-

Posts

2,733 -

Joined

-

Last visited

-

Days Won

7

Content Type

Forums

Downloads

Events

Gallery

Posts posted by gibbon

-

-

- Popular Post

- Popular Post

Having satisfied myself that there was nothing inherently wrong with the chassis fitment (as evidenced by others by the fact that's it's quite a common swap), most of the agonising I did was around how the engine would fit up to the body. most little triumph engine swaps end with a throwaway line like "and then I cut a hole in the body/firewall/chassis/made an ugly as hell transmission cover", which is something that I really want to avoid. so much so in fact, that I actually bothered to test-fit the body. so I'm juggling trying to avoid the chassis/bonnet/firewall, while trying to work out if I'm going to place the crank pulley over or behind the steering rack, while also being aware that the mx5 tailshaft is VERY long, putting the shifter farther and farther back, and the propshaft on a more and more marginal angle. But first, body momentarily back on;

note the battery plonked back in place as ballast to stop the bastard trying to fall off the back of the hoist

the gt6 engine mounts sit at 60 degrees and the mx5 engine mounts sit at 30 degrees. So a gt6 engine mount bracket on it's side becomes a 30 degree bracket and matches up to an mx5 engine pretty good. (did I mention I am impatient, and rough, and lazy)

str8 in m8 no fukin worries

-

16

16

-

- Popular Post

- Popular Post

the engine plonks on and sits between the strut towers pretty good. the stock engine mounts are no good as they cater to two nonexistent cylinders. This pic has the engine rotated a little too far, it needs to be pretty flat to clear the bonnet as of the mounting plan at this time of writing

the mx5 gearbox has some major alloy hanging off the side that needs to be dealt with as it fouls the frame. as far as I know any early rx7 tail housing will bolt on but I value money more than time at the moment so I just laid into it with a grinder and buzzed it all off. otherwise the clutch slave seems to clear OK and aside from a wee bracket on the other side, there are no clearance issues with the chassis that I can see

With the initial "I just want to drop the engine on it and take a photo" frivolity out of the way I stripped everything off the chassis and carefully documented everything into piles of bits on the ground and piles of bits on various tables. I misplaced all my tools but some of the other guys were away so I borrowed theirs and misplaced them too. The chassis has a few cracks and the outboard ends of the outriggers are torn, the hoist might've got them on the way up, although they didn't appear to have any cushions installed between them and the body so they might've already been pulled up hard against the underside and distorted. was hoping to get it off to the sandblasters this week but they're busy, so I had no choice but to continue fiddling around with it

-

16

16

-

- Popular Post

- Popular Post

So I pulled the body. I had a GT6 "workshop manual" which was totally useless. Didn't even mention disconnecting the radius arms or rear suspension. I don't actually have a photo of it with the body off and engine still in because by the time the body was off there was pretty much nothing left to remove so I forged on and tore the motor out. only thing I had was this reference photo of the propshaft angle:

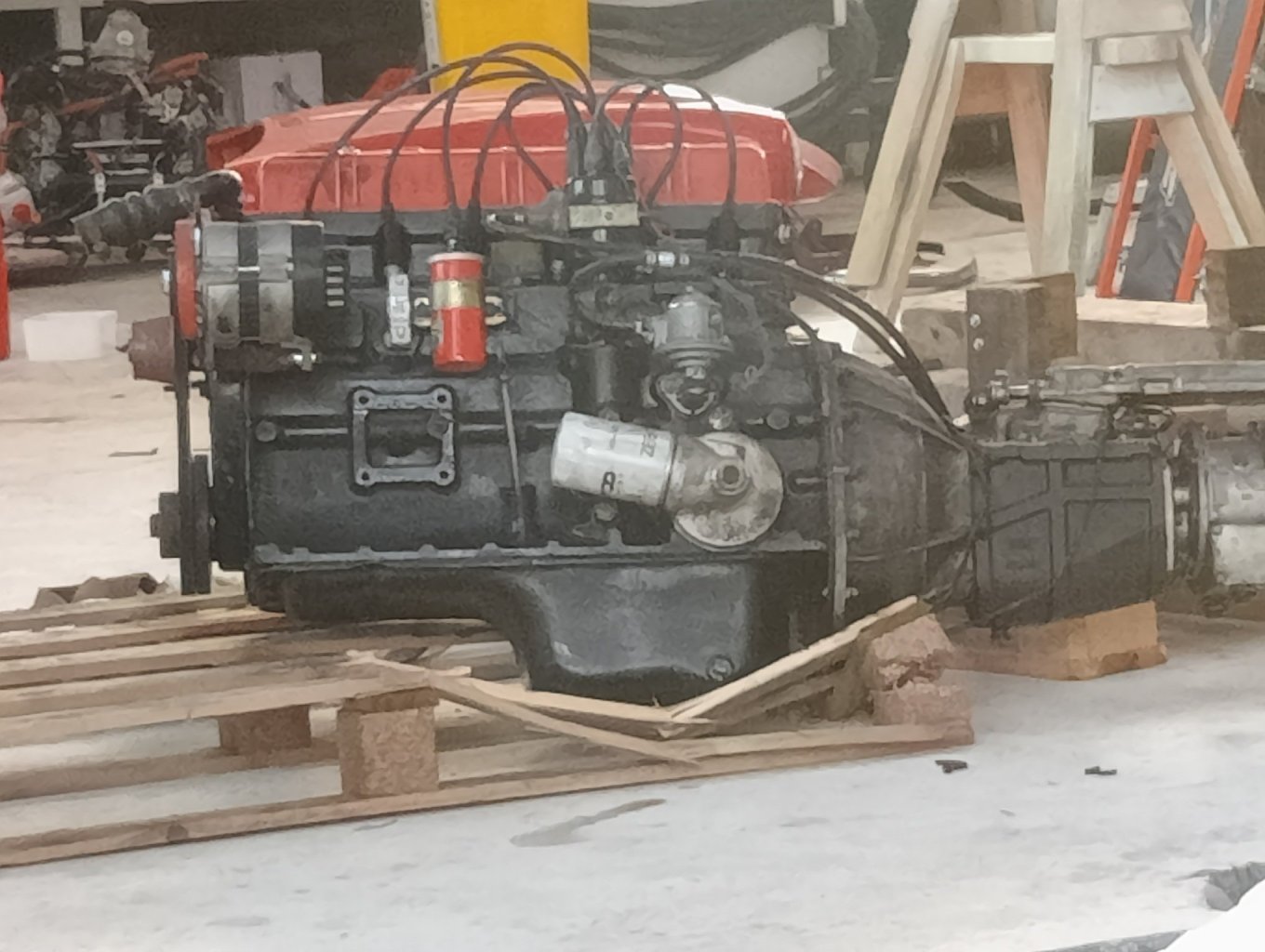

the motor was then removed and carefully placed on a pallet which it immediately destroyed because it is the heaviest son of a bitch I have ever come across

my phone decided to spruce up this photo, I don't know why

-

14

14

-

7

7

-

- Popular Post

- Popular Post

oh where to begin. this little car has been a part of my life for almost two decades now. one decade where it was driven, and one where it languished in it's current state. Here's a photo from better times

such a pretty, poorly designed car. anyway since another car took it's spot it's been relegated to hanging out in the workshop and generally getting in the way (luckily it's tiny). one day I woke up and thought we may as well sell it. so it looked it over, considered the rust in the sills and around the windscreen, how it's impossible to get into gear, how the brakes are jammed on, how the engine leaks like a sieve, doesn't like to start, makes weird noises when you select gears, has crankshaft play... and thought "why just sell it, when I could waste a lot of money on it and THEN sell it?" and so, this build began

The plan, aside from a general refurb, is a 1.6L NA MX5 engine and transmission swap. Nothing that I am doing here is uncharted territory. The MX5 engine is considered one of the easiest swaps and everything has been done before is documented... well, everything is anecdotally documented. ie there's a lot of build threads that encompass what I'm doing, but they all seem to skip over the nitty-gritty and focus on the successful bits. I am not a fabricator. I am impatient, and rough, and careless. I'm going to try and make a note of all the bits and pieces that I wish I had seen prior to starting this swap in the hopes that it helps the next guy

And if I totally fuck it up I'll just repost all the pictures in reverse order and pretend that I rescued the car from some butcher and restored it

-

25

25

-

1

1

-

if I'm going to do it properly then I suppose I need to reserve all judgement until that outer sill is off and I can say for certain that the inner and stiffener are ok (I'm reasonably confident that they will be - this thing has rusted from the outside in, not the other way around). At that point I think I can weld new lower lips to the outer sill and stiffener, and re-flange the floor as you suggest.

I suppose my original plan had the T section welded to the outer sill and floor, and butting up against the stub of the stiffener and the inner sill. The bodge of it would be that the top of the T wouldn't actually be fused to the stiffener. I guess I didn't want to unpick anything but yeah it's a keeper car so maybe I'll bite the bullet once the body is back on the frame. I do draw the line at replacing the whole floor just because of a rotten flange though

What are my chances of getting the outer sill off in a reusable state? It looks like it just has tack welds at the front but I haven't checked out how the rest of it is held on

-

I'll get some tomorrow. Probably going to start a build thread anyway so the whole internet can watch the disaster unfold

-

1

1

-

1

1

-

-

dredging up a dead thread as I too have stumbled across the suspiciously cheap AMR500. Is anyone running/still running one? how are they holding up? what's the story with the donut racing video, what did they do wrong? the internet won't tell me.

-

here's the underside of my gt6. the seams where the sills and floor have large corroded away, as they come from the factory with a nice chrome capping that traps all the rain and lets it fester

Both sides are the same. The thing is, it's ONLY the exposed part of the seam that's gone. The floors are fine otherwise, and I've borescoped the inner sills and they're fine too. and obviously I've hoisted the whole car and aside from the rusted seams folding at the hoist points, the body is still strong.

Because the seams are combination of the floor panels, the inner and outer sill, and an internal stiffener, renewing it would mean replacing all of those parts, even though it's only the exposed lower inch that's rusted

So would it be totally unreasonable to just grind the remainder of the seam off, fold up a long T section of approximate gauge, and weld it in it's place? Or is that too much of a bodge up?

-

hey @cletus just to save me asking the same question in the certs thread, what do you think about this, do aftermarket half shafts require a cert? Mine are "professionally manufactured" (according to the UK seller, who don't supply any kind of engineering declarations with the parts), and dmulally's are locally built

-

10 hours ago, dmulally said:

They then got spun up on some fancy massive machine to balance them and get a report for LVV and job jobbed. Cost me maybe $300 all up

that's a good point too, I'll ask CDC if their off-the-shelf axles come balanced. The LLVTA lists "axle modifications" as requiring a cert but reading into it, it looks like they might be talking about live rear ends more than anything

-

google says the cappuccino diff is rock solid up to 64 hp. jokes on us, it's probably based on a spitfire diff

-

1

1

-

5

5

-

-

lol im just looking at that too, it actually looks pretty close, comes in an LSD too

two on trademe

-

2

2

-

-

19 minutes ago, Nominal said:

I was looking at rear diffs for fwd-orientated 4wd cars (mazda CX-7 looked sort of ballparky) as they're generally not very beefy. at first glance I thought axles would be impossible as simply nothing is as narrow in track as the little triumphs, but plenty of cars have offset diffs and "short side" axles, of the thousands out there, one might be close enough.... but, I'm leaning towards just buying the bespoke bits as they guarantee hours of not fucking around

-

1

1

-

-

what's involved with chopping and changing CV axles? can different CVs be swapped around on axles easily enough or do you have to cut and weld the axles?

-

I refuse to believe the best option is still a fifty year old datsun diff which doesnt really "bolt in" in any way, shape or form. by the sheer weight of statistical inevitability, i assure you all that some korean designer in the last twenty years has unwittingly penned a diff for some unassuming van that fits up better, we just gotta find it

meanwhile in one of the most recent threads I've seen, some guy pops up and is like "I think I've found a solution using a 1974 alfetta hub" NO

-

1

1

-

5

5

-

-

20 minutes ago, Nominal said:

Just get an MX5?

What are you trying to achieve with a 200hp GT6?

I've found that simpler projects are more likely to get done in a reasonable time and I somewhat regret launching an 'all out' project.

its more than my gt6 is end of life IMHO and really will need an "all out project" to bring it back. the motor and gearbox are buggered, the sills are rotten, I think the front of the chassis is bent as the bonnet gaps are irredeemable.... the body's going to have to come off it anyway to address that, so yes it's going to be a giant can of worms. so I thought I might as well rethink everything. Honestly I think the MX5 part of it will be one of the less time consuming aspects of it. Fortunately I have a big workshop with a hoist, and several employees who also enjoy working on cars who I can bend to my will. will it ever get finished? maybe not. but it's not going to be driven again in it's current state either

-

5

5

-

1

1

-

-

for context I have avoided brakes, diffs and suspension almost my entire life because they are so, so shit to work on

and the way those yanks build their cars, looks like they could have started with just about any vehicle as it's all hot rod butchery by the end. seems to be a culture that never stops to think "surely there's an easier way of doing this"

-

4

4

-

-

9 hours ago, VitesseEFI said:

have an MX5 g/box in my GT6 mated to the Triumph six. It was a bloody mission getting it in there and I won't be doing another.

I feel like I should be more concerned about this than anything... I thought the mx5 setup was considered as close as anything is going to get, as far as fitting in without major butchery?

I would also be interested in your axle drawings, although they will probably have to be in crayon for me to make sense of them. I keep running into this circular argument where I want to use the blackline centre to avoid having to mess with fitting up an r160, but then I want to eliminate the rotoflex, which means custom axles which means I dont need to keep the triumph diff, so I could run a datsun diff, but wouldn't I like an LSD? well in that case just get the blackline centre for the stock diff, oh but the axles.... maybe I get an lsd subaru r160 and build custom axles for that?

As for this ominous word "machining" - I have a lathe, a welder and a drill press, how much more technical do I need to get?

-

16 minutes ago, Alfashark said:

Bit of Lego trickery there - The worst part of it is a distinct lack of 340s, Rover 100s and Mk4 Escorts in this part of the world.

Having just finished work for the week and after 20 something hours awake, I haven't looked at any measurements but would an MX5 diff/axle assembly be close to the right dimensions for a GT6?

on the triumph experience site a guy has just shared his project of fitting a complete mx5 rear end which he concludes was way too much work, I can only assume he fitted the entire rear end because just fitting the diff and axles was even more difficult

-

3

3

-

-

7 hours ago, VitesseEFI said:

Ok. Driveshaft UJs are probably the weakest link with the Blackline fitted. CV shafts are a nice solution. I was selling conversion kits for a while which used MGF/Rover 100 outer CVs and shafts with Volvo 340 CVs at the inner end also replacing the hubs and wheel bearings with Rover 100/MGF parts, but Rover 100s and Volvo 340s are basically extinct now. There are shafts available in the UK that bolt right up using the standard hubs and bearings but fairly pricey. There original rotoflex arrangement can reasonably reliable but only with DECENT donuts! It’s very scary when they give way in service.

The diff rear casing has a boss already in the casting which can be drilled and tapped for a drain plug.

if you don't mind giving up trade secrets, was there much involved in putting your kits together? There's a couple of MGFs for bits on trademe and Volvo CVs are still available..

-

10 hours ago, VitesseEFI said:

Late to the party….. small chassis Triumph diffs are a bit shit. Some are worse than others. For the purposes of this I’ll assume we’re talking about the later 3.89 /3.63/3.27 with round input flange. Theses suffer from

- Being too small for the 6 cyl cars

- Not enough oil capacity / no drain plug / leaks. So the oil gets cooked, is never changed and eventually turns to jelly or escapes and by the time the diff starts howling for help it’s too late.

- outright breakages are mostly either the cross-pin breaking or the carrier casting failing where the pins go through. The Quaife/Blackline copy solves this.

-It’s still a small diff though and you definitely can rip teeth off the CWP though being properly built and being full of decent oil helps.Absolutely this. Go drag-racing /drive like a baboon on meth and it will die. Maybe not on the first pass, but soon. Though as also mentioned, you might well break something else first - driveshaft, UJ, diff output shaft, gearbox.

200bhp/150 lbft is pushing your luck pretty far even with the Quaife. Though a friend of mine does race a 2.5 Vitesse with a Quaife diff and CV shafts. That has 180 bhp and 180lbft and gets driven with aggression. He’s not yet broken the diff, though to be fair other components (notably gearboxes) have been acting as the fuse. He’s recently gone to a T9 so we’ll see! 200bhp is getting close to the limit for an R160 too I’d think.

I’ve not (yet) broken a diff outright. I’ve worn a few out though. Vitesse is only around 140 bhp /140lbft though. I’m now running a Quaife copy as at last rebuild time all of my collection of standard carriers had problems. It seems fine - heaps traction without any odd clanking and snatching like the plate diffs.

I’ve also got a 3.54:1 viscous lsd R160 in stock along with a conversion kit from a guy in Melbourne. I’m procrastinating as I’ve been having trouble finding the right Subaru driveshafts (now solved) and want to beef up the spring hanger a bit as the Vitesse is fatter than a Spit/GT6.

@gibbon, is yours a rotoflex car, what engine/gearbox are you planning and how will you use the car?

thanks for the reply, I'm pretty confident that the Blackline would end up miles cheaper than building adapters and getting half shafts etc machined for the R160, as you say the other half of the equation is getting in there and replacing the oil, i guess welding a drain plug boss in at the same time etc

My car is a rotoflex (probably needs new donuts come to think of it). Plan is a supercharged mx5 engine and box. (although the bridgeported 12a and starion box languishing in the garage got a long hard look too) I doubt it'd be anywhere near 200hp but I'm playing it safe. Likewise I'm a placid driver, but I don't really want to leave an obvious weak link in the system, especially if it's fifty years old. If the LSD unit replaces the traditional first points of failure then that's what I was hoping to hear

-

40 minutes ago, ahebron said:

Plenty of free info on the net regarding the Datsun/Subaru diff conversion but it doesnt address the axles.

yeah I did notice most of the threads petered out around the time axles were discussed. thanks for weighing in, I saw your post on the brit car pics thread and figured you were an old hand at triumphs and the like

-

6 minutes ago, locost_bryan said:

Standard 8 before that iirc.

More than 100bhp I'd be looking at the TR/2500 diff. Would be surprised if there wasn't an off the shelf kit for the upgrade over the years.

like with all things gt6, I think there's significant clearance problems that prevent fitting just about anything else. even the driver is an interference fit

-

2

2

-

1

1

-

-

my understanding is that the diff was originally designed to go behind a 35hp Herald engine and the poms are the actual worst offenders for "if it ain't broke don't fix it" or rather "make sure it breaks, to help out the lads down at the Union"

-

1

1

-

Gibbon's 1971 triumph GT6 that everyone told him not to mess with

in Projects and Build Ups

Posted

transmission fits the tunnel perfectly except the shifter is miles back, probably just about under the handbrake. No wiring was disconnected prior to this photo it was all legitimately just hanging its guts out like that since around 2012

there is a well documented mod to move the shifter forward but it's still not quite enough to get it back to the factory hole in the trans tunnel. the mod places the shifter about two inches aft of the mount points showing which would have it coming just through the wall of the tunnel.

I decided I could do better by doing away with the mount points and bringing the shifter as far forward as possible. I wish I had just gone with the original modified point! the mechanism is EXTREMELY sensitive to misaligment and the selector rod will jam up if it is not completely, perfectly straight. right now the whole thing is sitting on a workbench jammed with shims and things-acting-as-shims, waiting for some brave soul to TIG some new mount points onto it. I might get a photo of the finished product, but let's just call it a work in progress

with the aircon pulley mounted just over the steering rack and the larger alternator pully sitting just behind, this is the nearest pinch point - the heater (I think?) outlet at the back of the head just sits off from the firewall seam (pic is taken directly down at the rear of the engine). Once I'm assured that this is a heater line and nothing more I'll blank it off and move the temp probe. My heater is long gone