-

Posts

985 -

Joined

-

Last visited

Posts posted by shrike

-

-

Do I need to crank my speakers or is it quiet? Great sound either way keen to hear it scream

-

Opps double post

I'm also keen to see how Toyota/lexus simulated manual setup works

-

3 hours ago, Bling said:

I think they are super wide compared to most things. For comparison:

https://magpi.raspberrypi.com/articles/teslonda-tesla-honda-powered-raspberry-pi

I would be thinking more along the lines of Leaf motor adapted to gearbag or similar, due to budget. But the rear end won't handle that so... But yeah I also think MX5 could be a better platform to mess with for that sort of thing. Has been done in the UK and looks pretty good.

I wonder if you could unstack the leaf setup and mount the PDM/Inverter elsewhere and then mount the Motor itself directly in the back

-

20 minutes ago, Bling said:

What would you do?

Any ideas i've come up with, on a budget (that I don't have), blow the rear end of an old Toyota to bits with torque.

Would a complete tesla rear motor setup fit in the rear of the corolla? With some tweaks of course

Batteries in the engine bay?

-

Whats the power goal in mind?

Go down @Romanroute with a 1NZ or v6 from the GR family?

Your not keen on Ford so ecoboost motors are out.

-

No option to fit a longer more modern Wiper blade setup on the drivers side?

-

Have you seen this? I posted in the comments on one of the videos to your thread but don't think they saw it

-

Check the rear mounts on the subframe that go to the mustache bar, they have a habit of cracking/rusting out

Had to get mine plated and welded up on my Gsr when I had it

Worth doing if your going to have it out anyway

-

1

1

-

-

7 minutes ago, yoeddynz said:

Chipping away at it. This project isn't the most important thing in my life right now but it's a nice way to chill out. I'll do an update at some point soon

Hope everything else is going well

just know how slow wiring can be to do so was just checking in :p

just know how slow wiring can be to do so was just checking in :p

-

1

1

-

1

1

-

-

Hows the wiring going?

-

6 hours ago, kws said:

Mainly because they eventually came through with the refund, so feel mean completely blasting them.

If you wanted to Import Your Car, it wouldn't be hard to work out who it is.

Any option for a holiday over to Japan and find one yourself?

-

1

1

-

-

How much left in the list till shed skids?

-

1

1

-

-

Keen for start up/running videos and shed skids

Are your J160 all stock internals? Or have you had some mods done (Circlip?) Any idea how it'll go with many revs?

I'm assuming power and torque are within specs for it?

-

47 minutes ago, Roman said:

The 2GR heads will be best, since they have huuuugggggeee valves because of the much bigger bore (94mm bore vs 83mm 4GR)

So as a result the valves are 7-8mm bigger diameter which is crazy.

If you put a 2MZ crank into a 2GR then you end up around 2.9 litre with a stroke that "should" allow 10 or 11k rpm.

I guess the thing is, first I just need to get a motor together and see what happens when it runs.

It is entirely possible that there is some insurmountable issue with the valvetrain (or whatever) so arguing semantics over which motor will do 11,000rpm is irrelevant when the whole thing explodes at 9000 anyway. Haha.

God I love wildly speculating though

Im assuming youll be upgrading valve springs?

-

Next update, and you have all the bits to build a frankenmotor for when this one dies haha, all cheap pickapart bits or FB marketplace etc

Do all the GR heads swap over between blocks?

Wonder which ones flow the best/are the best to port hmmmm

-

Welder and paint make me the welder I ain't lol

-

1

1

-

-

3 hours ago, Not-a-number said:

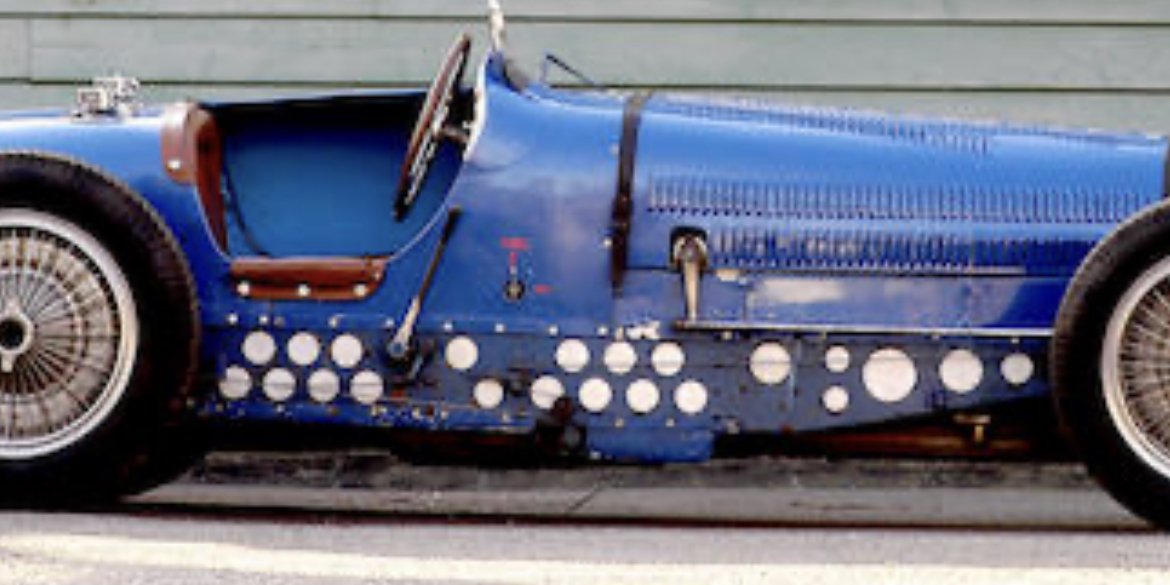

Yeah they do have speed holes. Backed with an ali sheet.

Can see them here.

Original material was a mild steel. Probably low grade (in todays standards and variable. ‘Low background’ pre war stuff so you can’t really buy that.

So they’re done from G250 mild steel (I think, maybe it was G300). Either way, in theory significantly more consistent and stiffer than the original.

Awesome, is there any logic to the placement of the speed holes? are they actually dimpled or just hole sawed out?

Guessing the backing was for weight saving/aerodynamics?

-

Did the original chassis have the speed holes (dimples) in it? are you using similar materials or updated to modern specs?

-

No plans to convert to electric power steering? Ie from a newer corolla, echo , vitz, prius or GT86/BRZ?

-

48 minutes ago, flyingbrick said:

Its a model D because it Dicks all over my BYD. that thing has got more range!

By the way, my BYD went in for its first service today. Its done 4300km. I could see it on the hoist and everyone standing around with hands on hips, then wheel came off, things got inspected with the torch etc.

They are going to call me back soon to install new rear wheel bearings. After 4300km.

4300km!

Did you previously comment about not getting expected range? Could failed bearings add drag? I'd hope it's just a bad batch of bearings and the next lot don't fail that soon. Is it too much torque for the bearings to handle :p

Did it make any noise? Could the hub flange be at risk of separating and you have the wheel/s fall off?

-

8 minutes ago, Hyperblade said:

Link have had one for a while

G4+ Force GDI https://dealers.linkecu.com/force-gdi 4 Cylinder only though, ($3000+)

And have their new G5 Voodoo Pro https://dealers.linkecu.com/G5-Voodoo-Pro ($5000+)

Not a cheap exercise!

I stand corrected good to know there is an option but gosh your right it's not a cheap exercise

-

2

2

-

-

Don't DI engines tend to have carbon build up issues on the valves?

Also I'm not sure of an aftermarket ecu that runs direct injection but I could be wrong

They also run alot higher fuel pressure (mechanical fuel pump at the rail?)

From what I've seen DI and Port gives best of both worlds if you can run it properly

Guess it's another failure point however

-

1

1

-

-

Why not get rid of clutch fork and go to a concentric clutch release bearing?

-

5

5

-

-

Didn't @chris r get some jets from Aliexpress or am I thinking of someone else?

Gav's AWD Lancer

in Other Projects

Posted

Chinese turbo that you've disassembled and reassembled to confirm quality control?