-

Posts

10928 -

Joined

-

Last visited

-

Days Won

4

Everything posted by SOHC

-

12 MPH your better be quick someone from Huntley is coming to look at it tonight thats if he even shows up.

-

I took that off, I want to keep it, they are easy enough to make, get a BOSH alternator I think 100 to 150 amps and bypass the regulator, the negative is the earth and the + positive witch would go to the battery is to the electrode, the armature + runs through a switch to turn it off and on like the ignition use to.

-

I have listed this on trademe, got a new head gasket coming, I will sell this minus the engine for $250, it will take any engine with a 1" shaft.

-

Thats pretty normal, those old 50s are woefully short of power.

-

what about if it has lap belts in the back would any one know any different?

-

With an Anglia estate the guy wants to fit seat belts in the back seat, would that need a cert?

-

Thinking of moving this on, I can sell with out this engine and chuck in a cople others that need work, one is a bigger 16 HP that needs the end of the crank drilled and tapped, has a good rod and piston, other engine is a 10 witch is identical to the 16 hp just with a smaller bore, and crank, this engine has a stuck exhaust valve I have a good used valve and a brand new rod. I am getting another project and need the space,

-

Looking at gaskets they all seem to be shitty like that or even worse with no fire ring, an old Kohler tec sed I should give it a light smear with red high temp silicon and put permex thread sealer on the head bolts.

-

Well things are looking up, I took the head off tonight and I couldn't see any cracks but oil was coming down the bolt hole, after inspecting the head gasket I can see the problem, if you look at the wrinkles in the fire ring the gas was escaping through there and then down that little perforated hole and through the fiber and slowly boring the hole bigger and because that cylinder head bolt hole is open on the other end it was dripping out. I need to find a less shitty new gasket,

-

I am just fucked off as i spent about $700 on that motor, everything inside is brand new. I am going to put some Permex thread sealer on that headbolt

-

I am getting oil round here, it could be coming down the head bolt hole from a bad head but it could be coming from a split bore on the right hand side between the valves and cylinder as its open in there to the other side. The head bolt holes are open to the air on the bottom 3 fins down.

-

I hope you are joking lol

-

The tractor got some hard use this afternoon and i can see oil is blowing through the fins on the PTO side, I think the block has given out fuck it. If I am lucky it would just be the head gasket but its unlikely. Actuality this whole pile of crap can go fuck it self.

-

I fitted a 4" pulley as the welder didn't need to spin that fast, it was doing about 12,000 RPM when the engine was doing 3500 RPM and the belt would slip, the welder dose about 7800 RPM now, if you go past 16,000 RPM they will fail. Got a bit of perforated steel for a grill from a fire screen, I did a welding job today and did alot of welding and after burning 2.3mm rods and checking how hot the alternator was getting it was hardly warm. Also the hour meter on the tractor started working, I took the power feed for the welders armature off the hour meter + witch it seemed to like.

-

Why when an engine spits back through the crab dose it make that relay nasty smell?

-

How do I get the rear disks off an 05 Nissan Presarge? they have the handbrake drum incorporated into them , they have no jacking holes

-

Everything is now painted, trying to work out what the brake shoes are off so I can get new ones, rear shoes are missing otherwise I would get new linings bonded on.

-

-

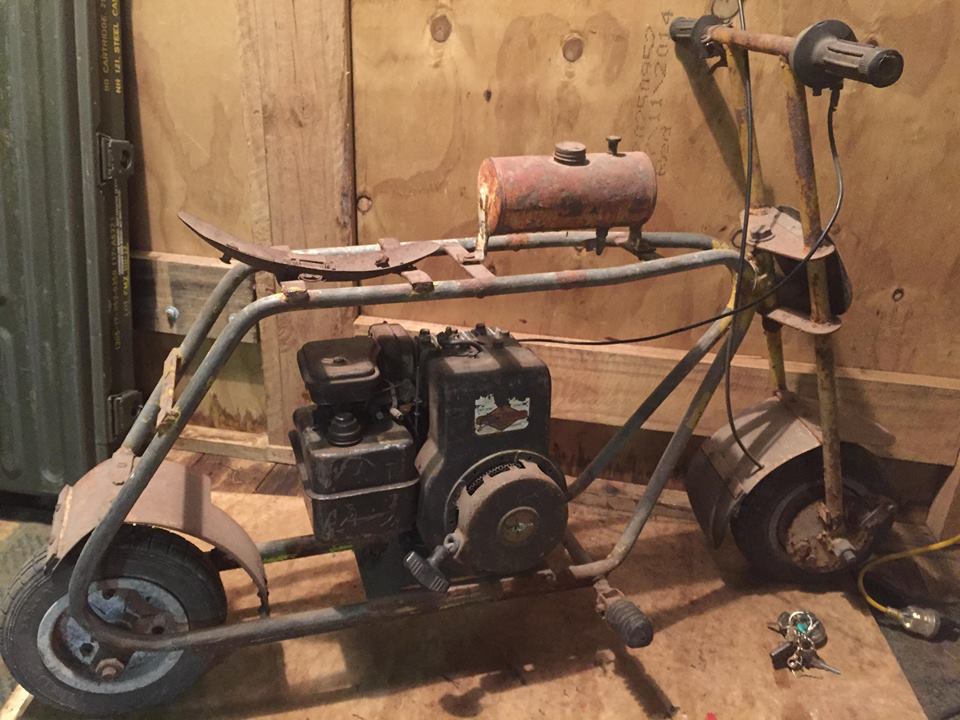

I also picked up this hunk of shit, its kind of cool, home made with 6" rims and home made front and rear drum brakes, it would of had a Villers motor I think. I will change the rear sprocket to run a #420 chain and fit my high compression B&S 5HP. and a new paint job.

-

-

BW 55 auto seems to be leaking fluid from somewhere, I did the sump gasket, but I think its coming from in the bell housing, it even empty's when the car sits around and is not driven. Should I dare to put in some seal conditioner?

-

Yes dont remove that alloy plate untill you remove the carbs in one lot

-

Must be a stuck float or dirty float needle valve? You have to be pretty brutal to get carbs off, pull one side up then the other, sometime you need a pry bar, and put some rubber grease on the boots when you refit them

-

I have found it dose not really matter where the seam is, but schedule is important, I bent the frame on the red bike using a shitty pipe bender, its made from 27mm OD no problems with nice bends, just have to make sure its a nice fit in the swage