-

Posts

3265 -

Joined

-

Last visited

-

Days Won

2

Everything posted by kpr

-

send me some stock ones and some kinda way of knowing what space got to work with. will see if can knock something up for you. I'll take over the roman dave go fund me OS donations to pay for materials haha. Whats the od of the tube? Yeah that part is pretty sensitive, and seems like another indication anti revision chambers are bs. Almost looks like that pipe in pic directly after the merge has a choke section then a cone out. well a peasant version of that setup.

-

Yeah youtube money ain't nothing. unless your pulling 200k+ views per video @Roman how much stuff is in the way / how much of a straight run is there after that collector ? maybe can slice the collector off and extend them?

-

impressive so little damage to head. keen to see how the 1.3 goes

-

3d printed pistons

-

can you do some extra janky stuff to the pistons, to lighten them. take a little stress off the rods

-

2.06 is up there! assuming the 1.3 will want to make power at higher rpm, with all your top end on it. i see more flying rods in your future Also being picky, but the 4a/7a combo is 1.78. no one likes an inaccurate graph

-

Would be amazing for a big rev engine. but yeah custom rods wouldn't be very budget friendly. @Roman says the rod ratio on these engines aren't bad to start with. so a 1300 crank in the 1500 block would be some motorbike kinda rod ratio

-

+1 for jamming the 1300 back in for now.

-

If hard up it for that long, would be pretty normal. would suggest getting it checked if unsure on the tune though

-

hmm yeh pretty sure you'll be still in the hole at that length. I'd try another 50mm longer. taper along the whole runner, thats a little less aggressive than whats in those throttle bodies. bendy ones like you had before will be fine. long as long radius. maybe can use the radius of the bend to fit the injectors on top side with less angle. either way will be worth trying longer with/without the outboards. something like so,

-

I've asked you a million times. but what is your runner length to head, and guesstimate to the back of the valve? as you say maybe long enough already. or in the no mans land before getting another "peak" Maybe try similar to what you have, but put a taper across the whole trumpet. a few degrees included angle is good. seems to be a tiny bit in it.

-

Its pretty silly how far can oversize the inlet runners with only small negative effects at low/mid rpm. Which makes sense for the majority of the 80's/90's "performance" heads with massive port entries and runners. easy just to overkill it and take a small hit low down. going too small on the runner you can actually see engine hit a brick wall and flat line. with only a small benefit down low. unfortunately there doesn't seem to be any sweet spot that will get you a significant gain down low without restricting top end. If make the runner small enough to gain anything significant low down, it will loose top end. Not saying there isn't something in getting the diameter right. but far less sensitive that you would think if err on the big side. also, there are plenty of people out there that will show you big gains down low/mid from a small diameter runner. which is usually a band-aid fix for sucky exhaust side. as your increasing intake pressure to overcome a reversion issue. they will have lost top end power doing so.

-

Think I will do a little bit of a revisit on intake runner lengths, now my engine has vvti. I think the length I was using with fixed timing will be at least still very close to where it needs to be. Tuning the intake to where engine where it wants to make peak power. Then using the vvti extend the peak power both ways

-

Calculators have there place getting you ballpark. or if have no idea on starting point. can cut down on testing time, if that's the case. Or at least a good learning exercise. As a lot of people still seem to go with a blanket "shorter is better for high rpm, long is better for low rpm" Yes if make the runner shorter it will push the tuning higher in rpm range. The part they miss is, if make the runner longer and drag one of those previously unreachable peaks down to where the engine naturally wants to make peak power. you have just had a big win. as said peak you have pulled down, is stronger than if you shortened the runner, to push a peak up the rev range. Plus you get the benefit or pushing all those other peaks down the rpm range and gaining midrange power as well. you can see this in my videos pretty clearly. if the runner is too short and the peak falls off the end of the rpm range. it chops the top off the power curve. So yeah im actually using the longer runner to make more peak power which melts most peoples brains There are of course other things to overcome than just length. but yeh, gets you most of the way there.

-

This ^ Pick up that jumbled up box of lego. do some illegal moves according to internet theory, and lots of testing

-

Not much to add since @Roman has it covered, Although a graph would be nice? The few bendy runners ive used. the centerline measurement seems to line up pretty well with a straight runner. in regards to length tuning

-

Re driveshaft, easy way to think if it. is the shaft is going to be spinning the same rpm as engine in 1:1 gear. (usually 4th) Then punch the numbers into that calculator @cletus posted. Single piece becomes a bad day fast, on a high rev engine that will be generally matched with short diff ratio. if going to use it on the track etc I usually avoid running anything up on dyno in 4th gear with a single piece that's going to pull some revs

-

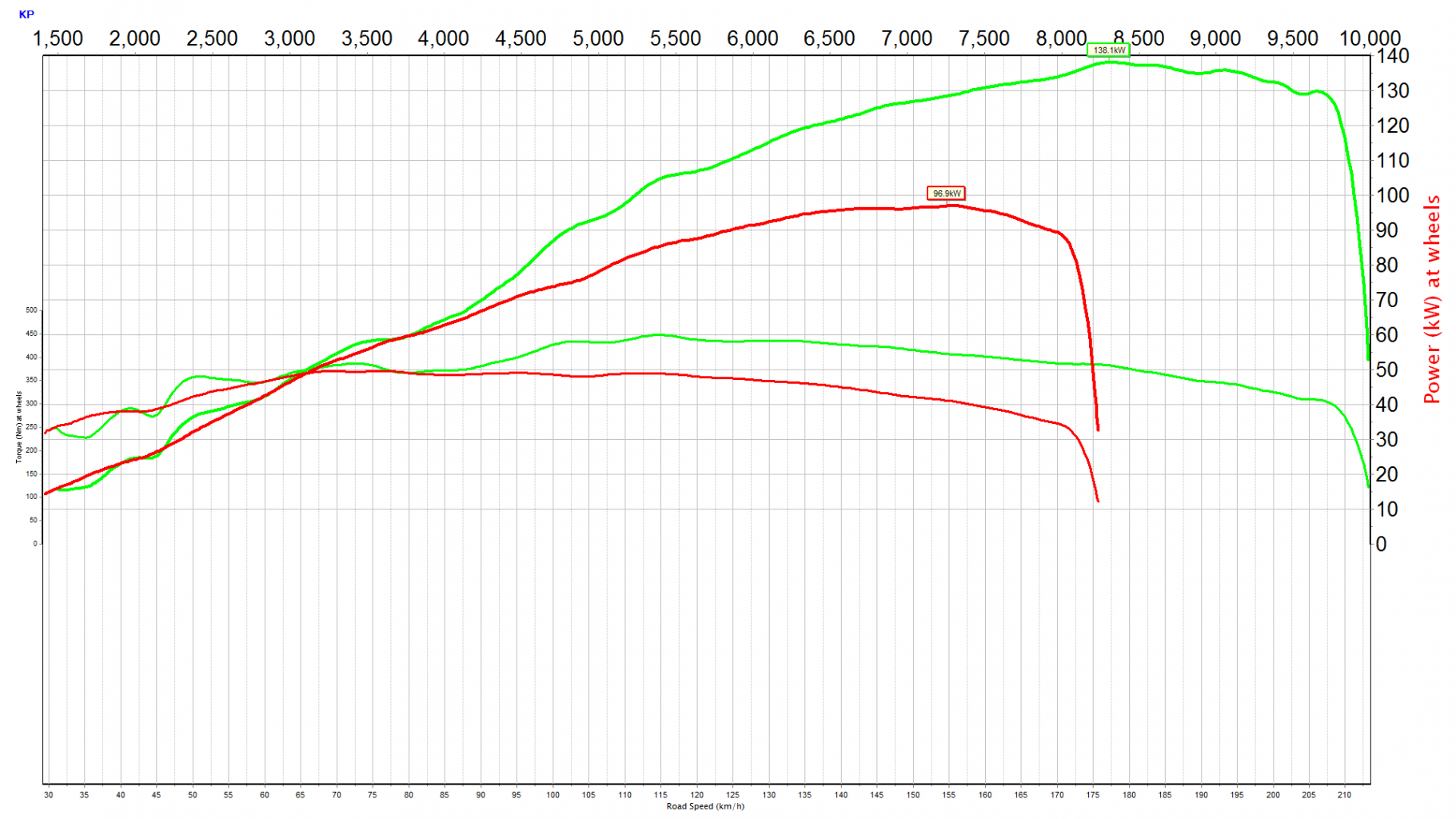

Possibly. On stock stuff you kinda have to think about what the manufacturer is doing also. since their game isn't just what makes max power everywhere. This is what it does on my turbo junk. if just want to look at graphs. 8:18 for exhaust and 5:54 intake

-

Looks faster at least

-

Yeah its doing pretty good for what it is. blue line is my "good engine" with fixed timing. Can see where im heading with this.. @mjrstar Yeah can see how it would be more benefit in some situations that others. My turbo engine seems to like the same numbers as an na engine. both with stock cams. but in saying that its only running low boost on a turbo that has plenty more in it. so pressure ratio will be pretty good. On my na setup, the exhaust cam is usually pretty happy to stay where it is, even after some fairly aggressive changes to inlet. Will be a little bit in it. but not enough to bother going dual vvti. coming from someone happy to scrape up a few kw here and there.

-

I probably (most likely) done a shit job of explaining what i meant. The exhaust valve is long shut before the compression stroke starts. so doesn't matter when the air fills the the cylinder on the intake stroke. long as the amount is the same. it will squish it the same amount on compression stroke and make the same power. so lower dynamic compression just means you lost cylinder fill / power? Guess its just the fact the intake valve is open to intake manifold after bdc that its acting like a smaller cylinder when air speed low. /1nzfxe

-

@mjrstar Is all about the intake cam. I never really got how everyone says need to run more compression to compensate for big cams. seems like something from the past, when installing bigger cams engine has to lose bottom end power. so add more compression to compensate, plus can get away with more compression since it doesn't make power till higher in the rpm range. But if do things right you can jam at least as much air in over the whole rev range. even without vvti @Dudley only 1/2 race bro, cant go full hectic all at once

-

More graphs and loud noises , shows better how big the shift in cam timing is

- 216 replies

-

- 14

-

-

-

-

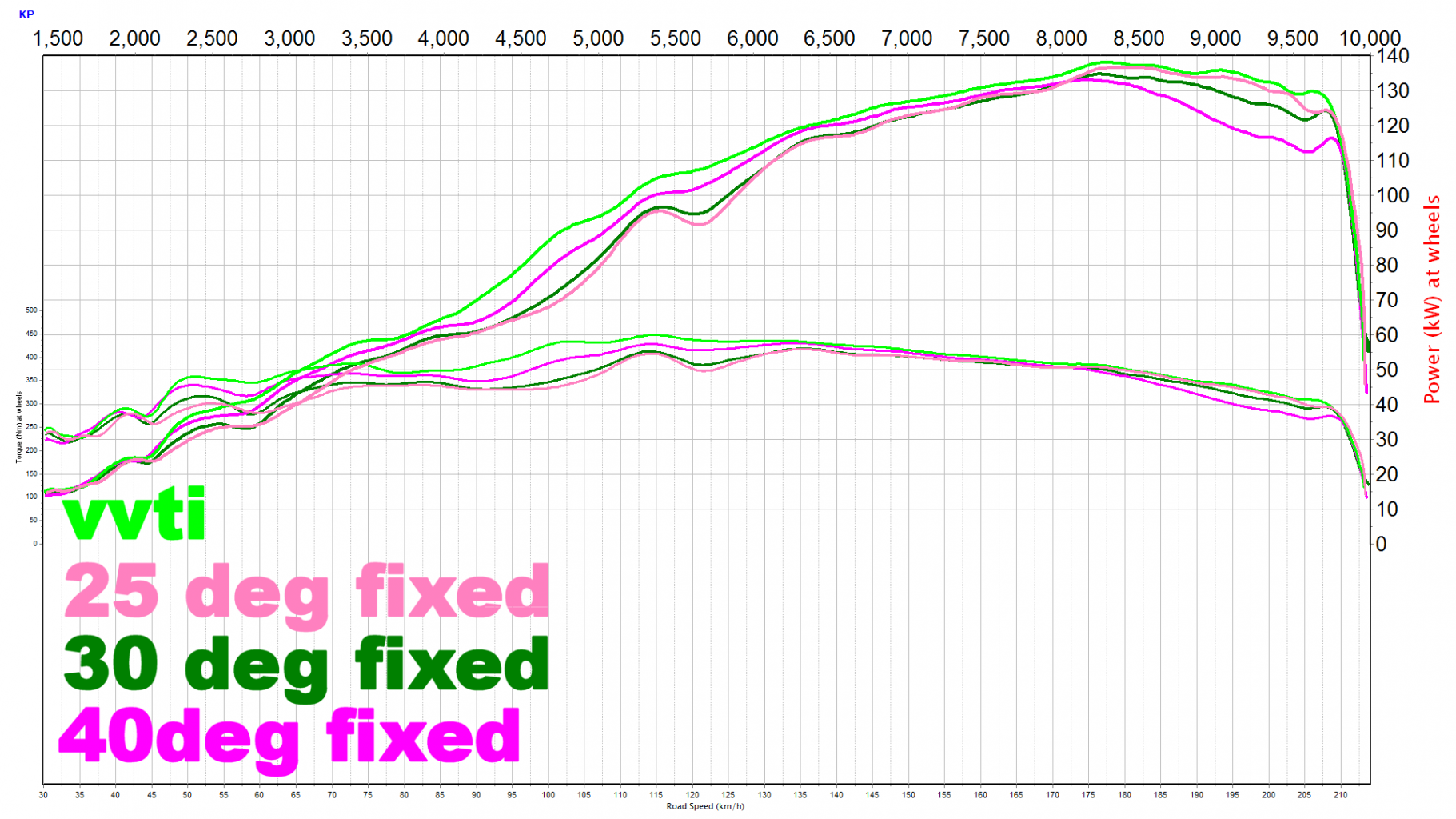

You'll loose bottom end using big cams and modifying your NA engine. Ok i'll take the hit at 1700rpm The vvti works amazing on the bigger cams, nothing like the weak gains on the stock cams. Some fixed timing compromises: Light Pink (salmon?) 25 deg- pretty much matches the peak power. but massive hit in midrange Green 30 deg - kinda blah. may as well run 25 as above ^ Pink 40 deg - probably good compromise for midrange while not loosing a whole heap of peak. good if didn't want to rev past 8500. Bright green vvti - all the power everywhere. actually using way more range that i thought i would need, about 45 degrees. I didn't spend very long at all on the vvti map. so some tweaks may get another kw here and there. and yes it made 138kw!

- 216 replies

-

- 31

-

-

-

doing a massive burnout to get the oil temps up helps!