-

Posts

2009 -

Joined

-

Last visited

-

Days Won

1

Posts posted by nzstato

-

-

If the wallet would support me I'm keen on the Clipper, but may head down and see if the A35 is within reach...

-

13 hours ago, Muncie said:

I want to build nice compact looms that can maybe be tucked away a bit easier than a stock one without old crispy connections.

Ive always managed to get stuff working but yeah no more bullet terminals time to up the quality and water resistance.

Working for Rocketlab spoiled me.....

You work for Rocketlab? Guy I went to school with is VP of propulsion, lucky bugger....

-

I think @danger knows the spot I'm talking about. If you take a drive out the back of Palmy you'll see a whole bunch of 80s/90s mazdas slowing rotting under a tree. Been a long time since I've been out there and have since lost touch with the family.

-

2

2

-

-

Also, can you unpick the panel to work on it off the car? Would make the job a whole lot easier...

-

4

4

-

-

34 minutes ago, NickJ said:

I will quit my job and complete a 5 year panelbeating apprenticeship if it saves me one day of sanding bog, this is the extent of my hatred towards that satanic dust

I'd suggest sorting out the damage on the arch first before tackling the broader area of the panel. With the look of that arch it'll be pulling the rest of the panel hollow and you might risk over stretching the center in the effort to get the line back.

-

1

1

-

-

22 minutes ago, Bling said:

House finish came up really nice!

Hate to say it, but the mis-matching of timber levels on the steps makes me sad. Though they may be temporary, if so no worries. I'm a stickler for details though and it gave me a mad twitch.

Good job either way.

On the side of the steps? Yea, the top boards are close to cover up the framing timber behind, kind a rock and a hard place with what we could do to make it functional and attractive.

-

1

1

-

-

-

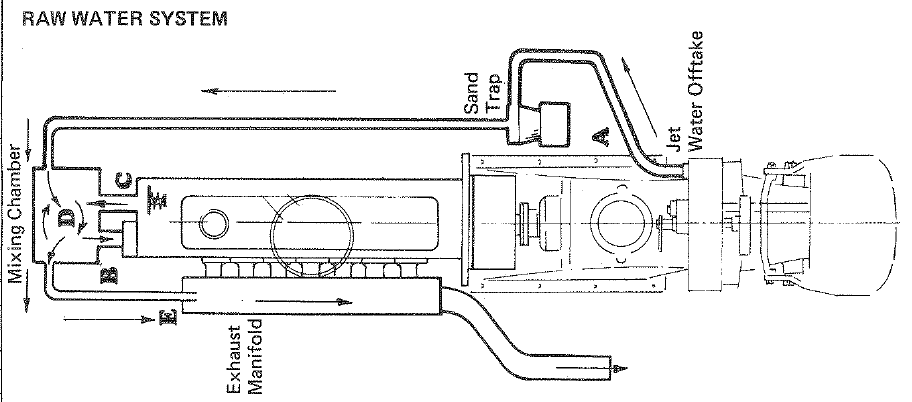

If you line up the jet in/exhaust out flows like in the diagram you dont necessarily divert the flow as most will pass through with some minor turbulence for your engine cooling needs - need to match inlet and outlet pipe IDs. The aim is to mix a the engine hot water outlet with a portion of the raw water to supply water inlet at your thermostat temp (I found a thread which suggests 83deg for holden v6).

-

Have you looked into fabbing a mixing tank? Its the best way to try to limit temperature surging in a raw water application

-

1

1

-

-

Choice, another trick is to mix dry ice in Acetone. The dry ice will sublime and leave the acetone at -78, not as cold as liquid N2 but with a higher head capacity it will suck the warmth out of anything.... extremely dangerous so only under adult supervision kids...

-

2

2

-

-

-

This is the TM pic, its currently sitting in my sisters garage in Invercargil till I can get it up to me.

I'm figuring its going to be pretty simple, main query is if there are any hidden grub screws/pins if I have to pull the quill to replace the bearings.

The bandsaw is the same as this model (https://www.trademe.co.nz/a/marketplace/building-renovation/tools/power-tools/saws/listing/3211603883?bof=Rd0yoNg7 ) but is in very clean condition. Its at my dads but came from wifeys grandad who was an engineer for F+P. He did have an even larger Tanner drill (except it had a nasty repair) but another family member took that.

-

7

7

-

-

Does anyone have a Barry source for old Tanner engineering gear? Manuals or technical drawings? I've acquired a HD band saw and a drill press for a song, seem to be in good nick but want to refurb the internals to have em last another 50 years...

-

-

Just got Council contribution fees for the subdivision, works out to be ~10k....

-

1

1

-

-

In terms of supply issues I think we've gotten off pretty light, the only minor points were:

The exact model of heatpump wasnt available, went for a similar unit at close to equal price

The exact carpet was on backorder, went a shade lighter which was in stock

Doors were 2 weeks late

Tilers were in short supply, put final fitting away a week.

Pretty minor compared to what I hear described....

-

1

1

-

-

And the debate continues.... are the grooves really to 'breathe', the increase in surface area would be marginal.

Final touch ups this week (I see alot of post it notes everywhere) and have finally been able to lodge title. Was suppose to be a month ago but hopefully that doesnt hold us up.

-

1

1

-

-

-

- Popular Post

- Popular Post

-

-

- Popular Post

- Popular Post

Its moving day....

Here it will be sit for some undetermined amount of time... I may be able to get the wheels/tyres refurbed while it stays in storage but there wont be much of an update on this until I build my new shed. Been a good fun project so far and am itching to get the rest of it completed and on the road...

-

26

26

-

Rhodium and Platinum are coming off recent highs so realistically the value should come back on cats. Its the price of Rhodium which has gone nuts and caused the craze.

-

With a few extra dollars in my pocket I've shelled out and ordered a new trim nozzle.

Been on the cards for a little while, should improve launch and keep the spray off the kids when on the biscuit.

Last run I think the wires off the bilge pump got too close to driveshaft and ripped them clean off. Bought a pair online so I wired one in with a terminal block and still have an extra if need to replace easy enough on the river.

Also think I've chased down my last few leaks so will sort them out when I fit the new nozzle.

-

4

4

-

-

Sams 1UZ Squirt

in Other Projects

Posted

I'm waiting on some new M8 studs but have gone through mockup. Bit of faffing around but we're getting there. Cant wait for L2 to go try it out....

Nozzle goes up....

Nozzle goes down....