-

Posts

1,719 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Flash

-

First thing this morning I pulled the gear selector base plate and pivot pin out of the vinegar bucket. Front end of base plate is looking mint as is the pivot pin. I've put the other end of the base plate back in the bucket and hopefully that will sort out the last of the rust.

-

Kicked the day off by pulling the gear selector bits out of the vinegar bath. Gave them a quick rinse in warm water and they are looking lots better. The base plate is back in a vinegar bucket to do the front part that hasn't been in the solution yet. I also dropped in the pivot pin as the flat end is still looking a bit crusty.

-

- 740 replies

-

- 14

-

-

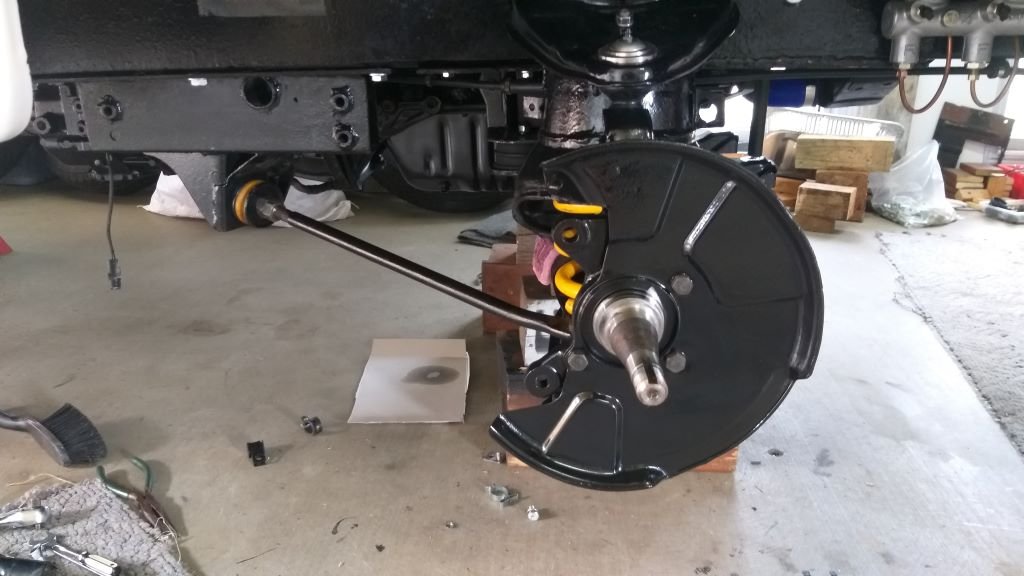

I've spent the last few mornings rebuilding the rear brakes with the best bits harvested from the two Toyota back axles that I have. The backing plates needed a good clean and I gave them a protective coat of fresh paint before assembling everything. Managed to get the back axle re-installed just before I packed up for the day. Tomorrow I'll install the drive shaft and back shocks and then it's just a case of connecting up the rear brake line. It's going to be interesting to see how bleeding and testing the brakes goes.

-

Took a trip to the local wreckers today and picked up a replacement Mitsi Express gear selector mechanism to replace my current one which has seen a bit of hackery in the past. Looked suitably crusty but I stripped it down and then gave it a tickle with a wire wheel and its now languishing in a vinegar bath. I've got the bushes and swivel pins soaking in degreaser. Will give them time to mellow and then a quick spritz of paint and it should be good to go.

-

- 740 replies

-

- 14

-

-

Vegetable eating day today. One you don't look forward to, but you know you'll feel better once you get through it. Used a combination of degreaser and the wire wheel of death to clean decades worth of crust off a few rear axle related parts. The smaller brackets are now languishing in the vinegar bath and I rewarded my efforts by splashing a bit of "eau de rattle can" on a few of the bigger parts. I'm hoping that the calliper paint will be okay on the rear drums.

-

Slapped a few coats of 2K black on the rear axle today. In between coats I gave the gear selector cover a light tickle with some sandpaper so it's now ready for a splash of primer next time I've got a gun full.

-

And that's the Thames spring perches and shock mounts all glued on to the HiAce axle. Celebrated the occasion by splashing a bit of primer about the place. One more coat of primer to go.

- 740 replies

-

- 11

-

-

Speedo Cable - Chapter 4 With the way forward finalised all I need to do is give the cable a bit of a birthday before I chuck it in. Talking about that there is one minor snag. The cable needs to pass through an existing 19mm hole in the cabin floor. Only issue is that the plastic retainer on the Toyota cable measures 24mm so I'll need to open the hole up a bit with my step drill. Hopefully I've got an appropriately sized rubber grommet in stock. I'll only know how accurate the speedo reads once I've done a road test. There is a place in Victoria who supply a little calibration box that the hot rod boys use on the 5 speed Supra gearboxes and I'm hoping that one of these will work with the HiAce speedo drive. Time will tell, I guess.

-

Speedo Cable - Chapter 3 I currently have the instrument cluster out for another round of wiring, so I figured it was worth seeing if the Toyota cable would fit into the back of the Thames speedo. Instant success! The square drive engaged nicely and even the moulded plastic bit on the HiAce cable clamps perfectly onto the speedo housing. Flushed with success I grabbed my battery drill and clamped the gearbox end of the inner cable into the chuck. Gave the drill a whirl and to my relief the speedo needle actually moves and is nice and smooth despite the fact that I haven't serviced the cable yet. I use the term speedo needle loosely as the speedo uses a little moving band to show speed. I’d forgotten this extra little piece of quirkiness. Yikes, I’ll definitely take the win. Photos to show the happenings:

- 740 replies

-

- 13

-

-

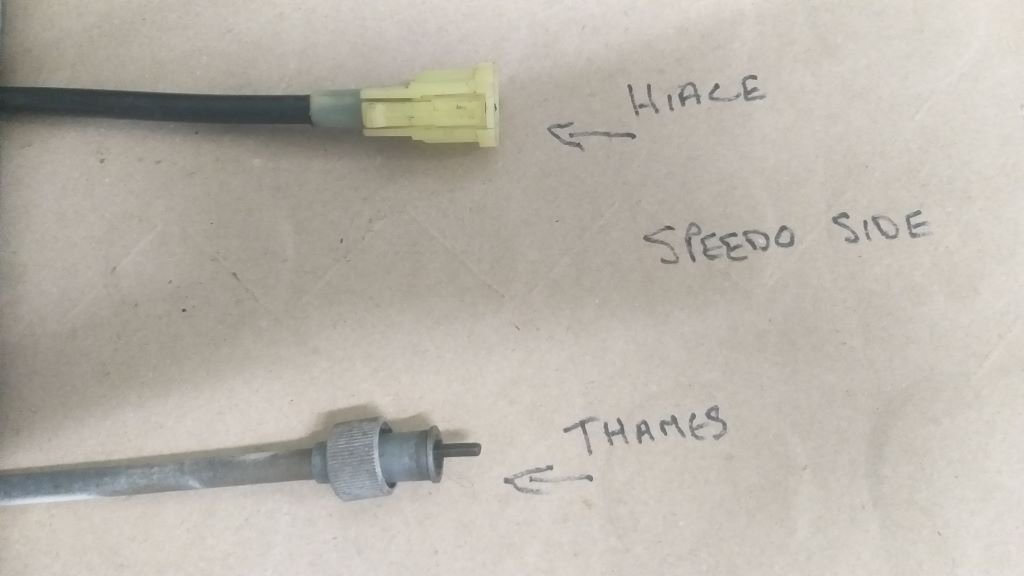

Speedo Cable - Chapter 2 Next I compared the speedo gauge side of each cable. Surprisingly the square drive on both inner cables look to be the almost the same dimensions. Who would have guessed? Looking at the outer sheaths the Thames one has a big nut whereas the HiAce one has a moulded plastic clamp. Again, side by side photo included below:

-

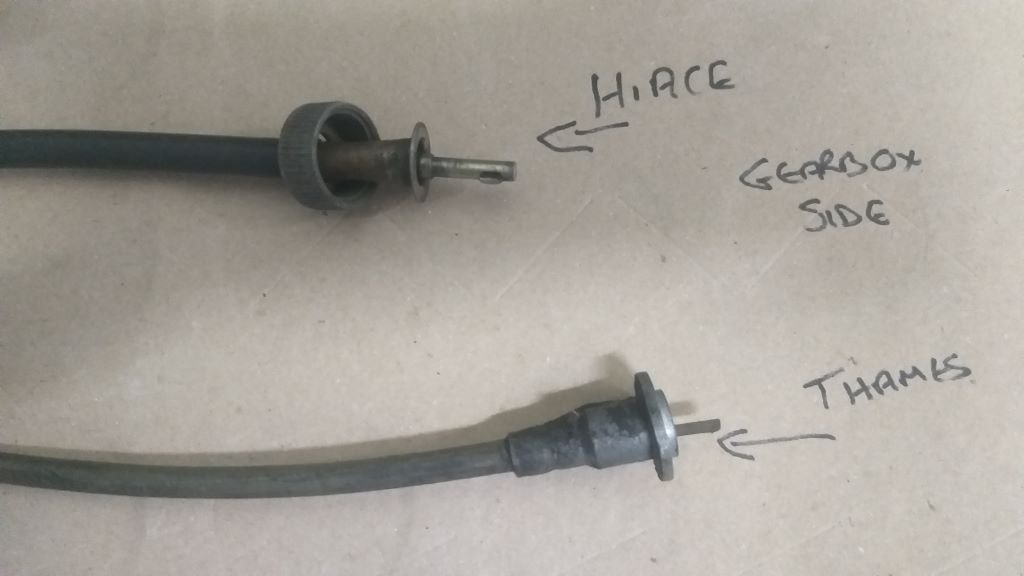

Speedo Cable - Chapter 1 I've been shying away from looking at the speedo cable for a while, but now that I am approaching the pointy end of the project, I thought I'd best put on my big boy pants and tackle the issue head on. Rummaged around amongst the shrinking pile of parts languishing in the back of the Thames and pulled out the original Thames cable as well as the HiAce one that I pulled from the donor van. Comparing the gearbox ends of each of the cables I can see that they are way different in terms of the way each inner cable terminates as well as the method for fixing the outer sheath to the gearbox housing. Photo below shows the two cables side by side:

-

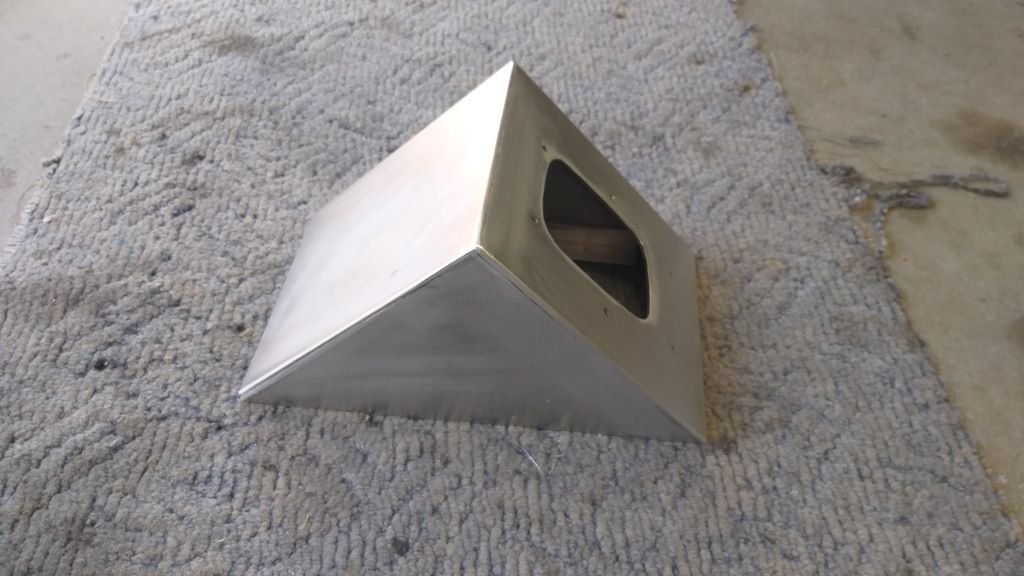

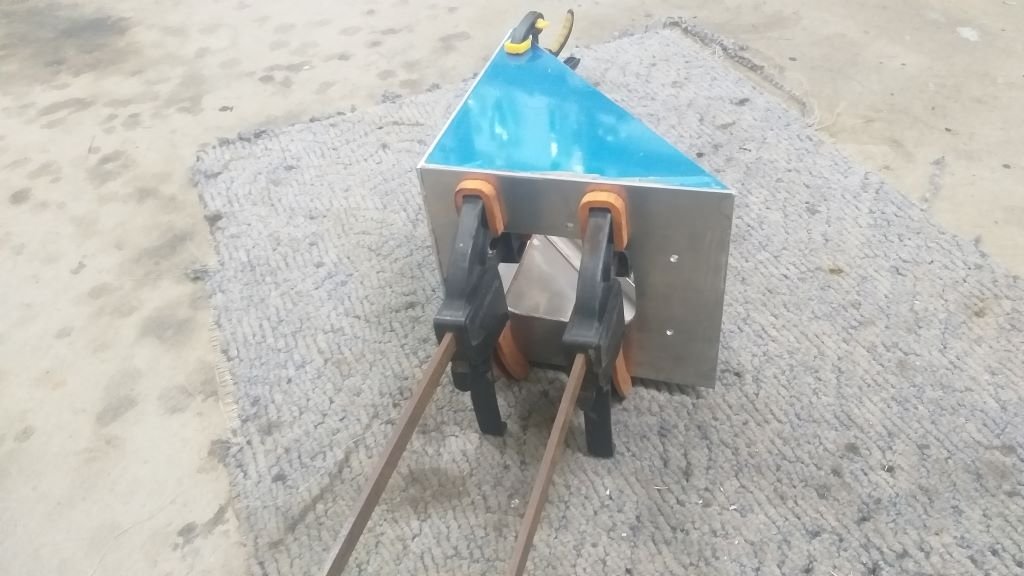

Just another fine example of the precision work undertaken here at Rough and Ready Restos. Last piece of the gear shift cover bonded into place:

-

I'm still slowly plugging away at the gear selector cover. The issue is having enough space for the holding clamps whilst the panel bond goes off so I've been limiting the activities to one panel per day. I'm due to bond the last panel tomorrow, so should be able to show you my handywork on Thursday. In the meantime, I've been finishing off some electrical related items. Today's focus was replacing the original sealed beam headlights with H4 semi sealed units. The sealed beams were mismatched, and one had blown which left the van looking like it had a black eye. So the H4s will be a vast improvement. Originally the front parkers were incorporated in the turn signal lamps which use a double filament globe. I purposely bought the new H4 units that have the little park light built in to the housing, so this morning's task was to reroute the wiring for the parkers. I ended up drilling a second hole in the headlight bowls and have wired everything up. Just need to wrap the wiring. I'm thinking of using a small spiral bind rather than cloth tape, so I'll need to source some. Thanks for looking.

- 740 replies

-

- 11

-

-

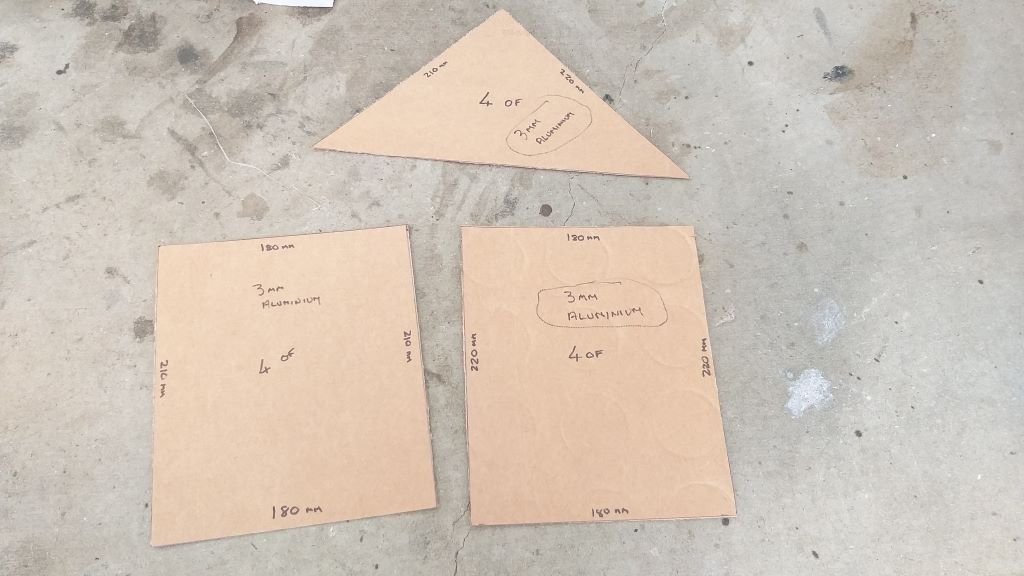

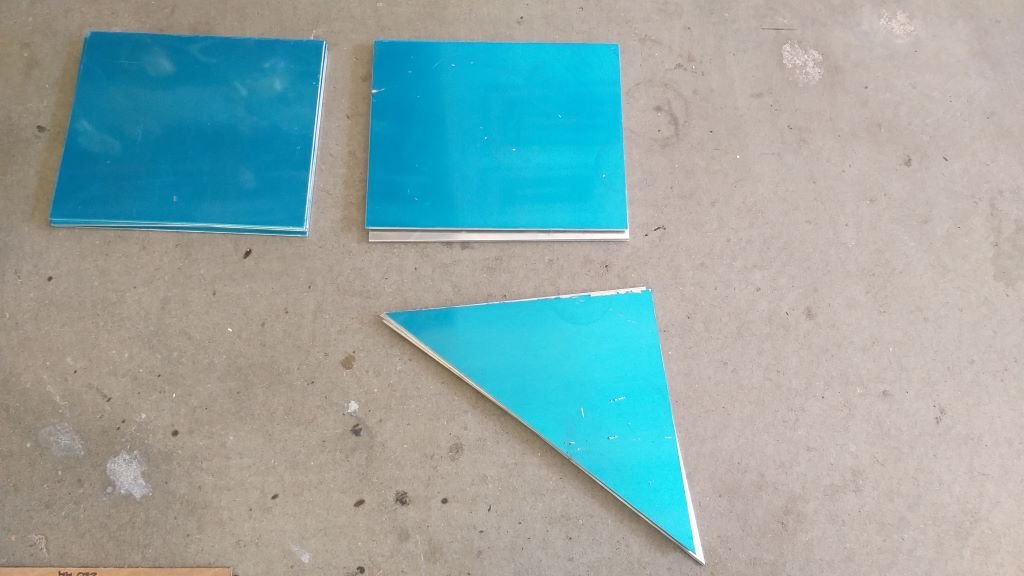

I didn't feel like dragging the welder out today, so thought I'd make a start on the gear selector cover. Earlier in the week my good mate Cameron swapped some 3mm aluminium offcuts for a bottle of red wine. I got him to guillotine me some spares in case I cock anything up. First step was to cut the opening for the gearstick out of the top plate. The plan is to use a small aluminium angle strip hidden on the inside of the panels and then glue everything together with panel glue.

-

Nice to see another Queenslander on here. Car is looking awesome mate.

-

While I'm still trying to source a set of new rotors for the front I decided to crack on with the rear axle. Had to temporarily fit my front wheel hubs to get the van back on its wheels so that I could finalise the pinion angle. Then I used the dodgy straight edge that I cobbled together earlier to get the rear axle perfectly aligned. After taking countless measurements I'm now confident that the rear alignment is correct, so I've tacked the spring perches onto the axle and its back out again. Next step is to fully weld the perches.

- 740 replies

-

- 10

-

-

After morning smoko I cracked into installing the power steering rack and associated steering related bits. And that is another item ticked off the list. New ball joints and tie rod ends feel overly tight to me, but I still need to pump in some grease, so hopefully that together with some use will free them up a bit.

- 740 replies

-

- 14

-

-

And that's the other side done. I'm holding off on installing the hubs, discs and callipers for now as despite earlier reports I'm attempting to source a new set of rotors. My local spares shop says only one set left in Straya and they want moonbeams for them, so I'm investigating other suppliers.

-

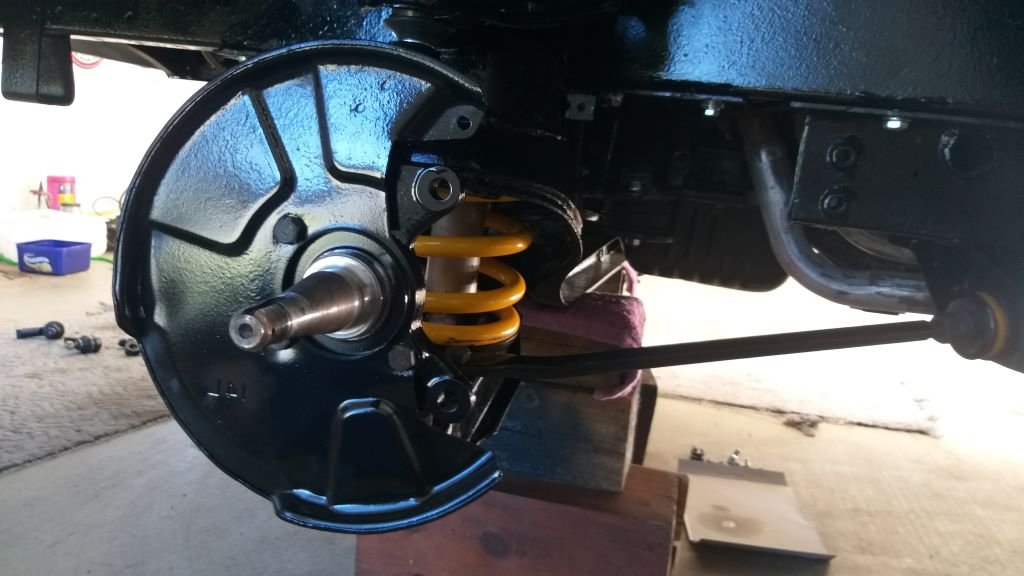

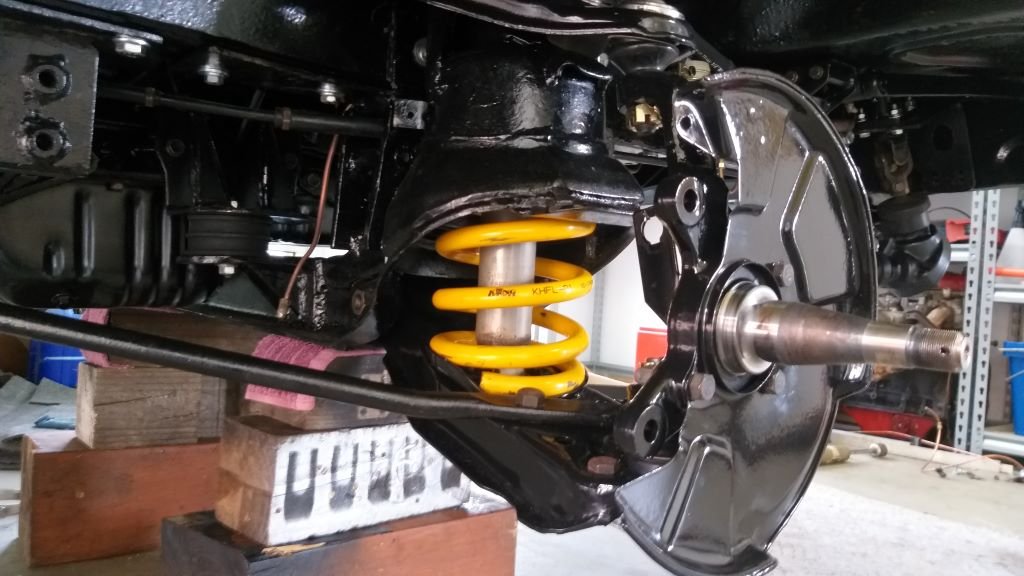

Thought I'd treat myself to something other than cleaning, sanding and painting today. Driver's side front assembly coming together nicely. I decided to leave the King Springs and Monroe gas shocks in their supplied colour for a little bit of contrast.

- 740 replies

-

- 13

-

-

I got to drive the Mitsi Express donor van before I pulled it apart, so I know that the power steering rack that I am using is a good one. Gave it a good degrease and hit it with a bit of sandpaper before I treated it to a rattle can reco. Used that VHT brake calliper paint which goes on really well. Did the same to one of the front hubs whilst I was about it.

-

Earlier in the week we took a trip into town and I dropped by the brake specialist. We came up with a plan B for blanking off the two redundant outlets on my brake line junction. Hopefully this pair of 3/8 plugs will do the trick. Also took along my existing front brake rotors to see if I could get replacements. Bad news is that he had none in stock. Good news is that he took some measurements, and the existing rotors are still well within spec, so I'll just give them a clean up before I chuck them back on. Also dropped by the bearing shop and he was able to match up a set of front bearings and seals for me. Photos of the new bits because my life is quite sad:

- 740 replies

-

- 11

-

-

-

Brilliant, thanks very much.