-

Posts

2,350 -

Joined

-

Last visited

-

Days Won

2

Everything posted by Kimjon

-

-

Ah, so the lack charge coming in definitely points towards alternator then eh. I found a refurbished one on rock auto for $33+$45 postage. I'll have a think about it, may look at upcoming swap meet too?

-

Is the regular a part thatbi can replace? Or do I need a new alternator? Fyi, its a sbc 283 motor in impala.

-

Back to the problem. I'm thinking I take it for another run, wait until the charging stops on the Bluetooth app, pull over, test alternator at direct source? This should tell me if irs actually the alternator, or if its the battery?

-

Seriously cool bit of tech. Only $30 off ebay. My main use is for each vehicle I have, with an alarm set at 80% remaining charge. So I sets off an alert for me to hook it upto a charger.

-

Here's my story: I noticed my car wasn't starting after a 30 minute drive. I'd have to wait until the motor cooled before it would crank. I brought a Bluetooth battery monitor and it shows this: Basically the ctek charger brings it to 12.8v give or take. Over a month, when not on the ctek it slowly drops to say 12.6v. When I drove it today, it showed initially 15v of charging going on for about 10 minutes. Then it just drops from there on to about 9v as I got home after half hour drive. It wouldn't turn over when I stopped it and tried to started it. So battery seems to not be receiving a charge after 10 minutes? Battery problem? Alternator problem? Other? Its back on the ctek and looks like its taking a charge okay. So my intuition says Alternator? But im an electrical retard.

-

My new bike was purchased as a roller, with a blown engine. I paid fuck all for it, so all things considered im still very happy with the deal. However its obviously been raided for parts while the dude left it at the Honda shop. Its missing little bits like nuts off swing arm bolts, radiators, a few plastic bits, swing arm spacers, exhaust header, etc etc, probably an icecream container somewhere holding these bits, or maybe been used to fix someone else's bike? I can live with that. The blocks that locate the rear axle into the swing arm were missing, so that was today's efforts: So: And tadah:

-

I work with cables for supporting structures for a living (yes, laying a cable is a standard joke). The rated shackles etc are really cheap. It would be less than $10 to buy a D shackle rated to lift an engine. Shaws or Cookes are the 2 biggest companies in nz for this stuff. In saying that, the dodgy Chinese chain on most engine cranes would probably be your weakest link. From my own experiences with Chinese made stuff, the ratings painted on the side are mostly fictitious. My engine crane folded and crumpled lifting a mates concrete bathtub. There's no way it exceeded the claimed capacity.

-

Then the blue vespa got the same treatment. This too had ample meat on the pads, but the entire front end shuddered under braking. This made a world of difference. Shudder is gone now, smooth as. I did an aggressive chamfer on the edges of the pads, I'm not sure if this makes a difference, but the old pads had squared edges and so did the replacements. The chamfer makes sense to me, so I put it on just cause.

-

Finished charging the impala, now its working its magic on the buell. I've got it set on motorcycle and reconditioning mode. Ctek recommend doing reconditioning mode at least once a year, so seems like a good idea to start off this way. The leds show that the battery wasn't very charged, so its a good save.

-

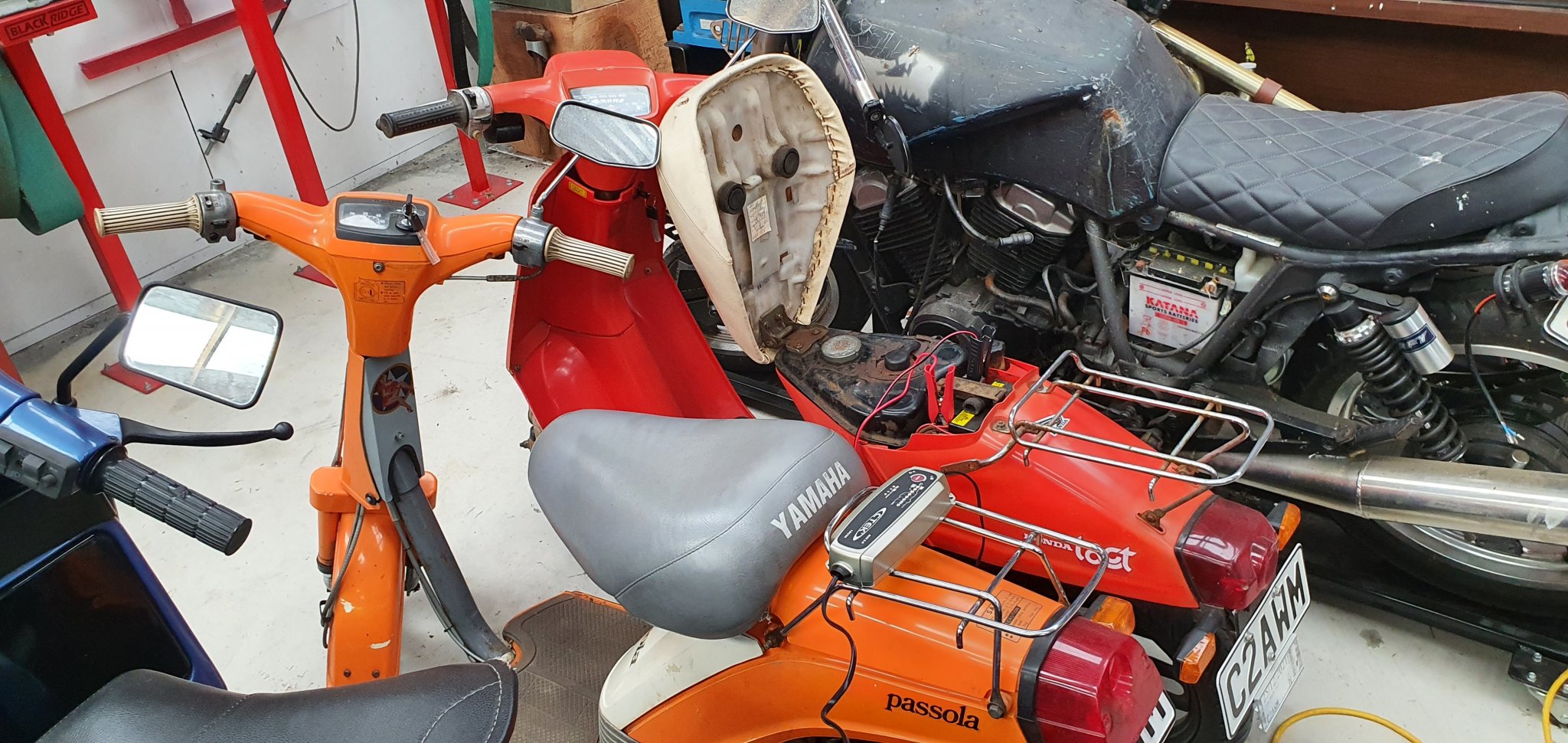

@flyingbrick put this idea into my head. I kept putting it off, but the other day as prophesied my buell nearly didn't start. I'm having similar issues with the impala as well, and going into winter these vehicles will receive even less use. So: Mmmmmmm...ctek...mmmmmm All that said and done, now all I have to do is unlock the rear compartment using the key, plug and play. Sweeeeeeet!!! Doesn't get much easier than that eh...or does it? I've ordered a Bluetooth sender, that will send live data to my cellphone on my battery condition. Same as this ^. If it works, I'll grab a few of them for my other vehicles with batteries. Fuck yeah, quite excited about it.

-

Thompsons track mission today with a few mates. awesome line up of 2 wheeled vehicles. Us posing for a photo about halfway up. About now we're seriously thinking that the track is so fucked we may not make it to the top, so we'd just pretend we made it. Another regroup at the actual top. quite an achievement given the current conditions of the track. heading back down, this photo captures the typical condition of the track. There were much worse sections, where my spirit still remains buried and forever lost to me somewhere in the mud. It was a great day, but I'm battered and beaten. The XR250R did so well, its a solid bike for sure.

-

-

You genius!! Solved that problem with precision and style...

-

That's just the stock motor. Its actually not that bad, it moves it along at a nice predictable pace, enough power to have fun with...but definitely not fast in any way. Years ago I had a YZ125 and it was rated at 37hp...it felt twice as fast as this XR does, so I'm not sure hp is a great measure of how a bike "feels" to ride? I do like this XR though. Its a solid bike thats such easy-going maintenance wise.

.jpeg.4abeb5253458a5b2a474691133c35f82.jpeg)