-

Posts

787 -

Joined

-

Last visited

Everything posted by Benno

-

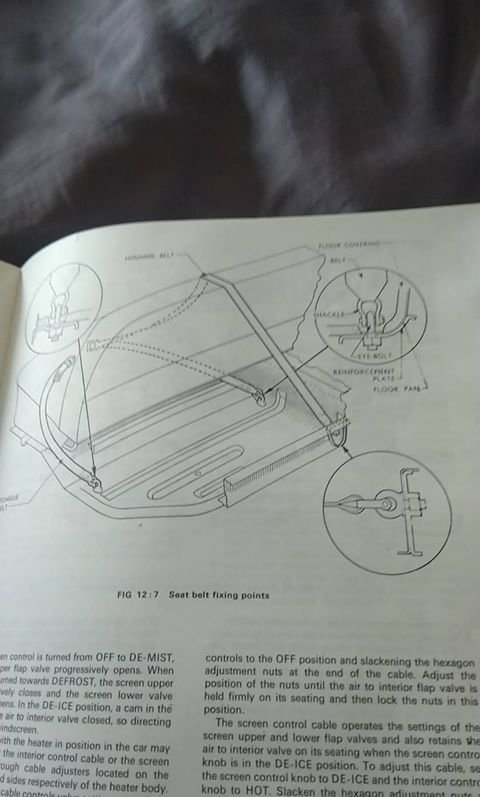

The motor that came with it had been pulled apart, most key bits were there but was missing a piston. The brother of the guy who sold it had a mk2 motor that was running when removed from a car 15 years ago. I picked that up at the weekend. Turns over, seems to have compression. Even if it's a dud it should have all the bits I need. A previous owner has poorly installed bucket seats and aftermarket seatbelts. The seatbelts have been bolted through the B pillar. I am sure this will be a problem with the revin. How are the seatbelts supposed to work? Do they anchor from the B pillar from factory? My workshop manual has the following, but most of the pictures I have found online seem to have a mounting point on the B pillar.

-

Found myself a new project. Car was last on the road in 1993, then the registration went dead but the rego is still in the system. Previous owner bought the car around '98 with plans of putting a 302 into it. A few years later he took the car to a panelbeater to get some rust fixed and bodywork done. The bill came back a lot more then expected so the car got mothballed to a hay shed. A mk4 zodiac came up a few years later that had already had a certified V8 conversion so he snapped that up and the mk3 stayed in the shed. The car only had minor rust (guards, doors, boot etc) to begin with, there was no damage to the chassis or sills. A bit of minor rust has come back since then, but a sweet barn find. The car was in Methven and had a heap of spares with it. It was pretty heavy towing back. It came with the engine pulled apart and a heap of heads, manifolds and bits. The guy that sold it to me knows someone with a mk2 motor that ran when pulled out, so I will snap that up. Long term plans for it once revinned will be some slam, wide steels and eventually an engine swap to a V8 or a barra. Am I best to get a repair certifier to come and look at it so I can get the rust signed off before I strip it back and paint? I'm thinking that might be easier while everything is pulled apart rather than taking through revin in primer, then pulling everything back apart to paint. Any ideas on how hard this would be and cost? Discuss here:

- 34 replies

-

- 30

-

-

Been pretty useless updating this. Scrapped the front lip, decided it didn't really suit the car. Since my last update, I've done a few things. I've fitted a set of DHLA 40 sidedrafts and a new rocker cover. The sound of the side drafts is amazing and throttle response is much better. Got a new rocker cover. Purchased from jrcast.com, took a couple of months to arrive but worth the wait. Stoked with the quality and finish. I 3D printed a FORD badge to attach to my oval style front grille. Really happy with the result, can only tell it's not real when looking clsoely at it. Got a new project coming soon, will put a thread up when I get the car.

- 16 replies

-

- 15

-

-

-

What software did you use? I used to use eagle before it was sold to autodesk. Haven't tried it lately, dunno what the free license is like now

-

Diode probably not really necessary, there to protect against any back EMF from the automotive circuits. Battery should basically act as a massive sink and absorb any spikes from large motors such as the starter but I already have a few 1N4007 diodes lying around which should do the trick. I'm generally not stressing about protection etc, if the rev limiter fucks out then I won't be any worse off then I am currently. I'm not planning on revving to hit limiter every time I drive it or anything.

-

I was thinking I'd just use a LM7805 with a diode and a couple of capacitors, but something like that would probably be a better solution. Although so far my spend has been about $10 bucks for the arduino nano, some resistors, zener diode, relay module and an IP56 enclosure to suit. A $5 regulator to protect my $2.50 arduino nano and $1 relay seems a but overkill haha. Once I get it working properly I'll chuck up a schematic, a parts list and my code.

-

Managed to get my first prototype working. https://youtu.be/Z-gVERQfiXk I've got an Arduino set up which is reading the RPM and switching the relay when the RPM exceeds the limit. I haven't looked at the 2-strp functionality just yet. Kinda hard to hear over the fan, but it limits at about 5000 in the video. I will get an Arduino nano and sort out a voltage regulator circuit and should be good to go hopefully.

-

I was also a bit concerned about the life of the relay, but then realised I (probably) won't actually be revving it to hit the limiter that often. If I was, the relay probably wouldn't be the first point of failure haha. Under normal use the relay will just be in the normally closed position not actually switching anything. Certainly something to think about in the future though.

-

Did some work on this, pretty happy with progress so far. I've smashed together a basic circuit with some diodes and resistors and am able to fairly accurately and reliably read the engine RPM (+/- 100 rpm) using an Arduino. The circuit is connected to the points output/coil negative terminal. I've got an arduino nano ordered off Aliexpress which should do the trick nicely. I've ordered a couple of these https://www.aliexpress.com/item/5V-Low-Level-Trigger-One-1-Channel-Relay-Module-DC-AC-220V-Interface-Relay-Board-Shield/32801667044.html and am planning on putting the relay between the points output and the coil. The relay common will connect to the coil -ve. The normally closed contact will connect to the points, the other contact to GND. So with the arduino I'll be able to pull the coil -ve to GND, essentially cutting spark. When the arduino is not energised everything is wired as normal, so if there are any issues I can just pull the power to it. I will cut spark for a time somehow proportional to the RPM. Will have to do some testing to find out exactly how long this needs to be, unless anyone has any suggestions? Any idea what normal rev limiters use?

-

I'm not convinced that is a terrible idea, if I'm driving round nanaing it I won't be reving it much higher then 4K anyway.

-

Yeah? I was more worried about the gearbox tbh, I've seen escort diffs behind V8s with no worries but have seen a gearbox shatter with the massive power of a 1300 haha

-

Cheap though? I'm not keen on paying almost $100 for a reasonable unit, I am aiming more for the $10 mark.

-

Did a little more research, some sort of adaptation of something like this could be do-able http://www.ti.com/lit/an/snaa088/snaa088.pdf

-

I'm keen on rigging up some sort of rev limiter for the escort and reckon it would be pretty cool to get some launch control/2-step. What would be ideal would be a normal rev limiter set to say 7000 rpm with a micro switch under the clutch pedal which reduces the rev limit to say 4000 rpm when the clutch is depressed for some hilarious launches/annoying the neighbours. The escort has standard dizzy and coil setup, nothing fancy. I am keen to rig up some sort of device that triggers a relay which pulls the coil negative to ground when the revs exceed the set limit to cut spark. Has anyone done anything like this before? I am reasonable at electronics but not feeling super motivated to design and test a frequency counter type circuit from scratch. My first google search didn't come up with much, thought I'd ask here before I pushed on too much further. I see you can get something like this from AliExpress but not convinced that would be any more reliable then something I rigged up myself. I have also contemplated getting a cheap adjustable shift light, gutting it and hooking it up to the relay contact but maybe not super cheap by the time I bought two.

-

I like the idea of different locations, not too bothered though

-

Not relevant to the topic, but please don't do that stupid F shit. This isn't facebook, commenting F does not notify you when there are replies. Do this if you really want notifications for this topic, don't spam up the thread.

- 8989 replies

-

- 13

-

-

Ideal, cheers.

-

I want to check my tappet clearances, but am not sure exactly what I should be setting them too. I have a Ford 1600 crossflow motor with an unknown cam in there. The car has a fairly lumpy idle, but I don't have a clue what the cam is. Not overly keen on taking too much apart to figure out what the cam is if I can avoid it. The haynes manual says to set the clearances to intake: 0.25 mm, exhaust: 0.55 mm. Kent Cams specifies 0.36 mm Inlet/ 0.46mm Exhaust for a BCF2 cam. Suggestions what I should be setting them to?? What is worse, too tight or too loose?

-

It's currently got a 2 piece driveshaft with UJs. I will look into getting a single piece shaft for it, seems like the best alternative.

-

Loose flywheel, the bolts had all loosened off until they were pretty much finger tight. The bolt holes have a tiny bit of damage to them, but should hopefully be sweet when bolted back up properly. Didn't look like there was any loctite used last time. Will get it skimmed, new clutch, new bolts and get it all back together with some loctite on this time. Doing the diff swap while I've got the driveshaft off.

-

I'm currently in the process of swapping my diff head (4.1 ratio) with a new one (3.5 ratio) in my escort. When I had a read of the Haynes manual, they talk about the Escort 1600 having a CV joint in the 2 piece driveshaft and the 1300 having the UJs. Is there any point in trying to track down an escort 1600 driveshaft? My current one is in decent condition, no issues or vibrations but the centre bearing probably needs some attention.

-

I'm also keen to find out. I phoned Canterbury Brake & Clutch and was quoted $280-$500 depending on what work is required, I have been recommended Undercar but haven't given them a ring yet.