-

Posts

8,221 -

Joined

-

Last visited

-

Days Won

10

Everything posted by Unclejake

-

VVT is a genius response to keep low-mid RPM driveability but have a semi screaming engine at higher RPM. The best fun n/a engines are largely either 1) smooth high tourqe groaners (think MGB C, Jensen Interceptor) or 2) barley driveable screamers (think anything period Lotus). If you're committed to this Mazda engine consider going old school mods. Balanced rotating assembly (probably already good from factory TBH), light flywheel, high lift and duration cams (Kelford or the likes will make you a pair) and fluff around a bit with your intake and exhaust tracts. Barely driveable can be fun.... and then you only need to add a chrome Ramflo air filter to become a legend

-

This could be the electric parking brake of beds.

-

Are you thinking scissor jacks too? LOL

-

Are you trying to level a mattress when parked on uneven ground?

-

Thanks for asking Rusty, but there's not much to report. I have the clutch working now but the tipper still won't go up or down and paid work has seriously gotten in the way of truck progress. We'll get back into hydraulic systems diagnosis in a week or so.

-

I had a 4.6 in a $50,000 vehicle 20 years ago and it was nothing but trouble - even back then when it wasn't very old. Eventually the cylinder liners and block separated so I happily walked away The 3.9 has shown far greater longevity and can see pretty good performance (using American carburettors and a few other tricks). Based on the above dimensions a 3.9 sounds like a much better choice, but I do know you need to be careful with at least oil viscosity vs. the hydraulic lifters if you're pushing those motors hard

-

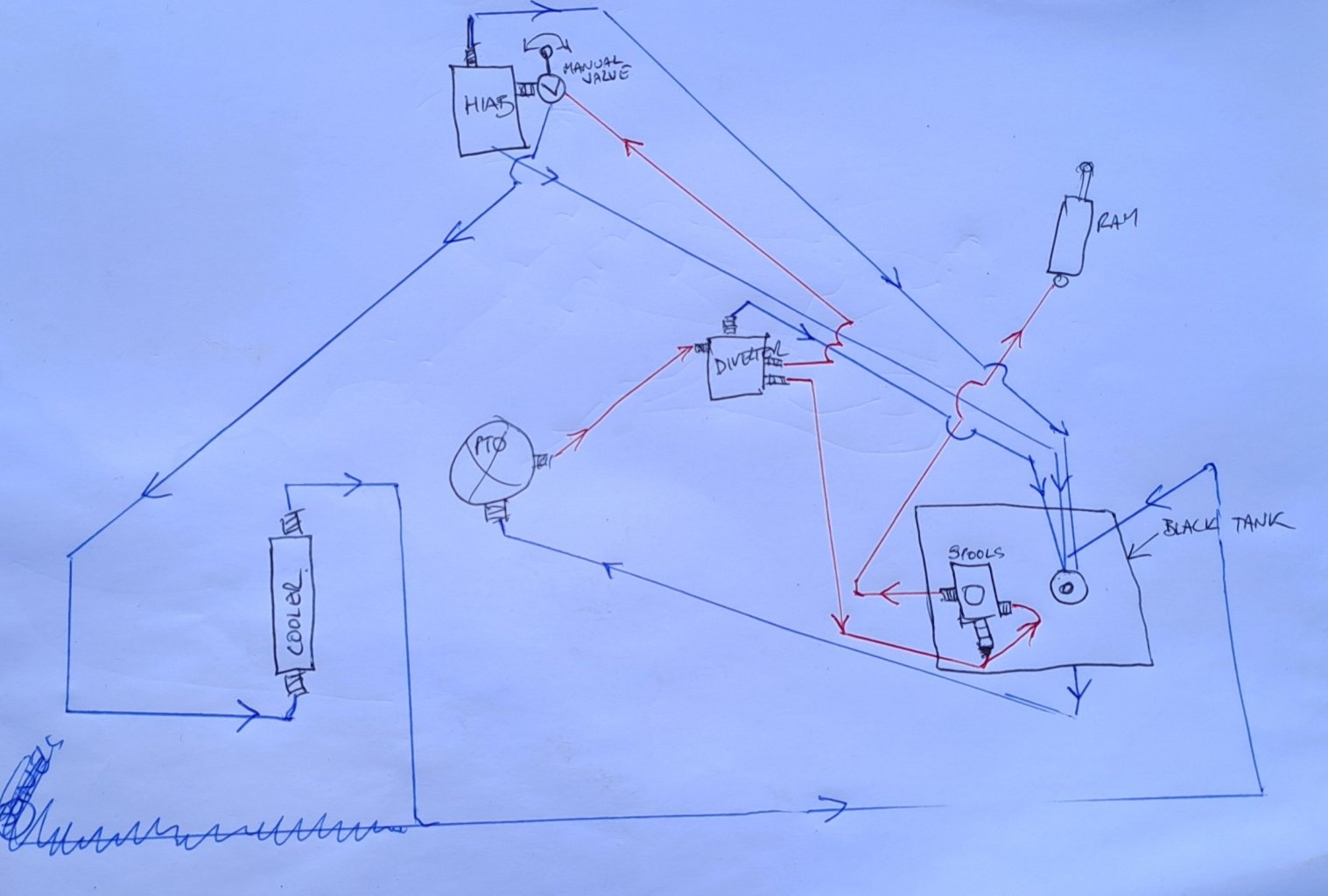

Yes, the hose marked in yellow comes from the diverter. Deleting the four return hoses would give me a filling point, but I will need to have a filler hose as the deck would make it otherwise difficult to add fluid. Good point about the breather. I hadn't thought of that... but I can just drill a hole in whatever I cap the hose with. I need to get the clutch fixed, get a working hiab back in to lower the deck, and then drive the thing into the shed. I'll do that once all the bundy tube arrived (possibly Wednesday). EDIT: Perhaps there's a removable plate in the deck for topping up the hydraulic tank already. I will look on my next visit. My biggest hassle is the diesel gushing over the PTO and grass when I run the engine. It's a PITA and right where I need to work

-

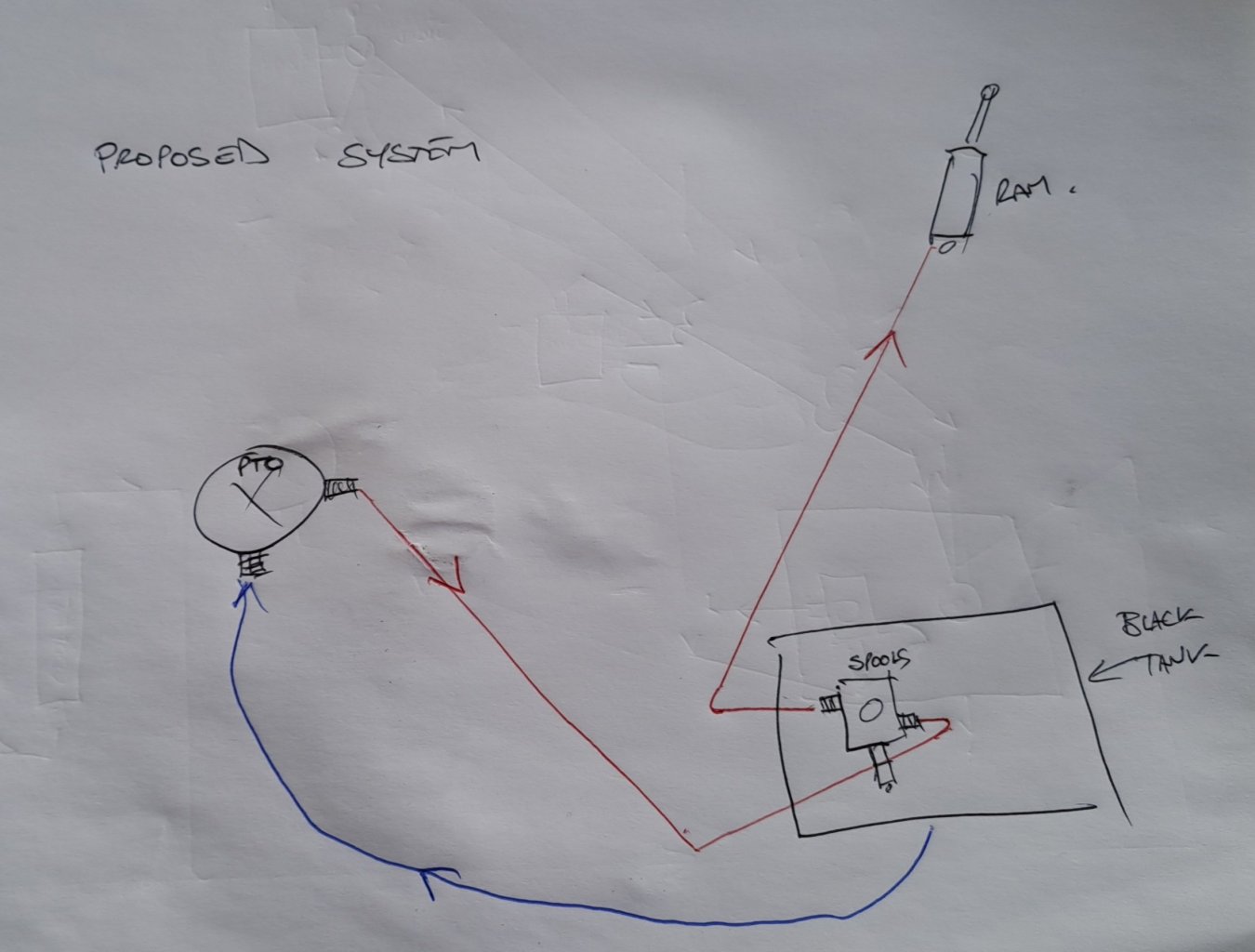

I'm guessing as the ram retracts it discharges fluid into the black tank via. the spools? If so perhaps I can delete excess failure points and get to this state. Unsure.

-

-

The PTO doesn't seem to be engaged. I guess a crook cable? Unfortunately it's too hard to get at without jacking the truck up off the ground so it'll need to wait until all the other parts have arrived and can push the truck into the rented shed. I only get the shed for seven days.

-

Good morning everyone. The clean looking valve assembly seems to be hoist up and down control and lots of return lines into the black tank. The tank is a bit over half full The dirty looking valve assembly (inside the chassis) is a diverter that is fed directly from the PTO pressure line. Hoses from that diverter go to places. I'm not entirely sure where yet... but one of them goes to the Hiab Either the diverter or the PTO isn't working as I still can't lift the tray and have no apparent hydraulic pressure at the ram, but I didn't have the correct spanners to crack open the pressure hose from the PTO to the diverter yesterday. I'll try again this afternoon.

-

Edited for truth

-

Pretty sure (without being certain) the wrapped line marked P is a gravity fed line to fill the black tank from the Hiab tank. There's no other way to get the oil into that black tank. I'll get a photo from a better angle tomorrow

-

Yes. Those bastards. They have wires! Guess they're hooked up to the diverter switchbox.... and now I am thinking just how handy a Hiab would be! LOL

-

Did you see the 'things' on the inside of the chassis too? I think they are for the Hiab.

-

Sorry for slow posts and edits. Chatham internet is not swift. So far I'm into the project a few interesting hours, $750 for batteries, $150 for Hiab lift, $400 for bundy tube.... and I guess $400 for hose repairs. Add some extra dollars for hydraulic oil, brake fluid and a few more days effort and we may have a fucked truck that actually goes. JOY!

-

There's so many hoses simply joined to each other it's hard to be certain, but you could be very right @rusty360., but I think the armoured 'P' on the right of the screen is actually the tank filler hose that comes down from the Hiab tank. I am told that the tipper worked two years ago, and no-one has touched the hoses since, so the plan is to sort the clutch, replace the failed pressure hose to the tipper ram, and then start deleting redundant pipework once I know the tipper works. With that approach - if I fuck something up I know I fucked it up the same day, and not something someone else did two years prior Now the deck is up I can see the 24v pump is completely stand-alone. It doesn't connect to anything we can see in the photos. The two (smallish) hydraulic hoses from the 24v pump are just connected together under the front of the cab.. I'll remove it and keep it as it'll come in handy for something. @Transom was correct that the 24v pump would have just been for broom lift. In fairness: Whomever did the hydraulic work did a pretty good job.

-

Also correct

-

Yes sir. A new/repaired hose will probably be ready by the weekend... as may be a new clutch hose. The future looks bright

-

-

-

I have rust holes right through the chassis of my 2007 Land Cruiser V8 ute - which has only been here since 2016. This yellow truck is basically concourse.

-

It was Downer for certain and 24v pump for broom up and down only makes absolute sense now you mention it. I'll start deleting the spare hoses etc. after confirming the hoist works in its present configuration. I'm too scared to modify anything hydraulic prior to getting to a known state.

-

Some good news: The thudding I was hearing when operating the broom up or down switch came from two different valves (spools?) at the top of the black hydraulic tank. The only bad news is that those spools operate regardless of ignition switch position... so I figure that's why the previous owners had so much trouble with flat batteries. I reckon the two different spools thudding bodes well and confirms what you fine chaps thought: The system is electric over hydraulic. I didn't start the engine as it gushes out too much diesel onto the ground and I don't have much spare hydraulic fluid.... but the mechanic will repair the damaged pressure hose in the next few days. Another bloke is coming with a Hiab to lift the deck soon too. We will see which of them gets their job done first! Ha

-

Thanks man. Engine oil is no cheaper to fly in than any other liquid of the same mass. Airfreight is based on weight. Sea freight is on volume. Air is about $4.30 per kg. Sea is about $460 per m3

.jpg.0321ed4a824f7c705abd7a63492e26e9.jpg)

.thumb.jpg.17e1a5791611749b7a6a028c73cc3bb9.jpg)

.jpg.87de5cc4791fa95755bff4efcc2e185c.jpg)