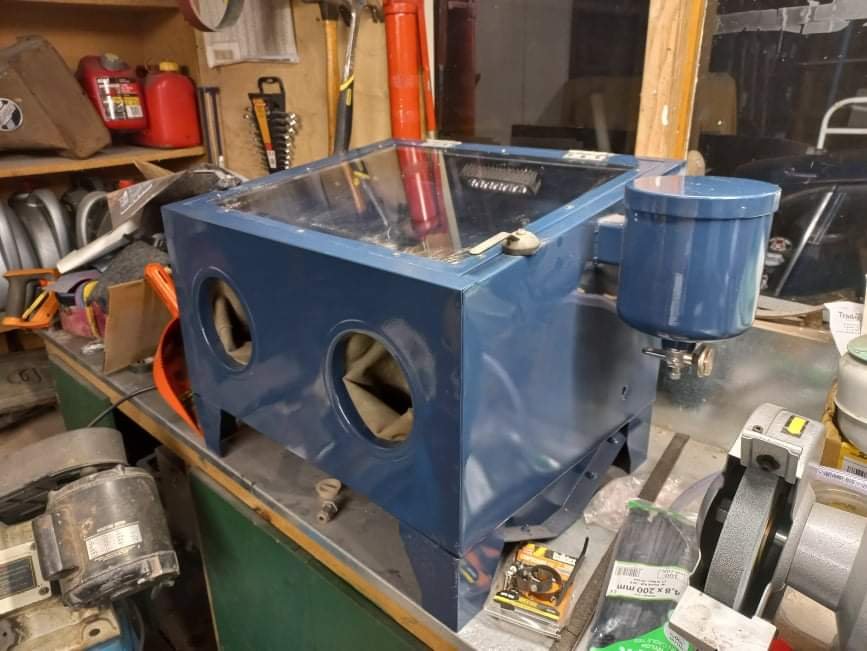

Nowhere near as fancy as your guys setups, is more of a test bed for a custom full size cabinet.

Was give a cabinet from my old work that someone had raxxed the gun and screen out of. Took alot of inspiration from Sheepers cabinet and came up on this. Still have a bit of tutuing and and finishing to do but seems to work considerably better then before.

Have a gavity feed hopper on the side which makes a huge difference, just super consistent flow and good pressure from the 2nd smallest tip. Has a 12v ali x light bar in the side but will probably go to a light bulb like most of you have. Have it going into a shop vac but have a cyclone extractor to use, just struggling for room atm.

-

6

6

-

-

- Popular Post

- Popular Post

Something I have been working for on and off a year or so.

@Dogwatch is keen on gardening and always figure that I have the shed for car stuff she deserves a shed for garden stuff. Looked at all the mitre 10 cheap shittas and they all looked horrific. Ended up seeing a crowd in TGA called the shed shop selling prefabbed sheds with basic wooden framing. Pulled the trigger and got free delivery through the home show.

10/10 would trade again very sturdy proper gutters and no rattles. Was awesome they clip wheels in the edges and roll it to where you wish.

After a bit of exacvation

Had a good pad to put shed on. @Beaver and @GuyWithAviators gave me a hand to make up a base to sit it on to get the shed off the ground, then made up a floor for it.

Lined some walls, made a bench and put a bit of trim round the window and it was ready for paint. All the planks in the shed are planed down old fence palings.

Gave it a lick of paint, popped some shelves in and made up some steel hooks and its good to go. Finally got the aliexpress solar lights in this afternoon shit they go good.

Stoked at how it turned out is a bit fancier then we both anticipated but she does alot of gardening so it gets used alot. Its amazing how much nicer it feels inside with lined painted walls, feels like a proper shed not a cupboard.

-

44

44

-

1

1

Hiluxs are worth a mint!

in General Car Chat

Posted

Shit thats a good load Yetch, very exciting. Will have a dig for other photos of overloaded hiluxes.

Were a few bricks in this bad boy