-

Posts

1,399 -

Joined

-

Last visited

Content Type

Forums

Downloads

Events

Gallery

Everything posted by shrike

-

I am actually trying to save weight were I can, and long term ill be swapping anything I can to composite panels (hopefully carbon fibre) But atm ill compensate with more boost once I turbo it Cage and subframes are/will be Chomoly As I added more weight to the rear end im keen to move the battery more central, and clean bay/space is at a premium, though looking at the below pic of a factory bay I stole from the internet. I might be able to put it a small battery where the Powersteering fluid tank is, especially if I reduce the size of the washer tank (or remove it) Engine and gearbox oil coolers will be in front of the drivers guard or somewhere in that location. Haven't decided what side ill put the half rad yet but most likely itll be on the Passenger side Remind me which lithium battery you use? Ill be keen to get one as I currently don't have a battery for this car Factory battery spot is where the air intake will be going (I actually had the battery tray removed as well)

-

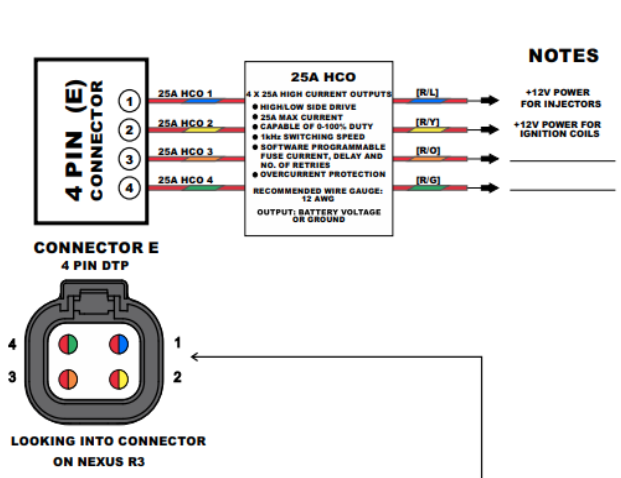

The NEXUS will be providing the power to the injectors and coils (1 and 2) 3 and 4 will run the fuel pumps Factory fuse box will manage the Rad fan and anything else that needs power the NEXUS can't handle Thanks everyone that helps

-

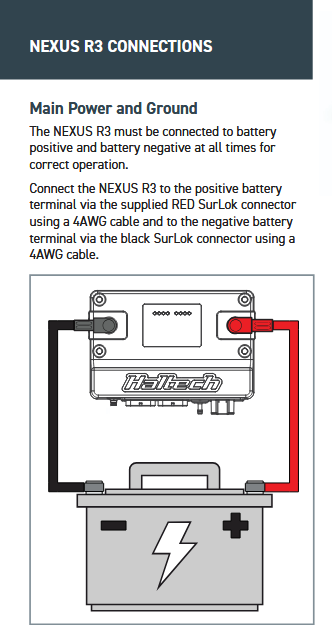

Shes still asleep but seems to be doing ok atm thankfully Good point about the battery wire sharing for the ecu, ill double check the Nexus R3 manual but from memory all it said is it needs to have both sides wired to the battery, and ive found a few people running distribution blocks etc for that Main thing for me is its all coming off the same battery terminal I can run a separate fused 4awg cable from the battery + terminal as itll be a short run, was just trying to reduce the amount of cables I run Edit: yip manual is as per below

-

If you could insulate the pin so its only ground when it's in locked position and run a wire to an LED in the dash that turns on when the pins in ie use the pinlocks as a gnd switch that could work right?

-

So as im sitting in hospital for my daughter im making wiring notes. Just thought id run it past the hivemind My battery had been relocated to the boot but I think with the cage I'll move it to be mounted behind the passenger seat. Will try reuse wire where I can I think from memory it's 0awg sized wiring already used, with Gnd bolted to Chassis via a seatbelt bolt. (I didnt install this it was done when I brought the car); Battery box also had a Kilswitch on the +side Current thought is Positive side Battery terminal to Killswitch (0awg) Killswitch to Bulkhead stud to Engine bay (0awg) Interior side of Bulkhead stud to 120amp ANL fuse then to Nexus R3 (4awg) Engine bay bulkhead stud to Engine bay fuse box (0awg) Engine bay Bulkhead stud to startermotor (I cant remember if the factory wiring is fusebox to Starter (if it is ill do that) 4awg (100amp starter) Pretty sure alternator charging was direct to the battery so ill put that back to the Bulkhead stud as well, will use biggest cable I can fit or maybe dual smaller feeds. Bulkhead studs should also allow me to jump start from Engine bay if needed etc May also run but not connect another fused 4awg run to the boot for future expansion off the battery terminal or Killswitch if there is space. Current fuel pumps won't push more then 15.5amps max so can run both 12awg outputs direct from the ecu to run them (staged) Ground side Battery Terminal to Bulkhead (0awg) Interior side Bulkhead stud to Nexus R3 (4awg) Battery terminal to Chassis (space allowing) (0awg) Engine side Bulkhead stud to Starter (4awg) Engine side Bulkhead stud to Engine (4awg) Engine side Bulkhead stud to gearbox (4awg) Engine and Starter ill probably also ground to Chassis in the bay. Coils ill ground to head, I cant remember where the fuse box is getting the ground source for the relays (need to track down wiring diagram) but if needed to ill ground it to gearbox. Reason im keeping factory fusebox (ill have spare relays) is id like to keep factory controls for headlights etc and I want to run a relay for the fan (ill also wire in redundancy) Any of this sound silly or over kill? Im not bothering with a Bulkhead connector for the ecu loom as ill make the hole big enough to pull connectors though and use a grommet. Will have the injector and coil looms as sublooms

-

Currently no factory LSD option for it and aftermarket is quite expensive but if the states start using them that may change (place in the states has plans to make/is making an LSD) There is two in a local wrecker may go have a look when I get a chance as I want to grab a crv box and axles etc anyway (maybe spare transfer case) Is a couple of these in Wreckers in NZ as well Changing diff mounts isn't a big issue but not ideal, and im not sure about the rear shafts Need to do research on if they can be modified to fit Jag axles are 28spline CV into hub 24spline cv onto axles shaft GT4 are 26spline CRV are 23 Spline The Honda guys are running them upside down Im curious on what the axles shaft diameter is

-

Anyone want to help me math (Edit Jag X type X400 rear diff may be a close rear ratio) If I swap to an auto Transfer case on the manual gearbox i could run a 35 sidewall front tyre and a 40 sidewall rear to align the difference in diff ratio? Front would be 0.4km faster then the rear at 9000rpm and 0.2km at 8000rpm and 0.1km at 3000rpm Auto Transfer Final Drive Transfer Gear Transfer Ratio Rear Diff Ratio Difference 4.389 0.393 0.904 2.928 4.566 0.1766 4.562 0.393 0.904 2.928 4.746 0.1836 4.764 0.393 0.904 2.928 4.956 0.1917 5.062 0.393 0.904 2.928 5.266 0.2037

-

Yeah I think your right, its ok there isn't any off the shelf gearset that would be low enough so id be looking custom anyway The CRV transfer case gear would probably be easier to machine so I think if I go down the CRV gearbox route thats what ill have to do, or change rear diffs There is a C4 Corvette rear diff thats close to the idea ratio haha bu im not super keen to change diffs at this stage

-

Notes for me if I need to go for a Honda CRV gearbox, Honda Axles are big enough to shorten and respline to suit GT4 CV joints Honda 5 speed CRV Half shaft 44500-SCV-A00 CRV Front Left 44306-S9A-N00 CRV Front Right 44305-S9A-N00 Can all be brought new but id probably hit a wrecker up Current rear diff is T series from what I can find I have 2 GT4 diffs and I may have an AE115 Rear diff in my spares as well T = 6.7" te71/72, ae86, ae95, many rwd corona/celica/carina, 90's 4wd wagon, gt4

-

Shrikes Will it ever be finished Toyota Levin AE111 AWD

shrike replied to shrike's topic in Projects and Build Ups

So Maintaining Momentum ordered some more parts. with some going straight to NZ (oil coolers/line) and some coming to me first for quality control/checks etc Ordered 5M of PTFE Stainless and Nylon braid hose -AN10, -AN8 & -AN6 got it from a supplier one of my clients regularly buys off so confident it should be ok. I am mainly using hard line but this should cover any hard line to fuel rail/ fuel pressure reg, Gearbox and Engine oil coolers etc 10 Row Oil cooler for the gearbox, ive got the factory one but for the price id rather get a new one installed (its -AN10 but ill adapt it down to -AN6) I may add an inline thermostat to this later 19 Row engine oil cooler, already have a Oil filter relocation and thermostatic plate etc on the way along wit some banjo to AN fittings encase I need more clearance (All -AN10) Semi scope creep as not needed to get the car going but both id rather do now A whole heap of AN fittings to add to the collection ive currently got with the car Aftermarket fuel rail encase I have issues with the factory one Aluminum crush washer kit O ring kit Aftermarket Thermostat housing & upper Coolant housing (I can use this with normal silicon hosing but allows me to go to -AN20 fittings later as I already have them) On the fence if I do the K20 oil pump now or wait till later, as I can stick with stock rev limit to get it all going. I have a Turbosmart FPR2000 so will be plumbing it up as a deadhead system similar to the below diagram (Bottom pic) Will be 5/8" Hardline from the Dual pump/fuel cell in the back to -10AN and 1.25"X3" filters (40Micron) -10AN to -8AN (Male to Male) I think ive got some fuel shut off valves so may put one in the front and one in the back -8AN 1.25 X 3.5" fuel filter (60Micron) (I have two more filters from the GSR project I had that I may reuse (one post FPR) -8AN Hose (one end will be 90degree) FPR2000 -8AN to ORB -8AN FPR2000 ORB -8AN to -8AN fitting bottom Port will return back to fuel cell via 1/2" hardline (I am hoping I can run the hardline right to the bottom of the FPR but can run a flexible braided hose if needed) Need to order a fuel flex sensor and fittings (may be a future change) but would plumb this in onto the return FPR2000 ORB -8AN to -8AN -8AN Hose with 90 on each end -8AN to 5/16" (factory fuel rail barb) I also have the gear to do a -6AN feed if I decide -8AN is overkill or want to save the hose for when I go to a different intake/dual injectors etc If factory rail doesn't work ill throw the aftermarket fuel rail onto it ORB -8AN ports and ill run a M10X1 adapter on the return side or middle port so I can have a fuel pressure sensor Will have Fuel pressure guage on the FPR and Fuel rail Will order the Haltech Nexus when I need it, im hoping for an EOFY sale coming up I brought the FPR2000 back in 2020 -

Has @Romangiven you the graphing tools so you can plot the frequencies? Fabrication/welding porn as always, keen to see the tuning results

-

Might have been where I got all the partnumbers :p

-

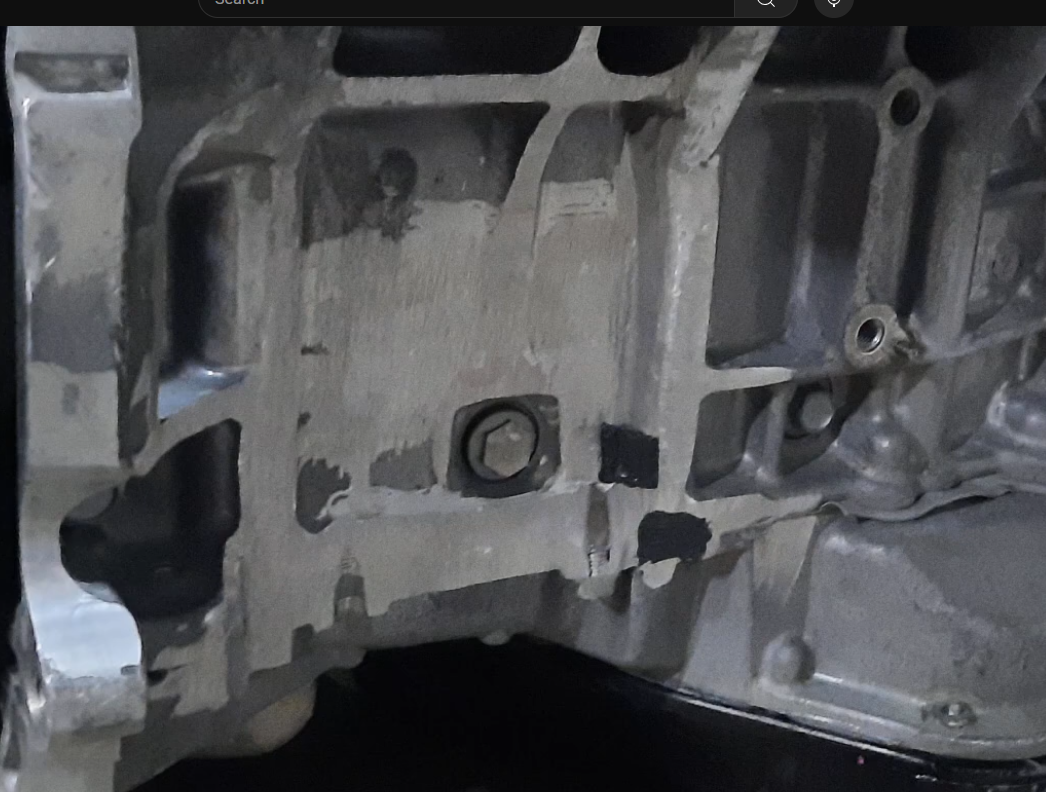

Yes fully aware of the K20 pump, need to use the baffle, chain and bolts etc and block a drain Oil pump needs notching as well P/Ns are Oil pump 15100-PRB-A01 Oil pump chain 13441-PCX-004 Oil Pump Chain Tensioner 13450-PNA-004 Oil pump chain guide 13460-PNC-004 Oil pump guide bolts 90004-PNA-000 (x2) Oil pump bolts 1x 95701-080-7508 1x 95701-080-5008 1x 95701-060-2508 Baffle 11221-PNC-000 Baffle Bolts 95701-060-1408 (x6) Oil return bolt 90004-PE2-005 or might be M8 x 1.25 1" bolt and washer Good call out though

-

So also to help explain how some of my scope creep happens, I've just spent the last 2hrs thinking about crush washers I have a few things that I have to use AN fittings for based on current parts acquired, as part of these fittings I have a few ORB fittings that currently have O-rings At least 5 in the fuel system So ideally I want to go to Aluminum crush washers (assuming the orb fittings don't have a seat for the o-rings) So I need some Orb -12AN, Orb -10AN, Orb -8AN for that at least And then if I end up running a gearbox oil cooler I probably need some M14x1.5 ones but -6AN should work Need to run Aluminum as the AN fittings are all Alloy So may as well buy a kit of -3AN to -16AN (10ea) as that way when I convert the cooling system to AN Ive got crush washers for the -16AN to -20AN fittings I have and spares for when I do an oil filter relocation/cooler + Turbo etc And ill probably get some spare o-rings as well encase using a crush washer isn't an option So then its the Nitrile vs Viton o-ring options ha Then its finding a good price for the above and getting it shipped to me for when I bring it over later :s I think ive landed on raceworks kits for the seals/washers at this stage All my AN fittings are Aeroflow Though I do have a selection of Aliexpress AN fittings on the way to do some quality checks on

-

Not sure if you've seen how much grinding is required to make the 2GR fit with the Transfer case I am not sure how much grinding into the block im comfortable with so will have to see how it fits to start with Honda diff ratio isn't close enough, copied from the other thread Honda AWD info "Transfer gear ratios are 0.434 for the Manual and 0.393 for the Auto, the transfer case is the same between the two (transfer gear on the diff is the same between auto and manual, difference is the gear it connects too in the transfer case I had to look up the part numbers to confirm this) Factory CRV rear diff is 2.529 Ratio (USA) for reference the rear GT4 Celica (7.1" or 6.7" T series?) diff is 2.928" Plan would be either a Transfer gear made at the correct ratio (0.3778) for the CRV box (transfer case gears are already being made commercially) Or get a Custom rear diff ring gear and Pinon made with a ratio of 2.549 Hmm seems some corvettes have a 2.59 rear diff ratio as well

-

Yes its me :p Thats a pic I haven't seem but I have seen all the MR2 (SW20) conversions so know the FWD E series at least is doable

-

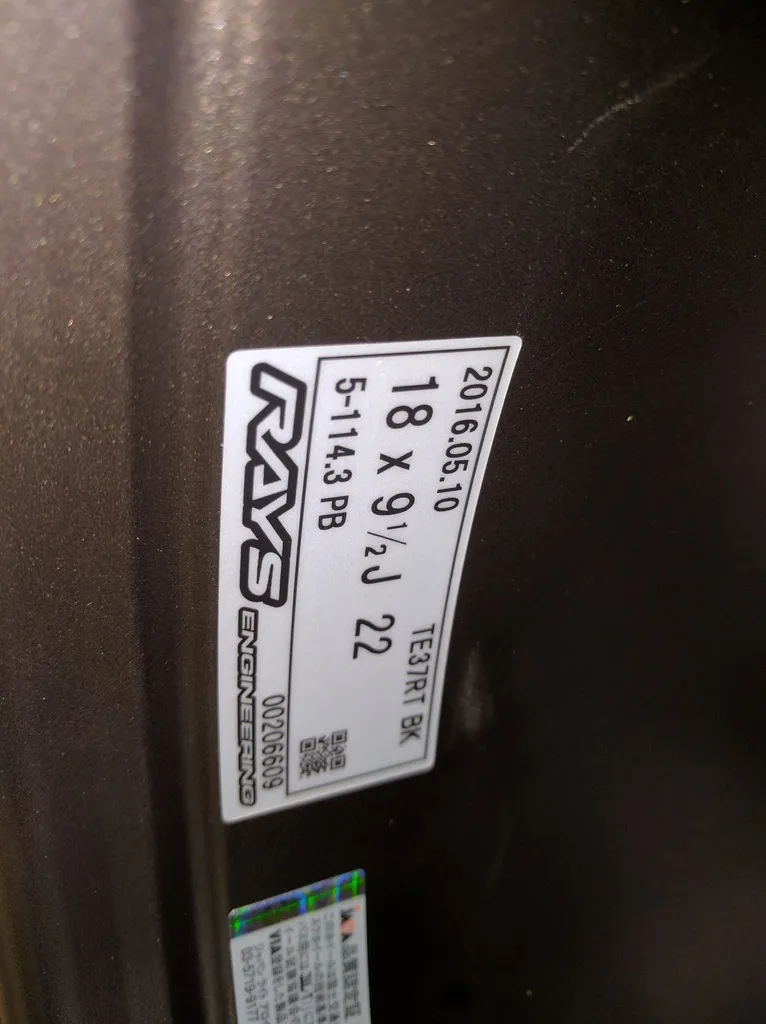

I am not that much of a glutton for punishment Current thought is throw a Pulsar 6262 on the K24 and run enough boost to get around 300kw but aim is to get everything running and I can then add things to a running driving car Was actually just thinking about ordering some tyres so we can do some mock ups and work out what needs widening and am now doubting my measurements I've been thinking 265 wide tyres but going back to my original notes I think I had 235-245 wide (id like wider however) Because of the below math I used to have 18x7.5" +43 and 215 wide tyres with factory struts so would have more clearance with Coilovers potentially but I can't remember how close the wheel/tyre was to the strut body My new rims would have 4mm less inner clearance as they are 9.5" and +22 offset, but my new brakes are slightly higher so I think that allowed for more clearance I know of a car that runs 15x8" and +20 offset and based on the pics fits the guards Which would stick 29mm out further then my old rims My new rims would be another 17mm wider then that without tyres So 46mm wider at the front which lines up when I was thinking front guards would need to be 50-55mm wider as I rounded up (rear guards I think was thinking roughly 60mm) 9.5" is what 241.3mm so a 235 should fit and a 245 may if I have strut clearance But based on someone fitting 15x8 +20 I may only need 20mm more guard width to fit (might need some camber though) I am pretty confident that the rim will clear the front coilovers but we haven't test fitted it as the ST185 Knuckles still need the new bearings installed and the RAV 4 drive flanges pressed in along with all the brake kit put on And then it needs to be put back into the car I do roughly recall the original rims being close to the spring perches Think ill hold off until we get one side back on the car :s

-

Hmm thats not terrible, and then you need a 2ARFE head right? 12.5:1 is probably a little high for what I am planning on doing once im all done (turbo) but if the normal 2ARFE is similar price thats not terrible Will keep it in the back pocket, I am sure I can find something else to do with the K24 if needed but will see how it fits up to start I have parts of a 20v 4age (2heads etc) and a complete 7AFE I also need to work out what im doing with now (resisting the urge to by another AE111 to throw my spares into :p)

-

I did consider originally dropping the 3sgte I had in it as well (motor was also unknown) but decided I wanted to keep the purity of the 4A Motor and keep the engine bay looking more factory, that with the weight of a 3S The AE115 I got as a parts car we could have actually used all the running gear out of and just added some extra mounting points for the diff cradle (still can I think) but I clearly didn't want to take the easy route :p Height of the K24 should be ok, I know of a couple K series swaps. Worse case existing bonnet will get some further mods and ill do a custom carbon fiber one longer term, or we will modify the sump which I am open to doing anyway if I put a k20 oil pump in it (I want too but again thinking about just getting it running) Also post @Roman comments I have rethought going to an EWP and will stick with a factory mechanical waterpump (with a few mods) for now as it also means ill have things running sooner Though ive now got 2 extra ORB -16AN to -20AN fittings along with two extra -20AN weld on fittings ha as most of this car hosing will be braided or hardline because im a sucker for punishment In saying that to get it running and moving I may just through some silicon hoses at it for now I am not a fan of DSG option at this stage though I see the appeal, so right now will be keeping a clutch and trying to get some form of 5speed working After some research if I go for a Honda CRV AWD box I can use the CRV axles and get them shortened/resplined to suit the Celica outer CV joints so thats not a terrible option I can still buy CVS, complete axle assemblies etc so thats a good thing. I may pop down to the wreckers and grab a couple to take some measurements (if they are thicker may be good blanks) Was also thinking having it moving Front wheel drive isn't a silly idea either and I know an E series box can work if its FWD I do have a E51 that just needs 3rd gear sorting and ive got an E50F as spares etc so may be a short term option as well I know they are around, but given I am out of country its not been super easy to source things when TM is a dumpster fire now and FB marketplace isn't very user friendly Also trying really hard not to get scammed or rely on other people too much :p I also haven't had much luck with wreckers getting back to me Whats a running 2AR go for currently? I'm not in country so can't just go to the wreckers and pull one Late model one on TM for 6.5k Over here im looking at around 3K from a wrecker if they supply it Though ive found two pull your own places that has 5 camrys between them (not the hybrid versions) so about 500-600 if I pulled them myself but nothing under 200,000km Also from what I can find the 2AR needs more work to pull out some extra power and not alot of aftermarket support yet A complete 189,000km K24A3 (including loom) with delivery cost me 1200NZD so bang for buck is ok so far and its already got more power then the 4age 20v had

-

I did consider 2AR as an option and I did want to keep it Toyota, I have seen Frankenstein Motorworks doing some good RND on them and get 230hp out of them with a cam swap They are also a newer motor I may re investigate at a later stage But at this stage K24 is just more popular and has more support etc and given ive just brought a K24 :p Also given how challenging its been even getting a K24, finding a 2AR in good condition looks more challenging Some of them also had block issues which im not keen to deal with at this stage

-

I am hoping we can adapt the GT4 box, ive got 3 bellhousings so can always modify one but plan atm is adapter plate. There is mixed info on if the GT4 transfer case will clear the K24 block and I may pickup some Rav4 ones as they are meant to be smaller, plus happy to do some clearancing on the block/transfer case If it doesn't fit ill go for a CRV AWD box and do a custom transfer gear and a few billet goodies as I want to match the GT4 rear diff ratio (ive got two of them) Rebuilt GT4 boxes seem to go for good coin still and more if they have a front LSD so I can always sell my current box on and then build a well spec'd Honda box. Only issue is I may need to shorten/modify Honda Axles to work with Toyota CV's or get a custom setup done EP3 is 32mm 26 spline DC5 are 36mm 28spline Can't remember what the GT4 Diameter is but its a 26 spline, so I may be able to mix and match K20 swaps been done before so I have some info at least https://www.k20a.org/threads/toyota-trueno-ae111-with-k20-swap.97615/

-

Discussion for

-

Not sure if this is classed as old school or if its special enough but its special too me, clean versions of this car go for what I consider to be silly prices over here in Australia So I brought this car back in 2008 and it was a daily/main car until I pulled it off the road in early 2010 if my old thread post is correct. Its a White 1996 Toyota Levin BZG (prefacelift) with Superstrut suspension (TRD adjustable but non coilover) a few minor engine mods, 5Zigen GN+S 18x7.5 and a full toms body kit in hindsight I should have just done some minor things and left it stockish but I was a young guy with dreams I would have approached things very differently if it was today, I actually had an ST185 celica and a few other cars after this including the R32 I have in my display pic (funnily I brought the ST185 as spares for this and then swapped it for the R32 :p) This car is for me the definition of scope creep and given its still in NZ and I haven't been in a rush its dragged out Trying to consolidate things here in one thread from a couple of other forums, pics aren't always the best and this cars been moved around a few houses and has been at Frost Motorsport since 2016 So original plan was AWD conversion with the 4age blacktop and then a turbo Then the plan was 7agte, then 9agte and then twincharged So Ive collected many parts and ive got various pics but I think ill just post some more recent ones Latest direction is K24 turbo To add context to the K24 decision, while I have lots of scope creep the whole point of this car was to have off the shelf parts available and being able to have aftermarket support Bearings, Pads, Rotors etc are pretty common (though im rethinking the 370Z rear rotors) Few brain dumps on part fitment (will add more as I remember) ST185, ST205 and ST215 Rear Hubs will fit with Factory AE111 suspension arms but require P/N 48780A (pic below to be modified) as its too long ST185, ST205 and ST215 Rear Hubs will fit AE111 Shocks but the lower shock mounts need the holes drilled out to the same diameter as the hubs mounting flange Front RAV4 ST185, ST205 and ST215 wheel bearings are larger then AE111 bearings but the inner Diameter is the same Machpherson AE111 and ST185 front steering Knuckles are similar ST185 Knuckles bolt upto AE111 Shocks, lower ball-joint on ST185 is larger diameter and needs a sleeve pressed in to work with AE111 ball-joints ST185 and RAV4 Front Wheel bearings are the same, RAV4 5x114.3 Drive flanges will fit in ST185 Knuckles AE111 Front wheel bearings can accept both ST185, ST205, ST215 and RAV4 Drive flanges so can be converted to both 5x100 and 5x114.3 stud pattern The pic below compares, the larger OD is the Rav4 wheel bearing Toyota Highlander/ Kluger drive flanges should work with ST185, ST205 and ST215 rear end. To be confirmed if ST205 rear bearings can bolt on and off as an assembly (cant remember) Car went off to my mate Steve at Frost Motorsport for a full cage and some fab work, has been there since. I am in no rush so Steve does things when he gets time Easter 2016 Made it to Frost Motorsport Tucked away with the other forgotten project cars Parts deliveries I've also had an E52 from a supercharged AE92 dropped off to swap bellhousing's onto the ST185 AWD gearbox . Moving around the shop Shops gotten busy (May 2016) Car being stripped more to be prepped for cage Moved around again Onto the Rotisserie Battery Tray removal and tidy up More Rotation (ABS on the floor) You can see the AWD subframe I got made up by Kiwi race cars in 2010 (they did it without the car) and the diff just hits the rear chassis rail. But it got the car rolling and that was the main thing, Steve is making me a custom front and rear sub frame which Ive got some pics of ill show later To make the rear end work ive got custom MRP AE111 Coilovers with ST205 Bottoms They also did a fuel tank mode for the drive shaft but ive got an Aeroflow 57L fuel cell to replace it with December 2016 Hidden in back of pics :p But new wheels turned up (I brought these from Import monster and got stung on GST in both Australia and NZ ) Plan is to have the car guards widened to fit these with 265 wide tyres considering a 40 sidewall but may end up with 35, I still haven't brought tyres. March & April 2017 More prep I also brought a Racetech seat and Harness around this time to go into the car July 2017 More seam welding You can see on the 2nd pic how the front suspension arm is just a hair too long to work with the ST185 rear knuckle (though might have been able to force it in) Steve made some custom ones back in 2014 for another customer and agile performance also do off the shelf kits (https://agileperformancenz.com/collections/toyota-celica-gt4/products/celica-st185-st205-rear-control-arms) November 2018 Hiding in the back Feb 2019 I brought some big brakes from MRP 5x114.3 329x28mm Rotors (Falcon) 4 Pot Wilwood Calipers Lines, brackets, bolts, hub rings April 2019 Ordered Akebono 370Z rear calipers from Jegs in the US to use on the rear with 350X20mm rear discs April & May 2019 Parts for a table (I was over in April and did seat fitment) Mounted in July 2019 At some stage I brought a complete AE115 Carib for parts and Steve pulled the running gear out of it Aug 2019 (Plan was to use the 7afe and box as a mock up for the 9A at a later date) October 2019 Subframe updates Old pic before it went to Steve but not much space, could have made it work) Reason for new subframe was to allow more suspension adjustments and reduce some weight etc I also brought a pedal box from Cardwells around this time as I decided removing ABS was a good idea 3/4" for Clutch 2x 5/8" for front and rear brakes Nov 2019 Some LED lights I would have liked a set of the black factory headlights but couldn't find any for decent pricing (might look around again) so ordered the below ones made out of Fibreglass (they didnt make the carbon fibre ones then) My facelift headlights have tabs broken as is normal for this car I also have the below style tail lights to go on May 2020 Moar subframe September & October 2020 Sub-frame Tacked July & Aug 2022 Playing with Gearboxes I brought a front LSD for the GT4 box from agile performance back in Feb 2020 (https://agileperformancenz.com/collections/toyota-celica-gt4/products/celica-gt4-front-lsd-1-5-2-way) along with all new Toyota bearings for it Goal was to put a A series bellhousing from the Broken E51 or from the AE115 Carib AWD boc onto the Celica GT4 Gearbox so it would work on an A series engine ie 4A 7A etc Box had been fully rebuilt back in I think 2010 or 11 Few custom tools got made to do this, though speaking with Steve Early 2024 the box hadn't been fully reassembled so it may go back to being a 3S bell-housing depending if the S or A bell works better for an adapter for a K24. If it won't work with a K24 Ill put it up for sale complete as a GT4 Celica gearbox with the LSD installed etc and the money will go towards a Honda AWD box. (PM me if you want to express interest) And I think this gets us upto date currently, I sat down early 2024 and decided that a 9A build is no longer realistic due to costs and part availability While this project has snowballed and scope crept I am trying to bring it back in and said to my partner the other night I want it in Australia by 2030, progress has been slow as I haven't pushed and have had other priorities and a big shout out to Steve for being so patient as it takes up space in his shop :p I just paid for a K24A3 with 189000km that will be delivered to Steve by the 20th I have a few K24 goodies sitting next to me or on the way and will be buying a Nexus r3 to run it Current plan is Get the K24 installed (will be deleting P/S and A/C) Confirm if it will work with GT4 Gearbox (if not Honda AWD box to be brought) If using Honda box will need to acquire new axles/cvs and modify as needed 7.5" twin/triple plate clutch Custom Prop shaft Finish cage and mount seat? Paint as needed Install front brakes and front end Install fuel system, I have all the bits to do a dual pump 2000cc injector system with a fuel cell Install rear end Confirm if I already have rear rotors and if not buy some May need some locating rings as well Handbrake setup? (cables I have should work, may need rebuild kit for drum brakes) Buy rims that fit current body Buy tyres for existing rims and modify body to suit Reinstall factory body wiring Remove anything 4age or redundant from factory fuse box (plan is to run body side with factory setup) and restore loom (Tesa tape, Loom sleeve, heatshrink and replace connectors as needed etc) Install cooling system (AN20) Wire in Nexus R3 for engine setup Exhaust? (as big as I can fit) Ideally want it movable so I can ship it here when im ready if time allows Turbo, Electronic wastegate & Intercooler etc Rear wheel drive intake for better intercooler piping layout Oil cooler and remote Oil filter Electronic power steering column and Steering rack (may need relocation) looking at GT86/BRZ as an option Ducting for cooling (possible undertray) Weight reduction options and body parts Some form of electronic (Heatpump) A/C and heating Demister vents etc

- 10 replies

-

- 19

-

-

LOL I was thinking of just swapping the Fuel pump relay wire thats ground off ecu to be ground to chassis and then every-time the car is turned on the fuel pump is running Is this your MAF? MAF Sensor Although most users of Haltech ECUs will be deleting the MAF, it is possible to use a MAF if you prefer. It also incorporates an Air Temperature Sensor, so if the MAF Sensor is removed a new Air Temperature Sensor must be installed in the intake. 1UZ Early The early 1UZ use a Frequency based MAF Sensor. It is not a normal 0-5V signal. Pin OEM Wire Colour Connection 1 Brown Signal Ground 2 Yellow/Black Air Temperature (AVI) 3 Yellow/Green MAF Signal (SPI or DPI) 4 Blue/Red 5V+ 5 Brown Signal Ground

-

Note you can add ethrottle to the Storm G4+ later if you need with an expansion module https://dealers.linkecu.com/G4RET Link do one but there are other DBW modules around that should also work