-

Posts

10,633 -

Joined

-

Last visited

Everything posted by h4nd

-

Thanks folks. Next: "Do you have that one with that guy who was in the movie that was out last year?" https://www.google.com/search?q="Do+you+have+that+one+with+that+guy+who+was+in+the+movie+that+was+out+last+year?"

-

Ummm, I think Karls guy? I'd have tagged Karl, but I can never remember his username.

-

Hi yo, ol' mate Warrick runs a shop doing panel repairs now, I think. Can someone fire me come contact details? Chur

-

Ah, once in a blue moon I look at facebook. I think an event has been added...

-

Strong .jp emphasis tonight. so I get to set the topic of every sharn... Oh, man, they have gluten free, so good!

-

Should be fine, give it a go

-

Yeah you want a 12V charger with up to say 30-36V input. Batt size depends on how long you want to run the stereo. Charger current depends on how fast you want to recharge (battery will limit this itself in practice, unless you crank the V up), and if the stereo will be running at the same time you're charging (probably), but, at a guess, one of these would do it: https://www.aliexpress.com/item/4000238066768.html It's for solar, but it probably won't care, and you get lots of displays and functions and settings to fuck with

-

Prezactly. The 'idle' circuit normally runs at tiny power, and the stereo normally draws more current (direct from the battery, thru that line) when the unit wakes up

-

-

BTW, those UNI-t clamp meters which go down to ~5mA dc are great for finding a random drain...

-

Nope, no need to disconnect. in either case (2x solar and charger, OR one solar, one isolator, 2x charger), each battery will get charged to it's correct voltage, regardless of if it needs e.g. 2A or 2.2A trickle. Same as using 2x 12V mains battery chargers - As long as at least one charger isn't ground referenced, all good! (keep the 2x solar cells isolated if you choose that, they'll be 12V apart. No sharing ground wires, etc). 24V from Alt may not perfectly balance, but (isolated) 2x 12v means each battery will eventually be correctly charged (if they're getting enough energy overall).

-

Or just have 2x 12V cells and trickle chargers, one on each battery? Job done. If you really only want 1x 12V solar cell, use an isolated dc-dc power supply for the 2nd trickle charger and battery, https://www.aliexpress.com/item/1005002553820256.html (There will of course be some inefficiency say 5% to 15% depending...)

-

EpochNZ's Teenage Wet Dream Sierra Estate - Discuss!

h4nd replied to EpochNZ's topic in Project Discussion

What's easy and cheap in pinto gearbox adapters? https://www.motorsport-tools.com/ford-pinto-zetec-to-mazda-rx8-conversion-kit-adaptor-plate-and-cable-clutch.html or, VW gearbag? https://dalhems.com/en/p/88b42a8e298b4c32913f4bc45c2e22b3/Adapterkit-Ford-Pinto-in-Vw-200mm-Gearbox -

4018 Presettable Divide by N Counter CMOS IC? https://www.jaycar.co.nz/4018-presettable-divide-by-n-counter-cmos-ic/p/ZC4018

-

Zoom Meeting: <link scrubbed> I start the meeting a little before 7:30, and be letting folks in from the Lobby then and for a while after. Cheers. Beers. Queers and fears, tears dears.

-

I'll post a link say ~7pm

-

I have a paid zoom, so can host bigger meetings, could have a beer and online sniffing shitposting session? (You'll have to make your own burgers..)

-

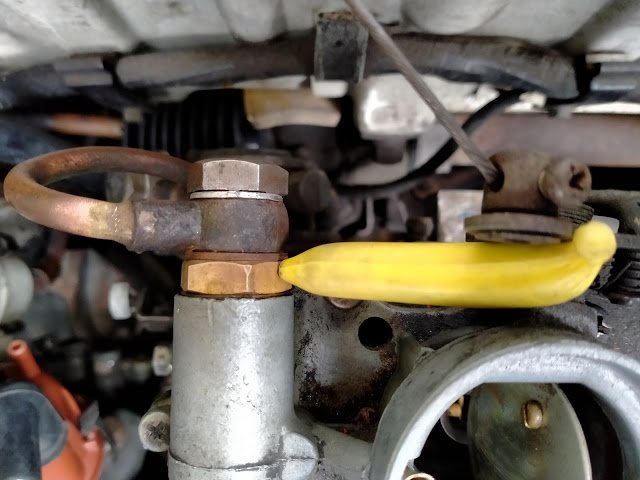

Then @EpochNZwanders over one day to have a look at VW suspension on the drive. After, we have a quick look at the DAi, and it starts on the jumper cables. Hang on!. The battery is showing 12.8V after settling after charging, (OK), but drooping to 10V and less under load when starting. So I head off to Faast fit who supplied it, he tests it (OK on the hygrometer, but poos output current). It's just been a dead battery, all this time! Faast replaces under warranty (good service), and I throw a wee brass strap on because it's a slightly different shape. Runner! Drive to work. It's oookay, but not running well, maybe a little lean? Found an online airfilter dimension search (finally), and toss one in, then change the carb back to the one on the right (no hole in the barrel from long screw), and back to normal for that motor. Sheesh, what a chore. I need to remember to check the basics first. Anyways, it bloody great to be punting this around town again, and now I can get back to important tricky jobs like changing the carpet.

- 90 replies

-

- 25

-

-

-

-

-

-

May 24, but not well, still fouling plugs. I know the air cleaner is a bit shit, so Here's a part number that the local agent tells me is unequivocably NOT a Daihatsu part number Gave it a wash/dry, good.

-

-

-

May 22, Ok, probably not spark? Looks little lackadaisical, so nipped up the plug gaps for a longer lasting spark. Carb trouble? Hoick a spare in... Carb spring spare by BIQ and mis=-matched cable bracket mods... Ah, starts! on ether.. once ???