-

Posts

11,673 -

Joined

-

Last visited

-

Days Won

2

Content Type

Forums

Downloads

Events

Gallery

Posts posted by flyingbrick

-

-

-

4 hours ago, anglia4 said:

Nicely done.

Those carbon foot pegs look ultra slippery though!

I would highly recommend spending a few grams on some skateboard adhesive grip tape to put on them. I did this with the nylon pegs on my bucket racer and it makes a massive difference when you are riding. A+++ wouldn't ride again without it.

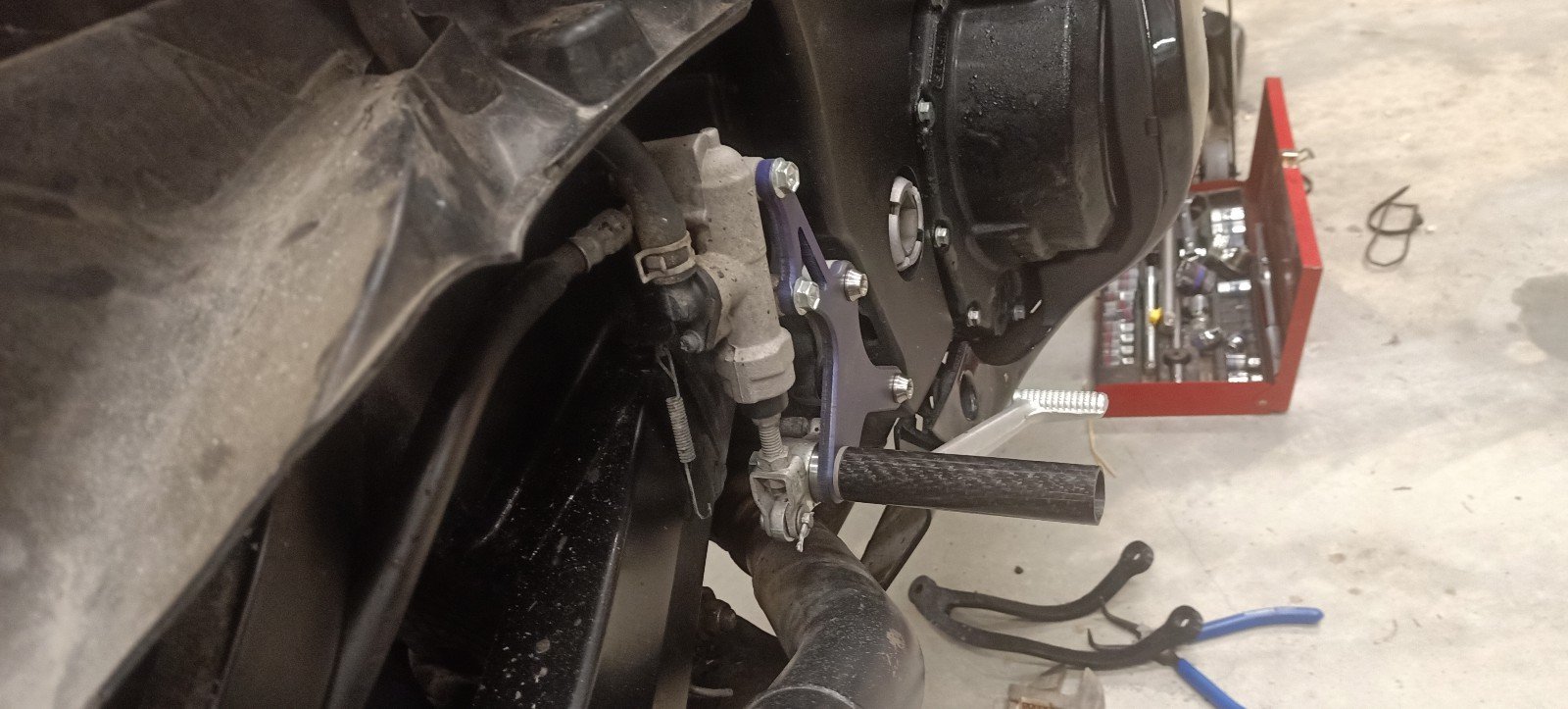

When I was picking up the aluminium bits from @Kimjon he says to me "how are you going to stop them being slippery"

I say, "im going to get some skateboard grip tape" and he's like " brb" comes back with a roll. Such a good chap! Grip tape is not on the pegs yet in the images- I wanted to abuse them a bit first with a hammer and with protected legs jumping up and down...it passed

He's also just machined up the steel pivot boss thing for my brake pedal. So dreamy.

-

6

6

-

1

1

-

-

5 hours ago, Willdat? said:

Such a cool project, do you mind sharing the cost of the titanium cnc plates and the suppliers as this would be reallllllly useful.

Of course.

I used a company called YUNCH, contact mandy.shi@yunch.tech. First class service. The cost of these two plates was just under $200. half of this was freight. Next time I'll be pushing for use of a cheaper freight option (But this was very fast, so i cant complain). One tip is to search AliExpress for services. Often they will have a product for $1usd. You purchase one unit, send them the drawing etc, get a price, then pay the rest of the bull by purchasing more units. This also means you get access to that super cheap (But slow) AE shipping.

Although that $200 may seem expensive, that is material, freight and cutting.

-

5

5

-

1

1

-

-

Hahahahahaha actually laughed out loud

-

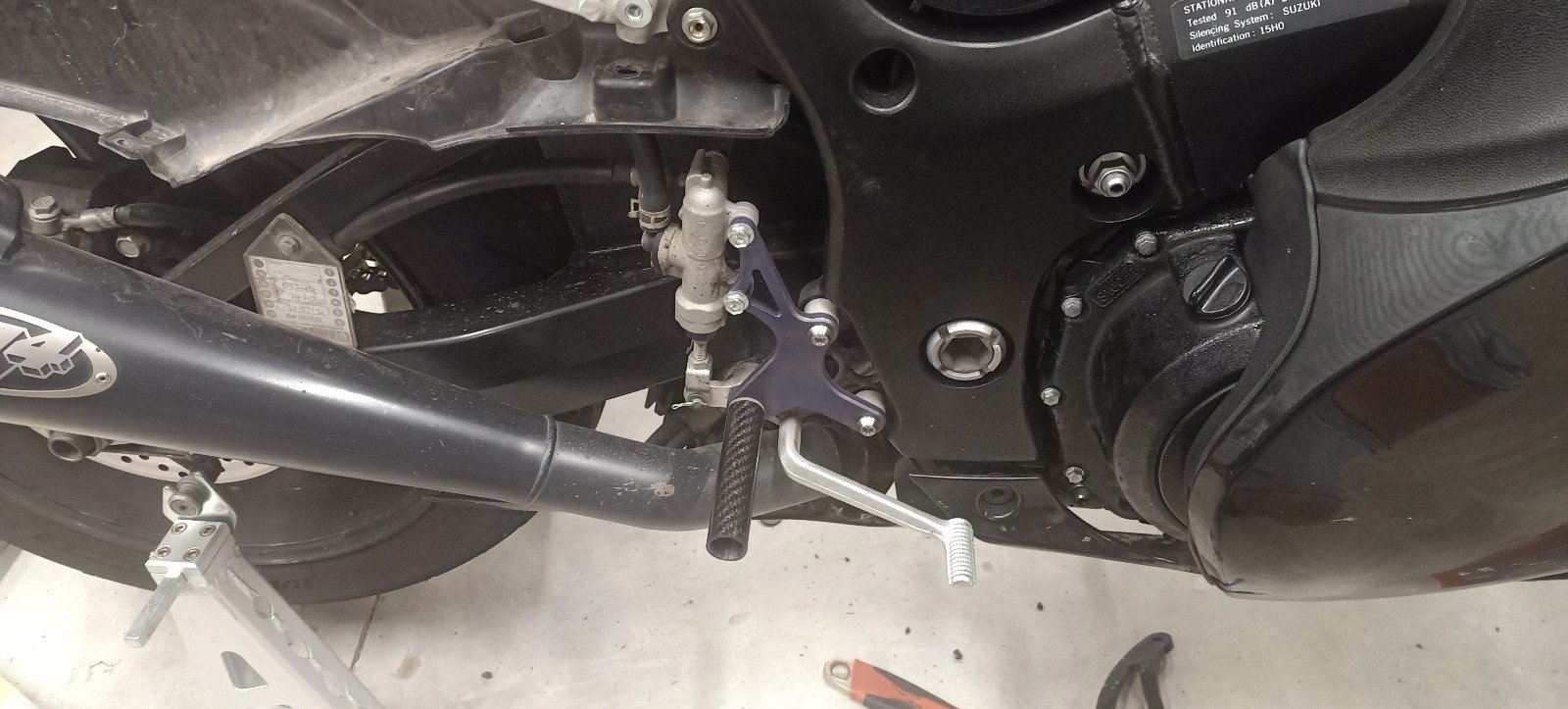

Left hand side peg assembly nearly complete.

Carbon bars

Titanium bolts

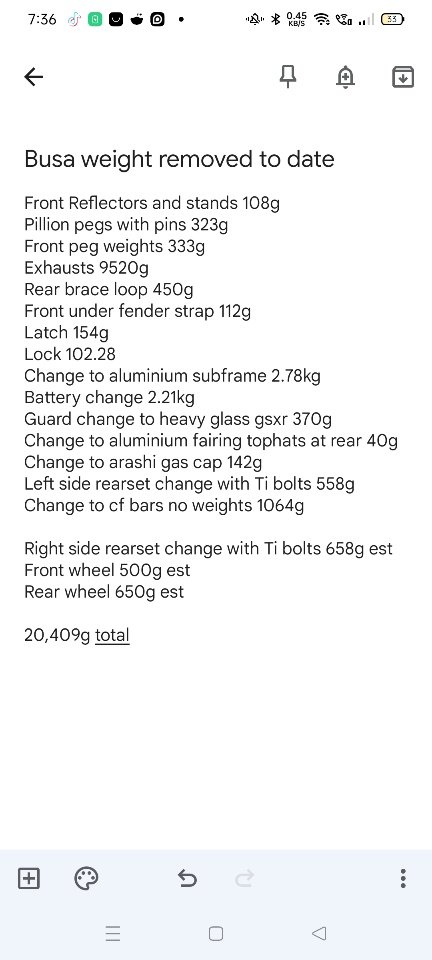

Iv got some assembly to do once some fasteners etc arrive but on track to a 20kg reduction vs stock weight. Enough to be felt! Once assembled that will likely be the end of this project because any more weight removed becomes fairly expensive...unless I can be bothered trying to mold some fairings.

Edit. Just spotted, total is already 333g too optimistic as have counted front weights twice.

-

5

5

-

2

2

-

-

On 03/07/2022 at 10:20, kempy said:

Noticed that too with auction sites on TM, stupid stuff like cheap Ozito tools going for much more than retail :/

English wheels seem to be quite expensive for what they are, to the casual observer

I guess they are big and heavy so freight costs for each movement is going to be extreme. Also, aside from that, damn the one in that auction is a sturdy piece of kit. I'd love a weekend with one just to get frustrated enough that I don't want one any longer

-

1

1

-

-

Gotta admit.. At first I didn't understand. But now we are 25 pages deep and I find your stuff quite impressive

-

-

The exhaust hanger thing was still Happening in the background. It's a tough shape that has to come out of the factory fairing in a very specific place.

To double check it's shape (so that I didn't waste any more of Davids printer flament) I took a scan of the factory part and merged them together. This worked extremely well!! And yes, it fit.

Ali express provided a new light weight fuel cap for an insanely good price. Very happy with quality too

-

3

3

-

-

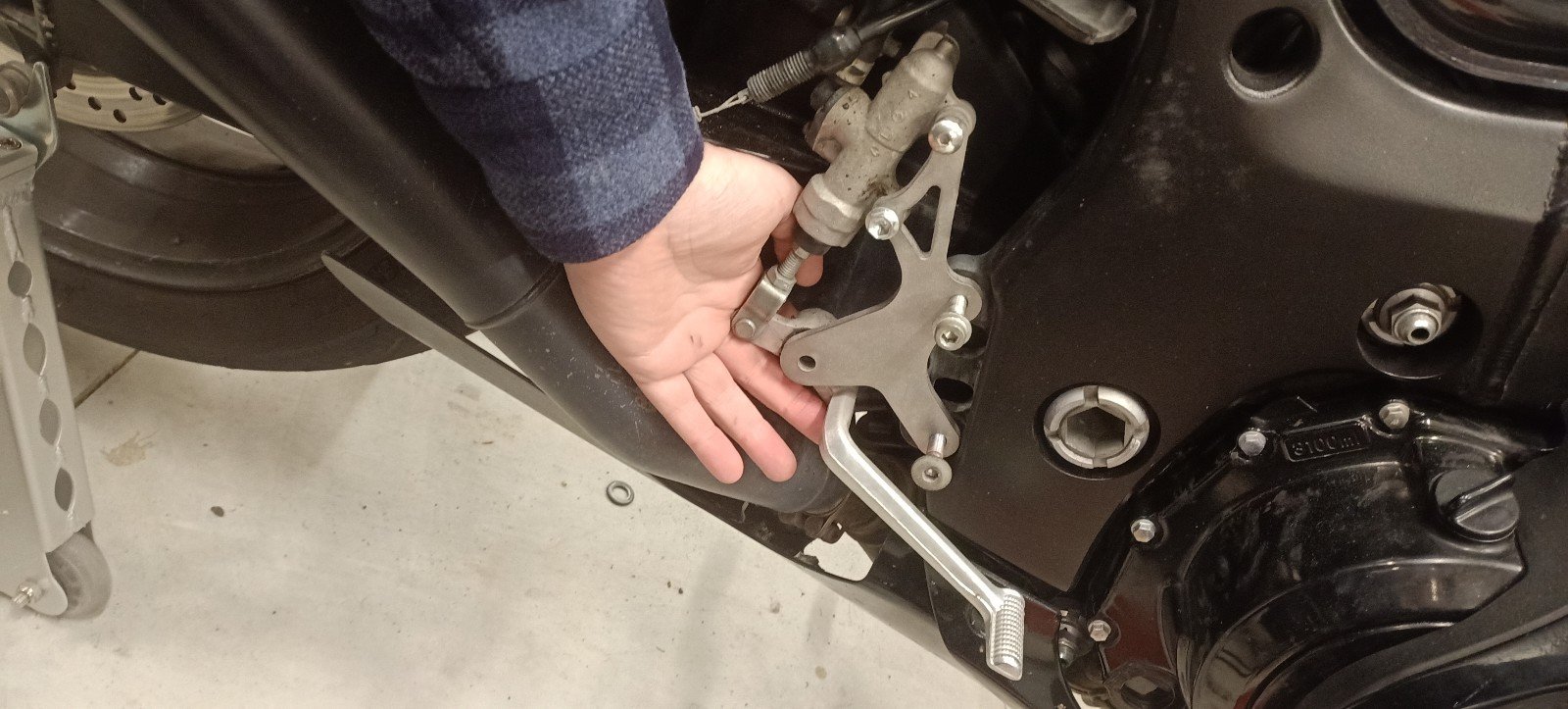

So I started again with grade 5 titanium. By this stage I'd stopped taking photos as I'd run so many simulations it was getting a bit old, but the results were good, the anticipated weight of each component was great, and I'd never played with titanium before so seemed like a good time.

I sent some emails out within NZ and China. Its sad because companies in NZ really can't be fucked with smaller jobs and the associated admin. I got a few replies after waiting a few days and these replies ranged from not being able to secure the material (they couldn't be bothered) to having a minimum cut fee which made this only economically viable if I got three sets cut (I ain't paying for enough material to make that happen).

China made me feel like a king with absolutely great customer service, though I was still not 100% that I wasnt getting scammed... But after a few weeks my titanium rearset plates arrived!

I haven't had much time for filling around but need to tap some holes and buy some pegs, then they are good to go on permanently. Weight saving from the change to these Ti plates is 500g, however when I include the change to the associated light weight pegs, nicer bolts etc will be well over 1kg.

Colour change is due to some DIY anodising- super easy with titanium!!

-

6

6

-

-

I decided to make my own, initially out of carbon fibre plates that would be waterjet cut. This was very very interesting as ended up using fusion 360's simulation package to calculate my designs strength. I ended up getting absolutely insanely strong parts designed in CF but at the last moment got a message from a friend (experienced in composites) saying STOP COME VISIT ME FIRST.

He gave me an extremely valuable lesson on carbon fibre strength and how f360 was not actually giving me an accurate simulation, and although they may work, the properties of cf plate were always going to place a question mark over their suitability and working life, so back to the drawing board!

-

2

2

-

1

1

-

-

Disks to suit the zx10 wheels turned up and some little aluminium spacers are sitting at work. Aside from getting a tire fitted it's all ready now to go back together

will be interesting to do a proper weight comparison (need to get tire pulled off the factory wheel first).

will be interesting to do a proper weight comparison (need to get tire pulled off the factory wheel first).

I have wanted aftermarket rearsets for ages but $$$ and I'm never happy with how the aftermarket rearsets all seem to be a series of aluminium plates stuck together with adaptors. Jankey as.

-

1

1

-

-

1 hour ago, Roman said:

I think you could be right about that.

If the piston is trying to fly apart, where the top of the piston is trying to carry on upwards, and the pin is pulling it back down.

So the material strength around the pin is the weakness.

Then on the exhaust stroke this force is lessened, and when the cylinder is full, on the compression stroke this force is lessened too.

The engine didnt fail when it was approaching max rpm, it failed just after a gear shift where throttle got cut to zero.

So the worst case scenario would be zero throttle, high vacuum, high rpm on the compression stroke.

I'm not sure if these forces are on the same magnitude as each other though.

However, I can indeed increase my piston return spring value.

I can use e-throttle to set a minimum high rpm throttle value to something like 10% or 20%, and then use a fuel cut and/or pull zillions of ignition timing out to cut power instead.

This might bring a host of its own issues, but might be a bodgey solution I guess haha.

Flat shifting, interestingly enough, would also help haha.

The incredibly clever @Lith made a calculator ages ago that works out forces on pistons/rods.

Entering 1NZ stuff. Peak accelleration on the piston at 9000rpm is 4991G!

I'm not sure what sort of numbers I was expecting, but thats bloody lots.

Then the PEAK piston speed is 41.7 meters per second. Which is 8200 feet per minute.

Which is zillions high when 3500fpm is the reccomended mean value.

interesting. That could be around 1500kg yanking on the rod, which would have a yield of like 15x that, but I have absolutely no idea what im taking about.

-

-

Hey guys with linuxcnc, what you doing for computing hardware and interface board, and what jitter readings do you get?

-

Anyone got some big old steppers to re-home?

-

I'm building a cnc too, it's been a bucket list thing for a while. I'm sick of farming machine work out.

Wanted to run Linux cnc on a rpi but they are sold out world wide, so instead brought an older desktop (for cheaper than a pi anyway) so waiting for that to arrive along with all my rails and ball screws. Excite.

-

3

3

-

-

1 hour ago, ajg193 said:

I'm running mach3, at high feeds in multiple axes it will start skipping. Otherwise it seems good enough.

Is grbl a proper real time solution or do you just send it g code via serial and pray it works right?

From what i can tell, it is a "proper" real time solution.....

However i think its only better at being "real time" and seems to suck at quite a few other things, like reliability and ease of setup.

You put GRBL on an arduino and plug that into the cnc. Then you use a "code sender" to send the G-code to the arduino. Then the arduino plods along by itself and runs the cnc. Most people seem to say that mach3 is far far far better and more reliable than grbl though- and grbl is going to have issues if your g-code asks it to compute steps faster than it can manage (This might be your issue if you have microstepping set real high?)

I'm 100% sure i want to use linux cnc now. I was cautious because I've had linux on a few PC's and although it was great (fast etc) it just didnt function as well as windows.

I'm going to run linux on a Pi. I'd have bought one today if they werent all bloody out of stock. Looks like an extremely nice interface and full of features that are not present in many other systems.

I've done a few hours reading about this now so I'm an expert. No practical experience at all- just google.

Anyway, you are welcome.

-

Why did you choose Linux cnc over the many other options?

I think I have settled on simple grbl but open to other better options too.

-

-

Hah funny!! I saw this (or maybe another author) on trademe and wondered about it. Even watched a few YouTube vids. I just wasn't sure if it was usable as a cnc for doing cool stuff or just for milling up kitchen cabinets etc.

-

1

1

-

-

Yeah buddy, slot anything in there so that it doesn't become a doorstop.

-

1

1

-

-

3 hours ago, RUNAMUCK said:

I have nothing of value to add except that someone who did a lot of research also concurred escort was the best.

I've looked lots for the bike and everything I read said that valentine was the best. They also seem to support their customers REALLY well with updates (i think you could even send your unit in to them to have it upgraded when there were hardware updates)

-

Italian shed ornament - Nick's cnc router repower

in Other Projects

Posted

Good morning friend.

Why didn't you install that pre-compiled (I think thats the word) version of linux that has linuxcnc pre-installed? That's what I set up on mine and it works great (jitter is a bit shit but within acceptable ranges)

Does that pendant interface with the mesa card?