-

Posts

1513 -

Joined

-

Last visited

Everything posted by ~Slideways~

-

I've been thinking about the lack of reverse, and the fact that I'll have fwd hubs doing nothing. Maybe I could have a reverse motor connected to part of a fwd driveshaft. There may not be enough room to do it since it'd need to have a cv and a solid mounted starter motor and gear. Maybe though.

-

It's a 2002 Kawasaki ZX12R, I couldn't pass it up. It was from an unfinished race buggy thing so came with everything I need: wiring, ecu, cluster, radiator, inline fuel pump etc etc all set up and running. It's a bit early to be buying the engine since I have a lot of body stuff to do but it came up for sale now, so what am I meant to do...not buy it? I will need to do some cutting to make it fit and the steering rack may cause me some difficulty but I'll know when I take the 360cc out.

-

Window regulator gear ran out of teeth in the Bunnings car park, while it was half way down. Which was annoying because I was only there to return their stupid pre-emptied mig gas bottle. New one: While I was in there, I put in some sound deadening sheets. Took a photo after I'd put the sheet in to the left, all that was from factory was the small bit in the centre. Weirdly, when I got this Safari it felt so quiet compared to my Landcruiser BJ73, will be interesting to see what a difference sound deadening all doors will make. After, almost all inside surface covered. When I closed the door it sounds and feels like a luxury car, so impressed. For example when I close the other three doors they close with a echo'y metallic bang rattle of sorts, or if you tap on the door skin its the same. But the door with the sound deadening sheets inside closes with a satisfying muted thud, it weirdly makes the door feel more solid. Will definitely be doing the other doors.

-

- 29 replies

-

- 18

-

-

Might have found an ae95 axle, will hear back over the weekend. They are 1325mm wide, drum face to drum face, which would mean it would stick out roughly to here: So it would work if using fwd offset wheels (easy enough being 4x100) and some flares. Or some nice negative offset alloys and bigger flares. Then I'd change the front to 4x100 using gen 2 Civic knuckles and have disk brakes too. Would need to have spacers on the front though. Hopefully having a look at a bike engine soon because I can't help myself.

-

Also the S14 speedo looks to have speed adjustment terminals on the back, interesting! It won't fit in the 180sx cluster though and it also did nothing with all tests.

-

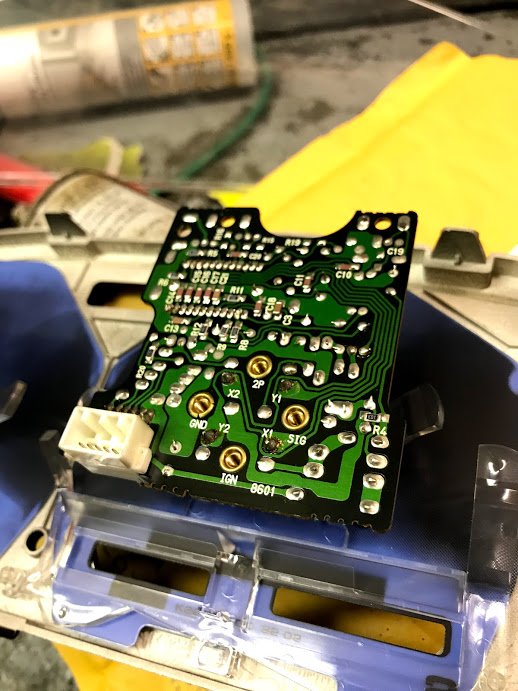

Not having much luck getting any kind of reading on the speedometer using a Yellowbox speed corrector, a Dakota Digital SGI-5E or just straight off the gearbox speed sensor. Both the Yellowbox and the Dakota Digital register that there is a pulse signal so the sensor and wiring must be ok. I am going to use the Yellow box to adjust the rev counter signal anyway, so I got the SGI-5E because it is meant to work with basically anything but I can't get it to register anything on the gauge either. The wiring on the back of the speedo is pretty simple, 4 terminals (2P (speed sensor input (EDIT turns out this is an output for the original Nissan ECU)), IGN power, 12+ power and ground). I thought maybe the 180sx speedo is dead. I don't remember whether it worked when I did a made dash test drive on totally private roads in the banana'd chassis. So tried the S14 one that came with the race car rolling body, don't know if it actually works either but assume it does because the rolling body was a rolling body because an sr20 threw a rod at Manfeild. Rolling body. Tried it anyway and got nothing. So I thought maybe the 180sx speedo could have a dry solder or something, took it apart and it looks ok. A little bit of crusty stuff around 4 of the solders but I think this is just the melted coating of the board. I resoldered these 4 anyway. I think the toyota speed sensor is a Hall Effect which is compatible with the Dakota Digital and it flashes showing the pulse so that must be fine. Not much info on what the Nissan speedo is expecting, I found a website saying that it should be 16000ppm which again should be fine with the DD. I've tried all 5 outputs on the DD and get nothing. I've tried the test function on the DD which outputs a few tests which should show on the speedo but it doesn't budge. Frustrating.

-

Good suggestion, I never knew these were solid axle! This random TM auction was they are 3.5 or 3.3 which is better than most but I need closer to 3:1 due to little wheels. https://www.trademe.co.nz/motors/car-parts-accessories/mitsubishi/diffs-axles/listing-1938017278.htm

-

Just found another option, AE95 Carib 4wd has a 2.929:1 solid T-series axle. AE95 Solid Axle (coils) T462: 6.7", 2.92:1, 2 pinions, Open4x100 1325mm Drum Being T-series an after market LSD is available. It's 4x100 with drum brakes but that's ok. Especially if I use Civic 4x100 brakes at the front. Does anyone know of a 4wd Carib AE95 wrecking?

-

This is so cool. What is it going to be used for, except being awesome?

-

A few options for a motorbike engined car 1. Either an MX5 rear subframe narrowed (but keeping stock suspension components/dimensions) and using mx5 diff converted to sprocket drive (mid engine chain drive) and shortened half shafts (hoping to just cut and respline if possible) 2. The same subframe using an IRS holden diff (normal prop shaft to front) and modified half shafts to mx5 rear brakes (maybe respline would work, maybe weld...dont like idea of welding) . 3. Civic diff and brakes converted to sprocket using in fwd format but need to shorten shafts. If that makes sense?

-

I have a Td27 pump now, not sure if the compensator can fit the td42 pump or if you change the internals of the td27 pump for 6 injectors. Guess I'll find out when I get to that stage.

-

Thats a cool idea, I would prefer a more fail safe thing than adding a 3rd fuel supply system. Maybe if I wasn't already using the water injection. Building a bigger injector pump makes sense. I ran out of water/meth the other day, so had to unplug it (no low level cut off switch). I immediately missed it.

-

The main goal is having a very light car with a high reving motorbike motor/gearbox. It won't be a track car, I have another car for that but I'd want it to not be a pig to drive and be fun on twisty roads. I originally thought about building a Lotus 7 replica for a similar weight. For a leaf sprung live axle, its the most simple to start off with except for making it 4 stud. But there is fabrication in mounts and custom making a sway bar etc versus going IRS. The MX5 rear subframe would be perfect since it is a flat floor area, they quite commonly used in kit cars now that I look into it. The guy who built the VFR800 N600 used an mx5 rear but had to modify suspension arms to move the shock mount so I don't know if this could be certified here. A live axle would need the floor cut for diff centre clearance but that'd be easy enough. I've got to think about the front end as well, the current location of the steering rack on the firewall leaves lots of room for another engine but it is a very basic steering to strut setup. So ideally I'd want to do something there too. I like the idea of using something more modern like a civic maybe, using the strut, subframe, steering rack, brakes etc etc. It would probably mean less room for an engine... which leads me to mid mounting. Edit, maybe the front from Honda City?

-

Interesting point about the side load, alternatively I could try the idea of changing the crown wheel to a sprocket like the fwd version.

-

Try change the battery in your multimeter, when they get low they read wrong. I had this once and google told me its because the internal battery voltage is used as a reference, or something like that. I had that with an old 4age alternator, read 18v. Changed Alternator, same thing. Turned out to be the multimeter battery even though the low voltage wasn't indicated.

-

I actually had a similar idea with a rear/mid mounted engine using a sprocket directly on an unmodified IRS diff. Such as using a complete MX5 rear end with shortened half shafts. It would be ideal with a vfr800 if I can fit it in there. Interesting idea having a sprocket on the driveshaft... hmmm. Packaging is always an issue in a small space but it open up some options.

-

Yep tiny hole saw, guess I'll see how they go. I do need to keep both sides in some places.

-

It would be pretty hard to get it to do as low as 4000rpm without running big diameter tyres, its more of a not going crazy doing a million revs while doing 100kph than matching what the bike engine donor would have done. I've started cutting out rust on this thing now and have bought some spot weld drill bits.

-

I'm pretty sure I check this a few years ago after reading about this being a thing, but I'm not 100% sure. A 'few years ago' was chaotic time with the first born so maybe I need to double check it.

-

Thoughts on leaf spring live axles?

-

I mean Escorts and Rx's can handle well with leaf springs...

-

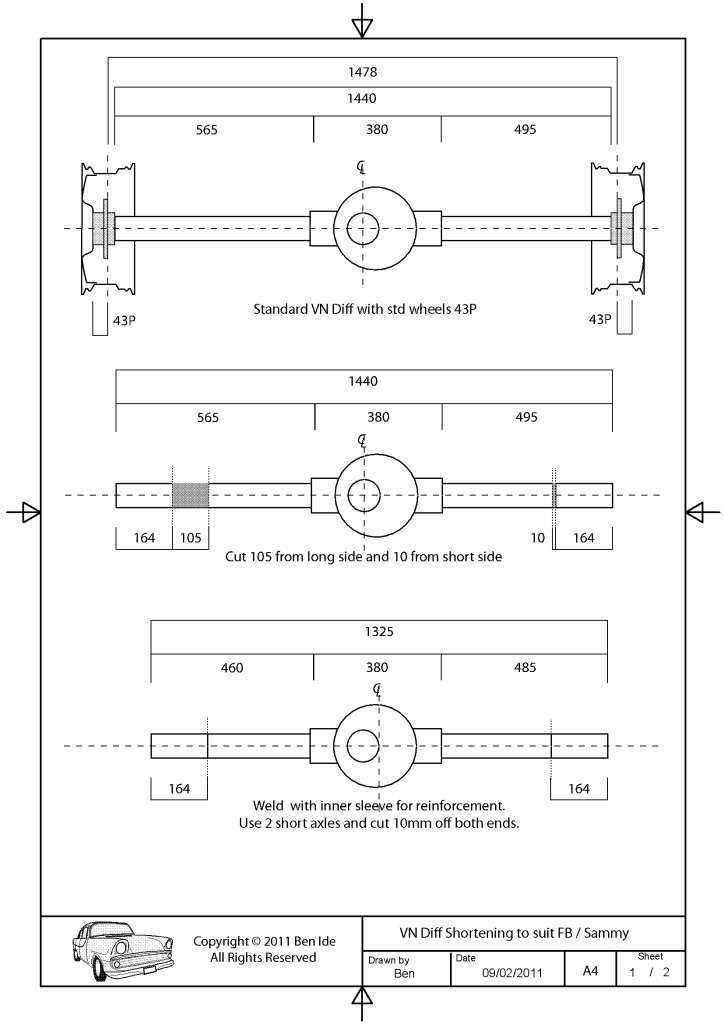

I went to Pick a Part and had a look at some live axles, the wheel base of the N360 is 1295 according to Wikipedia I'm sure that is with the skinny wheels though. Since it has leaf spring rear it's the easiest option for rwd if I go that direction. Its also the most horse and cart option handling wise but it's still be a rwd Kei car. The 4 stud makes it easier wheel wise. Suzuki Carry: Found a 1999 Suzuki Carry with coil spring rear live axle, its was about 1385mm. Could work width wise, but the diff ratio is going to be in the 5:1 range I'd bet. I need around 3:1 due to the small wheels, even then it'll be doing 5-6000rpm at 100kph. But it'll be able to rev to 13000rpm depending on the bike engine. Sounds bad but my old standard AE86 used to do almost 4000rpm at 100kph. VN Commodore: 3:08:1 is common, its a straight tube type so is easier to shorten. According to this diagram you can get it down to 1325mm without custom half shafts. But then I have 5x120 to deal with. Maybe I could redrill the stub axles and use 4 stud discs. Holden IRS diff in a MX5 subframe. Use a 3.08:1 Holden diff, cut up mx5 subframe. This would make it easier to fit a starter motor reverse since the diff doesn't move. This is much more complicated though, cutting floor, coil spring mounting points etc. That guy did similar with the VFR800 one, using some other diff that wouldn't be common in NZ. --------------------------------- Leaf spring rear is by far the easiest, also solves the problem of the probably stuffed standard rear drums and hard to get bits. How 'bad' is a leaf spring rear going to be for handling though? It's not going to be a race car 10/10ths thing, its mainly going to be a fun road car.

-

Update on the 50/50 water meth injection, it LOVES it, man what a difference. It revs out freely like a totally different engine, not something I ever expected and on the motorway it pulls way better in 5th. I'd heard that diesel turbo's love water/meth injection but man it really does! It really feels like a different engine. I'm looking at getting a TD27 turbo injection pump for the boost compensator bits, so later on I can get that built into a bigger TD42 pump since I am still on the standard NA pump with the max fuel screw turned up (might be a bit more in it still). But in saying that, it's going so much better that maybe I won't need it I mean the 50% meth is like an extra injector anyway. I'll need to tow a heavy weight and see how it goes.

-

I've read conflicting information, is it acceptable to modify/shorten/weld half shafts? EDIT: Looking into it, I don't think welding is an option but shortening and resplining could work.