-

Posts

2,727 -

Joined

-

Last visited

-

Days Won

7

Content Type

Forums

Downloads

Events

Gallery

Posts posted by gibbon

-

-

i know its a personal preference but i reckon youre hamstringing yourself by confining choices to toyota

12a drillport won't know what car it's in

-

2

2

-

2

2

-

-

Siamese block BEAMS v8

-

1

1

-

-

I can state with certainty that I'll have nothing better to do. Burgerfuel again is it?

-

-

Just has chassis number and vehicle weights on it... I can just make out a manufacturers part number on the bottom. So buy blank, fill it out, gotcha

....best way to fill them out nicely? It looks to be very lightly etched, not stamped

-

My dataplate is missing, how can I go about getting another one? Car has no VIN number, chassis code is visible on the firewall, car has live plates and is on hold, the dataplate was removed for rust repair on firewall by PO and subsequently lost

-

Yeah mate I reckon that'll work, can I have the rod to go with it? Tried to PM you but it wouldn't go through @kyteler

-

Passed a beaten up looking k11 2 door at the salvage yard just south of kerikeri today if anyone wants one that bad

-

2

2

-

-

this is the beast here. obviously it's supposed to be in one piece, seemed a shame to just chuck the whole thing

shoot me a PM if it looks like what you've got, thanks!

-

1 minute ago, kyteler said:

I have one of those that I snapped the jaws on. Top quality. Happy to send you whatever other turd part you want from it if it's the same.

hahah no shit, i was about to add "really just hoping that someone has one with a busted jaw" lol. I'll get a pic of the rooted bit

-

1

1

-

-

has anyone ever repaired or gotten parts for these cheap vices? turns out this baby is a holdin' vice not a crushin' vice, i stripped the main nut on it. the nut is a barrel and plug thing cast together, I see this type of vice for sale all the time so presumably someone's dealt with this shit before

in the meantime yo dawg i heard you like vices, heres some vice grips to grip yo vice while yo vice grips... (seemed to do the trick at least)

-

1

1

-

-

9 hours ago, Testament said:

What the shit, I've never owned a car younger than twenty years old and suspect I'm nowhere near the only one

-

2

2

-

-

- Popular Post

- Popular Post

things have occured. most are bad

painted the rear bumper and kit, chucked them on. the lights still need to come out and have the surrounds done.

where it promptly ran into some fitment issues. not too sure what's going on here, its almost like the bumper needs to be pulled back a good half inch, which would leave an ugly gap between it at the body proper. hmm. the kit can't go forward as it fits nicely in the wheel arch already. I'm almost tempted to just go without it if it keeps giving trouble, the car already has a pretty bulky back end JUST LIKE YO MAMA

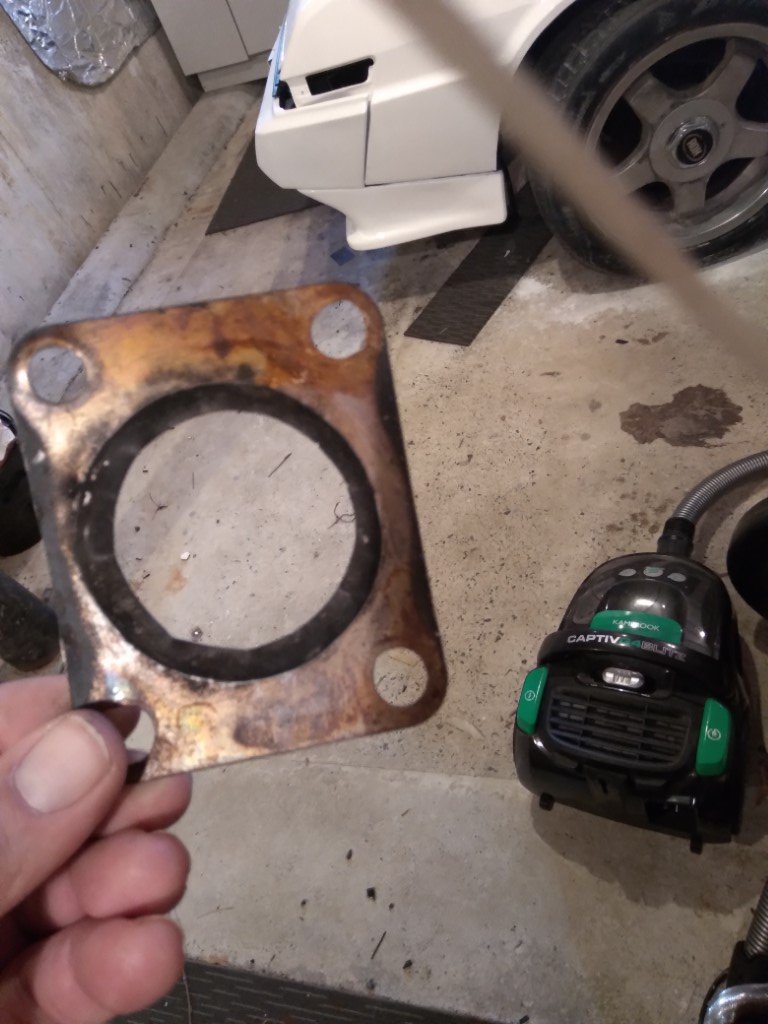

the dump pipe mk 1 had some fitment issues (and got its own thread)

and thus dump pipe mk 2 was born

which clears everything and allows the heat shields back in with a little adjustment. its made out of a stupid amount of segments as i didn't have nearly enough bends to create what is essentially a stupid corkscrew shape. it's ugliness has since been somewhat assuaged with a liberal coating of hi-temp shit weld hider. still better than what came out though! i swear!

anyway while all of this was going on i suddenly became aware of a burning smell and smoke from under the battery compartment area

so apparently the low light sender for the headlight washer reservoir just shorted out, whilst sitting in an empty and highly flammable plastic container. it would appear this thing isn't fused? I'm a bit surprised as I had only just reconnected the battery to put the windows down, but i have had it connected before with no issues, and I haven't really touched any of the wiring (although it is a mess). so potentially this thing was just waiting to burn up at some random point, fortunately I didn't leave it hooked up and wander off. The car doesn't have light washers anymore anyway so I might as well biff it. bit scary really JUST LIKE YO MAMA

some adjusties turned up, probably will never fit them because I loathe suspension work

had a chuckle at this too, it came off one of my spare turbos. "i dunno man, i fitted the bigger turbo but it just doesn't have the top end i'd expect". looks like it was slowly blasting its way through, he'd get that power eventually

so yeah, shit stuff, scary stuff, cool stuff, funny stuff. no actual progress.

-

13

13

-

Holy ass its busy. Saw an ex Lancer in the carpark

-

Congrats on the impending bubba btw

-

1

1

-

-

Yikes, luckily I don't think there'll be many of us to trouble them

-

Managed to find my keys and wallet so I'm good to go

-

1

1

-

-

39 minutes ago, tortron said:

2001 is old-school now

That's like a 1985 car in 2005 which is what this forum is built on

bollocks. 1985 from 2005 is 20 years earlier whereas 2001 was onl-HOLY SHIT ALL LIFE IS FLEETING HOLD YOUR LOVED ONES

-

1

1

-

5

5

-

-

reminds me of when i sold my 1992 mx6 to a guy who was "really into these oldschool coupes"

-

1

1

-

-

does it matter that the only "oldschool" car currently at my disposal is a "classic" 2001 SP20?

-

Confession time, I couldn't find my welding gloves so did the job today with a pair of rubber gloves. Nothing soothes finger burns like a cold can of beer. Parrotdog IPAs today

-

1

1

-

1

1

-

-

9 minutes ago, Nominal said:

Every job on a car project is worth doing twice, if not three times.

Yeah I'm really looking forward to pushing my car out into the sun for the first time and seeing how great the paint job really is :/

-

Any photos I'd share at this point would be more at home in the Design Disasters thread, but let's just say a new dump pipe has been tacked up which is miles away from the booster and about an inch and a half from the clutch master. What a mission

-

6

6

-

-

Toyota Engine ideas wanted other than jz or uz please

in General Car Chat

Posted

Does that work?