-

Posts

9882 -

Joined

-

Last visited

-

Days Won

2

Posts posted by Testament

-

-

the excess fuel was because it was injecting during overlap, and with the large injectors that time during overlap was a large proportion of the total fuel being injected getting blown out through into the exhaust. Worse with it being a supercharged engine, so a lot of exhaust blowdown during overlap from intake pressure > exhaust pressure

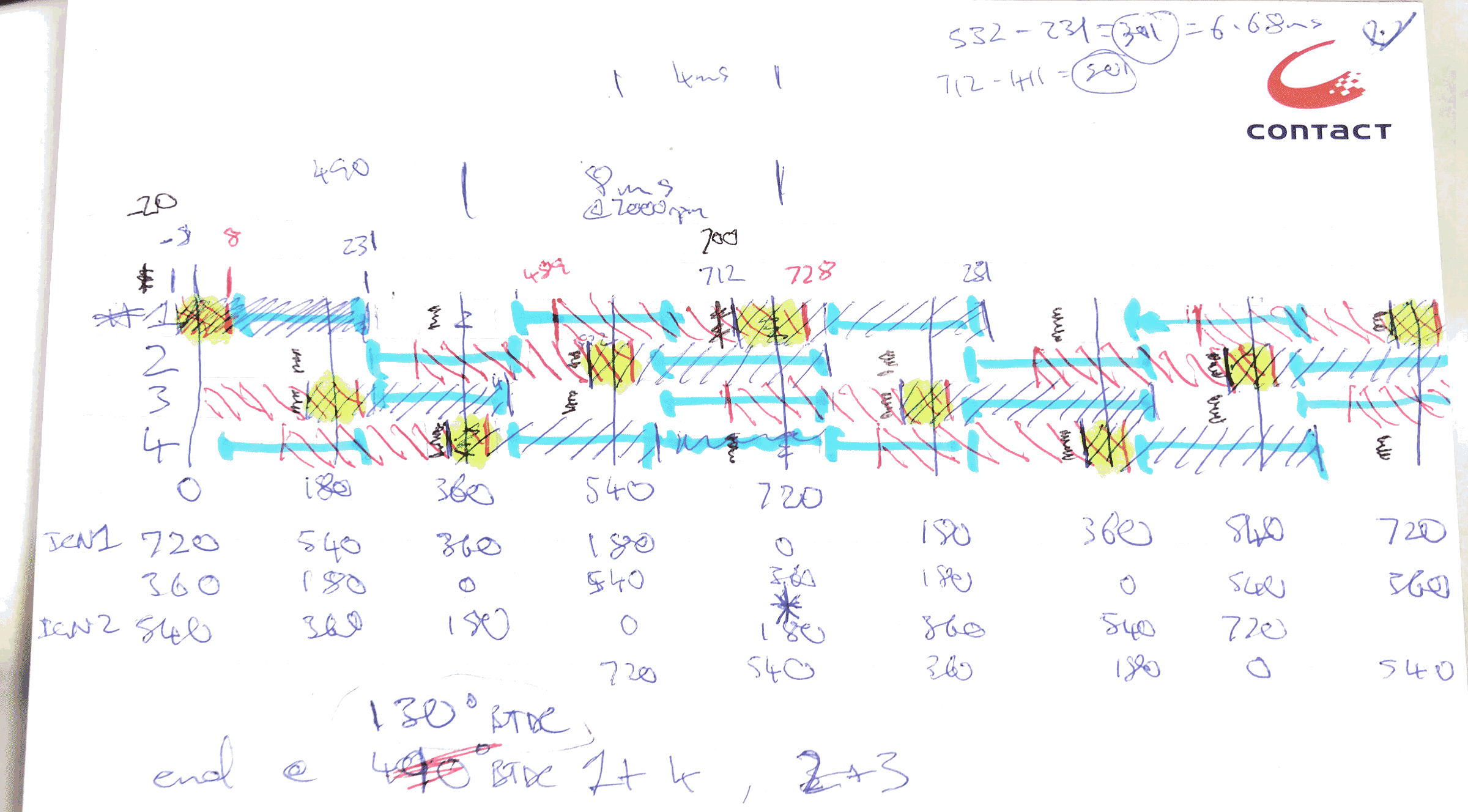

its a bit messy on my sketch but what I think I was showing there is

red \\\\ hash exhaust valve open period

blue //// hash intake valve open period

yellow highlight is overlap

$ish scribble is spark event (wasted spark setup)

light blue highlight is injection

360 deg takes 8ms

numbers are cam and ignition timing

cylinder pairing for injection and ignition 1+4 and 2+3

total require fuel is I think 6.68ms per cylinder there, and overlap is something like 1.5ms so injecting during overlap means 20ish% could disappear, splitting the injection up this way means only half that amount has the potential to go out the exhaust as the second half is all injected while the intake valve is open so should almost all end up in the cylinder.

at lower rpm this could be even worse as the overlap time is much longer.

-

1

1

-

-

corrected, 4 squirts, alternating then

-

3 hours ago, Roman said:

The recent idling improvements that AJG193 recently found by going to 2 squirts per cycle is basically a crude way of circumventing the problems of batch injection's asymmetrical injector timing.

If you have your engine idling and slowly advance through the injection timing range it makes such a difference it can either make your engine rev a lot higher or make it stall. As the combustion quality changes so much.I found this made a huge difference on the 124, likely due to oversized injectors and very short runners

2 squirts per cycle alternating I think is what they call it. with two injector drivers each one firing every 360 degrees but 180 apart.

each cylinder then gets half of its fuel at the right time and half 360 deg out at the wrong time.

before my engine would get to somewhere around 4500rpm and just pop and fart and not run for crap but if you held jandal it would clear up over 6000rpm somewhat. also the tailpipe always stank of raw fuel at idle.

switching to this and timing the half of the fuel at the right time to finish injecting just after exhaust valve closing made the engine rev clean right out and I had to pull out about 20% fuel or something.

just now it has some other issues, less fuel going through and I think the ridiculous IAT's at low and no load with no air bypass valve around the supercharger are causing random intake backfires, probably off the hot surface of the back of the intake valve or something like that.

-

1

1

-

-

electronic ignition definite upgrade if on points at present. usually later model engine might have a compatible distributor but I dont know toyota m_aybe series details.

programmable ignition would be even better but more involved to setup. still would be mostly wires and a couple of sensors so less than installing a fuel system needing pump and manifold and lines etc. etc.

this is vaguely topical

-

the tyre compound is more important than the tread pattern in general. but I wouldnt be all that worried if the car has original brakes and engine, and you know the car and drive it to its braking and cornering abilities. Get what you can that looks right, if possible from one of the more well known tyre companys, in whichever has the softest compound if you have that choice. ie michellin, yokohama, bridgestone, toyo etc. not cheapo plastic china brand that comes in a plastic bag and has less grip than a mcdonalds tray.

-

1

1

-

-

I find with panel steel I end up using longer wire stick outs usually.

generally start close esp with the first tack/weld on the panel when its cold but even after only a couple of tacks (depending how far apart they are) you often need to slowly increase your stickout/distance you hold the torch nozzle from the panel as it heats up.

also mig welding panel steel is very rarely going to look like instagram weld porn. be patient if it looks at all like that red glow is going to blow through or drop out get off the trigger and give it a minute or two to cool down at least

-

1

1

-

-

rough and ready way would be to look at the likely power of your motor and choose carbs from a bike of similar power level

this is presuming you are using 1 throttle/carb per cylinder and the bike was as well.

another way would be comparing to side draft choke sizing for one throttle per cylinder

off the top of my head for a 4cyl this very roughly goes something like

32mm - 120hp

34mm - 150hp

36mm - 180hp

-

1

1

-

-

I've got some spreadsheets that can grind about as much as a 9" if you need man

-

3

3

-

-

On 27/07/2018 at 18:06, AllTorque said:

https://vehicleinspection.nzta.govt.nz/virms/in-service-wof-and-cof/general/exhaust/exhaust-system

see line 5

as long as it cannot enter the passenger compartment, you are fine

The problem is the entire SWB 70 series landcruiser. Repeated testing with both factory rear exit and side exit exhaust on SWB 70 series landcruier at open road speeds recorded exhaust fume levels in all passenger seating positions sufficient to poison passengers with the side windows open or closed.

-

4

4

-

-

good things take time

-

1

1

-

-

-

-

-

-

Just with a grinder. the new bellhousing bolts to the pump so you just trim until nothing fouls. milling it would make a nicer finish but functionally wouldn't make any difference.

process was basically marking up where to cut with tape/sharpie pen etc. it is a little tricky in getting a good reference because from memory the bottom of the gearbox where the pan bolts on is not 90degrees to the plane of the pump/input/output shaft so you cant just plop it on the bench and reference it directly.

-

1

1

-

-

22 hours ago, BobbyBreeze said:

Rename thread to supercharger thread so I can post my awesome/junk DC3 cabin blower plz.

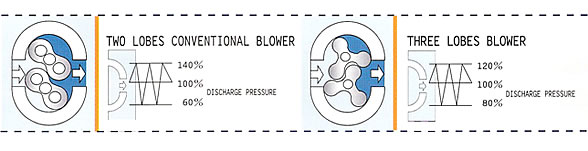

It could be a thing. Would need to be a 2 lobe blower on a 4cyl running 1:1. I suspect no one has ever bothered as most blower development has been on v8's and 2 lobes are obsolete.

p.s. @RUNAMUCK you want the pulse to arrive at the end of the intake valve event, not the start. Trapping 140% boost at end of the intake event would certainly be helpful.

Hey I run a two lobe on a 4cyl haha

16 hours ago, Carsnz123 said:On a carb setup the release valve if for the case of a backfire so the 1L plenum of fuel charge doesn't turn into a grenade or damage the supercharger with a massive back pressure. I've seen a video of a type 35 Bugatti being given a good squirt at night. There was fire spitting out the exhaust and out the hole in the bonnet which the release valve pokes through. The Delage GP car that was out at the Skope classic apparently has hydrauliced on an occasion due to flooding and the fuel pooling in the blower.

Yeah I have a tuning issue at present where there is a random intake backfire resulting in 2bar+ pressure spike in the intake manifold....and I removed that valve because it was in the way of installing the fuel injectors in the manifold......

-

what about brunox? sheepers seems to use that a bit? panel shop who did some work on my old delta used it for small stuff as well

seems like it is ok for small areas were you cant fully clean things 100% because shit access and don't want to cut out the whole thing because massive job and its not a visible area?

-

4x808 ?

-

4

4

-

-

-

I still think there is some merit in having an option for people who don't want to stay in campground type accommodation, some people have sorted that out themselves in the past anyway so more about just making it clear that your not being excluded if you don't stay at camp and just come to attend say quiz/awards and daytime activities. so nats entry fee separate to accommodation, which might have been the case anyway?

tbh the last 3 years especially I think my #1 part has been the scavenger hunts hooning around places you do or don't know to find random things usually with a random group of people has been really really fun.

also looking at the last three years

coro nats was massive so was always going to be hard to follow up, then the last two have been right at the south end of the north and then in the south which is always going to be a barrier for a number of people in the Auckland/Waikato/BOP area which presumably does contain quite a number of members. just a sad fact of it that it is harder to get people to travel further for numerous reasons money/family/work time off/effort/dodgynessofcars etc.

am a little disappointed in the lack of enthusiasm for trackdays of late, they were such a core part of the early nats, people just taking out whatever for a thrash and having a ball

-

4

4

-

-

-

On 15/03/2018 at 08:38, azzurro said:

Your question was "It seemed to me like there is not a huge amount of work needed...and don't have a very detailed knowledge of how many hours this will take?"

I always underestimate how long it will take too, so maybe running through what it would probably take me to do, one item on your list, + consumables etc:

– Cut out and replace an old patch repair in one sill, will need to be slightly curved, but no complex profile or fiddly end bits

- Car on hoist (10 mins, + cost of Hoist)

- Mask off glass etc, remove remaining things (1 hr min + masking and tape)

- poke around and look at area and mark out area for initial cutting (15 mins + cost of pen)

- cut out along initial marks. review cuts and cut a bit more out (20 mins + slitting disc and grinder)

- tidy up cut lines and surrounding painted area, clean out and inspect sill, call client regarding extra work found if required (20 mins + stripper disc, flap disc, shop vac, rags, phone and a brave pill/ciggy)

- make up patch pattern including trimming and etc (assuming CAD approach) 30 mins + card, scissors and tape

- transfer pattern to sheet steel and cut out (30 mins + various metal cutting tools)

- bend up sheet to match sill profile (1hr including back and forwards between car and various metal bending tools, including compound curves in sill lengthways)

- trim patch and hole for perfect fit ready for welding (30 mins including metal cutting and grinding tools, panel clamps, magnets etc)

- set up for welding (10 mins get welder ready incl gas, wire, PPE etc)

- Weld first pass (1-2hrs - this could be spread out between the welding of the other patches, with the first few tacks taking the longest, with progressive lengthening of the tacks into stiches then full butt welds but needs time to cool between sessions to avoid warping)

- Grind first pass welds back (30 mins + grinder and at least 1 flap disc)

- Weld second pass - eg pinholes (10 mins)

- Grind second pass (10 mins + grinder and at least 1 flap disc)

- DA sand area (10 mins incl DA and sanding pad)

- Prime area (from a can, 2 mins + can cost, if gun assume part of spaying of all patches once completed which has higher set up time but lower materials cost)

Based on the above this would take me around 5 1/2 hours not including tools and consumables.

Fuck me i must have 'saved' myself thousands!

you forgot smoko breaks, lunch shout, health and safety meeting, fire drill and getting pulled between working on 4 different jobs.

a bigger shop has the potential to be more efficient, but that also requires it to have motivated management and workers to take those advantages. the one man band in his shed is often more motivated as he directly sees the fruits of his efforts, and may also be happy to accept a lower profit in the interest of keeping a stream of work and not having to compete with other commercial ventures e.g. of this building would make more money if we had a bottle store in it etc. Also a larger shop might be more focused on main clients e.g. insurance work that provide their main workstream which may be more concerned with turnaround time and rework than absolute lowest cost.

but yeah regardless of all the economics of any of it you definitely save a massive amount given how much you would have to be paid before tax for $40,50,60,70,80 per hour to be less than your after tax hourly rate. question is really if you have the time, skills, space and equipment to do it yourself and the inclination to spend your time dong that rather than some other thing you might want to do and how much you value that other activity or venture.

-

just got one of the powerbuilt ultra low ones and its good. still requires a little finesse with the valve for a slow let down but a million times better than my old wham its back on the ground again jack. and the length+ low height are win, all for a palatable price.

-

2

2

-

-

Muffler Tech

in Tech Talk

Posted

tbh not so convinced of v bands after running them for a while on a low car. they are a lot more vulnerable to damage and leaks from the exhaust taking hits than a regular flange setup. great for ease of fitment and if the exhaust is tucked up and not getting road rash.