-

Posts

2,353 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Kimjon

-

Nowhere near enough to even remotely trouble it. They're 1340cc capacity and an unimpressive 70hp stock. The low hp figure is because they only rev about the same as a small block chevy, so say around 5700rpm if it was screaming Vs sportbike 18000rpm. My motor has been freshly rebuild with an Andrew's camshaft and all new parts etc...it will put out a little more than that, but it's no hayabusa for sure.

-

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

My parents asked if I could build them a shade house. Sure...no problem. Think my parents are planning on growing dope to fund their retirement? (***this may or may not be true***) Makes good use of a wasted space (sloping ground above septic system). May not tick council boxes for step backs from boundary, but I'm sure they have bigger issues to worry about than chasing someone whose nearly 80 years old. They're going to wrap it in shade cloth in their own time, so think my job is done. -

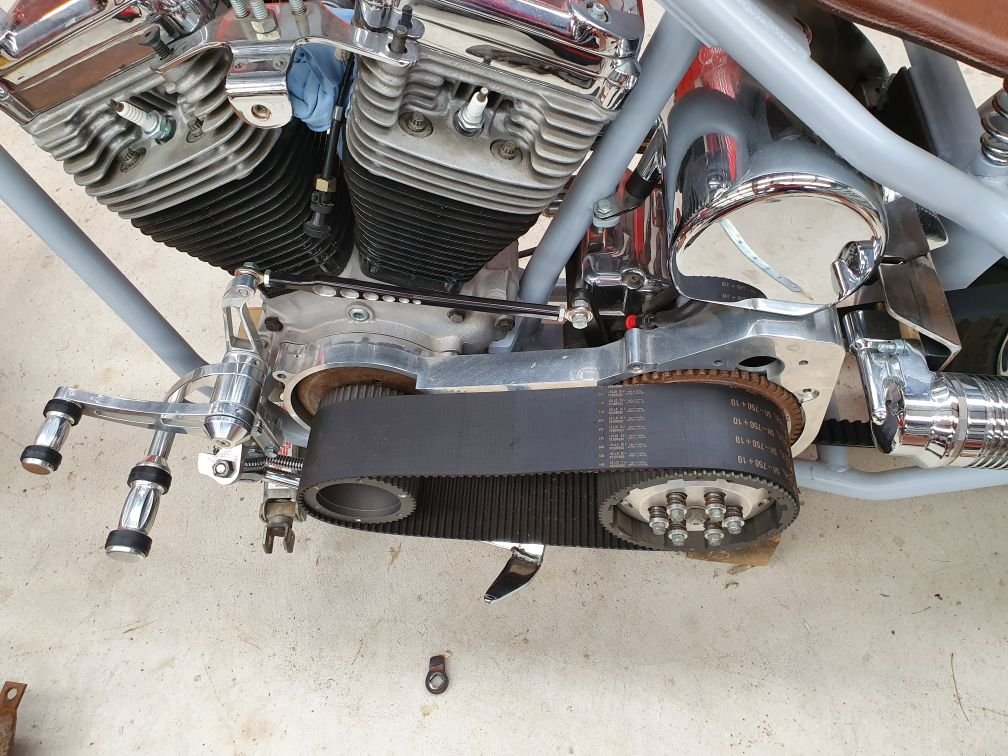

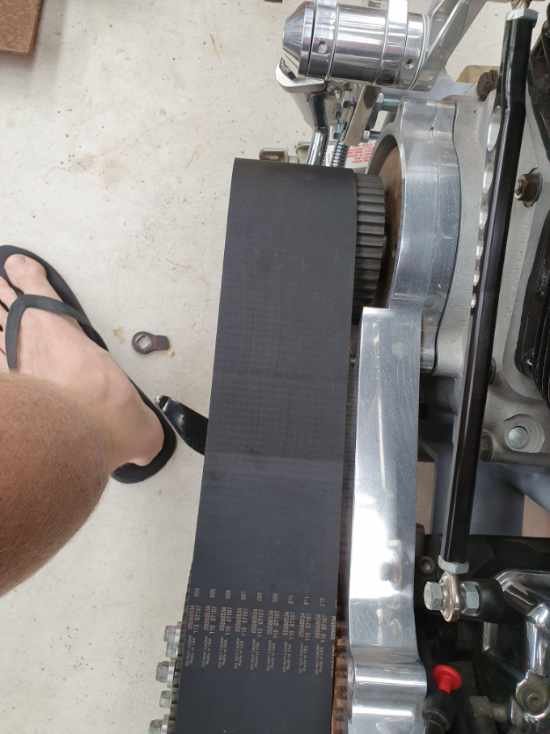

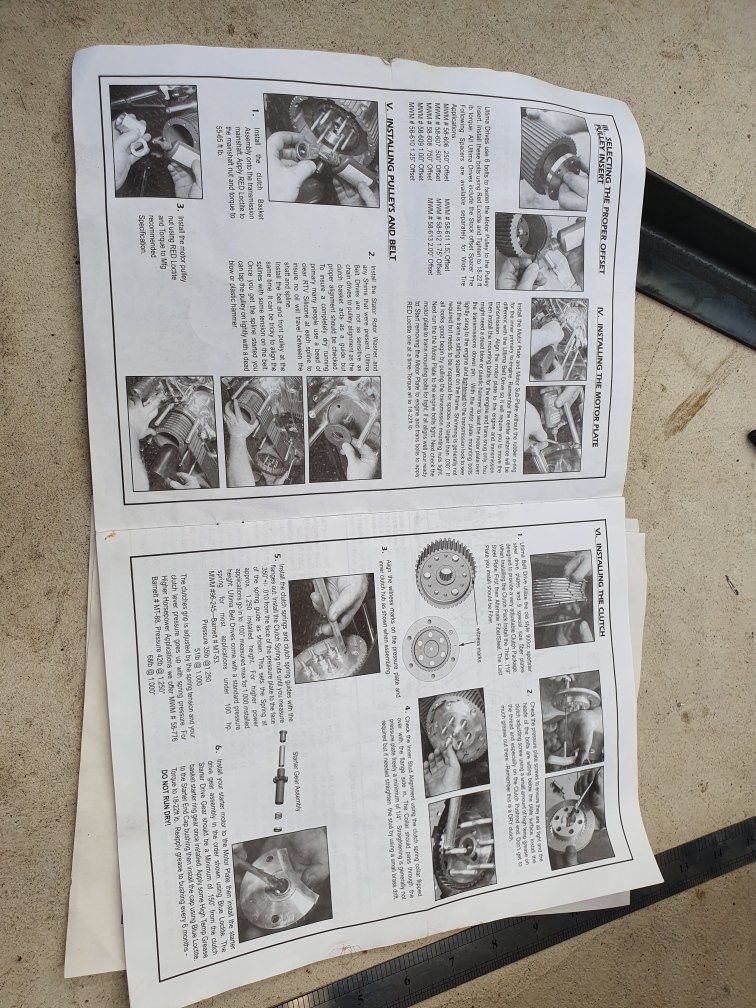

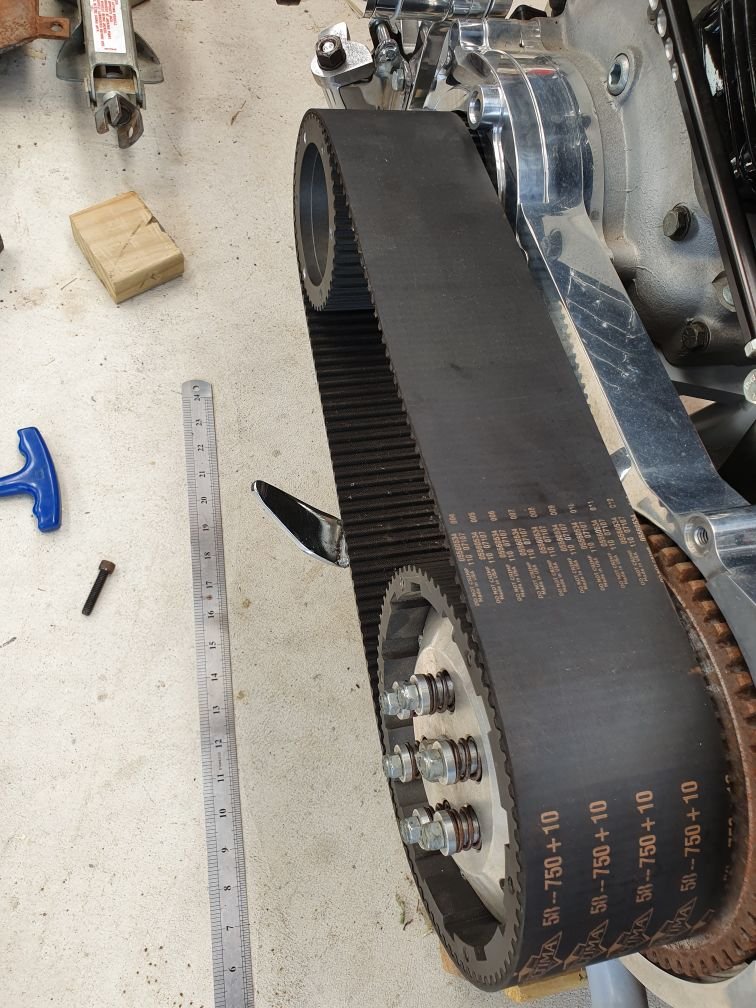

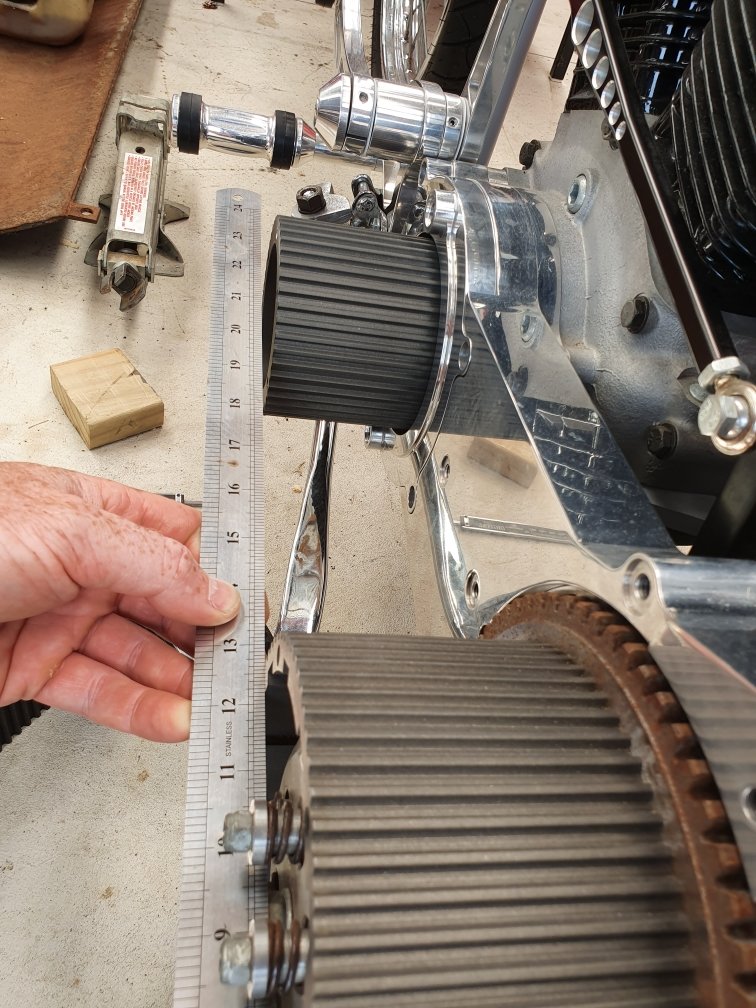

This is a job I've been putting off for a longtime. The pulleys didn't align correctly. Theres a 4.8mm difference between front and rear. Hmmm...yadda, yadda, yadda...something about using shims and a stator washer...yadda, yadda, yadda...blah, blah, blah. Instructions weren't a lot of use. What fucking shims? What fucking washers other than those already normally used on the motor??? Certainly would be helpful if they supplied these parts if you need them to make their kit work, one would think? But alas nothing like that came with it. However, as I've mentioned before; no problems just solutions... And test fitting after much time spent machining this up... Fuck yeah, like a glove!

- 299 replies

-

- 12

-

-

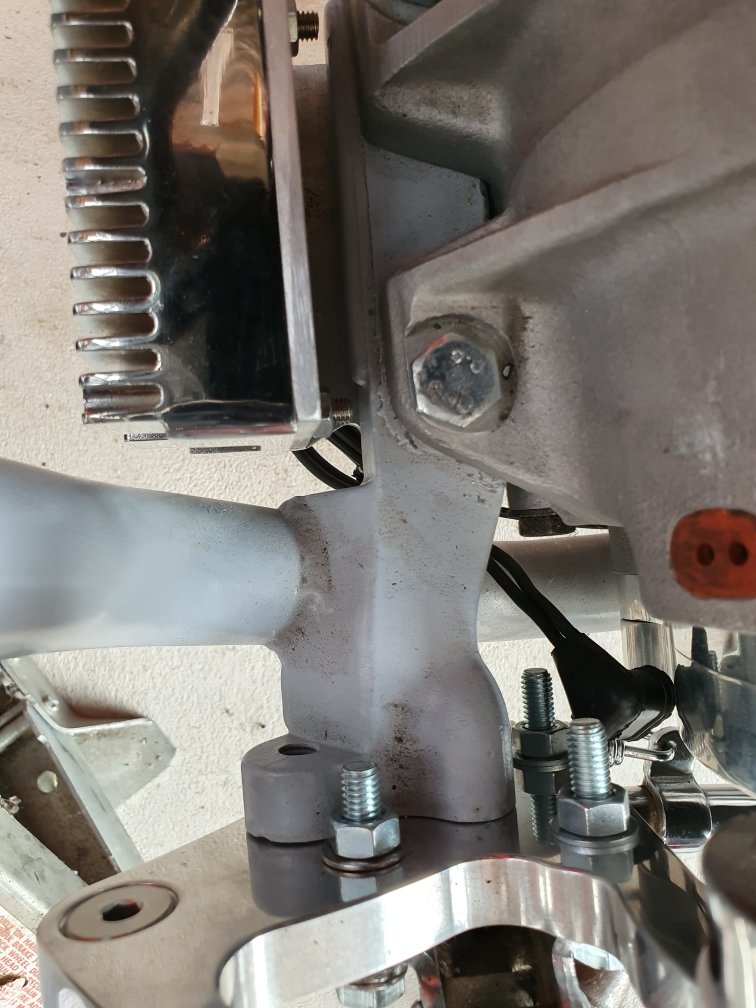

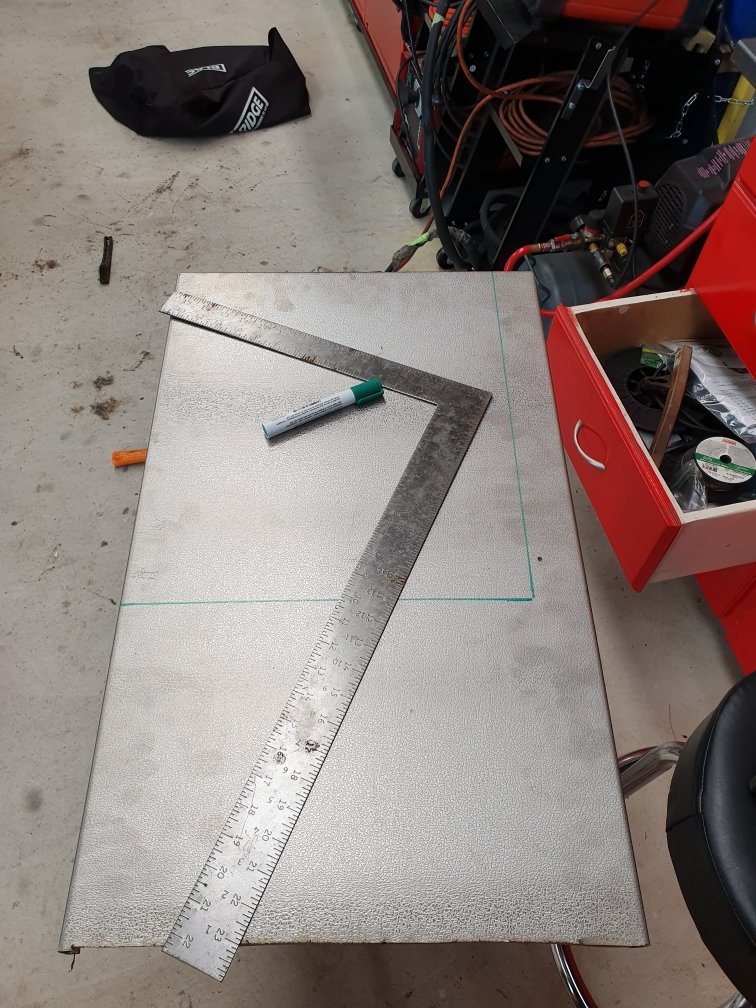

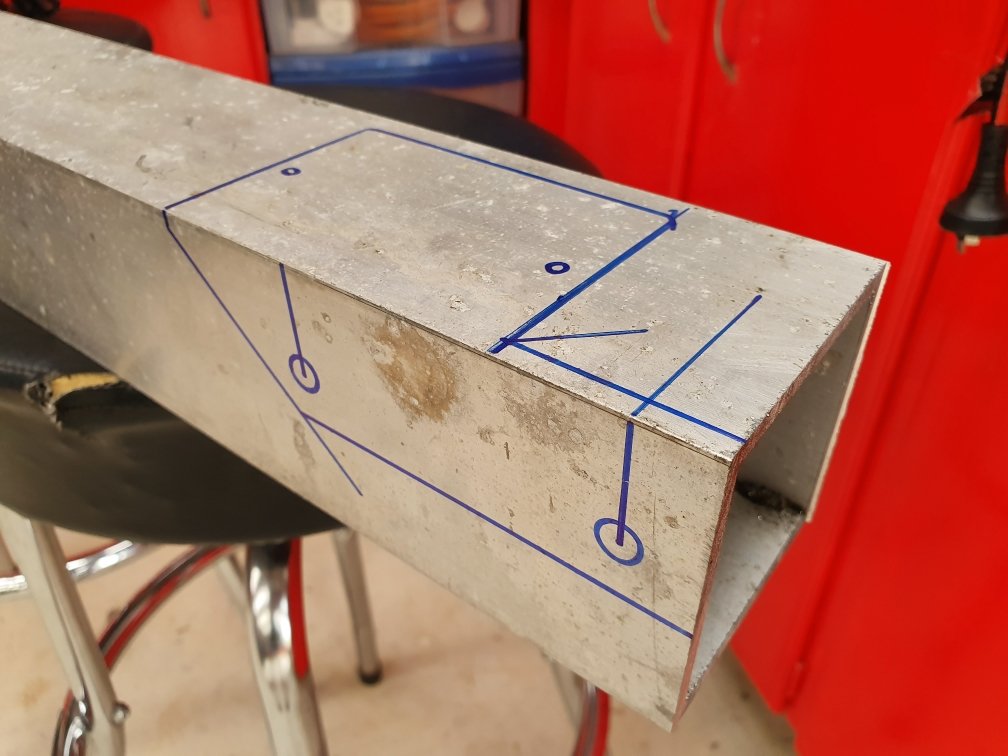

Okay, some days I actually struggle to take myself seriously. All of the above justification was complete bullshit...of course it not been centred annoyed me. I was totally lying to myself, in the same way a teenage girl heading away to university says to her boyfriend that she wants an open relationship and be able to date other guys - but everything is going to work out fine between us. Or your wife tells you that her Google search history of huge black Congolese cock is because she has an interest in anthropology. Anyways I digress. OCD is strong in me, and it just didn't sit well...literally! So fuck it, I faced up to myself and made it again, but different. Marking out. Finished bracket, sandblasted to match motor cases. Sitting in the center of frame. View from afar. Looks more in balance now, with it centre of frame tubes. Much happier now, I can actually look at myself in the mirror and finally take myself seriously again...thew!

-

My OCD kicked in and I was about to make another bracket. But then looking at how the motor sits in the frame from above, it's not like that's centred. It also looks like a lot of free space on the bikes RHS however there are brake and clutch lines yet to go in there...so maybe that space might come in handy. So talked myself into leaving it for now.

-

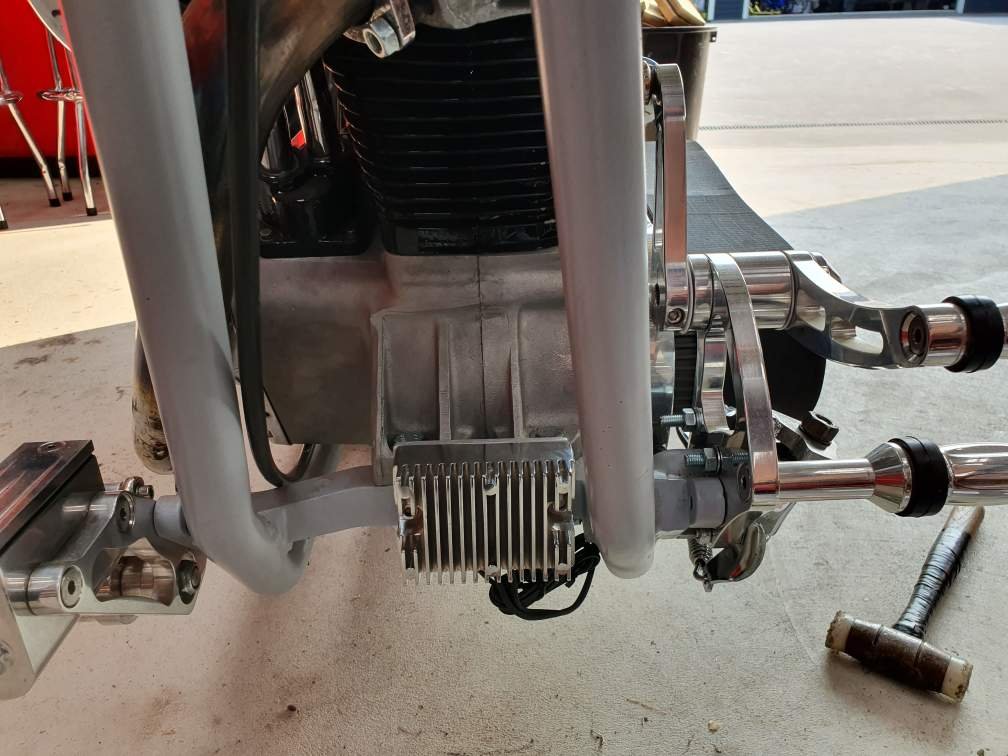

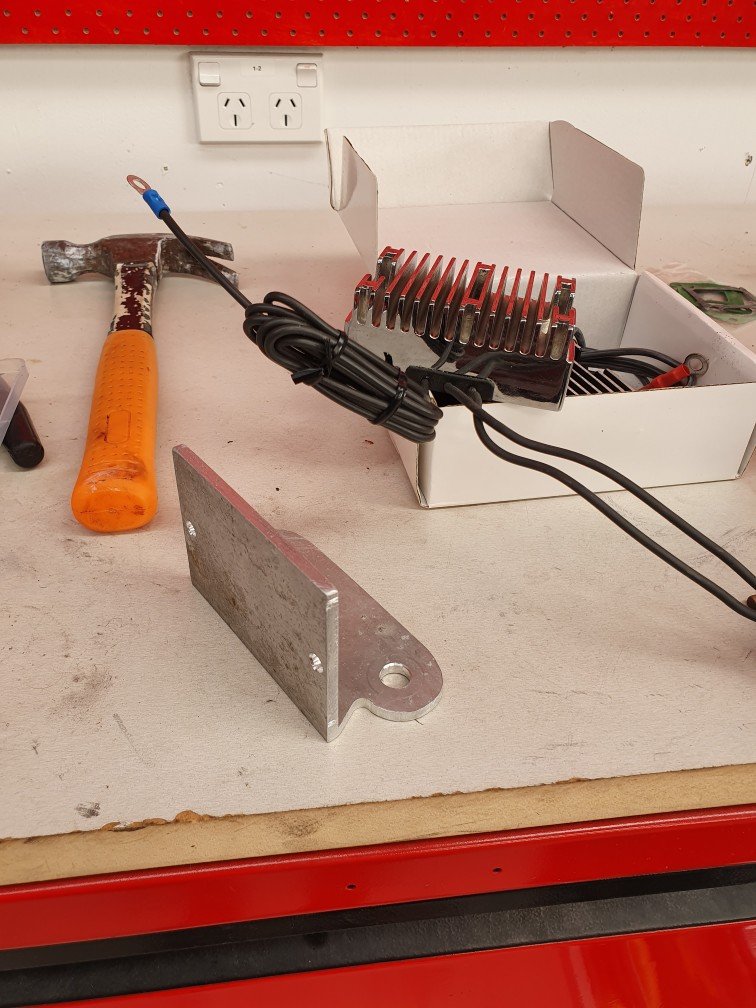

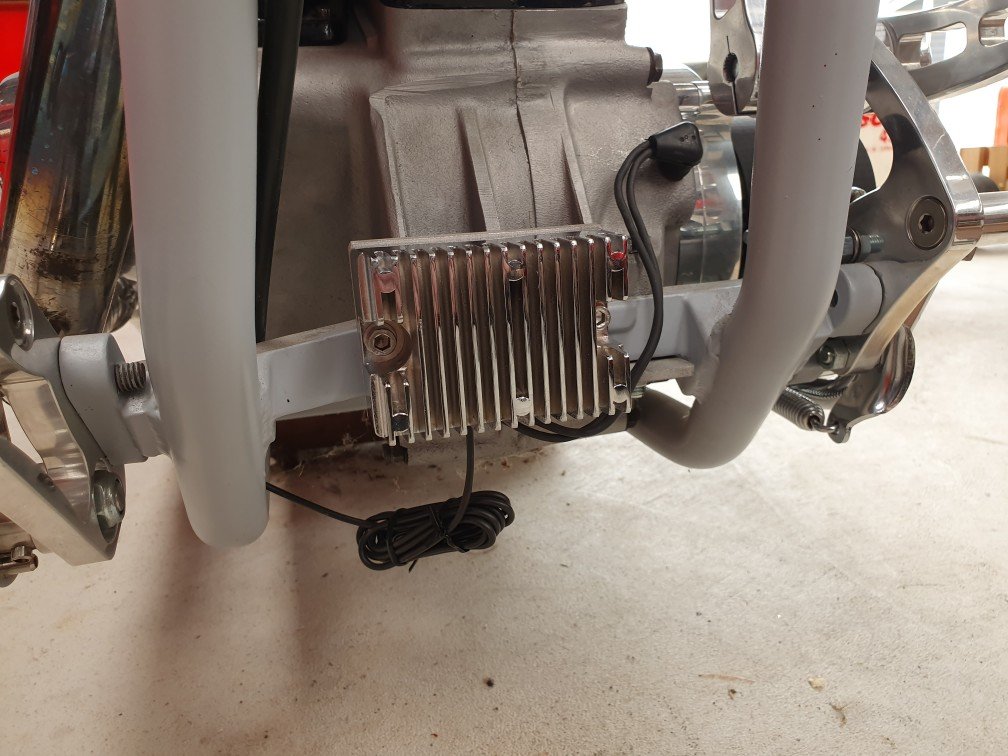

Regulators, bit of a headache. I have a 23amp stator and a 32 amp rotor. I brought a 32 amp regulator...but the pins are wrong size. So I brought another one in 23amp...which fits. My understanding (elec-trickery isn't strong point), is that the rotor is just a magnet and isn't going to affect the stator adversely and cause it to make more power. Plus if the demand is low, the system wont be making anywhere near 23amps anyways? So assuming thus to be true, I'm pushing onwards... 32amp, wrong pin size. Making bracket for 23amp regulator. I put a hook in the bracket for wiring to clear. And all done. I'll give it some saturation time for it to grow on me. I hate that it's not centred...however neither is the crankcase of this motor. In fact the entire motor is way off centre...so maybe it really doesn't matter? I can offset the bracket to force it to the centre if it really does fuck me off, but for now I'm not sure how much of an issue it is. Put it this way, I'm not in love with it...but I don't hate it either.

-

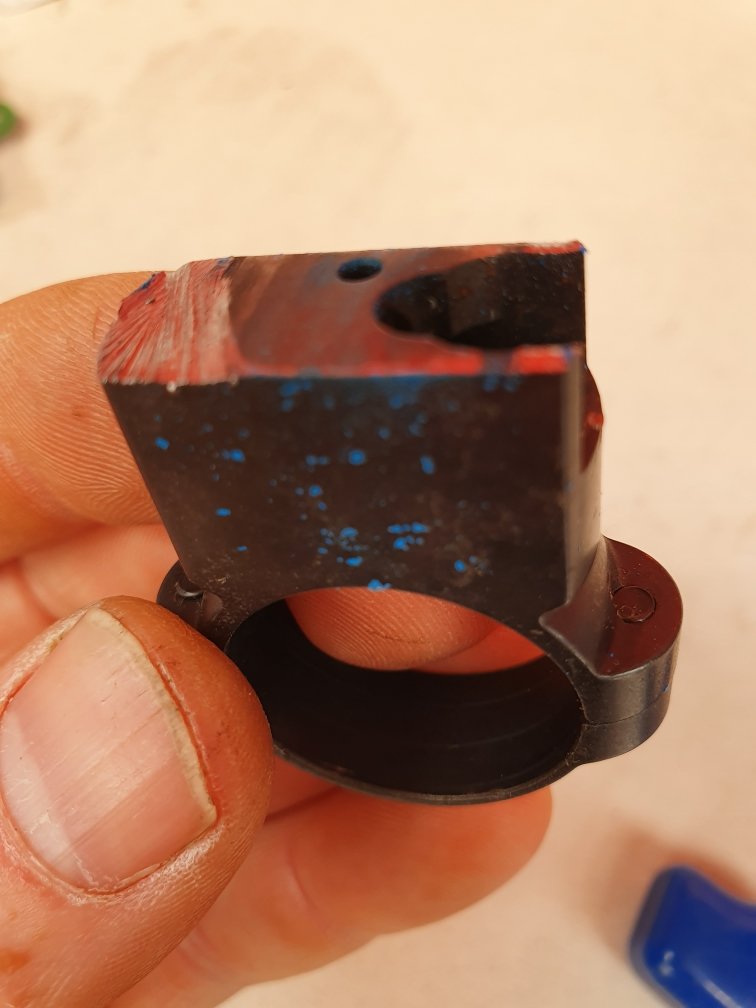

Jiffy-stand or kickstand; depends on what school you went too? Call it whatever you want...it doesn't change the fact they are an essential item on a bike. Now, the shitty thing is that Harley never made it to work on my one off custom bike I've made, that they don't know exists. Further more the shellfish engineers at Harley never designed their bikes with open primary drives like I've added to mine. So using factory Harley parts on a non factory bike "just ain't gonna work!" No surprises there. A look on Google didn't reveal any great solutions. Sure TC bros make a weld on stand, as do others...but if you take time to read a review or two, (unlike the headline only reading generation we seem to be breading) the people who actually have one of these dont rate them highly, saying not to park facing downhill the stand will fold back on itself very quickly and you're going to be picking your bike up off the sidewalk. The factory jiffy stand mechanically locks on a pivoting cam lock mechanism when the weight of the bike is on it, which is genius! Sure you don't want to really park any bike facing downhill...but with a factory original you can get away with less than ideal situations. So, the problem: The stand hits the primary belt drive. Easy - cut it off so it doesn't? Nope...that solves one problem and reveals another. The stand then dissapeared under the belt. The belt is direct drive to the motor...so its alway turning if the motor is running...aka "meat grinder" I had a sportster harley kickstand that took a hit for the team. Bit of metal hot glue action. If it all works out I'll get it chromed. Next issue, the stands locating lug wasn't working as it should. The stand could go past centre and fold back on itself. I needed to make a different design to factory to solve my first issue of the stand disappearing under the belt and the stand not really stopping where it should. This did the trick. Black one is factory part, new one installed is my new and improved version. The position shown above is folded back in the riding position. You can see I've added another lug/stop that limits the amount it can fold back, this keeps the tip of the foot hanging out enough so you can (funnily enough) kick it out, safely without putting your body parts too close to the "meat grinder"! You can see the tab just sticking out enough to get your foot safely on it with jandels??? Weirdly it's not in the way, as the riding position with the seat located way back forces you to put you feet behind and outward from the kickstand when balancing the bike in a sitting position. This wasn't intended...but I'll take dumb luck like this anyday. I'll leave it like that for now, and if need be I'll tweak it for extra ground clearance if its required...though I doubt it, as its hardly the type of bike you'll be dropping a knee on the ground during corners eh. The stand has about 30mm of upwards movement, so if it did ever touch...you'd hear it and still have a factor of safety of 30mm which is like 200mm of lean at handlebar height. So yeah, a fucking very long story about a simple kickstand...but its these shitty little problems that often take the most thought and effort to solve.

- 299 replies

-

- 10

-

-

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

Needs dark stain and add angle iron to the corners to tidy up those edges...then call it done. Like this...but imagine both corners floor to ceiling. I don't have any on hand, so need to wait until shops open maybe in a weeks time? The dark stain will make it all tie in, should really pop with the contrast and imperfections etc... -

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

Trying to make a timber feature wall. I brought 100 fence pailings (100×25×1000mm in size) at $0.85 each, some black thermo paper at $32 and that's about it really. I cut the gib at the cornice so I wouldn't have to redo them. This created a 20mm gap (10mm cornice, 10mm gib). This allows me to buzz the top boards down to 20mm so it doesn't look silly where it meets at the top. I thought about this problem obsessively until coming up with this as a solution. Fucking stoked with how this part turned out, as it would have looked ridiculous if it didn't do this step. I put black paper on the wall so if the boards shrink, the gaps will be black behind. also added more studs, so I could be a bit random with board placement. I didn't want it to look like bricks...all neatly stacked. I was more after a random rustic look. I ran each board over my 10" planner/buzzer to tidy up the surfaces. I did each board a different number of strokes varying the thickness of each board, once again to make it more random looking. I'll finish the corners in angle iron. The timber will be stained a dark colour. Then next is to make a new bed frame to try move my life out of the 1990's... -

Kimjon's - 4 doors more whores (64 Impala)

Kimjon replied to Kimjon's topic in Projects and Build Ups

Okay, I'm totally over working on cars right now...its time to go enjoy this thing and hit the streets.- 35 replies

-

- 22

-

-

-

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

On a mission today. Rifle scope mount welded to angle iron. This will hold a solenoid valve, that in turn is connected to a timer switch. This will automatically drain the water out of my compressor... Test fit Yup, nice! This will work, so paint it and install it tomorrow. Small things...but makes life easy if you never need to think about it again. -

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

Straight to the pool room! I had some scrap stainless steel that has been taking up room in my shed. The plan always way to make something furniture related, however I only had a limited amount of material to work with. After some careful thought, I realized that I could make a bench seat out of it, and not a scrap more... Cutting and tig welding it together along with some smacks from a big hammer...all this activity at 8am is sure to please your neighbors? *Insert bender joke* Folded and tig welded to keep it together. I had to do it this way due to the sizes of the scrap I had to work with. And finished. It's not perfect...but I had to work with the limited resources I had. Theres a few dia4mm holes in the left side that were in the material already, but hey you can hardly notice it and it was free...so calling it a win! -

-

Added a chainsaw style "pumper carburetor". I had to make an adapter manifold for it all to work. Luckily the spacing on these carbs is fairly standard on most chainsaws, weed eaters and gopeds. So I was able to mill up an aluminum plate and use a goped thermo plastic manifold to adapt it to the pocket bike engine. This is far better system, as these carburetors are fully tunable with a needle screw. Way better than fucking around trying out different jets and settling on something that's never quite right but runs. Another advantage is you can mount the tank anywhere, as it pumps its own fuel, unlike the gravity fed carburetor that's now filled in the rubbish bin!

-

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

Unlikely, there's about 300m2 of concrete with a purpose built turning bay facing the other way to back into. However if one of my wives friends comes for a visit...who knows, I wouldn't rule it out. Some of the fucked up positions they wedge their vehicles into always has me scratching my head in bemusement!?? -

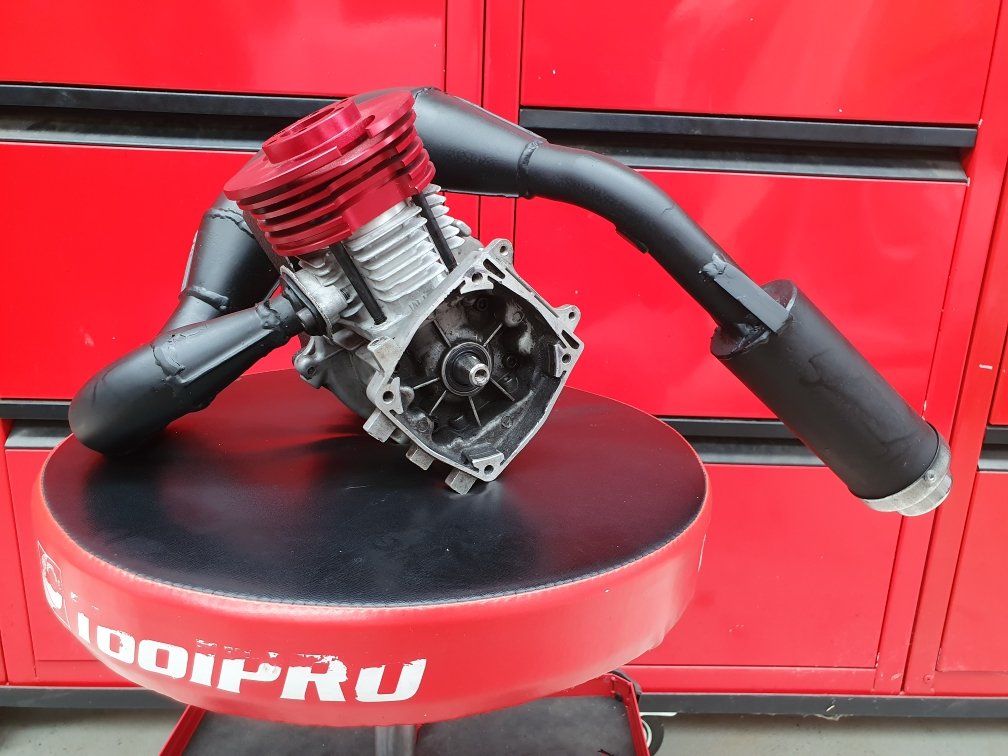

Started assembling the motor. Missing some keys for the crankshaft (both clutch and flywheel key onto a tapered shaft). But other than that its pretty much all there. All new SKF bearings and oil seals going in. Cutting gaskets to match the bigger ports. Thermal conductive grease, helps heat transfer from cylinder into top heatsinks. Long block fully assembled. I skipped heaps of boring steps...but you get the idea. That's as far as I can go without the 2 missing keys, but fuck yeah...its looking the part anyway...

-

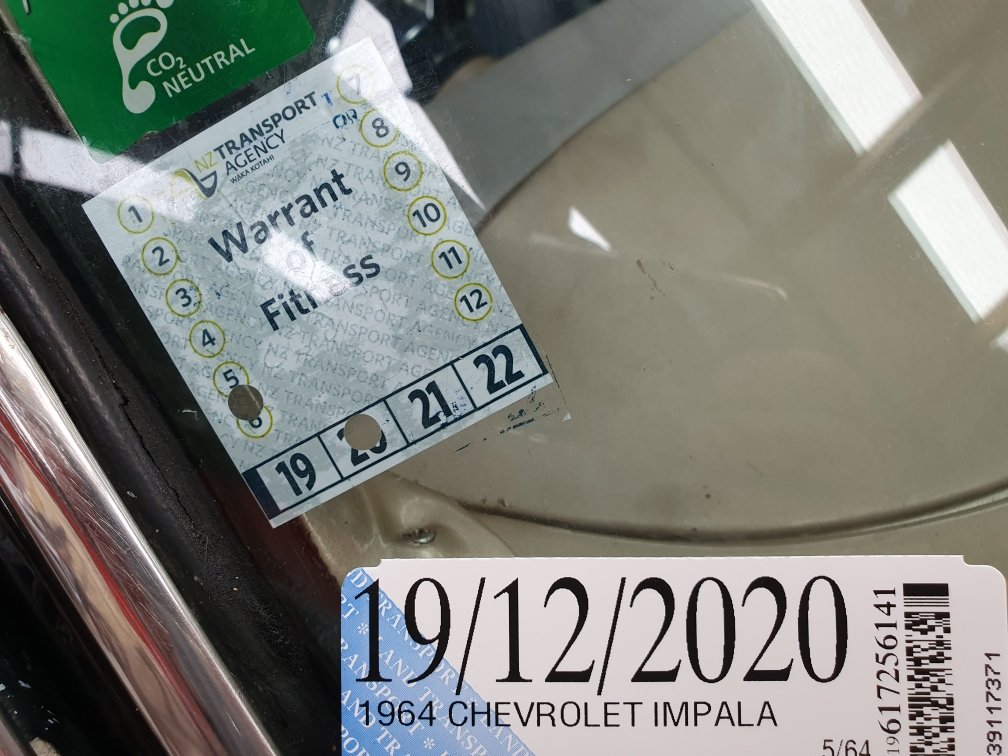

Kimjon's - 4 doors more whores (64 Impala)

Kimjon replied to Kimjon's topic in Projects and Build Ups

New shocks in front: Rides like a dream now on new shocks, plus all new ball joints and springs all done within the past 6 months. And legal as fuck! WOF/REG/CERT...fuck yeah!- 35 replies

-

- 17

-

-

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

Now you may be wondering how I achieved this engineering marvel... Well there's an entire chapter on health and safety written on the use of ladders... I ignored all of it, getting this 80kg colossus glass backboard all the way up there by myself. Its wose than you'd think, the glass backboard is one part, the hoop is separate again, and all of it is held in place by 4 M10 bolts with next to no room to access them. #suffersfromashorthose -

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

-

Kimjon's - 4 doors more whores (64 Impala)

Kimjon replied to Kimjon's topic in Projects and Build Ups

Yes!!!!! No reason why it shouldn't have, but I live with an irrational fear towards all things vehicle related that others have to approve... #wofphobia- 35 replies

-

- 15

-

-

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

My kids keep hanging onto my house garage door like monkeys and getting lifted up by it as it opens...little fuckers@!!! No matter how much I yell or threaten violence (that's half true) they wont stop, until I hear "dad...dad...dad...!!!" Yup - door finally shit itself. Quick YouTube tutorial and I'm suddenly an expert on all things doors... Springs pretension set. New track with a belt drive to replace the now fucked chain track system...and viola...all sorted. -

Definitely go hydraulic, those cable calipers just don't have the balls to pull these things up.

-

-

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

I was thinking of adding a pivoting arm that I could hang my water blaster off, kind of like those washworld places. But yeah, it will be used for the above for sure, as current I hang the odd deer in our house garage much to my kids delight and my wife's disgust. -

Random slightly cool stuff you built but not worth its own thread, thread

Kimjon replied to h4nd's topic in Other Projects

Had a full day off, which is rear lately. So not being one to waste a minute of the day... I'll give it a day or more to cure...then attached the backboard to the pole. Ridiculous over engineering at its best, but it looks semi authentic. Stickers and all from its stadium past, as a former lighting tower from a sports stadium now repurposed to continue bringing joy to people in it's new form.

.thumb.jpg.f426f267bd65c292e82b12db729522d2.jpg)