-

Posts

7,242 -

Joined

-

Last visited

-

Days Won

39

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Roman

-

I honestly have no idea yet. Just sort of hoping a good idea emerges when looking at the bits. Haha.

-

I'll add the alternator belt to my top 20 list of things that are gonna blow up. Place your bets!

-

Hey, looks like a great day for Pickapart! Time to get a bellhousing. So I using some fairly crappy tools I brought, after smashing a few knuckles and many swear words I got a gearbox separated from an engine. Luckily I didnt have to undo the torque converter, it just slid off. As that was looking like a whole other nightmare. I couldnt get the bellhousing off the box, and it's same price for a full box. So I decided I'll just grab the whole thing. However, my next problem. I'm down near the back of Mangere Pickapart and there are no wheel barrows or carts or anything. This transmisison is bloody heavy. I can carry J160s okay, but this thing is beefy. So, I made a little sled out of an engine heat shield and a seat belt. Instagram vs real life: Then I dragged it to the car on a piece of carpet. What a mission haha. The auto bellhousing is very short, but hopefully the idea of a cut and shut onto J161 front will work okay. That's enough punishment for one morning though.

- 132 replies

-

- 75

-

-

-

-

Ahh thanks guys! Thats a very good point ive not considered. It is quite a long unsupported length.

-

I found a belt path that hopefully works decently, with a very simple tensioning setup. If you undo the top bolt of the alternator and swing it down, it's not tensioned by the idler anymore. Ha! So you can get the belt off. Hopefully has enough tension on it this way. The trick to making this work was a smaller diameter idler pulley, that was on clearance sale at repco for 3 bucks. Which makes it sound like I'm smart so lets not discuss the $6 pulley and the $100+ of wrong sized belts that got me here. Either way, it's another small task sorted hopefully. Also! I've been doing scouting missions to pickapart whenever I'm near one of them for work. I've been waiting for a Mark X to turn up that's got the motor and box out for easy access. As I'm still looking for a bellhousing. I found one at Mangere where it's all out on the ground in front of the car. So will head back with some tools at some point and try wrestle that bellhousing out. It's tempting to just grab a whole extra motor and box, as they're cheap - Hopefully there will still be a few around when I've got a bit more $$ and space to put things.

- 132 replies

-

- 29

-

-

New benchmark for exhaust note goals. This is 3500cc 2gr motor in the lotus, so tack a few thousand more rpm onto this, and imagine that noise screaming out of an 80s toyota haha.

-

I initially thought they wanted to usr the v8 spec to get a wider bore spacing, to fit a bigger bore and shorter stroke. But was surprised to read it actually pushed the cyls a lot closer together. But makes sense. The motor had to hang way in front of the axle line because of the 4wd system. It would have sledged like a bastard if it was a heavy engine. Im lucky to be able to fit a fair chunk of the weight behind the front axle line.

-

Some off topic V6 sharns. Looking at history of the Alfa 155 DTM motor. The rules said they needed the bore spacing and bore centerline of a factory built engine. Originally they had to stick with the spec from factory motor which was 60 degree bank V6 busso engine. So this is how it was for the first few years. This was a problem because the spacing and vee angle means the V6 has one crank journal per conrod, and counterweights for each rod. They wanted something lighter and more compact. So later they bent the rules to say that they were using bore size and spacing of one of the 90 degree vee V8 engines. I have been scratching my head as to why they wanted a 90 degree vee. Turns out the benefit was that they could fit two conrods on a single crank journal. So the bore offset between left and right banks is reduced. The crank weighs a lot less with simpler counterweights. Then the block and everything else weighs less as it's more compact. Which is part of how they made it 50kg lighter than the busso v6. (110kg)

-

Daves new school holden shambles. Oops Rod knock deluxe today.

Roman replied to Muncie's topic in Other Projects

Yes it can output 0-5v, and you can scale the 0-5v to whatever range you want.- 756 replies

-

Gotta rememeber that 14point7 is a one man band, and he's an engineer type guy not a customer service guy. Where as other companies likely have sales people, support people etc. Not dissing 14point7, I'd happily buy more of their stuff, in fact, I'll be buying another same wideband setup at some point in future. But if you need some hand holding through installation or something (unlikely in this case) then bigger company might offer better support.

-

I can confirm that the spartan one does respond really fast by comparison. Closed loop fuel trim worked a lot nicer than before. But as the sensors age they seem to get a bit sluggy on response. Guess filled up more with soot or something.

-

Something else semi worthy of noting. Usually the go-to for loom plugs is DT or DT mini, but it annoys me that they have their own terminals separate to everything else on a Toyota loom. And they look a bit out of place. Then if you need a few plugs in the same place, there's risk of mixing them up and plugging wrong thing into the wrong thing. (True for any type of plug though) I found some Sumitomo plugs that use the same terminals as everything else on a Toyota loom. Ordered a bunch of 12 way and 16 way plugs to make a detachable loom from the motor. So if you used 2x 12 way and 2x 16way, and reversed the male and female sides on each of the same plugs. Then you've got 56 pins with no chance of plugging in anything incorrectly. https://www.aliexpress.com/item/1005001608539293.html?spm=a2g0o.order_detail.order_detail_item.3.26e5f19c0cNfX9

-

Daves new school holden shambles. Oops Rod knock deluxe today.

Roman replied to Muncie's topic in Other Projects

Yeah I had no end of issues with 4.2 or 4.9 bosch sensors blowing up. The quickest I had one shit itself was about 2 days. Some lasted a week or 2. was heart (and wallet) breaking. As Stu says, most of the fault was having the sensor blazing hot (like, you have turned the ignition key on, so the wideband heats up) while the motor is dead cold. I think where I lived at the time (Titirangi) was very cold and very humid, so lots of condensation in the exhaust. However, once I put a delayed start on it. Life was good. But sensors would still eventually crap themselves. Have since gone to the Spartan 3 and using the LSU-ADV sensor. Not only is it crazy fast to respond, but they're comparatively invincible sensors. As they were designed from the start to be cold start compatible for OEM use. I heard a good idea, which is to have a relay that runs from your oil pressure light. So the sensor only starts heating up once the oil light goes out. That way you're not consuming an output of your ECU and you dont need to worry about manual switching or whatever.- 756 replies

-

It's amazing how grippy even the PK6 is on there - if I turn the alternator pulley, it is holding on well enough to turn the crank (heads off though, so no compression) However I dont think it would need a huge amount of belt tension to work well. Currently has a PK61035 on there, have ordered a PK71080. Hopefully that'll be long enough to get the alternator bolted on correctly, either with a smidge of tension or slightly loose. It still cracks me up that with the 1NZ motor, the belt tensioning system is basically "Put a bar behind the alternator, pull the belt tight, do up the alternator" haha. No tensioner at all. 1NZ is a masterpiece of irreducible complexity.

-

If the belt path works like that, I'll just get another front cover so I get the timing mark back. Ahh yeah an eccentric idler pulley looks like a good scheme. Will see what I can find.

-

I'm using a Spartan 3, have used the early version with the analog output (as the canbus didnt work, so new later model one sent under warranty) and then with canbus. Both seemed crazy fast response time compared to 4.9 or 4.2 sensors. Not having to squish a range of results down to a 0-5v signal means you can get readings right out to 50:1 and incredibly rich as well. Which is sort of pointless, but when you're initially dialling in a tune it means it takes fewer steps to get to the right point. The best part though, is I'm still on my first and only LSU-ADV sensor. Where as I've probably got nearly a dozen blown up 4.2 and 4.9 sensors kicking around. Definitely an A+ rating for Spartan 3 from me. But make sure to get the LSU-ADV.

-

Ahh man I have been going 7 days a week plastering and painting my house outside of work hours. Which I think has taken a toll on my levels of brain juice for working on car stuff. As today I cut off the timing stand thingy - which was hollow so now there's a hole to patch in the timing cover. Then I couldnt figure out why the tensioner wasnt going to work at all. Because I was trying to run the belt the wrong way. So I took the tensioner off and had a look for how it might run without it. I could probably just tension it by pushing the alternator into its proper place. (With the correct length belt - This one slightly too short) Which means I didnt actually need to cut off my timing mark. Also I bought a 6PK belt when it's a 7PK. (wtf does it need 7PK for?!) If I can run it without the tensioner that would be good, for sake of a 2kg weight saving. But I think I need a decent rest before doing any more brain based activities.

-

Ahh yeah I got the e-throttle stuff working a while back @Themi. I decided I will use one bank with the onboard e-throttle, then second bank controlled over canbus. Rather than both over canbus. Reason being that if my setup shits itself, I can still limp somewhere with one bank running. But not if both are being controlled by the same external device. I've still been trying to find the right plugs for e-throttle. It looked like the 2 pin ethrottle plug was the same as the mazda RX7 IACV or the Toyota radio filter. However it's the right shape etc but just slightly too small of a plug. Then the plug I bought for the 6 pin TPS didnt work either. Think I will just change it over to another 4 pin TPS instead that I've got plugs for.

-

Hah! Good point. probably not.

-

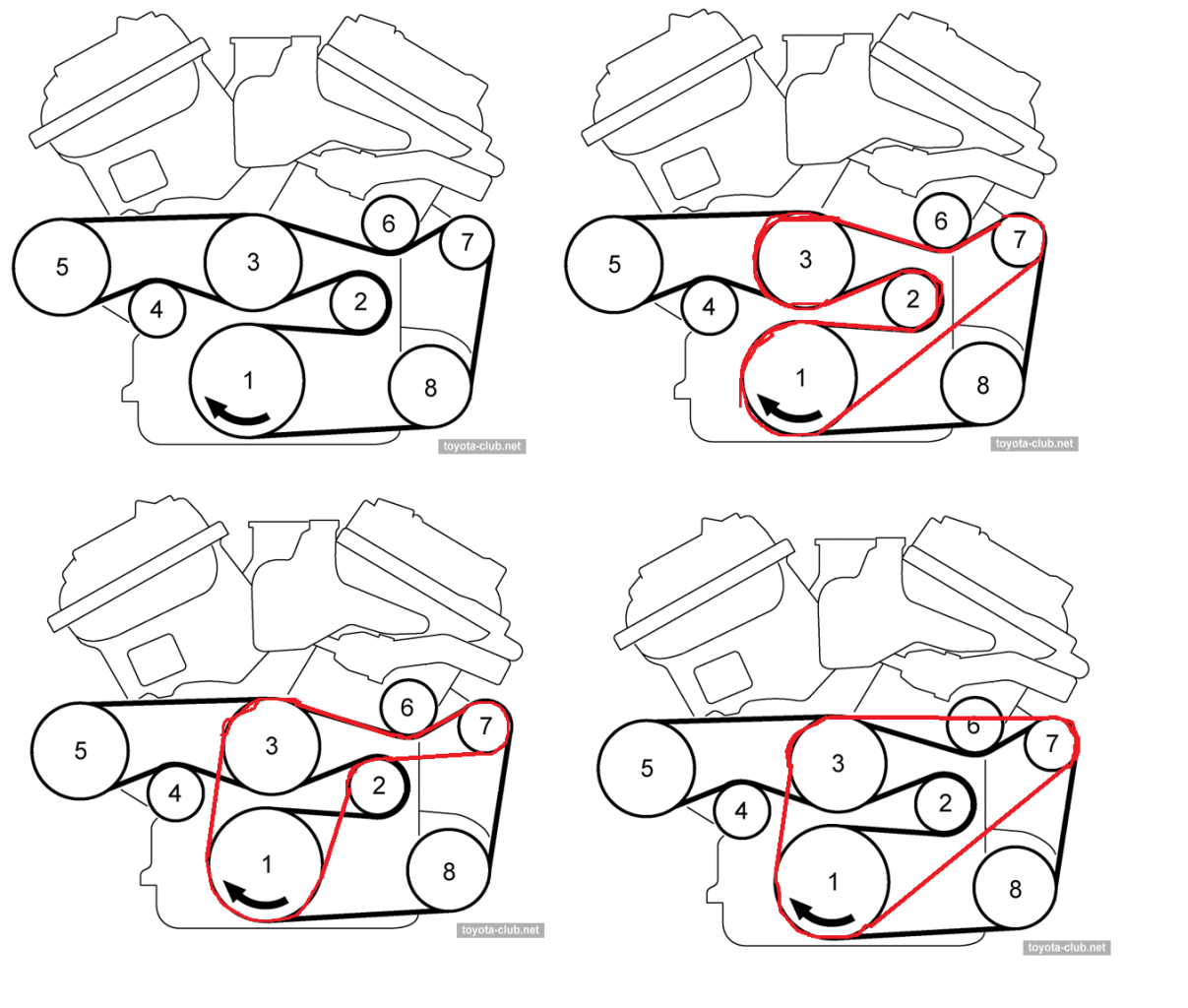

Yeah its easy to just reindex the timing mark. Just set the motor to TDC on #1 and then mark both the pulley and the timing cover at some point that's easy to point the gun at. Not really a big issue with the timing mark, it's just what you put a timing light on. Not the mark for setting the chain. So you can just put a new mark on the pulley and something close to it at any position.No drama. For the belt, I'm now only going to be running the alternator (pulley 7) and the waterpump (pulley 3) as accessories. Then pulley 2 is a hydraulic tensioner, number 6 is a static idler. So there are a few options for the belt path and how tensioner might work. I'm thinking the top left option is probably the best, as I get the most belt wrap on everything. Could maybe go without the #6 idler. Bottom left would be minimal path, least belt wrap, probably flap around a lot and need to be pinged up super tight. But either way, if I'm not running the belt around #8 (aircon I think) then I need to chop that timing mark.

-

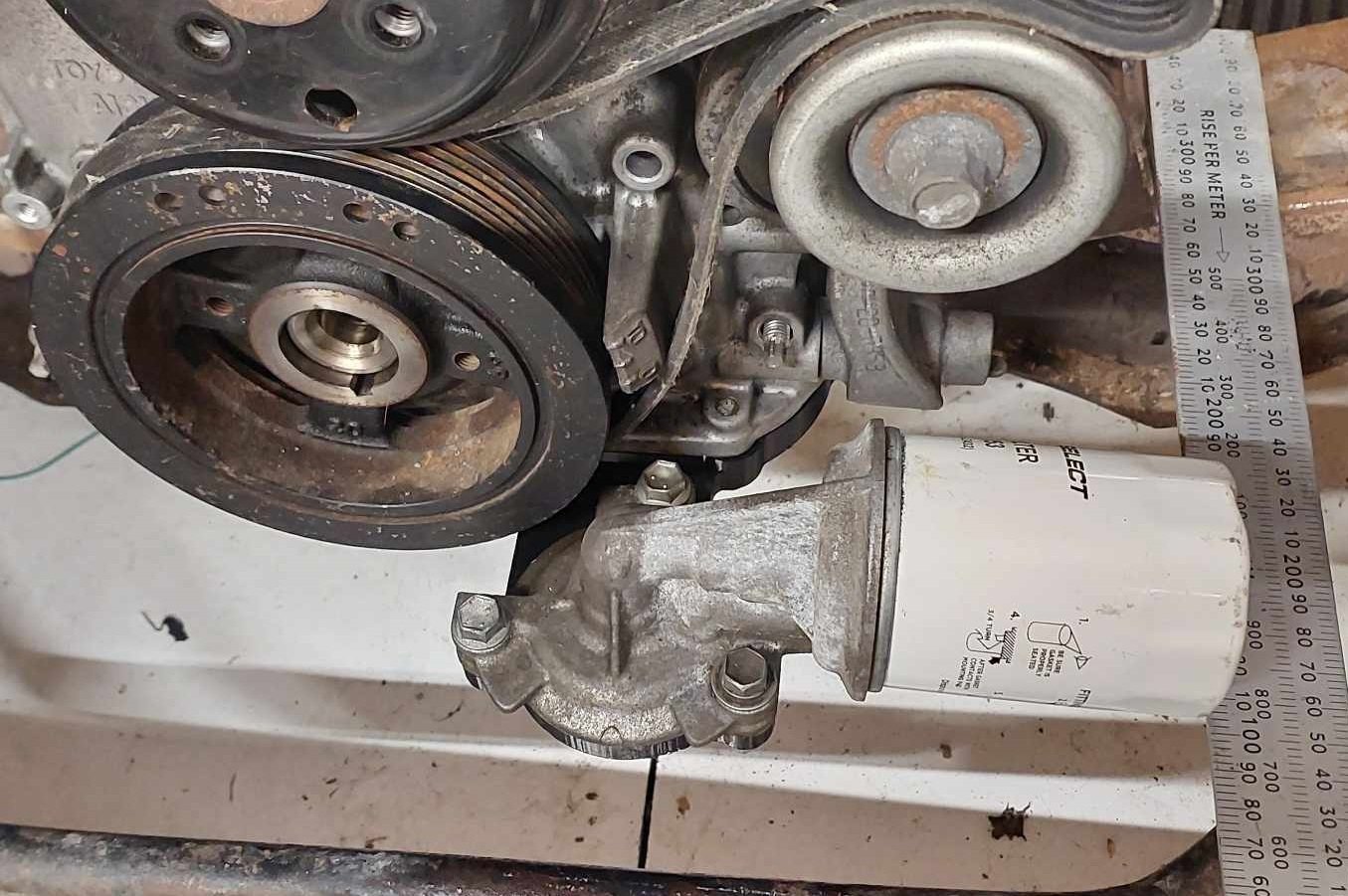

Sorted! Just 10mm further out and a 5mm drop and life is good. Probably dont need the 5mm drop. Now just need to go over my model with a fine tooth comb, and make sure everything's actually good with no weird geometry or whatever. Also, in testament to the fact that absolutely nothing on this engine wants to fit. I have to cut off the timing mark stand thing, to run the belt where it needs to go. FFS. haha. Hopefully this is the last in the series of punishing oil filter posts.

- 132 replies

-

- 33

-

-

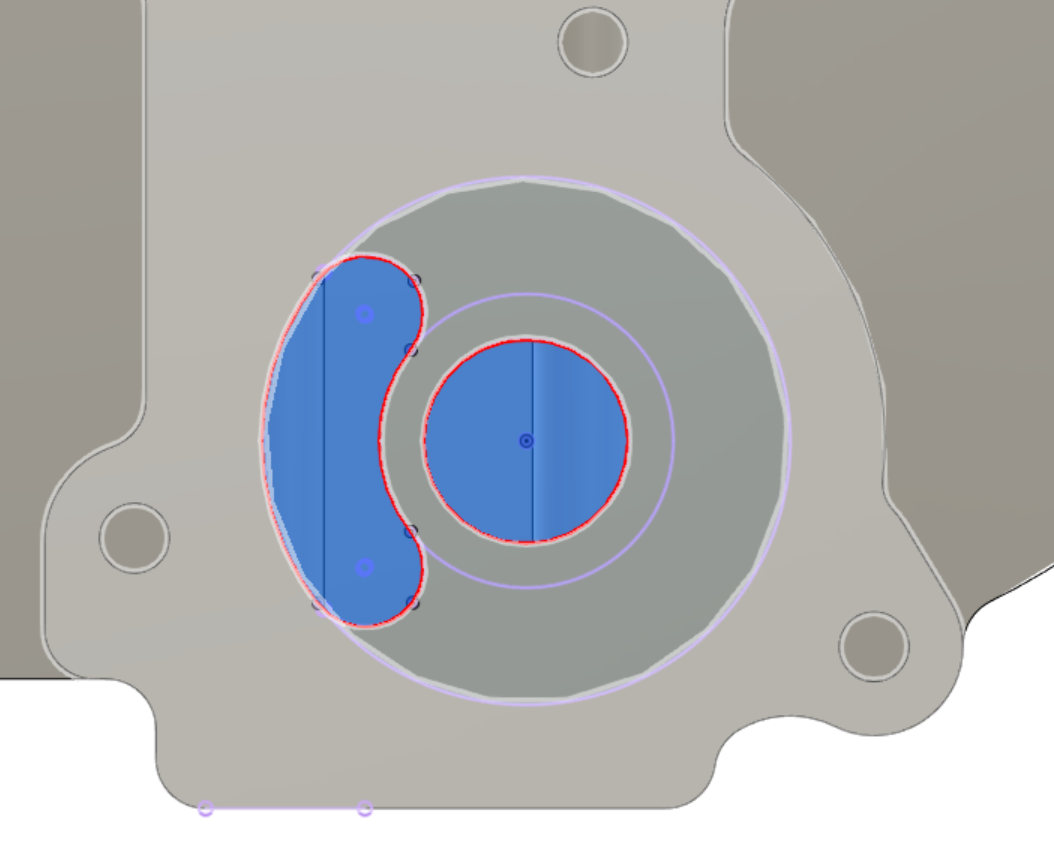

That outer red line in the picture is the outside edge of the O ring which seals it. Those two holes in the front end up getting plugged back up. Either screw in a grub screw like oem stuff does, or maybe weld a plug in. Its just the position of where it needs the oil gallery drilled. So that radius wont affect sealing at all.

-

Well its nearly there! Might need to be another 5 or 10mm further forward. Be good to drop it a little lower but im running out of thread depth. As the rear of the three holes sits on top of the gallery. Then I should be able to get the belt on/off with it in place. Need to remove the filter housing to take the pulley off, but thats probably only a task for major operations anyway. Can live with that.

- 132 replies

-

- 32

-

-

I found a few more contenders for oil filter options. The 4 bolt mazda one was a bit too chunky, and the orientation of the galleries further limited options. Then thanks to @ajg193 for pointing out that the 4K oil filter housing looks like a good contender - then thanks to @chrisR who found me one at pickapart on a 7K powered van or something. Looking like a better option! A lot more compact, and has the oil pressure sensor on it. Only downside is that the oil inlet pipe is 13mm dia. Where as my main galleries are 18mm. Which ends up around half of the cross sectional area. Makes me a little nervous to commit to it. I did some more pickapart scouring. I found another one one from a Suzuki swift that looked good. 3 bolt flange, but seals with an o-ring instead of a gasket which makes life easier. And the fully circular inlet makes it easier to orient it on any angle. Also the inlets and outlets look plenty big. sweet. Looking fairly promising with a test fit, keeps it nicely out of the way. So I've modelled this up, then I am just printing a test piece of the front of sump to make sure it will clear everything. I'd rather not have to remove the oil filter housing every time I need to take the front pulley off, or fit a new belt. The outlets of the 4GR oil pump have 250mm2 outlet/inlet area each. This filter housing has 330mm2 for the center hole, and 450mm2 for the bean shaped thingy. That puts my mind at ease! Fingers crossed this all works, then can fire off a final version of the file to get the plate cut. Exciting! Will end up turning an 18kg plate into a 3kg final part.

- 132 replies

-

- 34

-

-

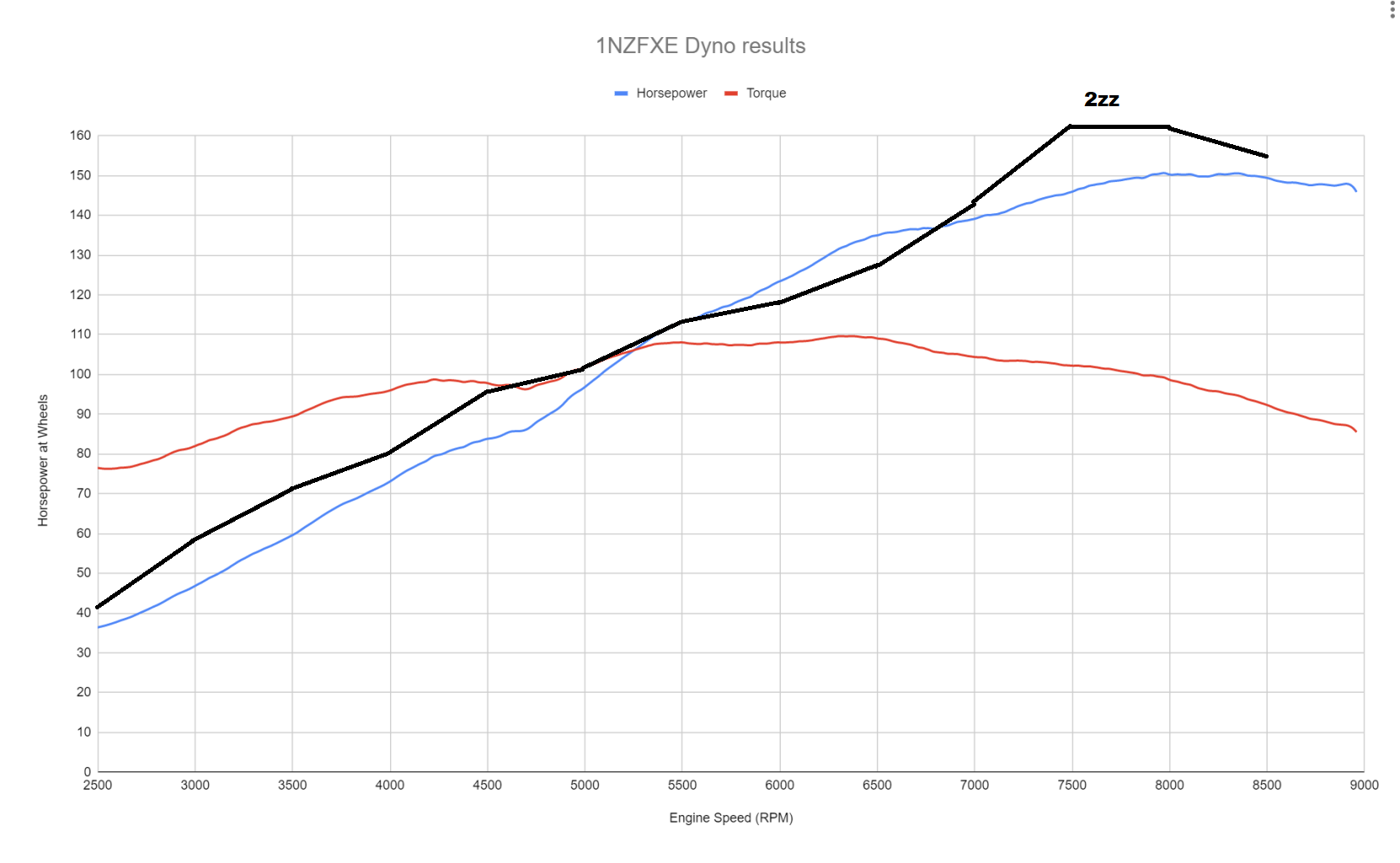

Assuming my motor made 150whp in its final config (second dyno said 200whp which was... optimistic) Here's a comparison. I wonder if they've got the exhaust choked up badly. Seems like it hates the big cam until high rpm. Hopefully they keep developing it, and dont just call it a day after that dyno session!

.jpg.ed28dc38513e105c70ac7c93d56338ea.jpg)

.jpg.84329cae040196a0a03c0bf9987c93b5.jpg)