-

Posts

3265 -

Joined

-

Last visited

-

Days Won

2

Everything posted by kpr

-

^ clutch was adjusted like that, to the point thought may have not quite been releasing. so gave it a little more, no dice It has the small 200mm friction plate. but will see if anything "light weight" is available without going too silly. Maybe will throw some fresh syncro rings and sleeves in it

-

my poor old t50 doesn't want to shift gears at 10k rpm. around 8k seems ok. just that bit more is a no go. All the gears seem about the same So yeah probably not a very common thing. But trying to figure out if its a limitation of the box, its just old junk i can fix. or if can modify it to work better. have heard of people filing the teeth down on the synco's or the likes Or same deal with J160 boxes. anyone used them at 10,000+ rpms? could be an option to swap to. Have tried the usual stuff btw, adjusting clutch etc.

-

"forged" likely the same process as toyota has been using since forever, they just started making them lighter in the late 90's. not like the 80's-90's stuff that you can run a zillion hp on factory bottom end

-

can you get in there to measure the valve lift at tdc with dial gauge or even by eye? should give you a pretty good idea if cam timing is right.

-

How much are you guys paying for a 90deg 3" from autobend? or any 90deg for that matter. I can sort roman out with some stainless, is about double the price of that sta stuff for bend. but sta stuff also sounds like it should go straight in the bin haha

-

I have no idea what happened to that engine. seems ive owned 3 20v's in my life, for shame. although only ones made it out alive

-

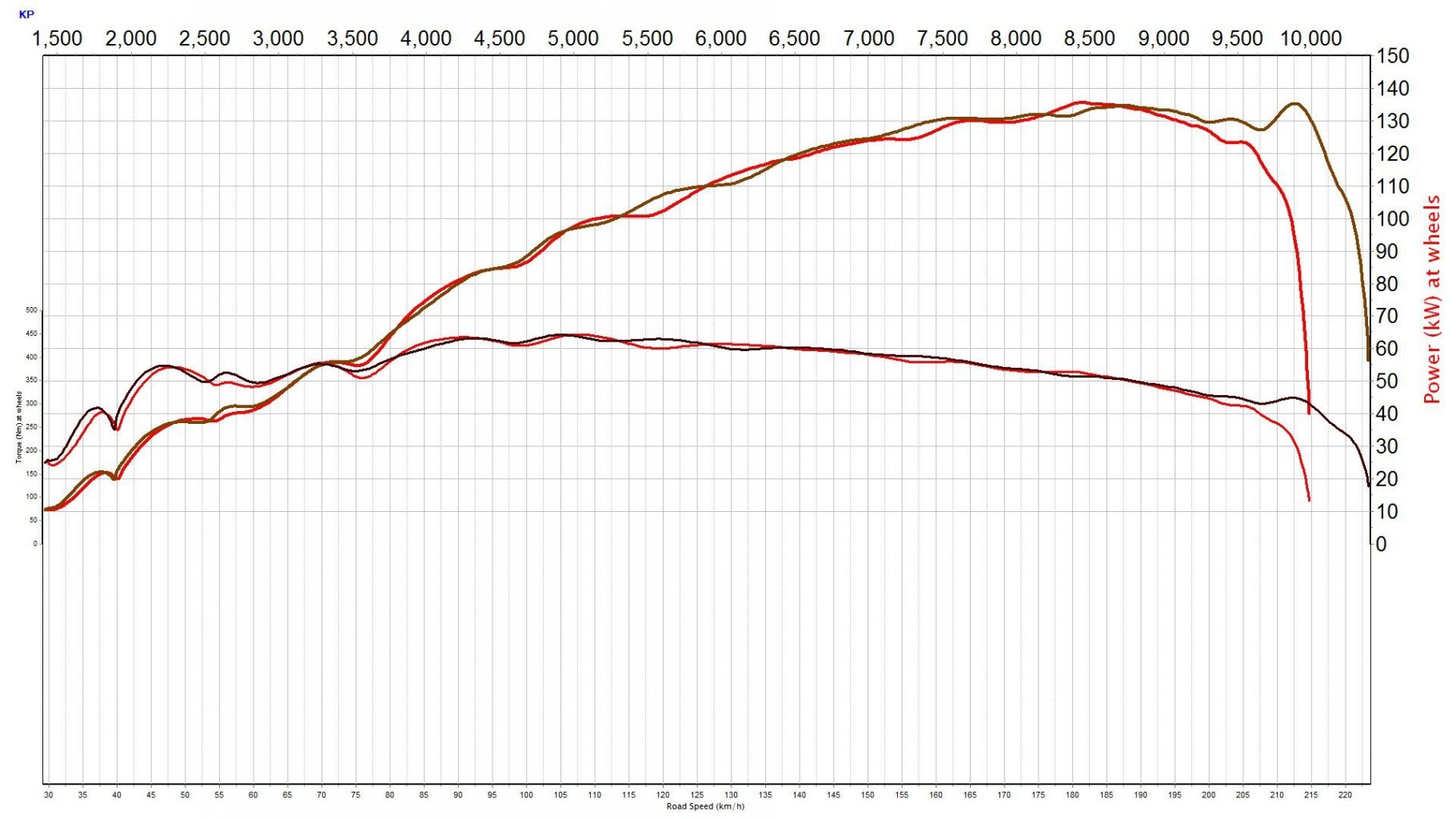

Can someone tell me if this a normal amount of smoke for a 4age? seems about right to me? 10200rpm on stock 2nd hand oil pump and 300,000k pistons/rings and crank. seems like the winning combo Yeah it really needs to come out. but want to put some run time on the vvti setup. Had a little play with some shorter intake runners. looses the peak off the top as expected, if just jam them on. same deal as with fixed timing. but after tuning the vvti, was able to pretty much match the peak of the longer runners and gain power after peak. Holding on real well right out to 10k with the little 193b cams. Looking good for the end game setup red is normal intake runner length dark brown is 40mm shorter - ignore bump at end of run dyno tends to have a frizz up there at that road speed. Both with vvti dialed in.

- 216 replies

-

- 34

-

-

-

wait till it snaps in half haha. As you said some kinda brace from bottom of engine will be good idea. Probably back to where the new pipes join on if possible

-

Done. Now a @Roman problem haha I'll quietly leave the room now. can sense the growing anger, due to the lack of graphs

- 1536 replies

-

- 47

-

-

-

-

Yeah back when you could buy a kp starlet with 4age and t50 for 1500 bucks haha

-

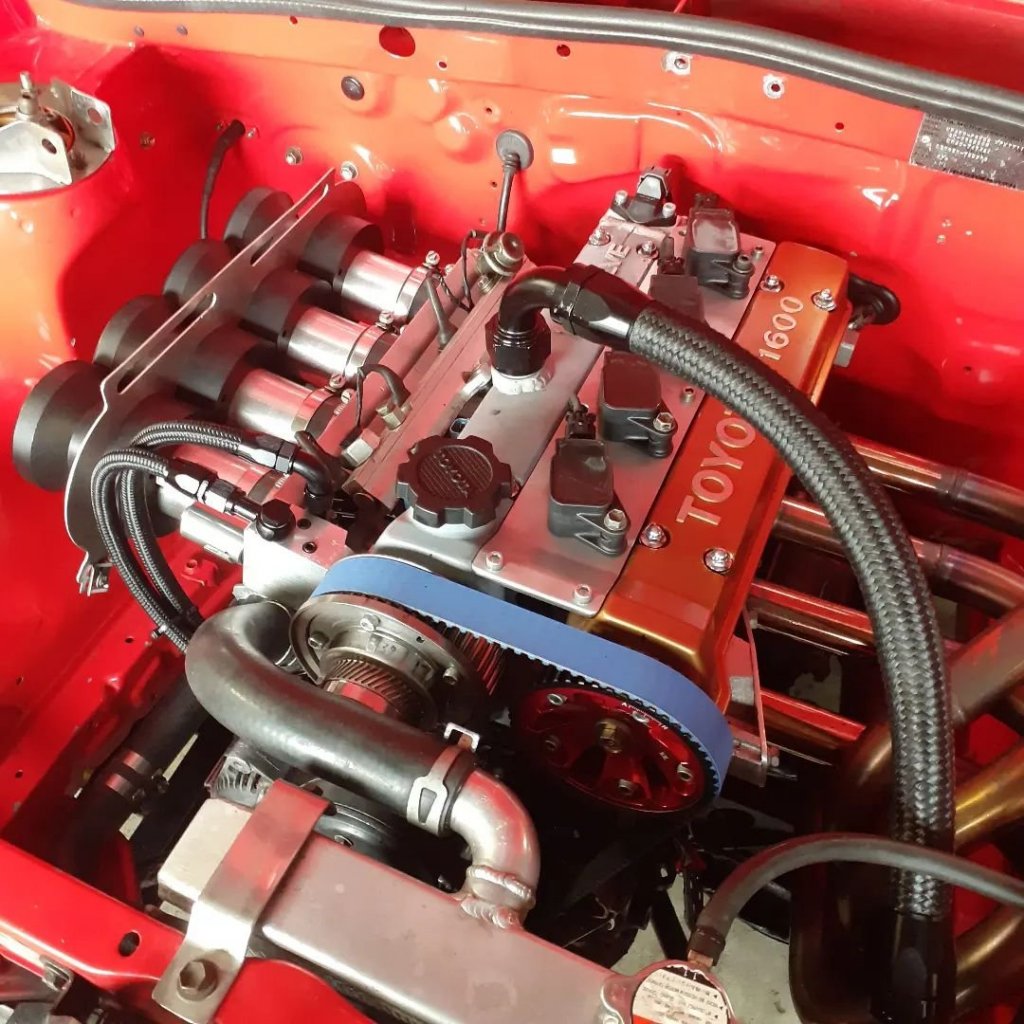

So, I'm onto version 2 of the vvti setup. main difference is the solenoid setup. the original setup I had the solenoid remote mounted. as was easier to do it that way and to confirm would all work. but ocd couldn't handle all the lines. more chances of leaks and stuff breaking. It had 4 lines. Pressure feed from engine, drain back to sump and 2 for advance/retard New setup eliminates the advance/retard lines. So just the 1 pressure line (feed from engine) and drain line to sump. yeah im still using the dipstick tube for the drain, ha. Solenoid now mounts in the block right by pulley and bolts to the other part. so all the advance retard ports and wizardry happens inside the ali blocks. Doesn't look too out of place. have done a small amount of run time with it. All looking good so far. Also moved the cam sensor. before it was hidden in the spark plug valley. but getting the clearance right was a pain, since the covers can move around side to side on the studs Now its on the top at back of cover. I had a little accident with the bran new genuine timing belt, so had to get this blue thing to get me going again.

- 216 replies

-

- 32

-

-

going by the pic of your exhaust, you should be able to still fit a reso after that abortion of pipes ^

-

yep runners made and welded. that was the easy bit, about 3 hours work. there is over a day just in the collector. just gotta weld runners to flange and stick the collector on and hope they fit haha

- 1536 replies

-

- 39

-

-

-

It depends what you are calling the "exhaust" There is plenty to be gained getting the sizing right after the merge. Lots of people hit me with "such and such motorbike or race car doesn't run an exhaust that big" In a motorbikes case, just happens the length of bike is about the right place to end exhaust. same deal with race car. either the car ends or not a full length system. Banging a 3" pipe on right where all 4 pipes join together will probably loose power yes. but going big at the right place onward, is the way to go. I'll place money that most of the gains roman will see, is in the midrange along with a bit of peak power

-

Yeah, flows more. but kinda means your exhaust is too small if makes more power. After the end of that pipe, idea is to simulate no exhaust. biggest straight through glass pack can fit straight after it. the rest of exhaust just needs to make it quieter, while adding little exhaust pressure as possible So yeah echo with 3" exhaust

-

Will work as is, but will be extremely loud haha. lt will also work pretty much the same, with the correct exhaust/ mufflers after it

-

Can't argue with that In other news, can we fire up that go fund me page again, roman gonna need a longer car kinda silly seeing it all out in a straight line like that. the length is roughly same as what i run on 4age still waiting on the straight pipe to show up. gone about far as can go now. collector and cone section 100% done I'll leave the last bit off. as really winging it for fitment now.

- 1536 replies

-

- 28

-

-

-

If could harness @Roman intake mods. In a perfect world the same 18psi would be about 316hp or 27hp more. not really apples to apples / dyno to dyno. but maybe a better comparison than most, considering both have a cork in the exhuast

-

Classic courier gag. only deliver half the stuff. But got collector tacked together Idea behind the fancy collector is try cut down some of the big open area over a standard merge collector. Its still there but over a shorter distance. Also transitions nicely back into diverging cone

- 1536 replies

-

- 36

-

-

-

looks pretty decent, looking at that dyno graph. looks like its making full boost by 4500 going by torque curve. 200hp by 5000rpm.

-

With turbo tech these days, Its pretty easy to use any engine you feel like. The limitation is just engine strength. from there onwards just a money pit of how strong can build the engine. Old mate you speak of has some good videos of explaining stuff. but end of the day its just stuff hes read or watched and put in an easier to digest format for the masses. he has managed to make a 4age make less power than stock though. If applied some of the stuff roman has done na, to a turbo setup would make stacks of power. some of it can't be transfered over, but a lot can. but yeh would just end in nuking engines till point of $$$$ billet blocks etc have been asked to do na stuff on 7a/4afe heads quite a lot. but is kinda pointless without any aftermarket support for cams. can only go so far with little stock cams dont get me wrong im obviously all for making crappy or different engines make power. but downgrading the engine you already have to try make power doesn't make a lot of sense /spam Pipes have been ordered for header construction

- 1536 replies

-

- 15

-

-

-

Thats a stitch up. you think they would enable the fuel cut at bit lower rpm based on speed or something my 20v junker wagon consistently does mid 6's/100 now. driving normally with the odd nang here and there. Messed around with the tune a bit on dyno watching torque numbers. It wanted a little more timing at cruise in places, around 45degrees. and smashed quite a lot more in at low load and revs. like what you'd use putting around in a 50k area. tidied up the afr a bit, and set it to about 15.2. along with some tweaks to overrun fuel cut to kick in sooner and down to lower rpm. previously it did low 7's. fucked stock ecu setup did high 9's. 6.5L/100 seems pretty decent for a shitty old 20v wagon

-

^ plus logistics So yesterday.. Cool someone some sent me a parcel. hmm yeh nar, one step above receiving 20v parts So to keep everyone in the science loop, i'll fill in the header construction part Stock are 32mm od diameter The aftermarket ones are 35mm od Seems to me the 35mm od would be a good size for the power chasing. Idea was to extend one set or the other rather than starting from scratch. because budget But dilemma was available tube size. can get 32mm od, same as stock. next size up is 38mm od. no 35mm. probably something in between if went to mild steel., but oddly enough can get stainless cheaper In meantime i made this amazing jig that closely replicates a echo floor pan and exhaust system. from potatoe 2 pictures @Roman sent me Back to sizing issue. after changing my mind 12 times. decided to chop up the aftermarket ones and go for a stepped setup. Chopping the collector off and running 38mm tubes from there onwards. 35/38. Because we all want to see that 10,000rpm 2nz anyway for reference 38mm od is what i use on my 4age headers. Need to order some stuff, but had a few leftovers hanging about for a bit of a mock up. looks like should work out all good.

- 1536 replies

-

- 31

-

-

-

Not sure how to explain the science behind it. but If mess around with sizes and cone angles etc can grab power in different places. the more aggressive the angle is seems give more bottom end. can do some massive megaphone setup. but fitment is an issue in most cases. the double cone setup ive been using on my stuff seems to be a good compromise. The "choke" section, basically want to go small as possible without restricting power. then cone out.