-

Posts

10928 -

Joined

-

Last visited

-

Days Won

4

Everything posted by SOHC

-

Random slightly cool stuff you built but not worth its own thread, thread

SOHC replied to h4nd's topic in Other Projects

- 1289 replies

-

- 13

-

-

Random slightly cool stuff you built but not worth its own thread, thread

SOHC replied to h4nd's topic in Other Projects

- 1289 replies

-

- 10

-

-

Random slightly cool stuff you built but not worth its own thread, thread

SOHC replied to h4nd's topic in Other Projects

-

Random slightly cool stuff you built but not worth its own thread, thread

SOHC replied to h4nd's topic in Other Projects

- 1289 replies

-

- 12

-

-

Random slightly cool stuff you built but not worth its own thread, thread

SOHC replied to h4nd's topic in Other Projects

- 1289 replies

-

- 13

-

-

Random slightly cool stuff you built but not worth its own thread, thread

SOHC replied to h4nd's topic in Other Projects

- 1289 replies

-

- 16

-

-

Random slightly cool stuff you built but not worth its own thread, thread

SOHC replied to h4nd's topic in Other Projects

- 1289 replies

-

- 21

-

-

-

Yes, I want to see that 19 HP V twin in action, I was contemplating getting a B&S Vanguard v twin but they are worth heeps, My driveway is good for drag racing, I got my Suzuki upto 100 once.

-

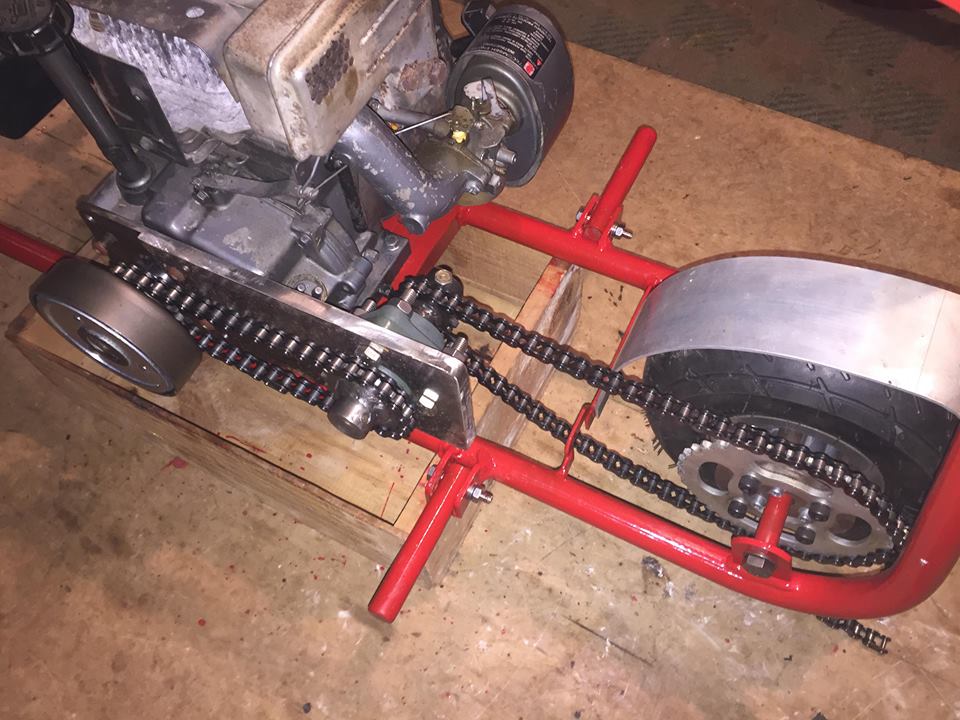

Would say the gearing is bang on, brake are inadequate I need to key the sprockets to the shaft, its been pretty hard on the holes, I will get a new bit of bright bar rather than black so its a tighter fit, Went flying across the nabours grass and carved a big muddy patch along it for about 70 meters then got stuck in front of her as she came around the corner. Off to look at a welding job now, going to take this.

-

Well fuck that thing goes hard, you wouldn't want to go any faster on it, it bakes up the rear tire and throws you back on the seat, its over 300cc

-

I got a clutch lever from an old 20s bike to use for my front brake lever, it need serous work to make it usable but its a good size, it was bent 90 degrees and its made from brass. also I got a throttle, that also needed fettleing to make fit, I wanted black hand grips but ended up with some strange ones witch look like coke cola, got a brake cable and a throttle cable, used a inner wire clamp off a Kohler engine to mount the cable to the throttle lever on the engine, need to make a return spring, All thats needs to be done now is the seat screwed on and the controls bolted on and it should go.

-

You have to fit a Coby to this, its the law in NZ

-

Is that that place on the side of the main highway heading west?

-

And west auckland

-

For about $110 anf fill out a MR2B form from this could be registered and WOF exempt, you also dont need to get it inspected

-

Got the sprockets on, managed to brake 2 taps, I shouldn't work late in the evening as I cut my finger the other night.

-

I have a power steering pump I was going to hook up and make a 3 point hitch

-

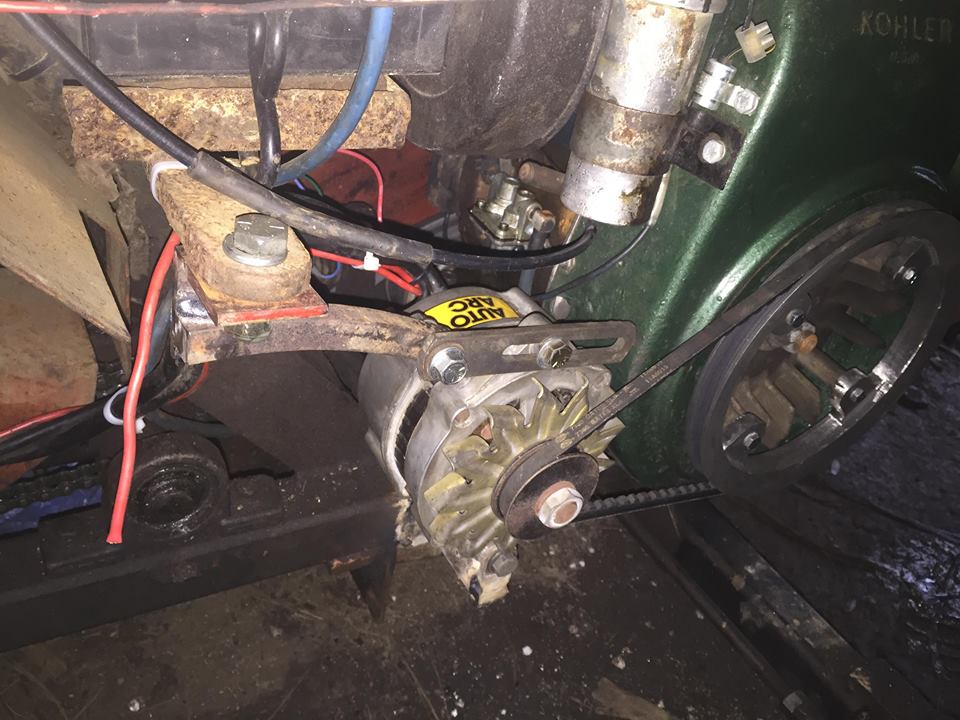

It works, its putting out 240 volts and the arc welder is also working, man dose it load the engine up, it needs to be at 3/4 throttle or it just bogs down when I start welding, the flywheel pulley is heaver than I wanted but I couldn't find the proper factory pulley, I will make a mesh grill for the front one day, DC arc welding is a little different, you can't weld into corners as well because of arc blow but there is less spatter, the arc makes a high pitched screaming noise instead of the buzzing AC makes.

-

I now now not to try to weld free machining steel, it dos not weld very well, I used a E6013 rod and did 2 passes, the smaller sprocket I bronze welded the other side just make sure its strong, Bored the holes, Need to thread the cross drilled holes for locking them to the shaft.

-

-

-

Hello, thanks for the offer, I will keep you in mind for the next project