-

Posts

257 -

Joined

-

Last visited

-

Days Won

1

Posts posted by vk327

-

-

-

if you get hold of an ALDL cable I can go thru how to setup tunerpro on a laptop to view live data which will talk without the BCM heartbeat signal, prob easier than that old tech 1. Trevor at Holden diagnostics sells the envyous customs ALDL to usb cables, looks like you need the memcal setup properly to delete the trans faults too, Trevor does memcals for my Jetbost standalone wiring setups so knows what works.

-

-

yep that diagram is correct, should be gettting 12v on pin P when ignition is on, check what the voltage is at your injectors too could have a high resistance relay or fuse feeding that circuit

-

14 hours ago, Muncie said:

My rough cold start symptoms persist still.... improved with new ecu but still there im not getting fault codes yet so something on the engines playing up.

Time to collect more data annoyingly the problem only exists from stone cold (morning) and 2-3 minutes,setting up for a data logging at 5am is a pain in but.

Ive got a brand new DFI that the car wouldn't run on i will throw back in as it fully seems ignition related.

Of note too the car runs hardly any different with the cam sync sensor disconnected revs a bit sluggish but not terrible.

unplugging cam sensor will throw the ecu to a failure mode back to batch fire injection instead of sequential, it uses the cam sync to identify the start of the injection cycle, iv got a whole dfi and ignition coil set here on the vr im parting out if you wanna give it a go and see if that changes anything

-

9 hours ago, Muncie said:

Cold start still shit as expected. However drives way better rev counter needle no longer flicking so must have been an issue with the CAN output to dash.

Hoping i can now flash a stock tune into it and that will sort the cold start. Did some data logging lastnight nothing untoward going on (no weird spikes or flat lines)except the ecu isn't commanding the IAC to do anything at idle hence very low idle.

Tachometer signal is direct wired from the dfi module, only think i think that would affect that is the ecu doing something screwy with the timing control, the commodore dash only reads fault codes oil light and temp from the aldl data line speedo and tach are hardwired pulse signals

-

1

1

-

-

from memory will need to load up a suitable XDF file in tuner pro 1st so it knows how to use the bin file data

-

1

1

-

-

chuck the new ecu in and monitor the same datastreams as the old one 1st and see if it gets any weird errors, it should be completely functional just wont start due to vats initially. id doubt wiring issues if the car hasnt been apart too much, I have seen faulty diag aldl cables before, when reading the ecu make sure the battery is fully charged same with laptop, and save save save the master file otherwise no going back (personally i save 2 separate read bin files from these incase one read fails)

-

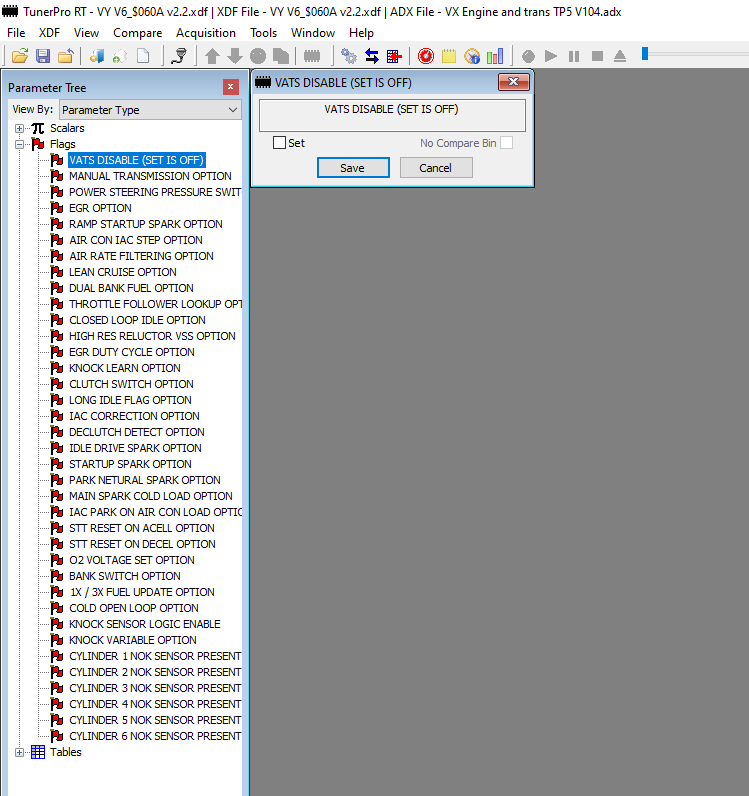

using OSE flash tool you will be able to read the ecu for its bin file, the bin file can then be edited in tunerpro to turn the vats flag off then flash edited bin to the ecu using the OSE flash tool again, id recommend reading both your current ecu and the new one and save master files, should be able to plug then new ecu into the car to read and write it, vats should be the only thing stopping it from starting on the new ecu

-

iv got a bunch of wiring diagrams for them , what in particular do you need? flick me your email in a PM and can send them thru

-

well the stock car guys do just weld a 2 barrell holley to the top to pour fuel in and just power up the coil on fixed timing with a three speed hq box, if ya get stuck with it Im in hamilton and can have a look at it, been messing with holden wiring for years now

-

1

1

-

-

so Trevor reckons could have a corrupted temp table in the pcm (possibly caused by a spike from the DFI rare but does happen) he said be careful trying to clone the pcm the flash ones are a pain and easy to brick, and it will need OSE flashtool to write, prob worth spending the $$ he does them for me for $85 and getting him to program the new PCM and pair it to your BCM and throw a tune on it at the same time, hes done a lot of these for my conversion setups

-

1

1

-

-

Could be a cam sensor problem i can't remember what code they throw, vs on they run a cam sync sensor as well, the codes and data stream issues in AED are odd, could be worth setting up tunerpro adx diagnostics and see if same stuff comes up, iv flicked a message to my tuner guru mate Trevor at Holden diagnostics as well

-

@Muncie also what's the issue your having when its cold?

-

in tuner pro v5 need to load the XDF (and suitable ADX if needed) file for a vy v6 flash pcm and then read the bin file from the ecu (or use equivalent bin file and write to ecu) from there the vats flag can be set to disable

-

1

1

-

-

Vy are all flash based pcms except the L67s, edit using tunerpro over aldl data line, not eeprom writing like the older memcal ones, delcowizid on the pcmhacking is the guru on v6 pcms

-

1

1

-

-

fuel is fine just need enough of it really where efi helps with the delivery basic link atom runs it mint , i run gull 98 now but have run z 95 previously with no detonation issues just a tad less timing than 98, starfire rods = black motor rods mine is running the original black motor ones with arp bolts, stock pistons in the black motor are utter junk they split thru the oil ring and the skirts fall off without a turbo also really thin thru the gudgeon pin area. Iv had several all with the same problem, red and blue motors used to split the tops off too thru the compression rings

-

th700/ 4L60 ex vn vp commy or an 80s camaro fit quite well , iv got a built th700 behind an ls1 in my HQ sedan all hooked up to the factory column shift using a b&m cable able to get the full shift travel down to 1st I had to clearance for larger billet servo housing but not by much, just chopped up a factory crossmember to suit, running a 3.55 diff sits about 2200rpm at 100k

-

2

2

-

-

1 hour ago, holdenman said:

To see the difference and get it ready for my other turbo engine, My current engine is a bit of a test mule that I have run various things on it. I have a couple more engines including a low compression black motor that I plan doing an old school turbo set up using a decompression plate and no ecu.

black motor comp is fine for turbo wont need to decompression plate will need better pistons and valve springs tho, Im running 11psi thru my black engine on a set of hypertec pistons on stock starfire spec rods

-

efi works well on the old 202, mines turboed running a link atom have a look at my vk build thread, iv used a 36-1 crank trigger on the balancer, deleted the dizzy and using an AU falcon coil pack wasted spark setup, pair firing the injectors, injectors and fuel rail is easy if the throttles have injector bosses, just need an efi pump and fuel reg to feed it. would need sensors for coolant temp air temp and TPS, can use a MAP sensor if you can plumb all the throttles to a small manifold, usually ends up using the TPS as the load value rather than map due to cylinder fluctuation and lack of a plenum

-

2

2

-

1

1

-

-

@robbie frew you will be best to talk to delcowizzid then being its not running a 3.8 or 5.0 , the basics of it will be getting familiar with the tuner pro software with the right bin files and definiton files to run the NVRAM it will need to be a custom setup bin file to suit the application you are wanting to run, its not an easy process and wouldnt recommend it for a 1st timer on a custom efi setup, myself and Trevor have been messing with these for years and still have issues with custom programming them. the aftermarket options like link and even megasquirt & speedduino have so much more user friendly interfaces

-

1

1

-

-

Trevor is in feilding https://www.holdendiagnostics.co.nz/ he also works in with delcowizzid (wellington) from the pcm hacking forum alot

-

a single phase 230v input to 3 phase output VSD will work fine for what you need providing that the 3 phase motor can be wired in 230v star configuration( some motors are wired for 400v only) a 1.5kw rated vsd should handle the 0.75kw load with lots of starts and stops fine, but for such a small motor it would be worth pricing up a single phase one

-

1

1

-

-

For ease of use I definatly recommend a link g4, the 808 is a capeable ecu but difficult to use especially without an electronics/programming background, get hold of Trevor at Holden diagnostics about it he can prob put you on to the right people if you want to persevere with the 808. Personally wouldnt waste my time with an 808 now that a link atom can do all the 808 can and more and really not that expensive. the 808 batch fires the injectors amd basic spark control, the atom has so much more flexibility for tuning and custom tables, my 202 runs an atom paired injectors with falcon waste spark coils and iv been able to run variable boost control and 2 step launch

-

5

5

-

Keltik's cast iron squirty thing

in Other Projects

Posted

would need to modify a vx/vy loom to standalone and run that the sistema and expanding foam is a bit crap haha, the ones I sell are in a proper enclosure