-

Posts

3711 -

Joined

-

Last visited

-

Days Won

3

Posts posted by kws

-

-

glue some sandpaper to it, she'll be right

But it's true, you can never really account for the "human" factor/stupidity.

-

4 minutes ago, kiwi808 said:

So today I went to take the little red Mazda out for a Sunday drive on Saturday. The intention was to do a bigger drive than usual 20 km round trip it often does. Probably going to be on the road for 2 hours.

So the first thing I do is check the tyre pressures as one of the tyres tends to have a slow leak. Do a full walk around the car and get to the tyre with a slow leak and the and the side wall has a huge split on it. I mean huge. (Yes check tyre pressure when warm etc etc etc but this tyre has a leak. So it needs checking BEFORE you drive on it)pull wheel off, head to town, replace tyre with spare I had in storage. Continue with pre prepared trip. Job done.

But that’s the problem right there. 2 weeks ago I checked and the tyre was fine. Today it was a massive accident waiting to happen.

I know to constantly check these things. Fucking tourists wounders in their shìt wagons have no idea.

We can’t trust people to maintain their cars. The accident statistics in Central prove that.

One must ask, how old was said failed tyre, and how old is the tyre you fitted that was in storage?

-

1

1

-

-

16 hours ago, Doug Hill said:

Always made me giggle, our old 2005/6 E61 wagon was an IBS (Intelligent Bowel Syndrome) car and needed battery coding, plus sensors etc.

My Camry Hybrid and Prius both do not require that. Go figure.

I had to disconnect the ibs sensor in my 650i or it would drain the battery for fun...

"Intelligent"

-

1

1

-

-

5 minutes ago, AE25 said:

Interested to see how this goes. Haven't personally seen speeduino used as an engine ecu etc. Usually megasquirt or mainstream ecus. Id just make sure the ecu can work with the particular sensors and the trigger wheel lobe count.

I have a few 2tgeu spares if required.Speeduino is very flexible, so sensors won't be an issue as long as you can work out the calibration of them, and most trigger patterns are supported now. Its basically just a cheaper, more frequently updated, Megasquirt these days.

Cool project, looking forward to seeing more progress

-

2

2

-

-

- Popular Post

- Popular Post

Another thing I had been wanting for a while but was hesitant to buy due to cost finally came on sale, so I snapped it up.

Since my car was a track toy in Japan it came with some goodies still attached, one of which was the Cusco front swaybar. This apparently takes the swaybar from the standard 18mm up to 20mm, which Cusco claims is "ratio with standard 138%", whatever that means. Either way, it's stiffer.

The bar is so dirty it's hard to see, but it's definitely thicc and blue.

I suspect this, along with my blown rear shocks and wrong rear springs, worked together to cause the handling at the last track to day just be straight up hostile. The car would not rotate, it was all over the place, and really wanted to push on in corners.

Since I've fixed the shocks and springs now, the one thing left to do to balance the handling was to fit a rear swaybar. The car originally had one when it was in Japan, but it went missing at some point before I got it (likely before it left Japan). The Alto Works apparently has a standard rear swaybar integrated into the rear beam, but I haven't seen how big this is, I suspect tiny.

I've been watching the auctions for ages now trying to catch a bargain on a used bar, since they weren't cheap new. I had no luck, but by chance I was having a nosy over on RHDJapan and noticed the exact bar I was looking for was on sale, so jumped at the chance.

So, here is my new Cusco 16mm rear swaybar.

It's both easy to fit and a real pain. The bolts that hold the end plates to the rear beam have to go under the lower spring pads. Trying to lever the pad up with a trim tool with one hand, whilst using the other hand to push the bolt through, is not my idea of fun

It also makes it hard to get the hex key into the bolt to stop it from turning as you tighten the nut. In hindsight, I would probably drop the rear shocks off and lower the rear beam until there is no pressure on the spring and just lift the pads up.

I got there in the end though, and the bar fits nicely.

As soon as I started the car I noticed a rather large issue; the pipe before the rear muffler was knocking on the swaybar end plate, badly.

Doing some research, it seems this is a common thing and the first thing to try is flipping the exhaust hanger.

I pushed the car up a ramp on one side to give me some extra clearance

Mine started on the stock side, albeit it had been raised up above the normal height (possibly for clearance when the car was lowered)

Zero clearance

I undid the bolt holding the hanger in place and moved the hanger to the other side of the bracket. I then reinstalled the bolt down into the stock hole, which has the captive nut (the visible nut is just a locking nut the previous owner used to secure it to the upper hole, which doesn't have a captive nut)

This gave me ample clearance

As a bonus, the exhaust is no longer obscured behind the rear bumper

As opposed to

A quick drive shows that the exhaust is no longer rattling its little head off, so that's a success. I haven't had a decent chance on the twisty roads to test the new swaybar, but already the car seems to corner flatter and feels more confident in corners. I'll take it to work later in the week and hit some twisties and see how it feels.

Since the car was already in the garage I took the chance to do a couple of other changes.

One was to replace the rear engine mount with a newer genuine part, and a Silkroad insert. The standard Type 1 mounts are known to be softer than the later mounts, so the new part alone should help tighten it up and fitting the inserts should improve it further, without the harshness of solid mounts.

New genuine mount, and inserts

The inserts fill these gaps

Like so. I slathered them in rubber grease and used a mallet to hammer them into the mount. The inserts are a flexible polyurethane.

Interestingly the inserts stick out on both sides of the mount

Here's the old mount in place.

I first tried to remove the bolt that goes through the small end of the mount and soon realised that no, it doesn't fit

The solution was to take the bracket off the gearbox

There's a little plastic cover over the hole in the subframe the big end of the mount lives in. This is held in place with a clip on each end, obscured by the swaybar

I don't know if it's because of the bigger swaybar, or if it's an issue with the stock one too, but there was no way the mount would slip out passed the bar. I ended up having to undo both swaybar links, and unbolt one end of the D bushes that mount the bar to the subframe, so I could lift the bar up high enough to slip the mount out

It turns out the previous owner had given stiffening the stock mount a go at some point. He had slipped some rubber sheets into the gaps and then slathered the whole thing in.. something. Glue maybe?

It didn't really help, there was heaps of movement in the mount

I slipped the new improved mount in, bolted it all back into place and reinstalled the swaybar.

Since the links were off, and I had new ones (because I had previously noticed that the old ones were stuffed), I replaced those too.

Unfortunately the nut on one of them was stuck and someone had stripped out the hex in the balljoint (not me)

So out came the spinny death wheel, which made quick work of it.

And the new links went in with no issue. I did have to source a new nut from my stash though, as genuine links don't come with new nuts (!).

With everything tightened up, and the wheels back on, it was test drive time.

Immediately you could notice the mount was stiffer. At startup and idle there is a noticeable vibration in the cabin. Not horrible (like my Integra with solid mounts), but it's there and causes a couple of small rattles. Once the revs are above idle though, the vibration is gone, and boy does the mount make a difference. There is no backlash in the engine coming off throttle, and gear changes are even more direct (they were already bliss). Everything just feels more solid.

I'll live with the vibration, it's just part of having a road going little track toy, but A+ definitely worth doing so far.

Finally, one last small change. I finally got the courage to add a third stage to the boost controller. I know from information about what the previous owner did, that the car used to have three settings programmed by CADCARS on the boost controller before it was exported, "comfort mode" - 14.5psi, "circuit mode" - 18psi and "mountain pass mode" - 21psi. Stock boost is 8psi, and that could be achieved by turning the boost controller "off".

I've had it set so A is stock 8psi, B is 14.5psi and C wasn't set. Since I was confident the car was happy on 14.5psi, and knowing it previously ran up to 21psi without issue (I'm not going to push it that far), I finally set C to 18psi and holy moly, I thought 14psi was fun!

Accelerating through the gears to 100kph is pretty rapid, but the real fun is around town, where you can just rip around like a madman, whilst still under the speed limit. Coming out of corners, second gear, 18psi, with the LSD gripping like crazy, whilst doing 45kph, leaves you with a massive grin.

AFRs seem happy, although intake temp does climb pretty quickly, indicating the little spooly boi is getting pretty close to its limits for not just making heat. Thankfully the massive Greddy intercooler recovers quickly and the temps drop back as soon as you're off boost.

Right, I think that's about it for now... *opens Yahoo Auctions Japan*

-

15

15

-

2

2

-

Good lord that gets me in the feels, little did I know the horrors happening only a couple of cars behind me.

Had I known it sounded like that when running I would've recommended just giving up straight away and not trying pulling to bits in the pits like we did.

That engine thought it ugga'd its last dugga that day.

-

1

1

-

-

Having had the 2ZRFE (factory) in a Yaris RS, its a very uninspiring motor stock. It had a thick wad of torque in the mid range, but other than that it didn't like to rev and felt kind of flat. No doubt boost will fix it.

It's getting on a bit now but i think the Mazda L series (2.0L LF-VE and the bigger 2.3L L3-VE) would be a good engine to swap into something RWD. Already comes RWD configured in the NC MX5 (2L) but the 2.3 can be converted to RWD too. I liked my NC a lot, and the engine and gearbox in it were great. Turbo kits are available, albeit expensive.

-

4

4

-

1

1

-

-

according to google reverse image search, this is the origin https://www.instagram.com/p/C3apOa7KHD7/?utm_source=ig_web_copy_link&igsh=MzRlODBiNWFlZA==

-

Cool little car, and awesome that it's been vtec converted, i bet it'll go like throwing a brick really hard. They rusted really badly in the UK, so hopefully yours isn't too much worse than what you have found.

Has anyone linked you to this yet? i found it when i was looking into the SMX myself https://www.motoroids.com/features/with-a-cabin-that-encouraged-love-making-the-honda-s-mx-wanted-you-to-see-the-letter-m-as-an-e/

-

1

1

-

1

1

-

-

6 hours ago, Colinstg said:

Hi Kws I have recently bought one of these Rovers 220 turbo Coupe and trying to sort out a intake manifold leak. The ECU is hooked up to the manifold so that's good but there are two pipes either side of the throttle body and not sure if they should be blanked off or connected to anything...can you help. PS these cars are getting sort after in the UK and prices are goin up.

Hi, yeah sorry mine is long gone. Your best bet is probably to jump on the RoverCoupe facebook group and pop some questions on there. They're an incredibly helpful bunch on there and should have you sorted quick smart.

I seem to recall that black one having had a lot of work done, including most of the common issues, so would be a good one to hold onto.

-

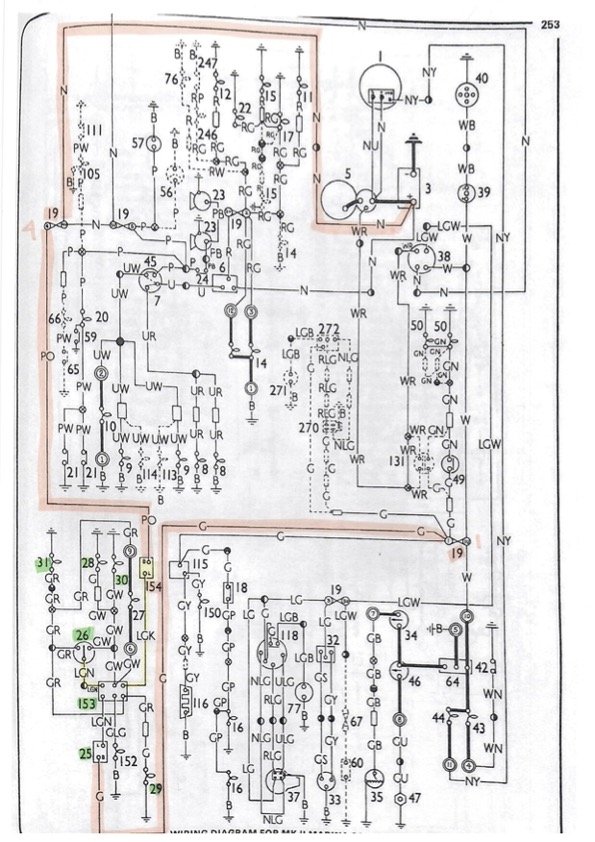

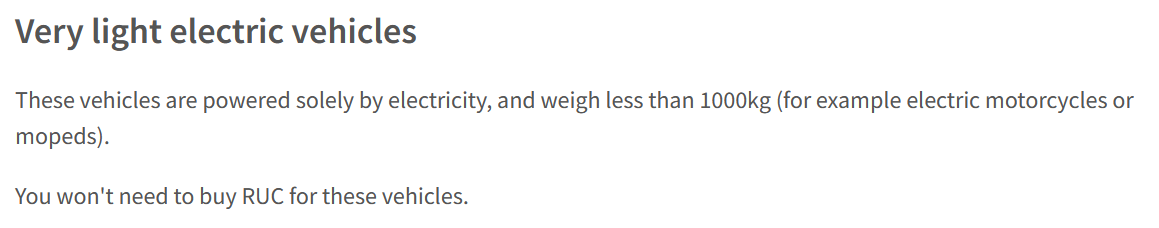

id still check the hazard switch and wiring as the lightgreen/brown wire you didn't have power on runs from that to the column stalks, if you have hazards but no power to that wire, there arent many places for it to be lost. I also see a lovely red plastic crimp in that wire in the photo too...

-

1

1

-

-

Hopefully this helps. Orange is the path of power to and from the indicators. My bet is on a dodgy hazard switch (153) and/or dirt connections on it if its not the fuse (fuse number 4). I seem to recall a similar issue in my Mini.

Might be unrelated to the radio unless you've fiddled the wiring on the hazard switch

-

3

3

-

-

Have you checked the fuses? I can't recall the location of the fuses on later cars, but could be under the bonnet or under the dash, and could be an inline fuse too. Check your grounds too.

Sounds like the wiring for the radio shorted something out, so I'd check with a multimeter that it's all wired as it should be.

-

1

1

-

-

21 minutes ago, tomble said:

NGL, i honestly think the car was designed to have the seats lowered in the first place and the big spacer was an afterthought, everything falls so nicely to hand now and its much better to drive. It cannot be understated how much better it is to be able to press the HVAC buttons without having to reach down and across.

I need to take you for a blast at some point

-

1

1

-

-

@yoeddynz, Based on this thread, the asking price is all your fault. $8K, not the reserve

https://www.trademe.co.nz/a/motors/cars/nissan/march/listing/4627249957

-

3

3

-

-

I've been thinking about these for a while, even before I got an Alto, as they are a common mod in Japan. I finally bit the bullet and lowered the front seats.

One of the biggest criticisms of the Alto in reviews is that instead of sitting IN the Alto, you sit ON the Alto. The two front seats, despite being nice fancy Recaros, are not height adjustable (lower spec Altos, including the RS Turbo, are) and you sit very high in the car.

For example, I'm not particularly tall and my shoulder in the standard seats, is about halfway up the window

The other issue was that on the track I had to slightly slouch in the seat for my helmet to clear the headlining. Not ideal.

Knowing I want to track the car more, and that slouching in the seat wasn't safe, I convinced myself it was a safety upgrade to lower the seats and gain more headroom. Yes. Safety.

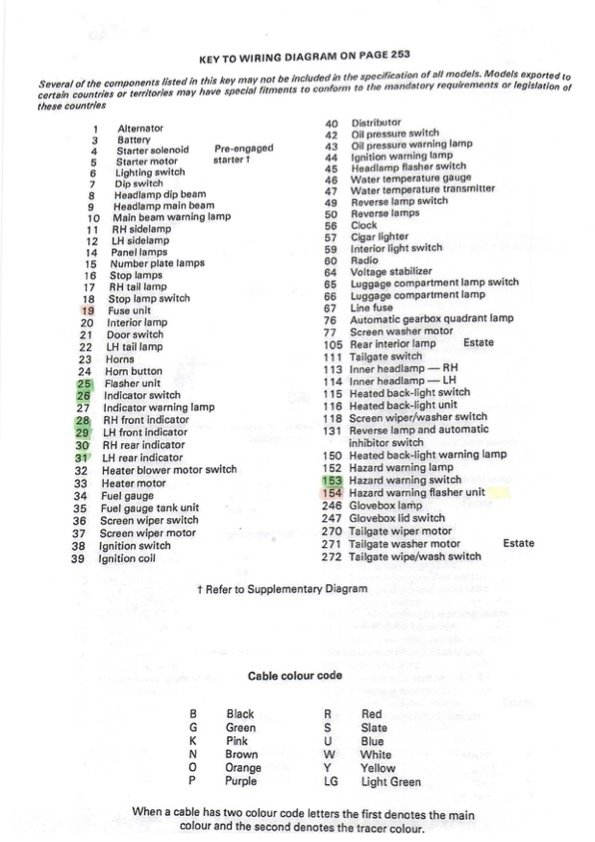

So I went on Yahoo Japan and bought a pair of TakeOff Low-Posi Kun seat spacers. These emulate the standard spacers by being one piece with a crossbar between the two legs

There are other brands, some of which offer adjustable spacers so you can change the height or the tilt of the seat to suit you, but the TakeOff ones are the only spacers to have the crossbar. I've seen what can happen to Recaro seats when the two rails aren't braced together, and the seat tries to splay them apart. I'm not a small or light person, certainly not the build of person the Alto was designed for, so strength is important.

The TakeOff spacers have also been strength tested in Japan and each set comes with an individually serialised certificate of strength testing. It won't mean much in NZ, but it gives me some confidence that the product is good.

The TakeOff spacer lowers the seats by 50mm. It doesn't sound like much, but when you put the two spacers side by side it's huge. The top one is the standard spacer, and the black one is the lowered spacer.

When put side by side, it's noticeable, as the example photos from the site show

Standard

Standard

Lowered

Lowered

A wad of money, and a few days later, I had a pair of spacers in my hands

They're a nicely made piece of kit. Very solid.

The included strength certificate

It comes with all the fittings needed, if they aren't the standard fittings (it reuses all standard fittings)

The thick brass washers are optional spacers to raise the seat slightly. It also makes the rails smoother to adjust. I'm not bothered either way and wanted to go as low as possible, so I left them out

I had seen a few different ways to fit the spacers. The most common is to just remove the seats from the car completely, but I didn't want to remove the seats from the car and get them dirty in the garage, so I opted to tip the seats back up onto the folded-down back seat and work on them there

The seats are bolted to the car with 4x T40 bolts. You can see the large fabric covered stock spacer here, between the rail and seat.

Don't forget to unplug the connector under the seat. These seats don't have side airbags, so I didn't bother disconnecting the battery. This is just the seatbelt and passenger occupancy connector.

I unbolted the seat and carefully tipped it back onto the back seat. I turned it so I could work from the back door opening

Disconnect the plug and unhook the wiring from the spacer and rail

The spacer is then bolted to the seat with 4 bolts (orange arrows) and 7 studs with nuts from the rails below them (green arrows, one side of the rail has an extra stud; 3 on one side and 4 on the other). All are 12mm.

I loosened all nuts and bolts before removing any of them. Don't forget to undo the large 14mm securing the seatbelt buckle on the side too.

The rail comes off as one piece

Leaving the spacer

Remove the four bolts holding that on and you have a bare seat. You will need to unhook the fabric from each end of the spacer, I used a trim tool to lever it towards the middle of the seat and unhook it from the metal lip.

I then affixed the TakeOff spacer to the standard rails, using supplied washers and the original nuts. Protip, don't mount the buckle yet, it has to go through the fabric on the seat first, so wait until the rail is mounted.

Then it was a case of mounting the rails to the seats. The holes are slotted, so I put two bolts on one side of the seat and slid the rail onto those to support it while I put the other two in. There is enough space to slip the seatbelt wiring between the spacer and the seat base.

I tightened all the nuts and bolts down and fit the buckle on the side. Once the wiring was clipped and tied in place, the seat was then lowered back down onto the floor, using the locating studs to place it. The bolts were then tightened down.

The visual difference was immediate

It's significantly lower than the stock driver's seat. I couldn't help myself so jumped in and sat on the newly lowered passenger seat, which made me even more keen to get the driver's side done next.

I followed the same procedure, which went quicker this time now that I knew what I was doing, and had the driver's seat installed in no time.

Tons of head space now. No chance of helmet issues next time I take it to the track.

The little fabric flap now just hangs aimlessly down covering everything. It's not attached anymore, but I'm sure if it bothered you you could glue or velcro it to the spacer to hold it in place. I've seen people cut the fabric or jam it between the spacer and seat base, but I'm happy with it as it is.

I've only taken it for a short drive so far, I'm planning on taking it to work tomorrow anyway, but already the differences are pretty big. Obviously, I've had to adjust all my mirrors and steering wheel down (speaking of, the steering wheel is now at its lowest position, so I can see why column spacers exist), but the biggest thing for me is that now I'm looking through the middle of the windscreen, not the top half, and the interior mirror no longer blocks a chunk of my left-hand vision.

In terms of driving, the seats feel more comfortable, maybe due to my leg position now, and the car feels a bit more confident in corners. I guess lowering a significant percentage of the cars weight (me) will help that by lowering the center of gravity. It really does feel like you're IN the car now.

The only downsides so far are that it's harder to do the old arm-out-the-window when driving, as my shoulder is now just above the waist line of the door, and I've hit my elbow on the armrest on the door when turning once or twice since I'm not used to there being something there.

I'm looking forward to my drive to work tomorrow and seeing how it goes around the twisty roads.

-

9

9

-

-

37 minutes ago, mjrstar said:

Yeah wife's new shape swift sport is almost normal sized small hatch and somehow weighs less than my ek civic racecar which certainly doesn't have any creature comforts..not sure how Suzuki do it.

I know how they did it in the alto, by making everything as thin and cheap as they could lol.

-

2

2

-

-

1 hour ago, mjrstar said:

^^ I reckon if you take the batteries out and fit a petrol motor you'd get it under 1000kg.

Is the 1000kg rule going to be gvm or tare. In my mind it kind of has to be gvm.

My alto is the same size and weighs 670kg or so

-

4

4

-

-

7 hours ago, Willdat? said:

@Bling called it, sub 1000kg you're golden, I wonder what happens to sub 1000kg diesels in future?

Dammit, so close. The EK X EV is 1080KG

https://www.trademe.co.nz/a/motors/cars/mitsubishi/other/listing/4513086447

-

1

1

-

1

1

-

-

I had a 156 v6 manual. Great car to drive when it worked. I had a bunch of issues with mine, including rust perforating the rear floor pans

-

3 hours ago, igor said:

Perfect inner city transport. Ideal for driving over inconveniently placed cyclists

"did you feel a bump?" "nah luv, its British, its normal"

-

4

4

-

-

I'm waiting on a battery tester to arrive so I can test the battery, but being it's from 2019 and spent some time on the docks/ships before i pressed it into regular service, it's probably not living its best life. Looks like the alt is ECU controlled and it's acting "normal" currently.

I am not too worried about it, I'm 99% convinced it was my fault for crawling along in second gear with the revs real low.

-

21 minutes ago, datlow said:

love that, what cool little cars. I wonder if you can use normal March/micra bits to convert to manual

-

10 hours ago, Bling said:

You'll always get some wanting to get that last bit of range. But for the majority of cases, a Leaf will charge faster than whatever you were / are driving. So maybe it's YOU who needs the special charger lol. I haven't seen anyone going for that 100% fill yet. Mainly people just parking their EV in the park because it's close to the door and not even plugging in. Why not plan ahead with your range? I've never needed to plug in publicly to get some more range, just done it because why not. That and to check my DC charging actually works since I don't use it.

Just up the charge cost after 80%, that will stop people doing it. Although I can stop mine at 80% and so it will still hog the charger if I lock the cable.

You're awfully defensive about it (not the first time in this thread either tbh), maybe you're the Leaf driver hogging the chargers?

I was driving a brand new EK X EV, which I'm pretty sure charges faster than a Leaf, has a liquid cooled battery, and has a 144km real-life range. I wasn't charging strictly because I needed to, but because I wanted to test the infrastructure since it was my first time in an EV.

KwS's Small Car Shenanigans. Making Altos work.

in Other Projects

Posted

In the early R06A engines like in my Alto, the crank thrust bearing issue is well known. I decided to preemptively replace mine.

From 2016 to around 2019, when they changed to the Type 2 cars (which basically just incorporated all the changes made through the production of the Type 1 cars), the crank thrust bearings have an issue where the metal was too soft, and the bearings could wear prematurely.

The issue is so prevalent that Suzuki Japan issued a warranty extension/recall in Japan for it, extending the warranty to 10 years/200,000km. Unfortunately this doesn't carry over to imports in NZ, and I've also seen reports that getting Suzuki to actually cover the work means waiting until the engine is basically toast from the bearings failing. Their "solution" is to replace the crank, block and bearings; a full rebuild.

My friend Tom @tomble with the blue HA36S, who unfortunately had an engine whoopsie on track earlier in the year, happened to order a spare pair of thrust bearings with his order of bits to rebuild his engine. Knowing my car was in the VIN range of affected cars, I obtained the bearings from him, intending to replace them before things went bad.

I was doing this preventitively, not because I knew mine were stuffed, keep that in mind. I had been ignoring the niggle at the back of my mind knowing my car could be affected by it. The usual indication that the bearings are starting to fail is a knocking when engaging and disengaging the clutch, as the force of the clutch causes the crank to move due to excessive runout.

My car was what I would consider quiet, for what it is. No noises out of the ordinary, but the other day when I drove the car to work my Android Auto was a bit slow to connect and the first couple of minutes of my drive had no music... and what happens when there is no music, you hear EVERYTHING.

At one point, I thought I heard a slight tapping when coming on and off the clutch in traffic.

It was quiet, and I couldn't be sure I wasn't just hearing things, my car does buzz and vibrate a bit at low RPM due to the inserts in the rear mount...

That day after work I picked the bearings up from Tom. I couldn't risk it.

Last night, after work, I put the car up on stands and set about replacing the bearings. Unfortunately they are inside the engine, so not a "simple" task, but overall very doable in a garage on stands, with standard tools (with the exception of a torque wrench and angle gauge, both of which are easy to obtain).

The biggest issue is that the sump needs to be removed. To do so, the front pipe of the exhaust needs to also be removed, so there is space for the sump. My bolts were a bit rusty, so with a lack of fire-making abilities, I aimed the heat gun at them on full blast and got them as hot as I could (pretty hot, really). With a crack, the bolts came free.

I completely removed it, but I guess you could probably just drop it down and leave it hanging if your rear bolts were unable to be removed

I also drained the oil and removed the filter. I did this with an engine that had sat overnight, so as much oil would be in the sump as possible, so I wouldn't have it dripping on me when the sump was off.

Next, I removed all the sump bolts and tried to get the sump off. The sump is sealed on with goop, and I battled for a very long time trying to break the seal. In the end, and I wouldn't recommend it if you have other options, I used a claw hammer to pry it free. It worked well with no damage, but you could easily break the sump if you aren't careful.

There were two points on the front edge of the sump that were perfect to pry from

With the sump off, I had access to the guts. It was very oily, so photos will be limited, but I removed the cap in question (second from the flywheel). With the cap removed you can see the bearings. Thankfully both of mine were still in place; when they get bad one, or both, can slip out and drop into the sump leaving the crank free to move back and forth.

The bearings are curved and wrap around the top of the crank, one on each side of the main bearing cap. Using a pick to carefully push on the end of the bearing, you rotate the bearing around the crank so you can slide it out

Well, it appears I was on borrowed time

This is what the bearings should look like; the old ones are the inside pair

There was no sign of any metal in the oil, or in the bottom of the sump, so I guess it's just been slowly grinding itself away over 100,000km. The new bearings (and the "good" old bearing) measure 2.5mm, the bad bearing?

It's lost almost half a mm of metal

You can tell if they are the original bearings (or at least not countermeasure parts), as the markings on the back will be different to the new countermeasure parts

Old

New

Thankfully the crank bearing itself looked great, plenty more track days left in it

The crank also appeared to be in good shape. The "bad" side had some slight ridges in it, but was smooth and still looked polished (some looked really chewed up when the bearing failed)

I cleaned and lubricated the new bearings, slipped them into place on the crank, and reinstalled the bearing cap.

Of note, was that before I removed the old bearings I could move the crank back and forth in the block by hand a small but noticeable amount. Now, I can't.

The bolts are stretch bolts, which means they stretch when torqued correctly. Normally you would consider them one-time use, and replace them, but since I would be waiting over a month for a pair of new bolts from Japan, I looked for an alternative.

According to the workshop manual, there is a spec that allows the bolts to be reused.

You measure the thickness of the bolt at two specific places along its length; A, where the bolt would thin when stretched, and B, where the bolt should be original thickness. Subtract C from D, and that leaves you with a value that needs to be less than the 0.12mm limit.

My calipers wont be amazingly accurate, they're ancient and weren't that expensive in the first place, but the main thing is that regardless of what the reading is, the value still needs to be consistent and less than 0.12mm.

Because I didn't want to be left with no bolts that are in reusable tolerance once I pull the bearing cap off, if mine were over tolerance, Tom was kind enough to supply me with his old bearing bolts, since he used all new ones in his rebuild.

I went through every bolt and measured them

All of them were within tolerance, some more so than others, so I picked the three best ones and knew I could at least rely on them if mine were no good.

I checked the two bolts from my engine, and one was 0.10mm, which is closer to the limit than I liked, so I swapped that for one of Tom's bolts and reused the other.

Using my torque wrench and angle gauge I started torquing the bolts up. The spec is 30nm to seat the cap/bearing, undo it to zero, and then 20nm, before turning to 45 degrees and then a further 50 degrees.

Both bolts torqued up fine, and the first one went to the two angles fine. Unfortunately when doing the first 45 degree angle on the second bolt the little lever that holds the angle gauge in place slipped, so I lost the accuracy of how far I had gone. I ended up removing this bolt and replacing it with another of Tom's bolts, which went fine this time.

The sump was pretty clean after draining the left over oil out of it, so I scraped all the old sealant off and cleaned the inside with brake clean

I then cleaned the sealing surface on the engine block, which is super fun upside down under the car.

Permatex Ultimate Grey seemed to be a good replacement for the Threebond called for in the manual, so I slathered some of that on the sump and fitted it to the engine

The bolts need to be fitted in a crisscross pattern from inside out, and were the perfect chance to use my little 1/4" torque wrench as their torque is quite low.

The sealant needs overnight to cure, so I finished by installing the exhaust front pipe

I wanted to make it as obvious as possible that the engine had no oil in it overnight

Today after work, the sealant was cured, so I filled the engine with oil and fired it up. After a quick check that nothing was leaking, everything looked and sounded fine.

It appears I dodged a bullet this time. I took the car for a drive, and it was noticeably quieter. I didn't think it was particularly loud beforehand, but there is less "mechanical" noise from the engine now.

The two main noises that seem to be gone are the knocking/clunking when I back up my driveway from a stop when cold. I attributed this to the gearbox, as I had to slip the clutch a bit and it wasn't too happy doing it. Now that noise appears to be gone.

The other noise was at high RPM, off boost, particularly when decelerating, the car would have a kind of buzzy tapping noise. It wasn't a bad noise, but it was there. This also seems to be gone.

Over all the whole engine just seems quieter. I guess the bearing failure was more obvious than I thought.

It's a good timely reminder that anyone with a Type 1 Alto (Works, RS, NA or Lapin), Wagon R, Hustler, or Jimny with the R06A engine is on borrowed time with their bearings unless they have been changed.

Some of them go fine for many thousands of KM, and some don't last to 50,000km. My car has had a very hard life, and at 100,000km the bearings were stuffed and probably had one more trackday in them before it fell to bits.

I'm very happy to know they have been done now, and extremely relieved to have caught that before it wore further and grenaded the engine.