-

Posts

6300 -

Joined

-

Last visited

-

Days Won

1

Everything posted by Muncie

-

Well im happy.! Has oil pressure accidentally pegged it on the limiter first start as a return spring was in backwards. Run 500ml of petrol through it so now i need something to put under it.

-

Just dawned on me i could build something 4wd with around 60hp if i scrap the scooter.....

-

Cheers ive found the pocket bike tyres are really a shit fit to the rim one i fitted had 5mm of slop on the bead so wouldn't even inflate. My current one is a snug fit with a tube and i used an adhesive similar to loctite to stop the rim spinning in the wheel, its a bit of a fuck around but finally takes the abuse im riding it 10ks at least every day at moment. I really want to bung an axle under it and make it a trike with some suspension.

-

Chook woke me up at 5.50 this morning..... so just waiting for repco to open so i can get some Rtv will get side cover on put oil in it should run! Gutted the governor completely it came with a new one, to me it seems like a failure point so see ya later fun police device. This engine is drastically different to my other engine lots of plastic covers but its very cleverly assembled, the rockers are held in by a pin that is held in by nothing but gravity no tools came out till i was ready to put crankcase cover on, except for the hammer i used to punch the governor out.

-

I may be able to get this.....it is a kart. https://www.dropbox.com/s/bwltxve94sdzg4w/received_784497652008254.mp4?dl=0

-

Im thinking hard about some sort of belt drive as a chain spinning constantly would chatter quite a lot. A Jack shaft would be the easiest fix. Its good having a look inside one of these engines as ive not cracked the other open yet probably should as the governor is still in there and has seen 2000rpm over what it trys to control..... might explain why it sounds like it has gilmer drives. Going to bang the cam in tomorrow fresh oil and see what it does.

-

I knew this when i bought it this runs a 1 1/8 crank so clutches drives etc are either bloody moonbeams or industrial spec and wont take more than 3000rpm. 1" is the standard off the shelf size i can either machine down the crank so im back in to 1" parts. I would like gearbox though..... any ideas? Rumour has it these punch out 25-28 hp peak so i may even have to run 2 centrifugal clutches to get the power out.

-

Seems all there.

-

-

-

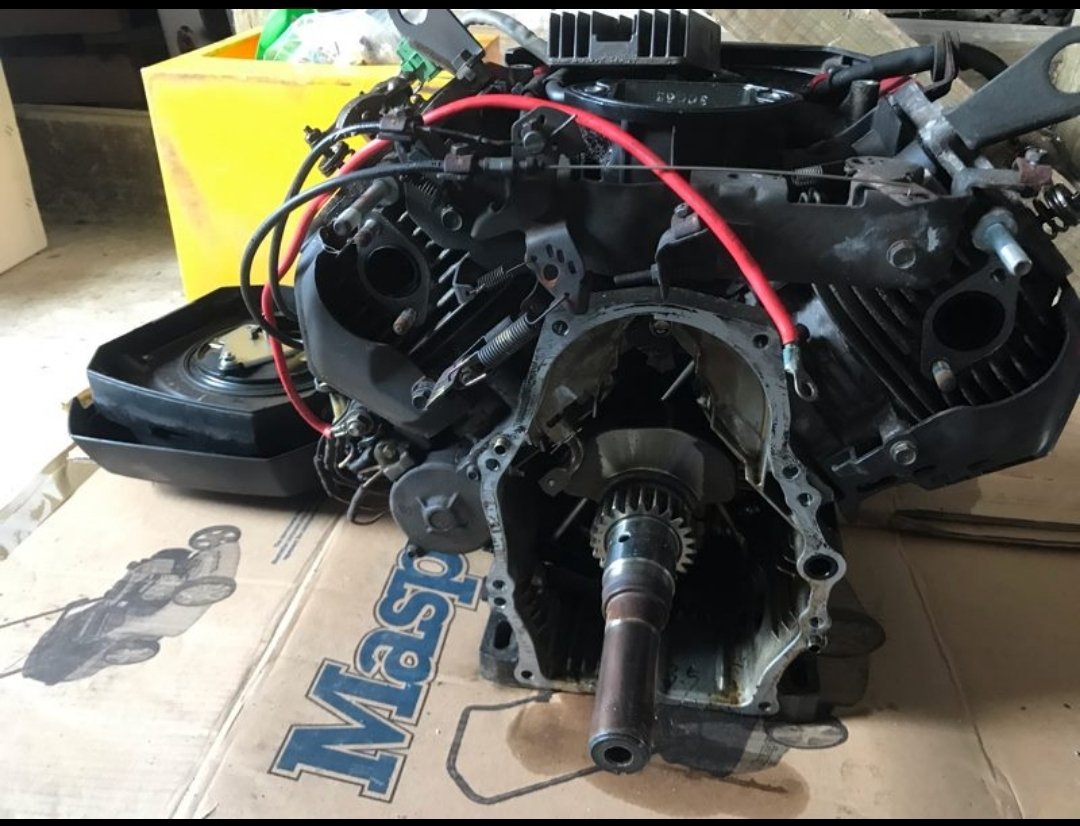

I've got it back from Auckland today from a Stihl shop mechanic who was quite switched on and had an equally cool engine project. Everything thing is there quite frankly i could make it run on the existing cam. Its the governor that failed (like it'll need that!!) The fibre gear on the cam is a bit worn but would work fine. Hmmm stand by im going to degrease it and make sure its complete.

-

Think this might end up with the Mikuni's on it.... i have a mountain of cool stuff ive stock piled for the other engine but have sidestepped for whatever reason. Could repower a Prius maybe. A cross kart is the dream machine and i have an uncle who races a polaris with spares i could potentially burgle.

-

I owe @Kimjon these fuel tanks for his projects problem is im riding it to work. Building a little one from a fire extinguisher this weekend to keep me going in meantime. Sorry mate will get them to you.

-

That ring that slips over hub has done wonders holding it all together i did a massive burnout on it yesterday nothing is showing any signs of duress. Saw one last night on a concrete saw sitting embedded in a traffic island just out of huntly must of jumped off a trailer.

-

I snaffled this off Trademe after watching it for ages it needs a cam which is no major so I'll order one off ebay and see how it runs. Been later model then my GX610 on the scooter it has CDI ignition bigger charge coil and is 688cc. Dont know what ill do with it........ Specs as below : Honda GX690RHTXF7 Horizontal Shaft V-Twin Engine Features GX690 with 1 1/8 Inch crankshaft TYPE Air cooled 4-stroke OHV petrol engine, 90° V-twin design, horizontal shaft BORE & STROKE2 / 78 x 72 mm DISPLACEMENT 688 cm3 COMPRESSION RATIO9.3:1 NET POWER 16.5 kW (22.1 HP) / 3 600 rpm CONTINUOUS RATED POWER11.5 kW (15.4 HP) / 3 000 rpm 13.0 kW (17.4 HP) / 3 600 rpm MAXIMUM NET TORQUE 48.3 Nm / 4.93 kgfm / 2 500 rpm IGNITION SYSTEM Digital CDI with variable ignition timing STARTING SYSTEM Electric starter FUEL CONSUMPTION AT RATED POWER 6.7 L/hr - 3 600 rpm LUBRICATION SYSTEM Full-pressure OIL CAPACITY 1.9ltr DIMENSIONS 429 x 410 x 438 mm (T-Type) DRY WEIGHT 44.6kg

-

-

I had 2x 20 megabyte MFM hard drives in my first computer i built from the inorganic rubbish collection..... thank fuck those days are long gone.

-

Excellent! Will try find them with reasonable shipping. I was thinking about going to go-kart tyres on rear but that means a new axle hubs rims etc. The front will definitely get a set though as its well sorted now i wont mess with again.

-

To be fair it would probably run happily for 100 years with beef dripping in the gearbox.......

-

We used hydraulic oil that we would use in our injection moulding machines to top up. Not because it was necessarily right but because we had it..... Ring a switched on oil retailer they'll sort you out.

-

The wheel hub brace works a treat i have absolutely torture tested this thing the last 2 weeks! Probably clocked up 70-100 ks on it now on gravel and grass fitting a bigger fuel tank and will keep riding. Have changed throw on throttle as it was very on or off now is heaps better.

-

If anyone has a hookup for 4" tyres for these rims or a few go kart wheels please pm me as my boy finally blew the belts out of these old grey tyres on sunday.

-

This thing goes still my boy has finally got the hang of properly giving it shit as of this weekend..... not sure whether i should be proud or shake my head.

-

Well thats the down pipe fizzed together guess i need to man up and get on to rest of pipes when possible at work. Got some cleaning up to do on this internal weld but thats this part finished turbo is all ready to be plugged in made the oil lines ages ago.

-

Will be welding the 2-1 collector on the turbo flange this weekend needs to be done with mig as our tig at work where I'll do the pipes is a bit better suited to light stuff. Going to be doing tuned length if possible like whats on there now but in stainless its 1" into 1 1/2" tube to keep the velocity of gases up right up till they smash into the turbine. Should be fun.