-

Posts

243 -

Joined

-

Last visited

Posts posted by kp60nick

-

-

-

-

21 hours ago, hood said:

^ Thanks brother, I appreciate the love

Wow, love the nostalgia. I vividly recall that day. In particular I used to roll the length of the southern motorway with the front in the air and the rear on the bumps. The dropshop did a nice job on that clip which I intend to keep in place.

Orginally in two minds to load this thread on here on Oldschool, but like I said theres been some clever work done to it in recent times thats certainly worth sharing, and since the old MTNZ forums are long gone I still miss the golden years of minitrucks in this country circa 2007 in my opinion.

Yeah its unfortunately collecting dust as we speak, but I'll get there with it.

FYI our friendly local certification expert used to be a minitruck enuthisist @cletusas we used to be in the same club too haha

Unfortunately I wasn't able to be involved at the peak of minitruckin in NZ. I just got the tail end.

Load up the thread man, the more the better. I reckon everyone loves a good minitruck, just no one is wanting to out lay the cost to build one.

I've always been keen to do a "where are they now" minitruck edition.

-

7

7

-

-

-

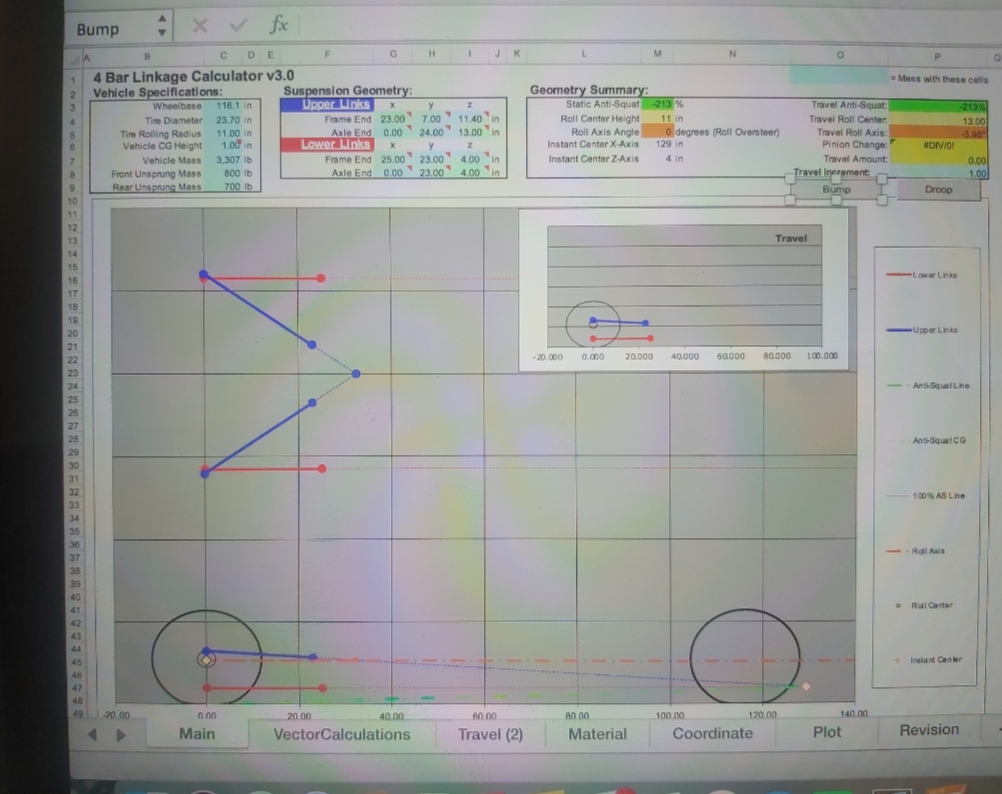

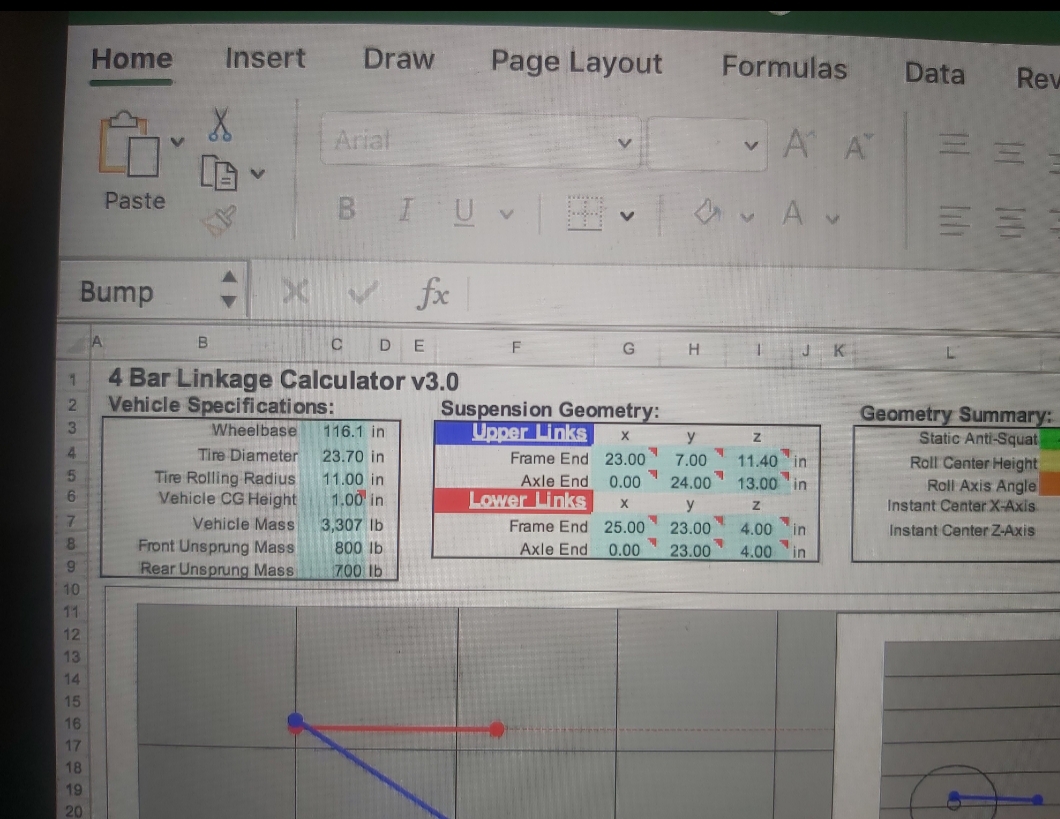

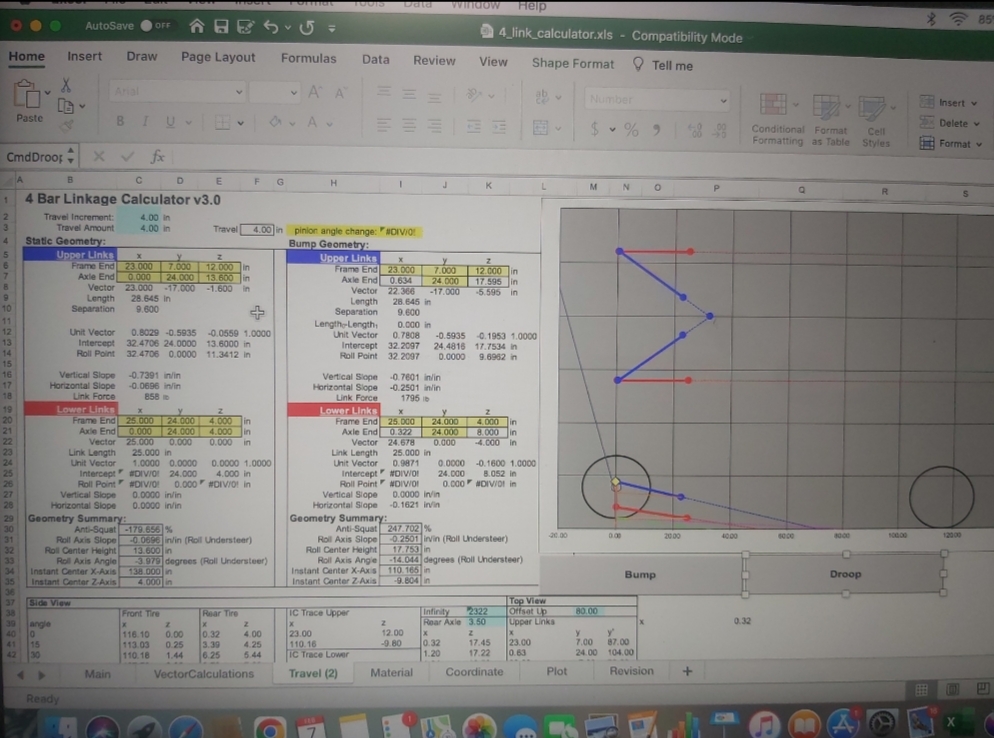

Haven't done any big progress still waiting for the c notch to get done. But in the meantime I've been working on my 4 link design. Thanks to the help of a few GC's on this site they have been steering me in the right direction .

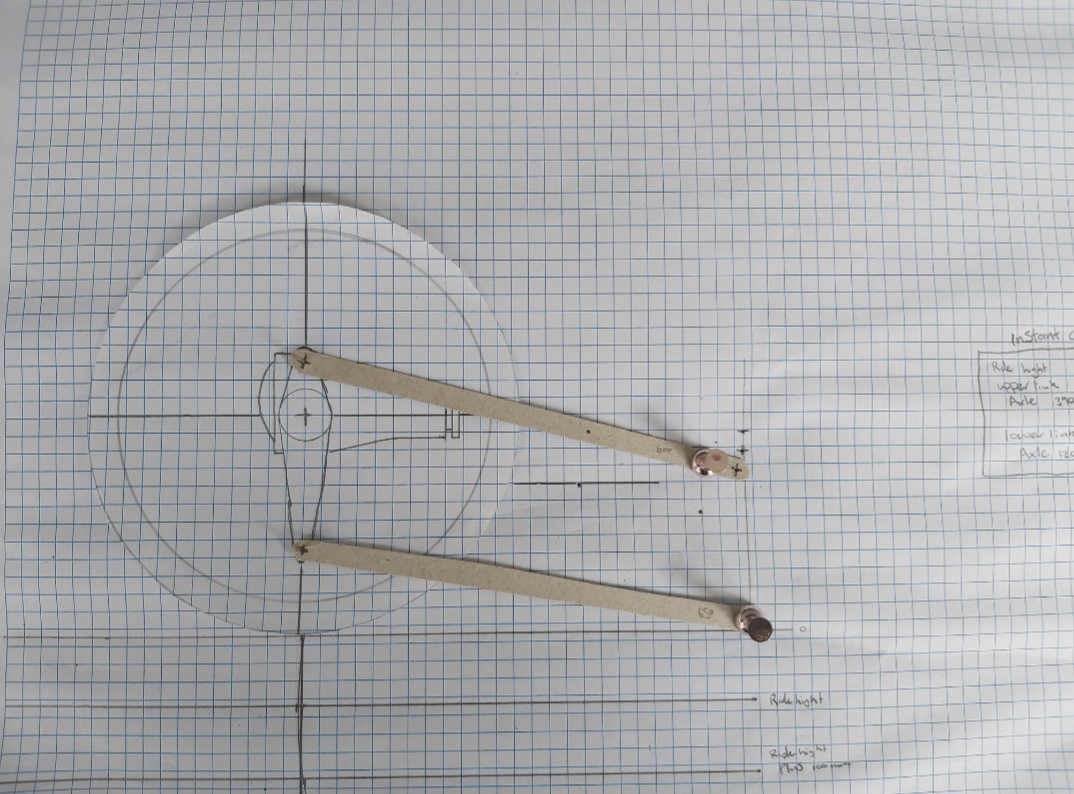

I've been trying out 4 link calculators and doing lots of of drawings and measurements. @RXFORD gave me some information from another bagged d21 that was bag on diff and put the top trailing arm to under the chassis rail which was super helpful and super helpful that I designed my c notch to be 100mm higher than it need to be. Once the notch is done I will start drawing up more brackets to get lazer cut.

Thanks for reading.

-

3

3

-

-

- Popular Post

- Popular Post

Cool to see a build thread for your truck! I've been a big fan of it for years. I had a look at the work matt is doing for the body drop and it all looks so good.

I've had this photo saved to my phone for a while now. I believe it was one of yours. I really liked it. I felt it was a bit of a time capsule. I have a poster on my garage wall of the green courier dragging.

Just a big minitruck fan.

-

14

14

-

2

2

-

Man you guys are are wealth of knowledge! Definitely haven't scared me off just yet. I'm looking forward to the journey ahead of me. Thank you for all your input!

-

So I have done myself a scale drawing on paper at this stage. In plan view. I Was wondering if this is on the right track? 30° bar angle and keeping all pivot points in same place gives me a nice 750mm center of joint to joint lower arm. If I go greater angle on bar it seems to compress everything up (shorten the bars.) Is this a bad thing? From research I've done so far, the longer the arm less pinion angle change through the motion?

-

Thanks for that guys. I definitely need to do more planning but you've given me lots of help.

-

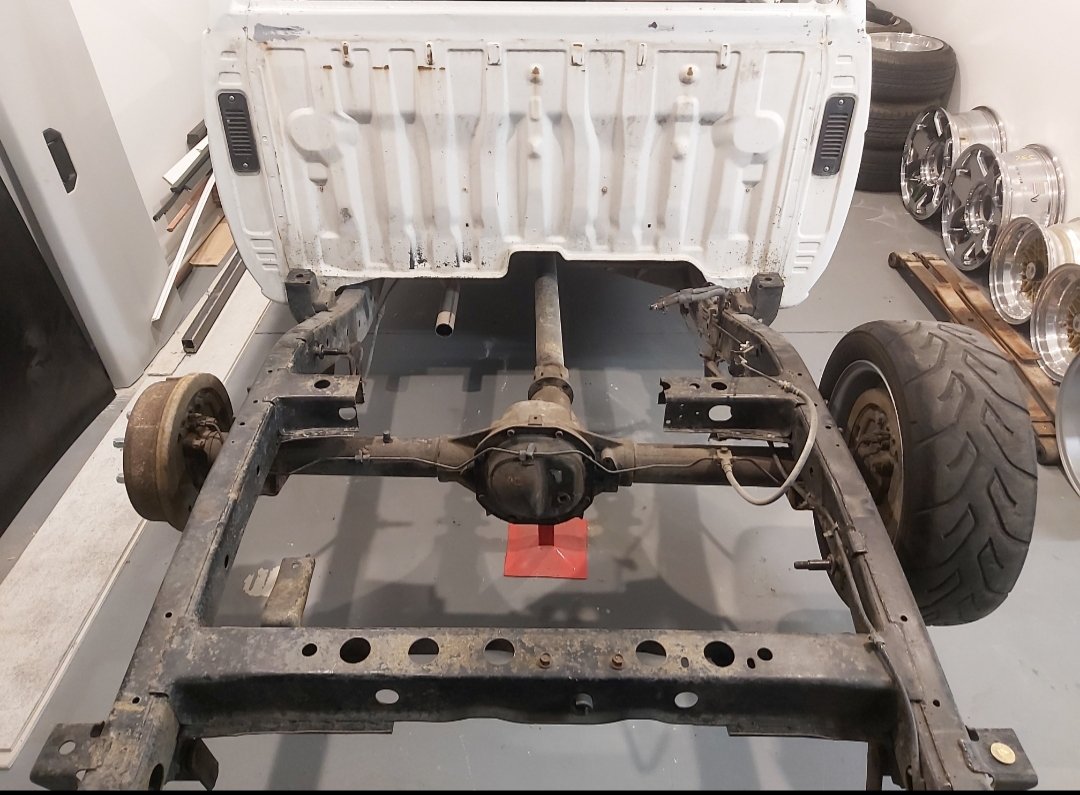

Hi guys I'm building myself a minitruck always been a huge fan and finally picked up my balls and actually doing it bags and everything. Here's my build up

I've been diving into the deep dive on the internet on air ride set ups and pros and cons of all the variations. The difference between bag on bar, bag on diff or bag behind diff (there is cantilever but looks way to tricky and want to keep everything low under tray.) Looking at it at first glance the easiest and best way would be bag on diff. Unfortunately due to the fact I have a cast center diff and I have to put my top link arms to the location where the bag would go instead of center like most other minitrucks with triangle 4 links.

So bag behind may work with a bracket off back of diff. Down side this requires more air to lift truck which results in hard ride and less lift.

Bag on bar really seem like the only option to suit my application. Gets good lift and rides softer. But I've never seen anyone in nz document bag on bar set up (maybe not looking in the right places.) I haven't seen any details on the bar size? or rose joint/ rod end size? The bars are carrying the whole weight of the rear. The guys in the states seem to use lots of rhs box for mounting their bag on bar. Good idea bad idea? I dont know. I'm a little lost.

Cheers Nick

-

- Popular Post

Over the break I got it running again. Extended the fuel lines and wires to tank.

Took it up and down my street. Out of the 3 I've owned it's been such a good vehicle starts first pop, drives really well for a 33 year old car. I guess its fairly modern compared to most on this site.

Got my c notch pieces back from being folded. Now just need to drill and tap the bump stop hole in the lower piece.

-

12

12

-

- Popular Post

This brings us up to date. I'm just waiting for the top and bottom of the notch to be folded up then I'll get it welded in. Also moved fuel tank to the back of the chassis it fits surprisingly well so I think I will use it there but just move it bit further forward once notch is done and another crossmember is added.

-

12

12

-

Got the caddy wheels on with new bridgestone re003. I always remember minitrucks having super directional tyres and big chromes.

Started cleaning chassis up for notch. Worked out how much clearance I need to get it laying frame on the 17s added a little more and made clearance for bumps tops on the underside of notch. Made a template out of MDF as I have an abundance of the stuff. My little brother luke is doing engineering at uni so got him to draw the cad file and sent it to one stop cut shop. 4mm steel and stays the same thickness as the chassis rail the whole way over.

-

9

9

-

-

-

-

- Popular Post

I got a couple of sets of wheels.

First set is Cadillac Escalade 17x7.5 that I brought from japan. Chrome is in really good condition just needed to get the center bored out to fit over the hubs. The inside condition is not very good.

Second set is a factory nissan wheel 15x6.5. I had seen them on an old boys ute and had to twist his arm to give them up. But we made a deal and got them. steel wool and repainted the inside barrel.

-

10

10

-

-

- Popular Post

-

-

-

-

-

I epoxy primed the tray. I think the following week I found on trademe I wrecker with one of these and I phoned them and brought the tray to see if it was any better. Only difference was this one hadn't had the clips drilled into the sides.

I've since given this tray the same treatment sandblast and epoxy primer. I still have both as they are pretty hard to come by.

-

5

5

-

-

.jpeg.a0a5c776ac75e1bb9483903b42d7d4b7.jpeg)

.jpeg.3446c91e50ebdb015e26673db21e99f9.jpeg)

.jpeg.0dd30bb47d2145061c343b06f7ca1601.jpeg)

Kp60nick's D21 kingcab Soon to be Bagged on Cadillac Escalade rims

in Other Projects

Posted

@Beaver I have plans on chopping this ones roof down to be level with cab. But if I see another one I will let you know.