-

Posts

205 -

Joined

-

Last visited

About Banga

- Birthday 20/09/1982

Profile Information

-

Gender

Male

Converted

-

Local Area

Wellington

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

Banga's Achievements

Advanced Member (3/5)

937

Reputation

-

my new problematic daily....its a mk1 focus st170

Banga replied to d.p.n.s's topic in Other Projects

Well that’s cheap enough to have a spare engine just in case -

So far so good, the cam covers on ST170s are notorious for the paint falling off. Suspect I’ll need to redo it in the future.

-

Quite possible he was with the Cortina club, a red Mk1 left a bit earlier than the rest of us. This was on the way to Napier on Saturday morning, the other green mk2 has a 2.3 duratec in it and the white mk1 has a super charged 302-.

-

Thanks! Yeah seems to attract a few yarns - it’s a 50/50 split as to whether modern engine etc is cool or sacrilege.

-

Bit of a drive over to Napier with Cortina club over the weekend, she was a cold start in Taupo on Saturday morning -1c and she fired up with no issues at all.

- 55 replies

-

- 16

-

-

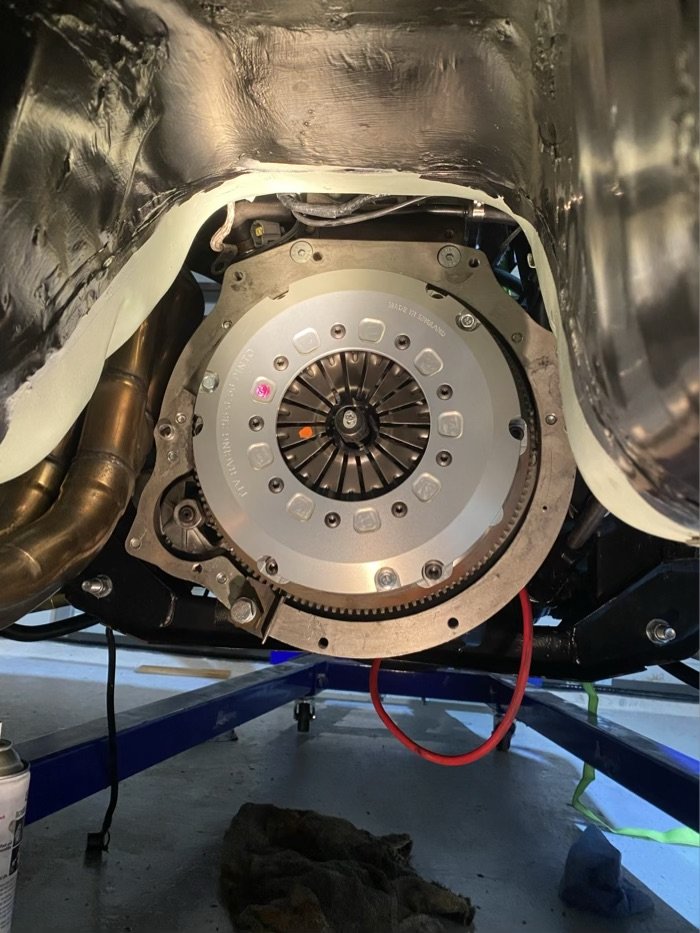

Gearbox install went pretty well, dropped the front subframe down on some 4 inch bolts to keep it all in line , whacked the gearbox on and lifted it all back up again. New clutch is a fair bit heavier but the last one was almost too light so this is a good change. Went for a drive to Hampton Downs the day after slapping it all back together to start the 500 mile bedding in of the new clutch. No more slipping which is ideal- did adjust the pedal height as suggested by a couple of wise minds in the discussion thread. The paint on the cam cover was looking a bit tatty after the engine lifting- these magnesium ST170 are apparently really good at shedding paint even from the factory. So Ive stripped it and given it a few more coats of wrinkle- really tried to scuff up the surface this time so will see what happens.

- 55 replies

-

- 22

-

-

Fancy new clutch bolted up, hopefully get it all back together this weekend. Will drop the engine and subframe, slap the gearbox on and then lift it back up together.

-

It’s a bolt in place job specifically for this set up- no room to shim and it’s been fine for about 3000kms, I think you might be onto something with the master cylinder though - I swapped over a brake master in my pedal box and might not have have set the clutch master back to exactly where it was in the clevis when I put it all back together. It was only slipping in 3rd under high load/torque when hot so fluid expanding could be right on the money.

-

Will double check when I throw it back together, running a hydraulic release bearing so no slave cylinder rod to check. Thanks!

-

6 months on and has gone through another WOF, didn’t really get out as much as I thought over summer but did a little bit. Has had a couple of teething issues, front brakes squeal when there are hot, tried copper paste and some squeal stop stuff but it eventually comes back. Bigger issue was that the clutch had started to slip when the car was warm, no issues when it was cold. Tried bleeding the clutch but no difference. The clutch is only “rated” to 180bhp and I’m right on that but haven’t driven it particularly hard. So decided to pull the gearbox this week, note to future self the trans tunnel is not big enough to pull the gearbox- much easier to pull engine and gearbox or potentially drop the front subframe. After much wrestling the gear box was out along with some paint and the clutch looks… fine. No signs of excess material and flywheel doesn’t look like it has been hot so I’m a bit confused really. I think I’ll still grab a higher rated one just in case and get the flywheel skimmed and through it back together, one bright side is I’ve found the source of a really high pitched vibration/rattle- the dusty shield was loose inside the adaptor Tell me I’m missing something here

-

So fucking awesome! Amazing work dude.

-

C - lovely wheel.

-

I think I’ve been lined up for the old man’s bonus next, 1 wiring job a year for me!

-

I used a Painless one in my Cortina, wires a labelled all the way along which made it much simpler for a noob like me. Full rewire and everything worked as intended and nothing caught fire- would trade again.

-

Pretty cool weekend, ended up down at the Cortina nationals in Christchurch with 120+ other Cortinas- some pretty amazing cars down there and a good group of people. Cool Cruising snapped some cool pictures too. Old Doris seemed to be pretty interesting to a bunch of people like this: Arrived home this afternoon and clocked up around 2100kms since I left here last Wednesday and averaged about 7.4l/100kms and I wasnt really taking it easy. Car was pretty much faultless the entire time - brakes squeal a bit so need to sort that out and will check my fuel filters as it did a weird down on power thing for a couple of kms and then sorted itself. To top off the weekend I walked away with 2nd in the poverty spec/non-GT mk2 category and best modified car!

- 55 replies

-

- 32

-

-