-

Posts

4,743 -

Joined

-

Last visited

Content Type

Forums

Downloads

Events

Gallery

Posts posted by zep

-

-

Yeah, it's more for looks than anything else.

-

I am keen to run my master cylinder to a remote reservoir with braided lines. The problem is that there are no threads in the master cylinder inlet, only these clamp on plastic things.

What's the best way to adapt this to braided lines that I can thread in to the reservoir?

My two thoughts have been using some kind of rubber bung and a push in adapter that is threaded on the other end, or welding on something threaded but was advised not to weld the master cylinder as it might warp.

-

*groan*

I wonder then, either my axles have less material on the gusset, it's been machined down to fit the disc, or the disc has been machined out to fit - or a combo of all of this. Need to pull it apart and look.

This is starting to feel too hard! Maybe I should just shell out for the full floating kit.

-

1

1

-

-

6 minutes ago, johnny.race said:

Those axles are from the 40's or 50's series of Luxers. I'm guessing LN56/57 given the 4 lugs in the register and the later style of bearing housing being used. They'd be around the 685mm mark in length OEM and were worth something before being blazed and having meat chunked out of the rear flange in order to get that small PCD to fit. Out of interest, are AE101 rear calipers the same as AE92's?

I thought they were from an RN40, but I don't remember. The diff came from the deep south about 15 years ago, paid squat for it!

Do you know the length of the early KUN axles?

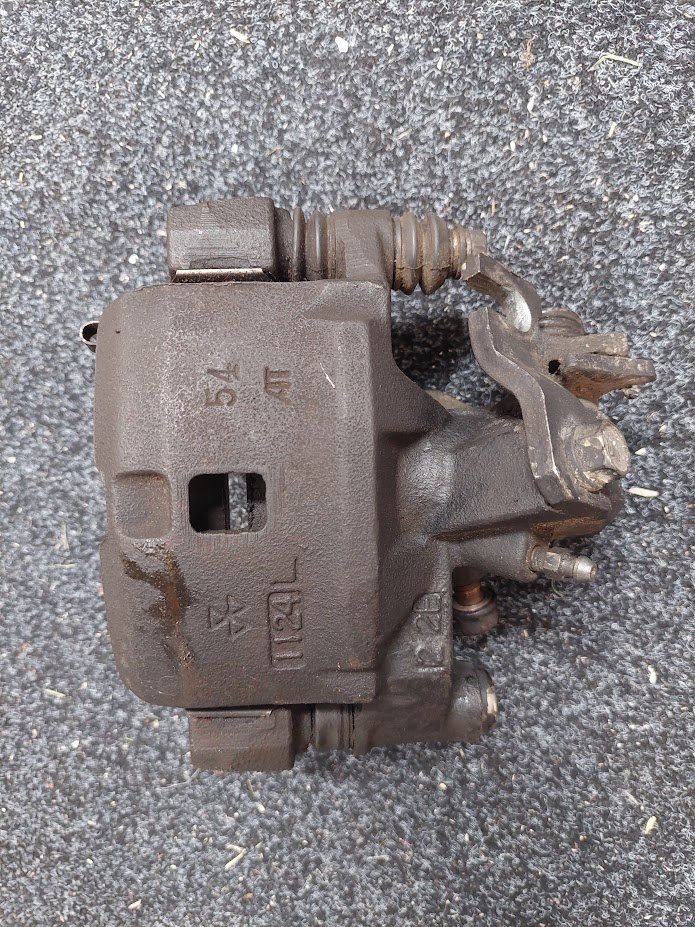

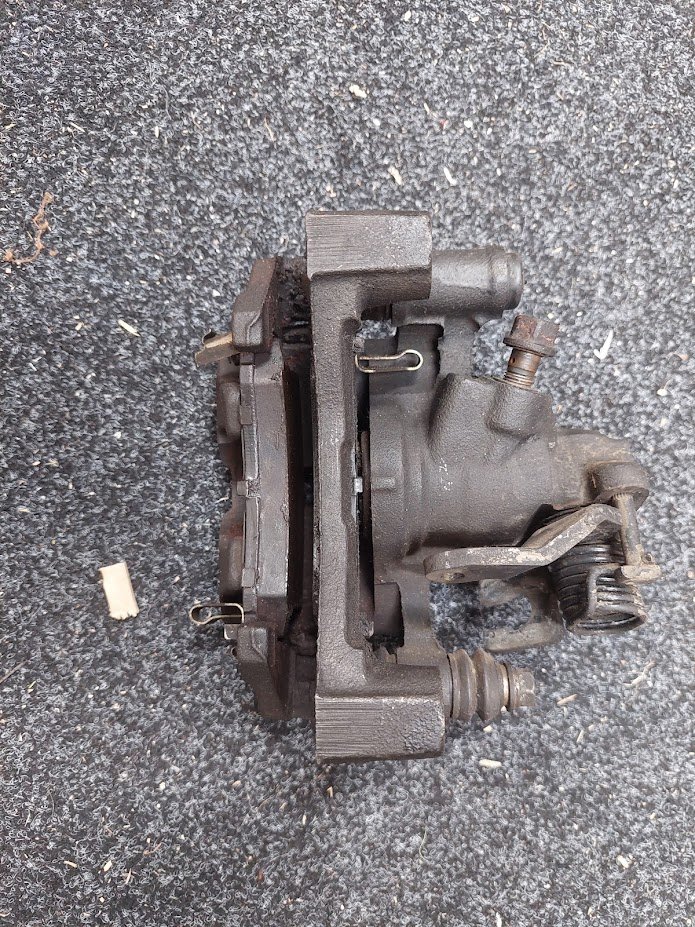

Not sure on the brakes. I've not seen AE92 ones. Here's what I have:

-

30 minutes ago, johnny.race said:

What does the axle brake hub register look like. Does it look like those in that first pic I posted or has it got two dork things sticking up like in the 3rd pic I posted. Is the housing the skinny welded type or the later round type? Your axles will be around 685mm long and if 6 stud - will have done a shit load of work. Just saying.

Here's some pics, my brake hub register is different to both of the ones your posted. You can also see where they were welded and redrilled - originally they were 5 stud. The housing is the welded type.

42 minutes ago, johnny.race said:

42 minutes ago, johnny.race said:Let me know if you do find one of those 6 stud Hiace ones that matches the width of a KUN. I've got a few of them here and they are not KUN width. But that's just what I've seen - you're mileage may vary.

It's difficult - I don't think the wreckers are going to just let me pull out a bunch of axles! Might just look for KUN ones.

17 minutes ago, cletus said:Just another thing to think of @zep if you are narrowing the axle, and you have calipers mounted further in than normal, due to the disc being inside the axle flange, make sure you have room for full travel and articulation without the caliper fouling the chassis rails or body etc

Yep @cletus, I've factored that in. Rear calipers all seem to have massive handbrake mechanisms, or have really small pads. I think I can make the AE101 work by shifting it and mounting the coilover above it so it the turret give it the necessary clearance. Any suggestions on low pro calipers that still have a decent pad size?

-

34 minutes ago, johnny.race said:

What wheel stud PCD would you be looking at? What sorta brake setup are you hoping to run? I know where there are a couple of 1350's and a 1365 I think. The pinion is centered in one of the 1350's and I'm not sure where it is in the other two. In anycase - they'd/it'd be offset to a lesser extent than the OEM Hilux all are.

I need to run 4x100. Currently I have AE101 discs and calipers on the axles/housing which I have been running for years (rotor behind WMS).

Not only am I wanting to shorten the axles/housing, but I'm also changing to coilover from coil/spring, and to 4 link from a 3 link ladder bar setup. Considering all this together is why I considered starting from scratch! I'd like to keep the brake setup though, it works well.

-

10 minutes ago, kpr said:

@zep that chart i posted was trailgear stuff. if got 2 short side rock assault, would be at a guess 1300 ish wide. which probably too short?

I want to go down to around 1350-1360 width.

-

Yeah, you're right. I need to pull my axle out again and measure it up.

I have found some axles such as this: https://www.nitro-gear.com/Toyota-8-8-4-Nitro-Chromoly-CTL-Axle-p/axt34060.htm

But even cut down to the narrowest I don't think will be short enough.

That's good to know about the spigot - I thought they were necessary for ensuring strength.

-

9 hours ago, kpr said:

I did initially when I was looking for something that was the correct centrebore. At this point I may as well just buy some blanks with extra long spines that can be cut down. Then I can just machine down the centrebore and be done with it. I'll have another look.

-

Yep, mine is the one with the weld down the centre.

It's starting to feel like with the work I will have to do I may as well start again with a Borgwarner or something, as they have heaps of drop in aftermarket heads and probably a lack of annoying axle tapers.

-

12 minutes ago, mjrstar said:

Does a 6 stud to 4 stud hubcentric bolt on adapter solve your problem?

That's what I did on my kp with hilux diff. I used a land cruiser disc and rx7 caliper in the braking department then used 2 left hand side r30 skyline handbrake cables.

I don't think so. I'm trying to shorten the diff and the space that the adapter would take up would mean I need to go in even further.

23 hours ago, johnny.race said:The longest axles that still make use of the conventional style Hilux wheel bearing holder housing register are the KUN's. You be wanting the early KUN that is sans ABS. 5 stud or 6 name your poison - they are both XL in length compared to the earlier stuff.

Is there a KUN equivalent of a Hiace? There are heaps of them at wreckers.

-

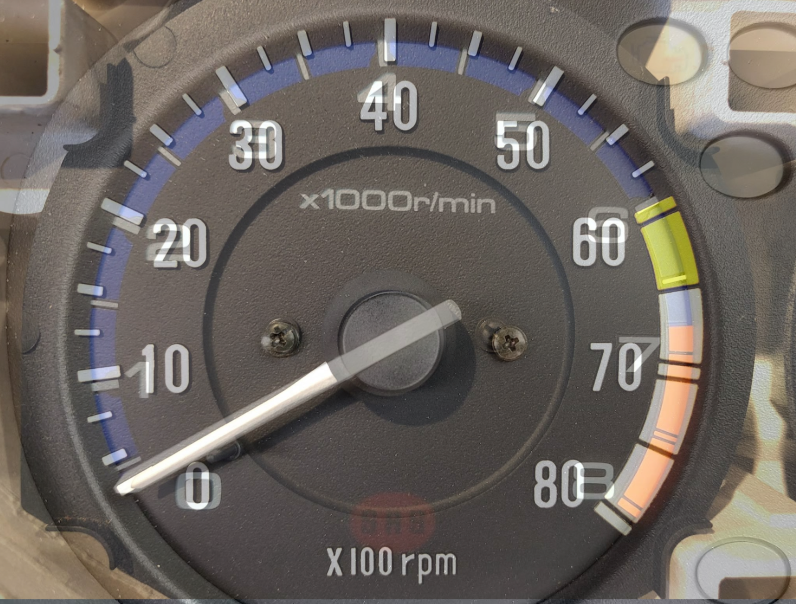

Grabbed an EK cluster. Turns out the tacho is also an air core but has a microcontroller integrated on the circuit board. It still takes oldschool inputs but doesn't have the potentiometer that I believe the EG has. Back to pick a part again I guess!

-

Wow! Thanks @johnny.race So it's not quite as easy as I had been told.

My current diff is one of the 1410mm wide ones. I'm essentially looking for axles that are the splines plus the tapered area longer, so I can cut it all off and respline at my required length.

Do you think there is enough material in the mounting face centre to machine a 6 stud down to 68.3mm from the stock 101.6mm?

As I mentioned above, my rotors are currently mounted behind the flange face. I need to pull them off and see how this was achieved as I didn't do it personally. Could be some machine trickery behind there.

Is there any reason not to just grab an entire 6 stud hiace housing and axles then, if they are more butty? Will my existing hilux diff head work with this?

-

1

1

-

-

1 hour ago, kpr said:

Some of the hiace ones are also quite long

I've heard this. Any ideas which ones? There are 5 stud 2WD and 6 stud 4X4 Hiaces. Hard to get a wrecker to go out and measure the wms to wms for me!

52 minutes ago, cletus said:I think some of the reasons for using 6 stud axles are the holes are further away from the 4x110 or whatever a Mazda is compared to a 5 stud axle

And they are cheap and easy to find

That's good to know that people use them.

Keen to know about that back side machining too.

-

Hey all,

My search for long toyota G-series axles has led me find that the longest ones come from 4x4s like a Surf. I should be able to swap from 6 stud to 4 stud without too many problems, but the issue is that they have a 101.6mm centrebore which is way too large. Does anyone have any experience in machining this down? I have my discs mounted behind the WMS so I am only concerned with getting the wheels on.

Cheers

-

Ah yeah, that makes trying to swap a speedo circuit/unit into an older gauge face/cluster a bit harder, as you'd still have to find a way to drive the trip meters.

-

1 minute ago, Roman said:

Hey,

IF you run your tacho as an output from the ECU, then instead of allocating it as being just a tacho, you can make it a GP PWM table.

Then you can output a frequency and/or pulsewidth that corresponds to each rpm point on a table, so you can get it 100% accurate even if the zero point of the needle of your swapped in unit doesnt line up.

You can do the same with a speedo too, I did this to both on my Carina because neither of them were accurate at various points on the gauges.I will probably do this. But I know others who are still running points/etc that might like one, was hoping I could develop something for them too.

I guess I could try and use the speedo too. What did you do about the odometer for the speedo? The stock one is mechanical and I guess is needed for a WOF.

-

This looks like it could help me, especially if the the EG and EK tacho units are the same.

https://honda-tech.com/forums/honda-civic-del-sol-1992-2000-1/eg-civic-tachometer-repair-3336440/

-

19 minutes ago, tortron said:

They often have a pot you can calibrate them with. That's how I gutted my mechanical GN125 one and fitted an aliexpress electronic one

The ali one had a pot?

-

Based on that image then, that might work well enough for me.

I wonder if there are any other ways I can calibrate the tacho without using an ECU?

-

29 minutes ago, mjrstar said:

I have the digital output from my ek civic ecu, tacho is probably within about 300 rpm I reckon.

That sounds ok, unless it's always 300rpm less!

-

A follow on question, how accurate are tachos? Obviously your eyes can't actually see micro variations in rpm and translate that to a number, but how close is close?

I found this EK Civic tacho is is pretty darn close. I'd hazard a guess that if I used this unit it would not be that noticeable. I laid it over the Gemini one.

-

3

3

-

-

9 hours ago, kws said:

You could use something like this, https://spiyda.com/smiths-rvi-rvc-conversion-external.html

Its the same guts, just in an external box, that im using in my tacho for the Marina. https://tasteslikepetrol.net/2021/06/project-marina-tacho-conversion/

Calibrate it via frequency audio files and then drive it with the coil.

Thanks, this looks interesting.

8 hours ago, kpr said:if drive tach from your link ecu, you can change the multiplier in the software so it reads correct.

I will be driving it from my Link, but I was hoping to create something that might also work for people who are still running the stock dizzy or a different ECU.

-

1 hour ago, Bling said:

For the face you could have someone 3D print it exactly how you want it to look.

I'm already all over that part. It's making sure that the needle is in the right place that is the difficulty.

Connecting clamp style hoses to braided

in Tech Talk

Posted

Interesting. I assume that the gate powergrip clamps have some kind of adhesive in them. I wonder how that would react to the brake fluid if any managed to sneak around. It's not pressurised, though, so should be okay.