- Popular Post

-

Posts

1247 -

Joined

-

Last visited

-

Days Won

1

Posts posted by piazzanoob

-

-

Another yearly update on this thing

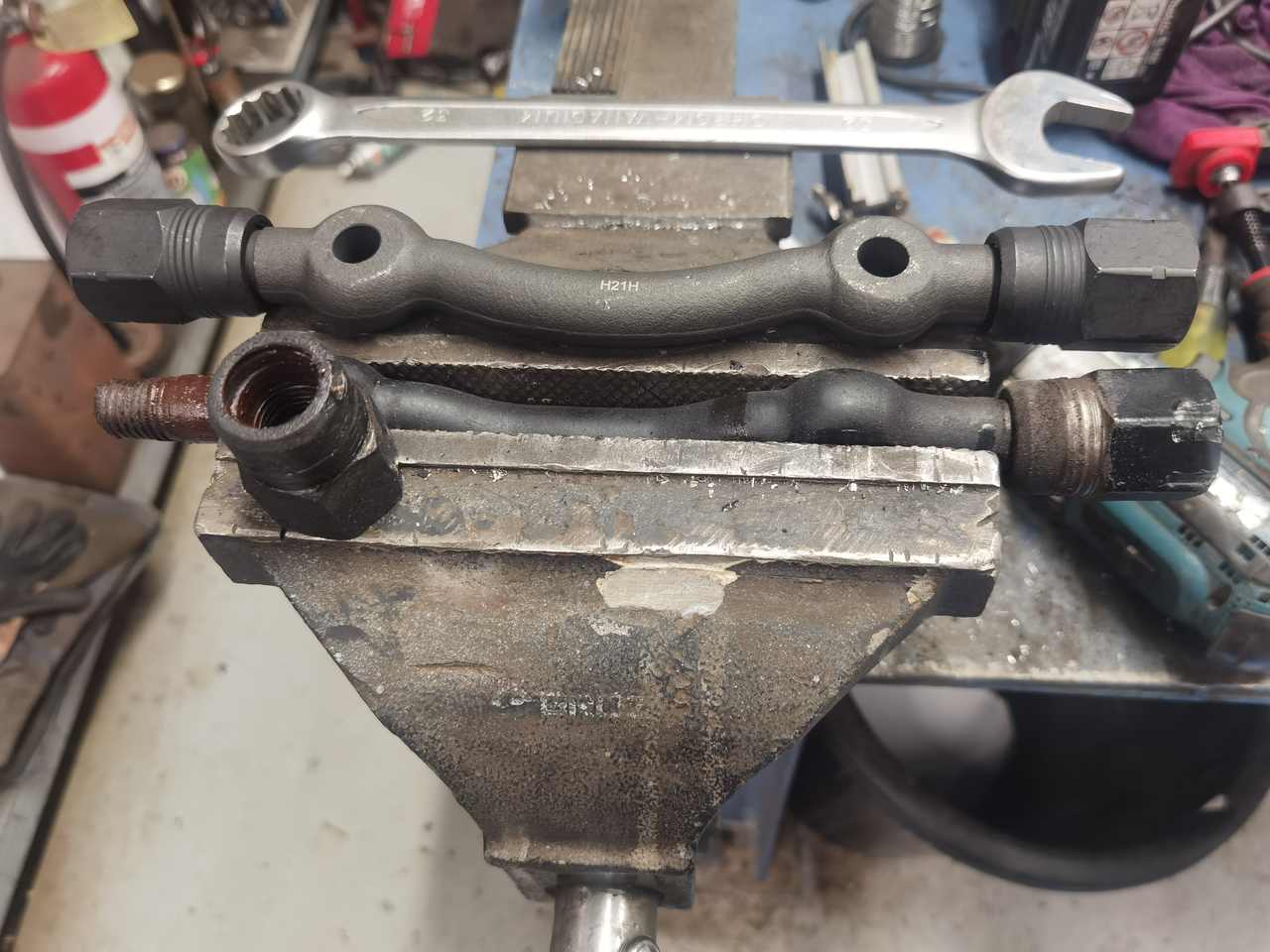

did a pre wof check on it myself and found some play in the front top inner arm bushes. so had to order the parts in from the USA

since ive owned this car i always had thought it had a rubber bush for the top inner A arm bushes. but no they actually have a nut and thread and use grease to keep them quiet and not wearing out. my car never had any grease nipples in there to keep them lubricated. bit of a shit design really but that's what they came up with.

pulled the arm off

with a view of quality factory welding

if you look close on the thread of the shaft that it has worn away the thread.

old vs new ones

fitted new ones to both sides and added grease nipples. now no play in the front suspension.

also while i ordered the shaft kits i ordered some bits for the steering wheel.

only had the part since 2019. needed the pieces to make it stay on the wheel.

after the repairs the car got another clean sheet wof

-

8

8

-

-

I would be checking to see if the cracking continues below the valve seat insert which would required getting the head to a reconditioners and getting machined out then following by a crack test.

repairing cracked heads isn't a common thing to do now most end up in the bin and find another non cracked one

-

1

1

-

-

-

On 03/01/2023 at 09:18, rdaum said:

G'day

Need to make new lines for my Eclat and there is a mix of M12x1,M10x1 and 3/8 UNF hardware. No where seems to have it all in stock in one place, does anyone have any recommendations for who might hold a good selection in stock?

Cheers

Either sterling clutch and brake or greenlane speedshop GSS

-

- Popular Post

- Popular Post

-

if looking for gauges on the lower budget side i would use.

trisco mechanical water temp. super accurate and easy to fit. have fitted these to quite alot of vehicles even just for testing

trisco electric or mechanical oil pressure gauge. if using mechanical gauge i wouldn't use the factory plastic line or a copper tube. have heard of the lines splitting and spraying oil in the engine bay and cabin which hot oil can catch fire. get some fittings and AN hose to suit.

-

9 minutes ago, mlracing.co.nz said:

Big fan of self punishment?

you got that right. daily occurrence for him

im sure he would be somewhat interested to do his magic when you are ready to move things forward

-

1

1

-

-

This looks like a great resto job for @RXFORD to do

-

59 minutes ago, SOHC said:

Having trouble again with coolant wicking through gaskets, put new head gaskets in the Ford and all around the edge I can see small beads of coolant, its not a problem if I use water but as soon as I put antifreeze in it starts,

Is there a product thats safe to use to seal the cooling system? I dont want to take it apart again, the coolant is not entering the combustion chamber or other way round.

after fitting new head gaskets its a big no no to put antifreeze in straight away.

normally the process is do some miles and heat cycles like 500 miles and retorque heads when hot then fit antifreeze.

have the heads been machined? and block checked with straight edge?

also copper spray is a good thing to put on the gaskets to help seal.

but if you don't want to strip it again i would drain all coolant and just add water and do some miles and retorque heads then add sealant pellets then coolant

-

2

2

-

-

- Popular Post

- Popular Post

-

for trans fluid use type f like you said

as type f is basically a trans fluid with no additives for like friction modifying etc. great fluid for old type transmissions.

but any old texron 3 will also be fine for a c4 or trans of same era.

and for the steering ram there not too hard to do yourself if you are mechanically minded. if you want pics i did the one in my galaxie build thread.

also driveshaft looks abit dodgy i would also pull it out and send to russell @ driveshaft specialists

-

1

1

-

-

shit that thing makes good power for a 4age

must mean it will be ready for OS drags in December?

-

1

1

-

-

12 hours ago, ~Slideways~ said:

I think ceramic coating would be overkill to be honest. The stock pistons could have handled it, if it weren't for fueling issues.

As for balancing, undecided. Inline 6's are pretty much the perfect engine for balance anyway, except v12's...which is just 2 of them haha.

if the piston weights are different between what was in there and new ones. like a decent amount the motor will need balancing if not done can cause issues like engine vibrations and unwanted wear on components. plus the engine will be used hard too

its not much money in the scheme of what your spending in parts and what it will cost if you had to do it twice.

if your not sure on weights or getting it done get your motor machinist to check and tell you

-

1

1

-

-

I think you and @cletus are on the right track.

i have worked on a early 60s plymouth which same in the rear end to remove the rear drums requires a puller because the drums get stuck on the taper of the axle.

i used for the job a axle puller and standard 3 bolt puller a big hammer and heat. i spent about a day trying to remove one drum with no success.

so i ended up die grinding around the wheel studs de adjusting the rear brake and removing the drum as alot of american stuff have the drums held on the hubs by knurling of the wheel studs. i was only changing a snapped wheel stud and was able to change it with the drum removed. and all other studs were reused as i only die grinded the knurling away carefully.

also at the time another tech said they spent a week many years ago to remove one drum/hub to do the wheel bearings as they get super locked up on the taper. on an old chrysler.

if it is just to do brake work i would just remove the knurling of the studs to get the drum off then drill and tap the hub and drill drum and use a tapered cap screw to locate and secure the drum to the hub if you were worried about the drum elongating the stud holes.

-

1

1

-

-

Its nice to see this is being worked on now that the holden is done.

i still remember going in this for one of the shed raid days

also a fan about the car having a cool backstory and history and for owning it for that long!

also what efi system are you going to run?

keep us updated

-

1

1

-

-

The new ride height looks much better.

Also on the fuel sender they earth through the tank and can cause all sorts of level issues. so all this old stuff i solder a wire or terminal onto the sender and bolt an earth wire onto the chassis somewhere.

also good idea while your there is to test the accuracy of the gauge and sender. and bend the sender to suit as much of the repro senders can be junk

great progress

-

On 31/08/2022 at 20:32, SOHC said:

looks like that side would be the outside. and the other side would press into the hub. hub and spindle setup im guessing?

as i cant see any other way the seal would be retained to the hub

most style seals ive used like that have a steel other flange and bottom steel ring to press into a hub. but the photo you put up doesn't look like its a steel ring to press in

-

1

1

-

-

1 hour ago, Bling said:

these clamps are a cheap and simple and quick clamp to use when in a production line. which is why they are used

but are more of a single use clamp as once they have been opened and closed a few times can cannot provide enough clamp pressure to stop coolant seeping past.

And they can be tricky to get off or move and are good for making you bleed or flying across the room.

-

1

1

-

-

6 hours ago, RUNAMUCK said:

Looking at hose clamps for my radiator hoses.

What is the OS hive minds opinion of T bolt clamps, versus standard style screw driver hose clamps?

I guess anything is better than the wire hose clips used by the factory.

What does everyone reckon?

personally would just run standard screw driver style clamps but the ones with no holes in them as it bites into the hose. can buy black ones too. i personally like zebra brand ones from wurth. And can't really overtighten the item as the clamp just strips too

have seen T bolt style clamps on standard rubber radiator hoses cut the hose on the edge of the clamp causing them to leak but that could be because they were overtighten or that brand were sharp on the edge. but personally think they can be quite bulky looking.

-

1

1

-

-

Used coastal towing last year for a non runner 4x4. was happy with the price turnaround and being informed. would recommend

-

- Popular Post

- Popular Post

-

I think the cooling issue you have is not a air flow related issue. More air will help but is a band aid for another issue. i think the problem you have is that the water is not spending enough time getting cooled in the radiator because the water speed is too fast.

A couple ways to solve it is too pull the radiator out and have it triple or double passed so the water spends more time in the radiator and has to flow in a circuit rather than straight in and out.

or machine a piece or use a frost plug and drill a hole in it and place it in the bottom hose perhaps which will slow the flow down. this is a trick that has been used before and from what ive heard helps. would be a good way to know if your going in the right direction without pulling the car to bits. this trick i was going to do on the galaxie to help with the getting hot issue.

ive also got some frost plugs so if you want to try it and know the size flick me a pm

-

5

5

-

-

Also seen some bc adjustable's on facebook marketplace if you wanted some second hand items

-

.jpg.53ff715ccf5f06f8cef68dd7f89399b6.jpg)

.jpg.6b2390fe6e1eff7140b591631aec95c4.jpg)

.jpg.120f29a0d28eae7e25bf6f66bcb6b0a2.jpg)

piazzanoob's 1964 Ford Galaxie 500 seeeedaaan

in Projects and Build Ups

Posted

Did some miles and took to beach hop in November with zero issues

t

Then did some OS drags prep

needed some other wheels/tyres for the day

ended up buying some new tyres for my original wheels. also got a bonus of getting a white wall one too

also managed to get my best bp this time round too. car ran flawless with zero issues too