-

Posts

10930 -

Joined

-

Last visited

-

Days Won

4

Everything posted by SOHC

-

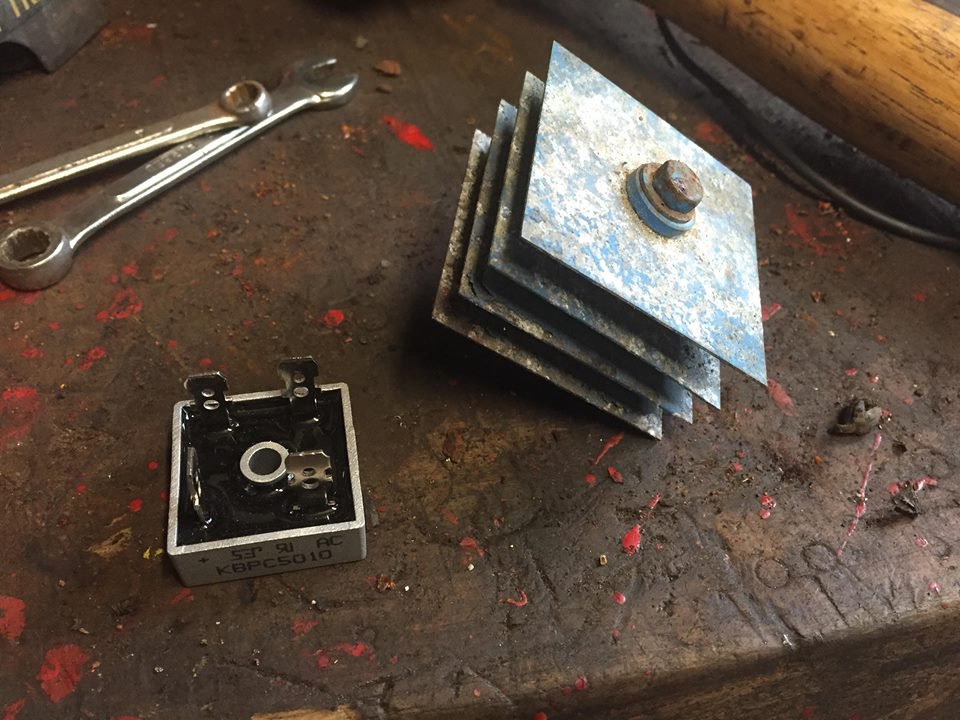

I got the new solid-state rectifier to replace the old slieaniam rectumfire, its rated to 1000 volts and 50 amps witch is 10 times what the old one will do.

-

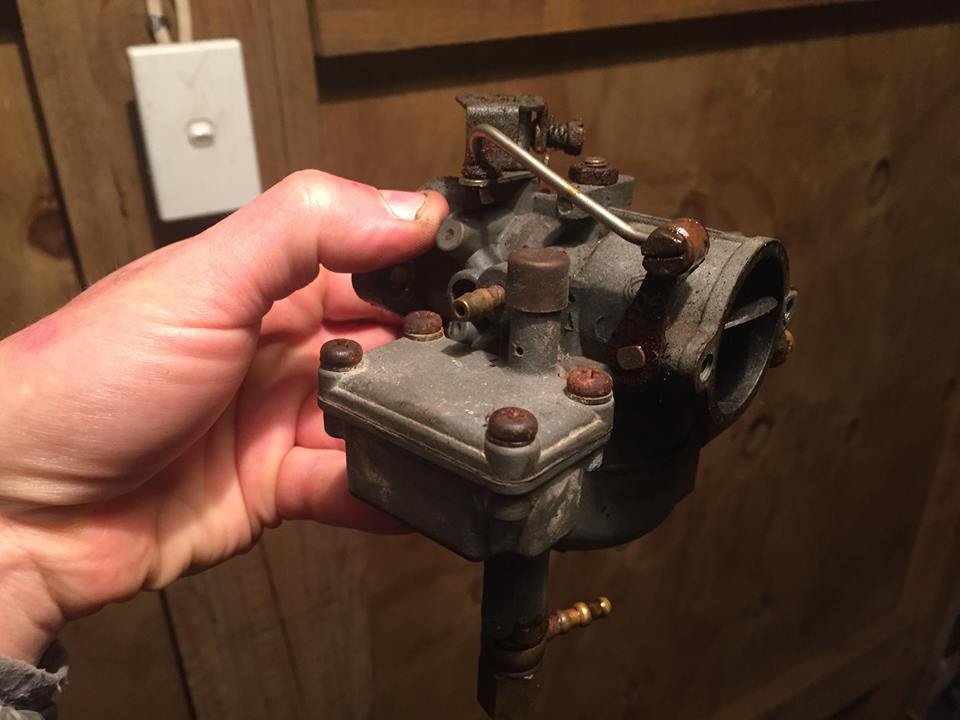

Spent a few hours taking the clutch apart and cleaning it, it was stuck like chuck and full of rust and crap, fitted new bearings to, the blue thing on the right is the hydraulic valve and reservoir, the ram is on the bottom, that was another shitty job rebuilding it. I did the carb to, took a lot of time to get that apart with out fucking something. the accelerator pump diaphragm mad gone hard and crispy long ago and had been removed but the piston was there so I ground the top off the rivet and made a new diaphragm from an old fuel pump diaphragm, it would of pissed fuel everywhere before. put the engine back in and made a new horizontal exhaust.

-

Been working out how the complicated governor rod and spring system works, turns out the bush was seized to the arm so it wasn't moving how it should. Going to start on the carb next, its like a Tillitson style, the main kerosene float chamber in under the center and the petrol starting is in the square one out the side, choke rod is seized like everything else. turns out the tractor is a lot older than I 1st thought, it has a slieaniam rectofire for the charging system witch would make it from the 60s.

-

those bearings were in the gearbox side cover, they where stuck to the shaft so hard that it made it impossible to get the cover off, I had to make yet another jacking plate, welded up the holes in the cover and boiled the chain in oil

-

Some ding a ling lost the oil filler cap off the chain case so it filled up with water till the cover developed a rust hole, that chain is a unique size to, the inks are about 25mm wide, I had to clean it up and reuse it, I could get a replacement of the same pitch but the spacing between the plates is a little wider,

-

SR2’s 1947 Vauxhall “Rigamortice” Discussion thread.

SOHC replied to sr2's topic in Project Discussion

If you want another free 186 drive down point Chevalier road to Coyle park and go down to the beach at low tide and you will see one on your right hand side -

I will try to get some photos tonight but I got the hydraulics off and both the outer and inner PTO chain case off, things seem ok, chain was totally seized, but the tension devices and sprockets are ok, the top bearing is totally fucked and thats why it wouldn't turn, outer cover needs some patches welded in, I had to cleash 3 of the bolt heads off so they need drill ing. Why do people leave shit out in the rain

-

Engine is back together, unzezed and all crap and rust cleaned out, valves and seats recut, and end floats corrected, tappets set, points gaped, ignition condenser moved to outside of engine rather than behind the flywheel, I have the head bolted down now. Need to find a strong person to help me lift it back in, I got it out myself but it is over 90 kgs The PTO shaft is actuality the end of the cam shaft, its huge like 1 1/2"

-

I challenge someone to find a manual for the Hinomoto MB1500 with TE-150 engine

-

I got a ring this afternoon, a Toyota 11B oil ring was identical

-

The engine is a TE-150, 630cc single cylinder, it has Toyosha on a sticker but dosnt seem to be in that list?

-

Ok I challenge you to find an online manual for a Hinomoto MB 1500 tractor

-

Thought I would put the cylinder on at lunch time, I broke the oil ring, this is a huge setback, I dont know what to do now, parts are totally unavailable Faaaaaaaaarrrrrrrrrrkkkkkk

-

then big end distorts and bearing is squashed = seizure. Much unhappiness

-

I cant find any info on toque for big end bolts, they are 6mm flange type bolts on a steel rod, what should I set them at??

-

Engine is ready to go back together, but I have no torque spcs for rod bolts or anything, I cant find any info not anything anywhere.

-

Would anyone in auckland have a bearing puller to get a bearing from a blind hole? I need to pull 2 bearings one has a 40mm ID and the other is about 30mm?

-

I have cleaned out the cylinder in this photo, it was full to the top with crap, and the inside of the exhaust port looks like the Titanic.

-

I wonder how well it would run on kerosene? the fuel lines run from both tanks to 2 different locations on the carb. 2 of the bearings I need to remove are in blind holes, dose anyone in Auckland have an internal bearing puller? Found another problem, the chain drive for the rotatory hoe has an open hole in the cap as the plastic is broken witch has let water into the chain case, I took the drain plug out and a drop of water came out, then I found it has a rust hole in the outer cover, I bet the chain and sprockets are fucked as its seized rock solid, if I am lucky the sprockets will be usable and I can just replace the chain and weld up the rust hole.

-

So Now I have this thing, it has hydraulics, PTO, and diff steering, it has 2 fuel tanks and a carb that will run the engine on petrol or kerosene, engine is 630cc 17 HP, It has 0nly 255 hours on the clock and is in very good condition, the only problems are it got water down the exhaust witch seized the exhaust valve and filled the cylinder with the inside of that Coby muffler, bore only has marks where the rings sat at the bottom of the stroke and I just gave it a hone with sandpaper, I had to replace the main bearings as they had water marks, other than that it just had light rust witch wiped off, crank journals are mint. exhaust valve had a slight bend so I have straightened that and valve seats and valves are away getting ground.

- 127 replies

-

- 10

-

-

-

What a fucken nightmare, a friend made a jacking plate and got an 8 ton hydraulic puller, had that done up to its max wile heating the boss round the shaft wile he whacked the boss with a drift, it made a hell of a bang when it let go. but its off, the worst one I have even encountered but its off.

-

yes, gave it lots of good wacks on the end of the puller

-

The problem with the morse tapper that its totally sealed and no oil can get down there. I took it into a shop today and they couldn't get it off but then went to an oldschool machinist who made a jacking plate, I will finish that off tonight and he has a hydo puller thing, and if that dosnt work we need to make a more elaborate device, I am really getting sick of this.

-

That hood scoop is super cool, I wanted one like that for my falcon

-

I am trying to get a flywheel off a 17 HP industrial engine, its on a key and tapper, it has x3 8mm threaded holes I tried using a harmonic balancer puller on but it bent, I have heated it and hit it with a hammer. but its really stuck, Can anyone recommend a place I could take it to or have some hydraulic puller?