-

Posts

3,392 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Posts posted by kpr

-

-

- Popular Post

- Popular Post

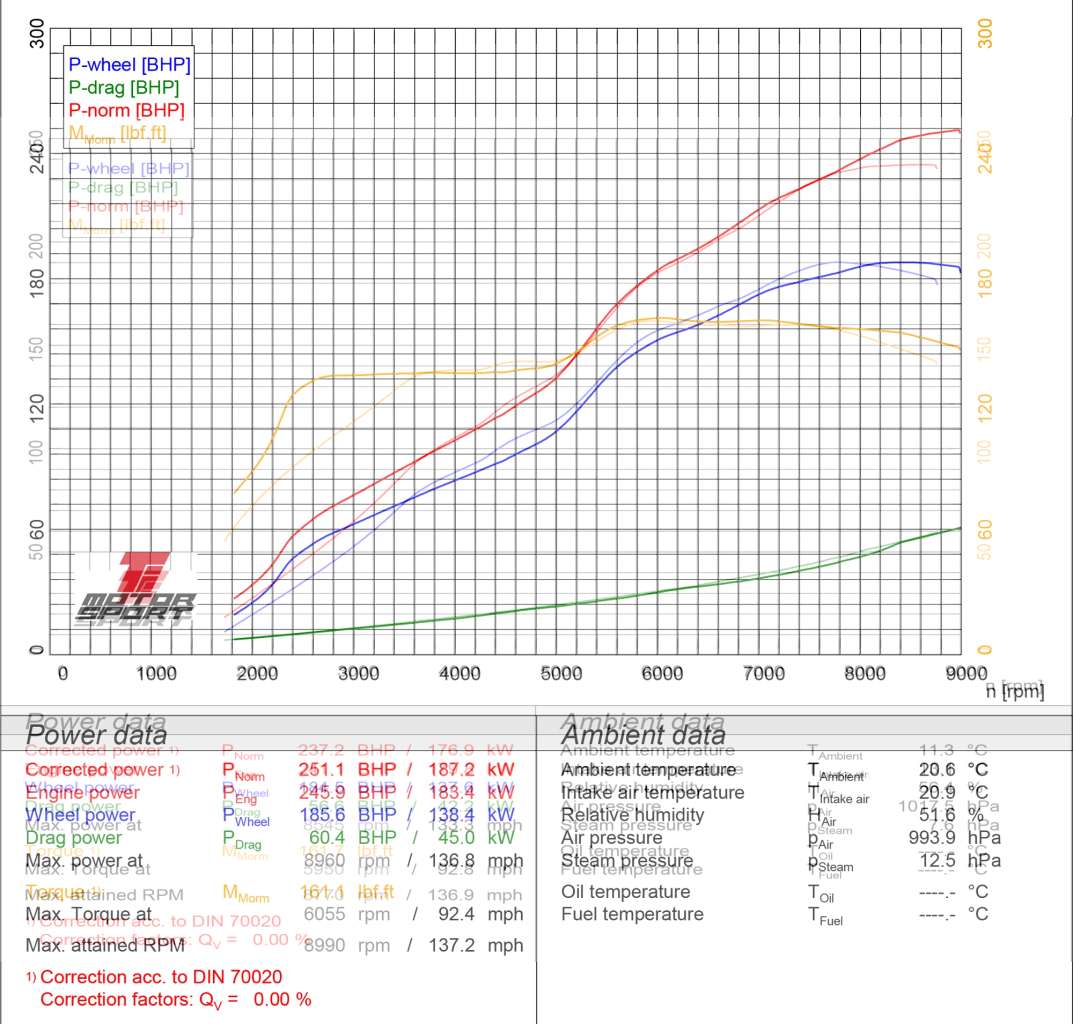

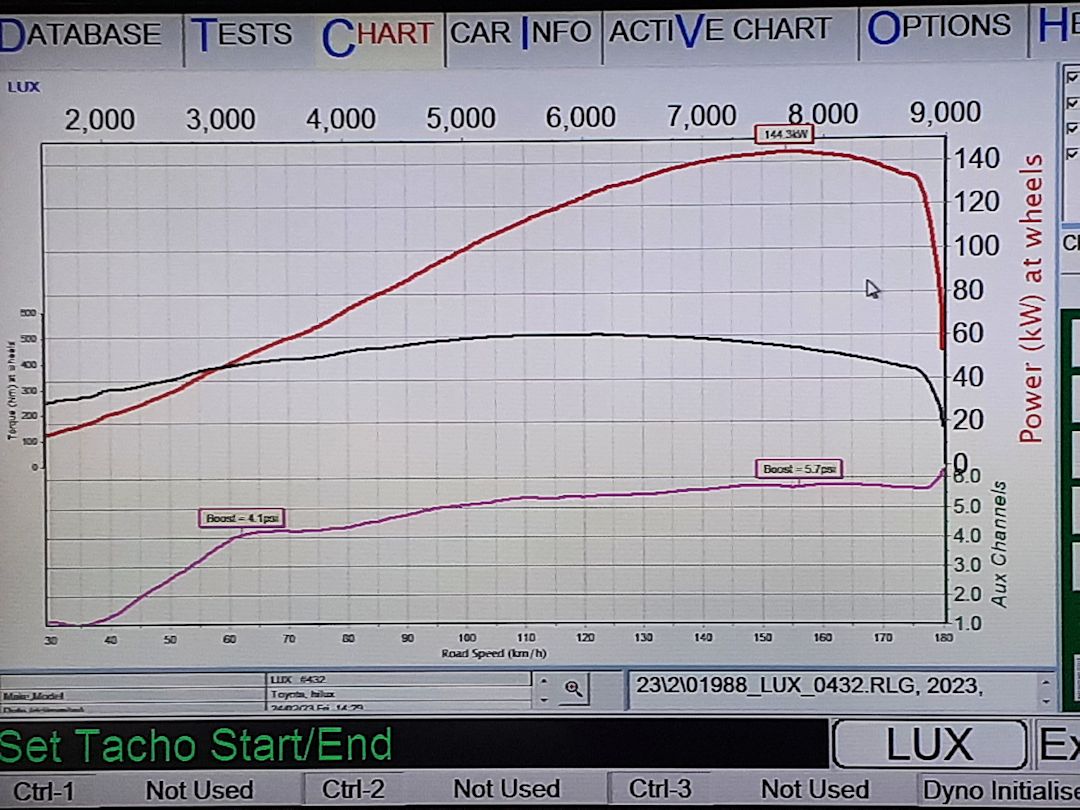

As above, I have been looking at some of the stuff they post. as been playing with a k24. They quote all these different gains in bhp, but the wheel hp on the same graph says something different. also mega driveline losses. Ive roughly overlaid the graphs blue is the wheel hp. red "engine" power. light lines stock intake, dark itb.

Looking at the wheel power. the stock intake manifold would be a quicker car. unless you could run between 8000 & 9000 rpm the whole time. even then wouldnt be anything in it.

Why, The itb's will probably flow more. but the runners are way to short to make any jam over the whole rev range. stock inlet will be running out of flow and or slightly too long to make power at 9k

ITB's only work good if you dial in the runner length and have the flow to go with it.

Seems to be super common with K series stuff. even the factory inlets. They are too short with big runners. or long with small runners.

I think those itb's you have will be a touch on the small side. possibly ok. but can get away with over sizing the intake a bit. not so much under sizing it. if make the runners small enough to gain in the bottom end (talking rpm you will never use in circuit car) will lose top end. if a bit too big, not much happens. not trying to lecture you, just wouldn't be fun to have to do it twice if you didn't have to.This is the intake i just made for k24. Big long runners. gains everywhere over RBC honda inlet. which is spose to make more peak power that the stock ep3 one they compared the itbs too.

-

8

8

-

3

3

-

Tuned a 1.5jz with all the good bits on it the other day. had those xpert injectors in it. maybe the 1350cc version, still a decap'd bosch either way. was happily making over 400kw, no drama tuning it.

you can also get the genuine 7 hole bosch injectors which are 980cc. if dont want a modified injector

-

1

1

-

-

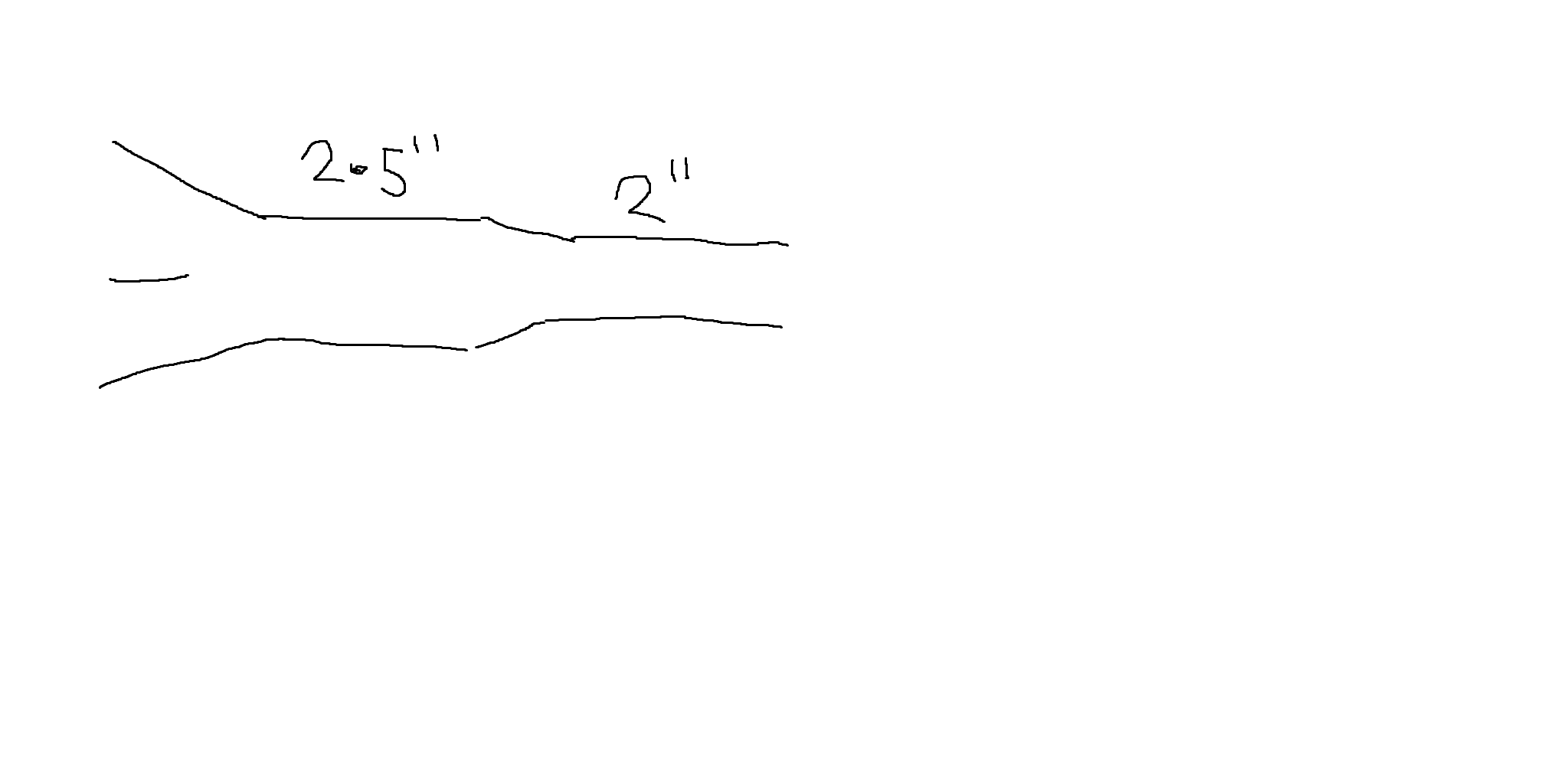

looking at your thread you have something like below. and are thinking of dropping smaller after the 2.5" collector?

This is what i was meaning. angle straight down to 2" or so where all 4 pipes collect. The big straight through is key to making it work. think of the exhaust ending after them. what you do after isn't so important. long as the pipe size is big enough not restrict airflow. merging into a single 2.5" probably fine in your case. but you cant make it too big. just makes it harder to cut the noise down. all the power is in the headers and the section before the first reso's

-

3

3

-

1

1

-

-

run the biggest glass pack straight through muffler /resos you can fit for the first mufflers. put the chambered ones at the back

sizes yeh you can drop down smaller, but need to do it at the merge. then go back out kinda like a megaphone setup. if you do it right and place said above mufflers in right place. will gain power off the bottom.

-

2

2

-

-

1 hour ago, xsspeed said:

would be interesting to see if you could, I'm guessing either the cranks are mounted higher in a 4gr or the piston compression height is significantly different between the two (or both) to account for such stroke difference. solution is only a custom set of rods away if need be

probably just the usual shorter block height on the 4gr, usually a toyota / most manufacturers move. save some material cost and make engine bit shorter. so yeah longer rods would be needed. probably giving a rod ratio well over 2. bigger bore, bigger valves bit more capacity. probably blow the budget, but would be pretty cool if the crank did swap over

-

1

1

-

-

2gr with 4gr crank.

-

4

4

-

-

- Popular Post

- Popular Post

ok ok, heres an update

-

12

12

-

4

4

-

2

2

-

1

1

-

Nar sorry, ones ive been using were bran new. ( they are about 220 on amayama)

yeah the small gear. it kinda looks like its backwards when its in the right way-

1

1

-

-

Ive pulled one of those (vvti pulley) apart a million times. pretty basic. but can put the together backwards hah. only thing i suggest doing is sitting it on the cam and making sure it freely rotates through tis whole travel. there isn't really anything that locates them central, if get them a little off can bind up at at one end of the travel. I usually put it on the cam and rotate it back and forward nipping up the bolts.

-

- Popular Post

- Popular Post

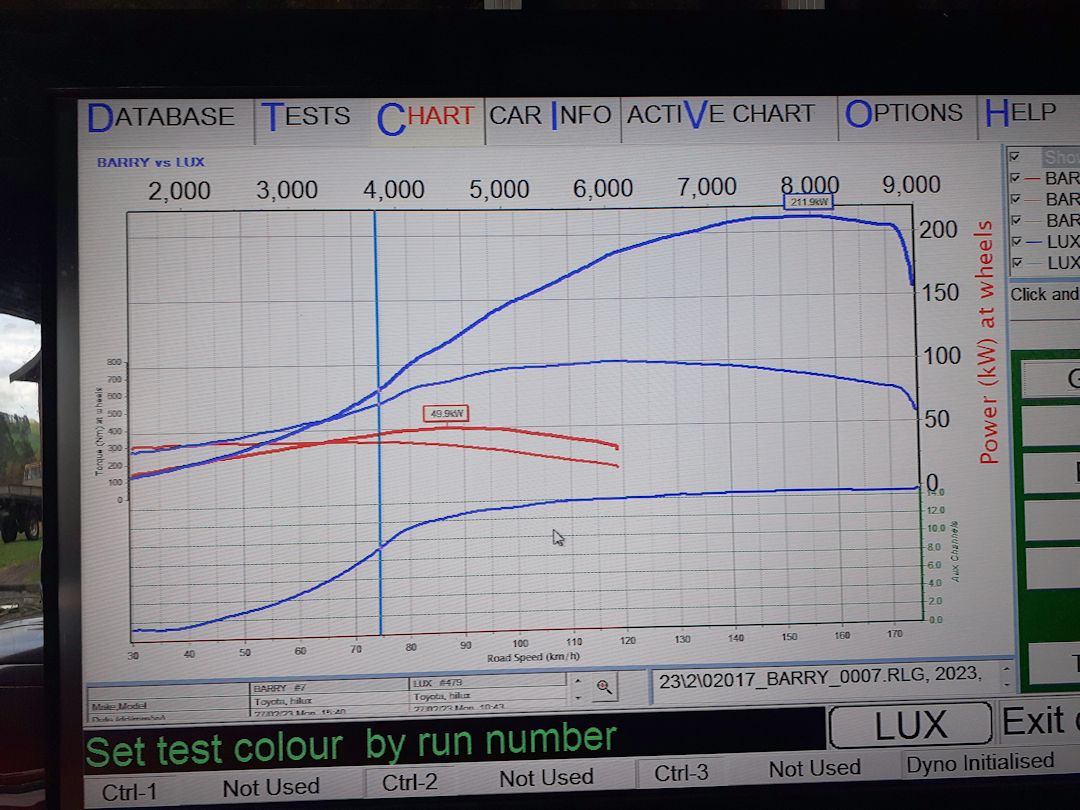

Soo, i finally tested the airbox. turns out there is less in it that i thought. not really any difference worth worrying about. few kw. what was actually worse, was the filter by itself in the engine bay. even with the bonnet open it made a little less power than both airboxes that pull cold air. oh well least the new one matches rest of the engine bay now i guess

I also acquired this thing, its yellow and rusty. no real plans for it. but its kinda cool how it is, and actually runs super nice

i threw it on the dyno today for a laugh after finishing up the tune on the white one.

3y, 2L or raw power. smashed out a massive 49.9kw which isnt too bad considering its rated at 65kw

makes a couple more kw than the 4a at 1500rpm. the scaling maybe off slightly in favor to the 3y, but yeah..

-

16

16

-

1

1

-

2

2

-

Valve to valve isn't an issue in my case either with wide angle head. piston to valve = yes. The exhaust cam timing is not so much that it can be off and work. it needs to be right and when its right, its pretty happy to work across the whole rev range. when its off it kinda sucks almost everywhere

-

2

2

-

-

- Popular Post

- Popular Post

So there was some cyclone thing and i lost power for almost a week. The plan was to re-tune it. as was never 100% happy how it was setup, after going to itb's some time ago

This engine has always had staged injection. as when built the engine for trueno, i was too cheap to buy big injectors. so used 8x 295's had hanging around which worked all good.

when going to the bmw itb's, they have injector ports in them which suit the long nose injectors. so used the same 980cc injectors as the starlet. so 295 primary 980 secondary.

staging was never bang on and did some weird stuff. but nothing noticable to drive or harmful to engine.

So attempting to re-tune it, i basically ended up in the same place the transition was all over the shop and extra fuel compensation was way more that than it should have been.

The first part of the problem due to lack of info, and injectors being so different. if the primary and 2ndry injectors are the same, doesn't matter deadtimes and the likes are a bit off.

second problem get to that later.

Soo decided just bin the primary injectors, and run the big ones

Now the my peasant g3 link only has 2 injector drivers. even with the injectors wired into 2 groups, was getting the epic fuel hammer. which sounded like a big end knock

so off to zebra to pinch all the fuel dampers. (some cars have them most dont) Test fit seemed to fix the issueNow had to block some injector holes so could bin the factory rail.

Probably should have driven to the shop and brought proper tapered plugs and tap. but holes were already right size for m12 tap, which i had. can just unscrew them and injectors will fit as normal if

need to at later date. Also block is muddy..Thats the damper thing on top of the banjo fitting. i think it was off a 1gfe! Had to move feed location on rail so cleared plenum ^^^^^^

When was doing this i just happened to blow through one of the fuel regs. yeah you shouldn't be able to do that! wasnt sealing off

This was my 2nd problem having to compensate will too much fuel under high/er boost. the pump could hold pressure at lower load but when fuel demand went up, reg would bypass to much fuel and drop pressure.

i must have picked up a dud reg out of my piles of junk, when originally made the rail for the itb'sSo, 2 weeks later. try tuning it again for the 3rd time??

tune at low boost first. everything working as it should

Turn it up. still works. amazing!

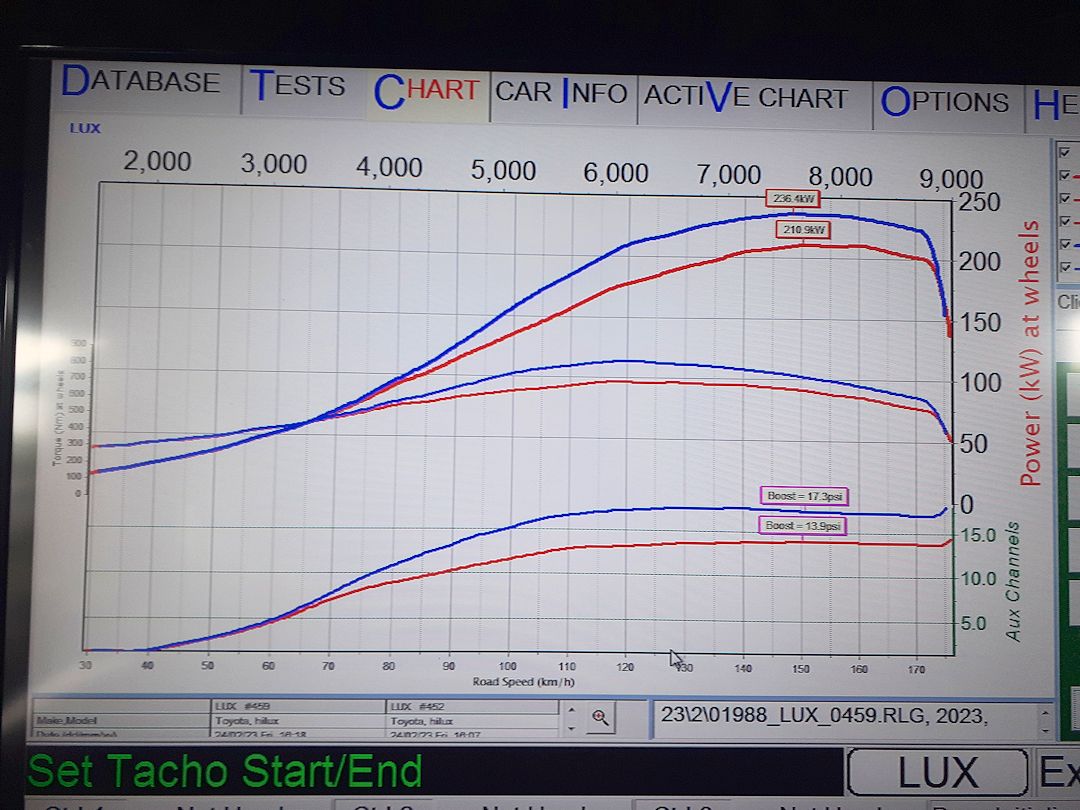

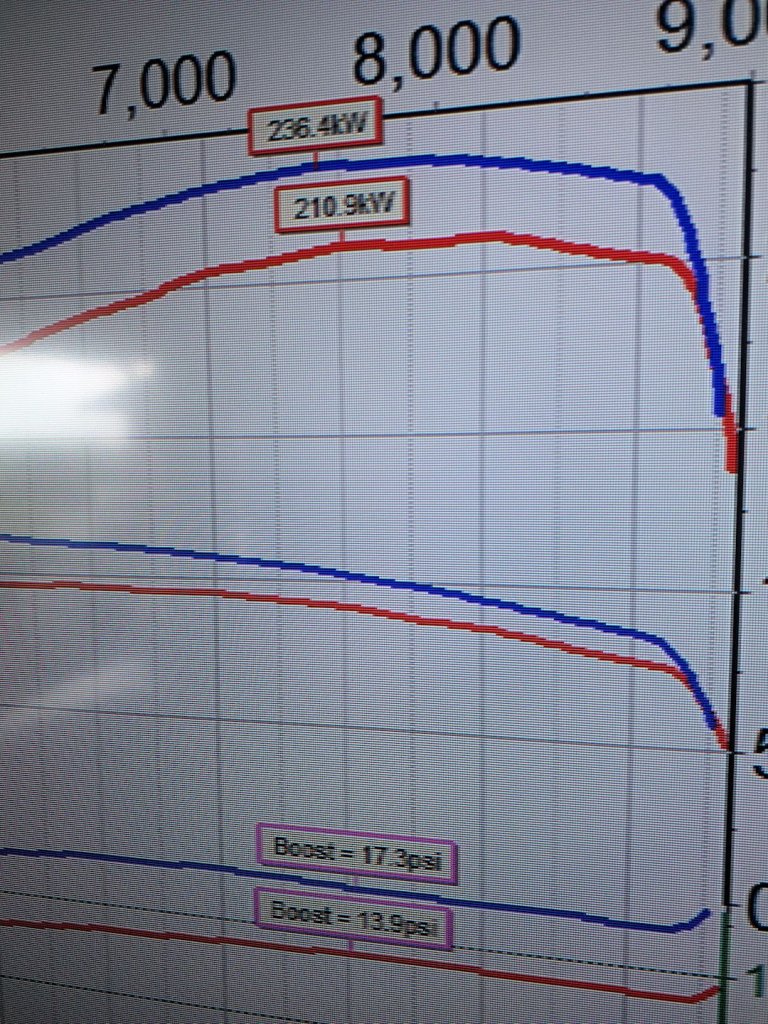

^ These runs are in 3rd gear with 31' tyres. usually see up to 10kw more when run rwd in 1:1 gear. so probs in the 240's if could run in 4th. but thats about 500kph in this thing

pretty good for stock cam engine . will drop the boost back to 1 bar and sort out the lazy boost curve, just wanted to make sure the fueling does what it should.

TL;DR had fueling issues. engine make 236kw on 17psi. still haven't tested airbox

-

21

21

-

1

1

-

If you wanted to try something in the meantime, you could take the spacers out of the plenum. Have some thick head flanges cut to space the manifold out at the head end, lengthening the intake runner. Maybe a couple at 25mm so can stack them see what works best. I'm guessing around 50mm would do the trick. Maybe could get them cut from something for some thermal insulation at the same time.

-

1

1

-

1

1

-

-

runner diameter being a bit oversized isn't actually much of an issue. unless its way oversized.

length is probably an issue though.you can see its doing something weird on the dyno sheet, which is most likely the intake runner length. looks like its wanting to work at 8500. which makes the dip at 7500. if the runners were a bit longer (most likely factory length) so it was tuned for 7800-8000rpm would make more power. its something that can be shuffled with the cam timing to a point also. your tuner probably should have already tried that though.

Ideally get those itb's on and make the intake runners way longer. nothing off the shelf will get you there either due to fitment issues, or too hard to make.

-

1

1

-

1

1

-

-

Oh and the intake plenum size. probably aren't loosing any power there, unless your loosing some effect from the intake tube. bigger plenum damping out the pressure waves, unsure how much of a thing that is. There will be a little bit in getting the intake tube the right length and size. but wouldn't expect big numbers from it.

-

1

1

-

-

Yeah numbers are degrees, but but dont reference to anything other than the pulley position . 0 being fully retarded.

from memory you can change it, so it shows referenced to crank position. but it just makes it confusing to setup/tune-

1

1

-

-

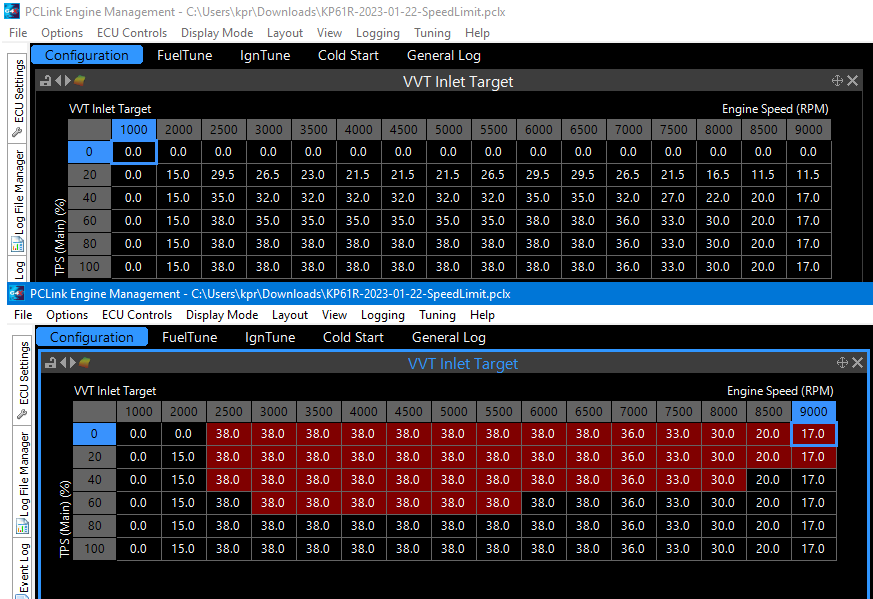

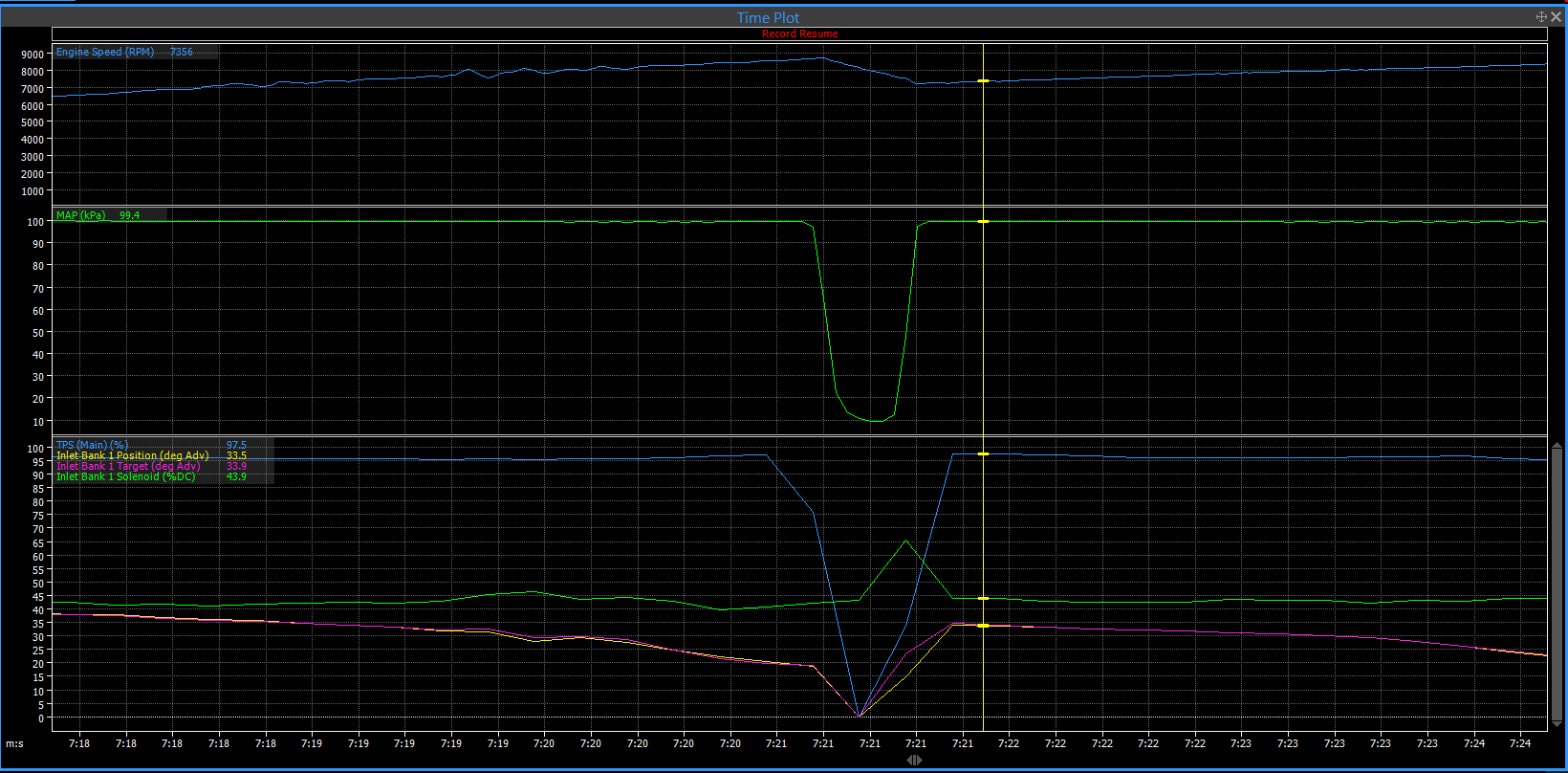

Yeah you can see the actual timing (yellow) misses the target (pink) by a little when you get back on the gas. but by the time your at full throttle its matching the target.

top one is your current "vvt" map. since race car and assuming you dont care about fuel economy, I'd run something more like the bottom. or a less aggressive ramp at least. so your always on target when get back on the gas. Not really much of an issue in your case but thought would explain it better.

Ive compared mine, which essentially mimics at 1j/2j setup vs @Roman daves 1nz setup and seems to react pretty similar. yours seems a little faster. either a honda thing or the control is a little better in g4x-

1

1

-

-

I was going to comment about probably changing the cam timing map. so it doesn't go to zero cam advance when throttle is closed. due to the mechanical time it takes the cam to re advance when get back on the throttle.

but looked in the log and looks like it keeps real well. nice one mr honda. so isn't really that much of an issue. possibly a little more crisp on the throttle if changed it.As for what cam timing it needs. will need to be done per engine. unless 100% stock to 100% stock. as changes to the intake and exhaust will change what cam timing it likes.

The shape of the cam timing map looks right. starts to retard at high rpm etcThis as part of the log @Hyperblade posted. cam stuff at the bottom

The vvti control works real well even on my old g4 link.

-

2

2

-

1

1

-

-

- Popular Post

- Popular Post

So I went to put this thing back together. but I had stolen the 3-4" silicone hose for the intake for the 20v.

Said silicone hose connected to the airbox i made from the stock 2L airbox

This thing loses 5kw vs just the filter by itself. likely due to the lack of area around the filter. plus the inlet in the side even though its 3"

Ive never made a better one because lack of space. plus would be a diddle to make something such and odd shape.

When done the intercooler i freed up a little more space and moved the ps reso to the other side. So thought i should at least attempt itstraight away made my own life hard using the same big 4" inlet filter. made a 3 - 4" cone that had to be cut into the lid of box on an angle.

yeah it probably would have been easier to make the top bolt onto the box rather than the end. but cant make things too easycutout on the bottom to clear intercooler pipe

4" inlet. needed to make inlet big as possible to cover up my sins of using a 90 silicone bend off the side. i had first made a ali bend/ cone to go in the side, but couldn't

get the box in/out of the truck.I only added a little rubber mount at the front, to hold it in place off the body.

It just hangs off the silicone joiners at the other end. Wasn't sold there would be enough flex in the silicone joiner between turbo

and airbox, if solid mounted airbox to body . since the body is rubber mounted to the chassis, it can move around a bit. First thing to

eat shit would be the turbo.next, to see if it actually works

-

27

27

-

There is a excel 4 link calculator floating around which is good. Its pretty hard to get a textbook setup. will likely end up with a compromise somewhere. but so is most factory stuff. I would suggest having a few extra holes either side of what the calculator spits out, at least one end of your links, where room is available.

From what i can tell the "instant center" is just a dumbed down way of getting you in the ballpark, that comes from all the other numbers being about right.

there is lots to it, some of it doesn't matter too much depending what your trying to achieve, other stuff does.-

2

2

-

-

They will rev cut if throttle is closed and revs go over x amount. if not running the water lines to throttle body, will idle higher when warms up. as uses the water temp to slow idle. might get away with adjusting idle screw or throttle stop. otherwise vac leak somewhere

-

- Popular Post

- Popular Post

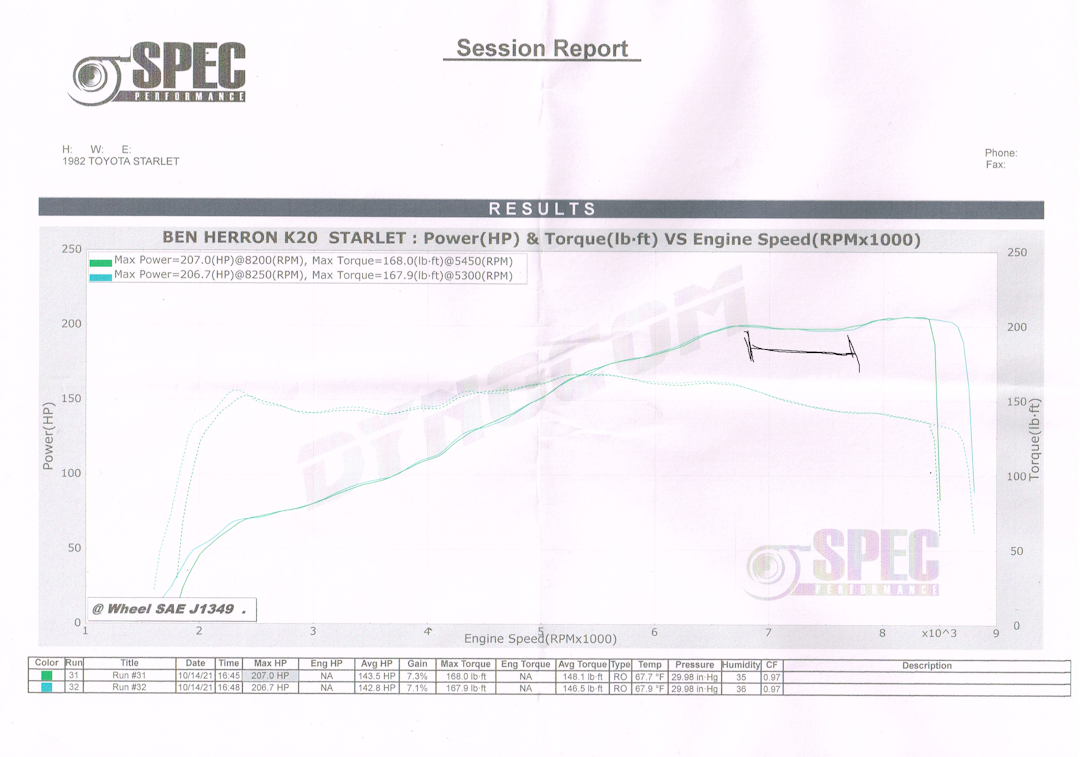

I tried the outboard injection again . probably easiest to watch the video than me trying to explain it. but the gist of it, seems like theirs a tiny bit in it cooling or mixture wise. maybe 1-2kw but it seems like to me, that it moves the tuned intake length around a bit. shorter runner acts more like a longer one. It did make 167kw though. which i think is the new record

-

18

18

-

sorry just seen this. the cam pulley sizes are the same between 16v and 20v engines. 36 tooth. is the bigger round tooth pitch. i forget the numbers now. I couldn't find much that matched to pitch and tooth count when was hunting for pulleys awhile back. most were 40 tooth. or the smaller pitch

-

1

1

-

-

I get asked punishing requests every day.

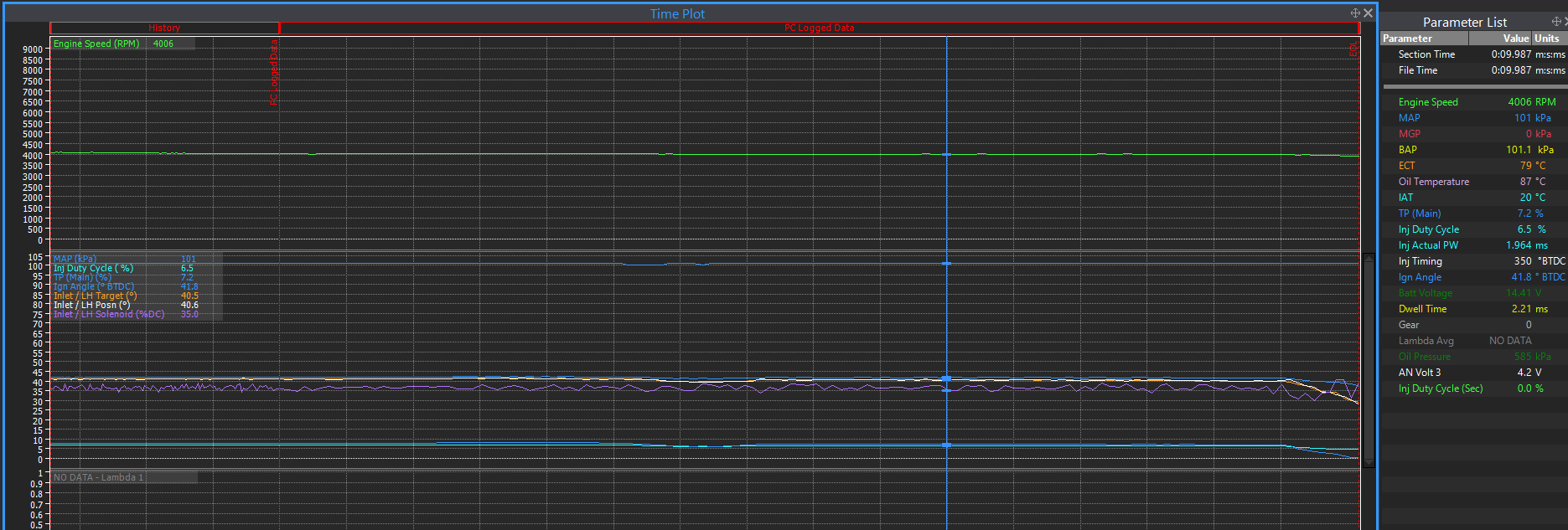

just happened to read this before going to fill up at gasser. absolute zero effort to tune any thing for economy. and its borderline tuned properly for cruise atm. but put this here for reference next time is on dyno as i'll forget the numbers.

yeah it pulls 4000rpm at 100k. so never going to be prius spec haha.

its like a cyclone out, and road wasn't completely flat so somewhere. ran it both ways. probably 8.5% throttle is 100k on dead flat. vvti 40 degrees. so have 40 to go full prius/retard.the dyno hp readout doesn't have enough resolution to do cruise stuff. but using the torque numbers and running in a lower gear to mulitply the torque, for more resolution works well.

-

1

1

-

1

1

-

Hyperblade's KP61 Racecar "KP61R" Discussion

in Project Discussion

Posted

Yup, thats the same inlet test i was referring to.

Have you looked into s65 bmw throttles? they are 52mm, spacing should be pretty close for k series. the also have an oval outlet similar shape to the port. Have a separate dbw module that can be used if wanted to go that way. but is known to crap out.

I'd probably target 8000rpm maybe a touch under for your intake runner length. about 320mm from port face should get you ballpark. you want to get the intake tuning right where the engine naturally wants to make peak power. will make more power and fatten it up that way. rather than kinda trying to force it to make more power right up top. like your current intake looks to be doing. The VCT (cam timing) is also your friend here. you can use it to hang onto the power past peak a bit longer. If do everything right it should at least match the power it has now right up top 8500- 9k and make a bunch more 7500- 8000rpm plus more through the mid range

The runner length on the manifold in video is around the 350mm mark, as was targeting bit lower rpm.