-

Posts

2,279 -

Joined

-

Last visited

Everything posted by Adoom

-

I wanted to remove some of the sound deadening bitumen pads from the floor because it was in the way of welding, it looks really horrible and I was looking for any more rust. So I bought 5kg of dry ice today and removed ALL of the sound deadening after work. Was 3kg of the stuff. I think It took about 3 hours. Didn't find more rust. There is a mystery tear in the floor, like it was lowered onto something sharp... I'll clean the remains up with solvent and wirebrushes and paint it with POR15. There is a really ugly repair to the floor where the handbrake mounts. I want to cut that out and do a tidier job of it.

-

The paint job on this car really is half arsed. I think the chrome trim was removed, then GLUED back on, but they didn't bother removing the lights or grill. Last night I started removing the fuel tank and drained it. I removed it the rest of the way tonight. I think I found out why the fuel gauge didn't work. The sender float doesn't.... float, it's half full of fuel. Inside of the tank looks to be surprisingly good. I also removed the rear lights and the rear loom. And cleared out all the carpets and stuff that I had just put in the boot. I really need to start putting metal back into it.... taking parts off to look for rust doesn't feel like progress.

-

Jeeez, and I was thinking you were some kind of rust demolishing god for getting from rusty mess to metal in like... a week!

-

Not loads of progress... Took the lights and grill out. Had to drill out some rivets to remove the headlight bowls. Didn't find any rust there! Used my mallet as a dolly and straightened this flange, just because. Scroll up to see how wobbly it was. Used the flappy sanding wheel on the grinder to remove the old welds. I'd like to go nuts in the engine bay with the paint/rust removal abrasive pad on the grinder, but the dust goes everywhere. Maybe I need some drop cloths for my 'kitchen'.

-

Drilled out the spot welds to separate the two parts of the firewall panel. The smaller panel needed to come off for access the weld the bigger one on. Removed the remains of the old firewall. And removed the brake, clutch, pedal box and steering column. And scraped some shitty old seam sealer off. Removed the battery shelf to make more room. I think I will bare metal the engine bay cause all the paint is fucked, then seam seal all the joins cause most joins are not sealed and the stuff that is is horrible tar stuff. Found some more rust after removing the radiator.

-

Before I did that, I removed the underseal used as seam sealer, so I could located the spot welds. Underseal...Dicks. I used petrol, a rag and a 3M paint removal thingy on the drill(on go slow so I didn't spray it everywhere). My choice of solvent was possibly not a fantastic idea cause I had to put all the rags outside and vent the gara...bedroo...kitche...lounge, by opening all the doors for a while, to clear the fumes.

-

Since the engine was out... And it's the last day of my 4 day weekend. I thought I'd remove the rusty firewall. I still need to remove this bit, I couldn't get in with the spot weld drill, so I just cut it off. The air box thingy for the heater was rusted up the sides too. Fortunately my donor panel does have those bits, but not all of the air box thingy, so I will have to weld it together. Aaaand the donor panel. The edges need some hammering to straighten them out. I'll need to drill out all the circled spot welds to remove the top panel so I have access to weld this to the remains of the air box thingy. I'm considering changing the bottom flange so it's not a shelf for water and crap to sit on. I would bend the end of the tunnel up, to make a flange and cut the flange off the firewall. It will also give me a tiny bit more clearance off the back of the engine.

-

I am having a 4 day weekend. So... instead of doing my laundry yesterday. The bits of wood spread the load enough that nothing bent. Most of the weight is on the strut towers. And out. Much easier to access the rusty firewall now. There was just enough room to roll it out from under the car, I had to take the gear lever off though. Anyone want to buy the engine and gearbox? It ran alright when I drove back from Auckland. Gearbox wasn't crunchy and it stayed in gear. Overdrive works. I don't know when it last had an oil and filter change.

-

It's a bit slow going due to current living arrangement. Keep getting grinding dust on the 'kitchen'.

-

The dog went to the vet for a few hours, so I took the opportunity to make the scary grindy noises. Cleaned up the welds enough so the next bit can go on top. Cut back some more of the box section as it was quite rusty on the top. Not quite sure how to repair the rain gutter, it's quite a complicated shape where it meets the top of the guard and it has to be just right for the trim to clip back on. Ideally I could cut one off another Triumph that isn't rusty there, but I suspect that most of them are. Ground back the big ugly welds down the A pillar, that had held the ....closing plate??...on. And the dog is back. She had to have a broken claw removed. She was still half cut from the sedatives.

-

Eeeewwwww

-

Looks like an engineer mate in Upper Hutt can add some to his next order for me. They have a guillotine, so they can cut it for me too. Yay!

-

Steel Traders? If I google them, I find these guys https://www.hja.co.nz/contact/ Is that it?

-

I should mention that I work in lower hutt and live in carterton. Metal shopping needs to be performed within my lunch hour. So I'm pretty much restricted to the Hutt valley.

-

Went to steel and tube petone at lunch and asked about 0.8 cold rolled sheet. They don't stock that size, they do have 0.6 and 1.0. They can order it, $100+gst a sheet. But they cannot cut it up for me, so I'll need a trailer. I have to find somewhere that has offcuts I guess.

-

I mainly use MIG. I do very occasionally use an oxy welder, to braze...badly and to make stuff hot to bend it. I don't have a TIG, but I could get one in the distant future. The only problems I've had with my Chint helmet are the sensors being blocked by stuff(they are at the top). And not being able to see if the weld area is not brightly lit. The lens cover also seems to get dirty/scarred by smoke/sparks/splatter easily. The viewing area could be bigger.

-

Welded the rest of the patch in after turning down the power to stop blowing holes. Need to sand down the welds and make the box section thing that goes over the top of this.

-

Turned the power down to 1. The welds still look a bit wobbly because I had trouble seeing. I realised afterwards it was because the lens behind the clear plastic was filthy rather than my cheap Chint auto darkening helmet being shit. Got a new clear plastic thing and wiped the lens. Now it's much easier to see. Haven't done any more welding since cleaning it. Was thinking about getting a better helmet and speedglas 9100xx looks great. But I don't think I can justify spending $750 on one from 'murika/Amazon.... Can anyone get deals on these? Still need to flap sand the weld down with the flappy sanding wheel on the grinder.

-

Where would I get cold rolled sheet from? In manageable sizes. I have a boc mig 170P. I have 6 settings for power and variable wirespeed. I am using 0.6mm wire. I did set it up with a couple scrap bits of the patch metal butted together. I set it as high as I could for tacking without blowing through. I suspect the original steel I am welding the patches to might be a bit thin in places. I'll try it on a lower setting this weekend.

-

I am using 0.6

-

The photo, it tricks you. The metal is new, with that grey/zinc whatever coating on it, looks white in the camera flash. The burn mark is because I burnt through into the guard where I hadn't completely removed all the underseal from the seam. I have removed the paint all around the weld area on both sides. The gap is the best I could do, most of it is 0-1mm, some parts might be 2mm. I do have the welder turned up quite high to get enough penetration on the plug welds I was doing. I'll have to try experiment with a lower setting without having the weld just sit on top of the metal.

-

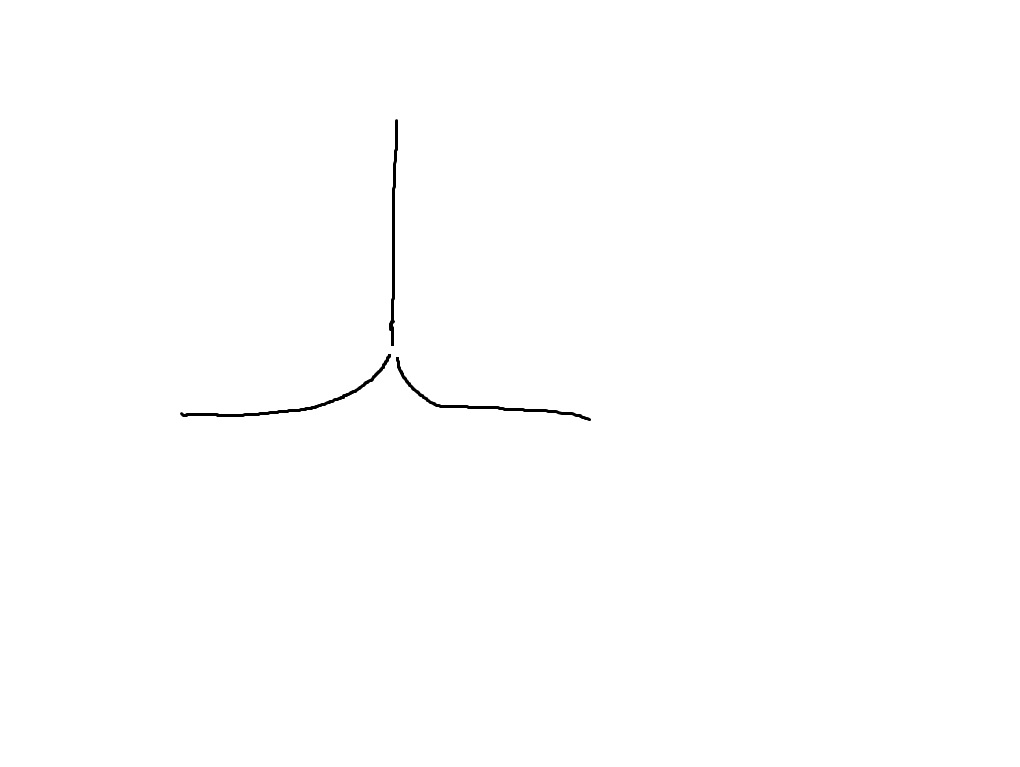

The weld join I am trying to make looks like this. The top is the patch I am welding in. The left is the remains of the inner guard. The right is the inner wheel arch(front). It's the left side of this patch, where the burn mark is.

-

So I have seen this technique where you put a bit of copper or brass hard against the back side of where you are welding some thin metal. It's good for butt welds and filling holes because it absorbs the heat and stops you blowing holes in the metal. And the copper doesn't stick to the steel you are welding. I've just tried this for the first time today, using a bit of flattened copper pipe. It seems to work well if you can get the copper to sit flat against the metal you are welding. But some of the stuff I an trying to weld is NOT flat and the weld blows through until it reaches the copper. I have one weld where 3 panels come together in a Y shape, so making a bit of copper fit nicely is hard. I've heard you can also use aluminium instead of copper... What about aluminium foil.... if I hammer a bunch of it into the back of the join it should conform to the shape nicely? Yeh, nah? Has anyone tried this?

-

-

Reposted all my photos in this thread loading them up to OS for hosting.