-

Posts

3265 -

Joined

-

Last visited

-

Days Won

2

Posts posted by kpr

-

-

brought some bushes for my corolla off spare-parts.co.nz no drama, stuff turned up.

-

2

2

-

1

1

-

-

That honda one may work if its steel like it says. is 6 rib but can zing the side off and weld it back on.

fd rx7 is actually smaller, 120mm so aftermarket under drive probably wont get me there, if its a thing.

-

My accessories don't agree with 10,000rpm's, trying to track down a big pulley for my p/s pump. needs to be bigger than 150mm diameter. If anyone have a spare moment, to do some measuring on what you got, would be choice. Ideally something with a 4 rib belt. Beams 3sge looks to be 4 rib and big ish looking, but cant find any measurements.

-

my max china rods haven't flown out at 10k rpm yet. probably made in the same factory as all the other cheap rods out there, and some of the not so cheap that are making bank. Like anything from china, roll the dice. some stuff is decent some not so much. Have heard their coilovers are junk.

-

1

1

-

-

6 hours ago, nobody said:

I've got Haltech 1500, running a 4g63, DBW, ITBs, turbo, its always been super easy to tune both on the older ESP firmware and newer NSP

Tuning method is "Volumetric Efficiency", Fuel Load type is TPS,

Base fuel map is RPM vs TPS but Ignition base map is RPM vs Ignition LoadI use an external map sensor because its turbo, I also run a wideband with long term trim enabled, a knock and flex fuel sensor

Not sure any of this helps but happy to share any info or tune if it would help

I run the same setup, just link's version of it, on my itb turbo setup. has an afr lookup table to tell the fuel model how much extra fuel with the map. assume haltech does similar.

works on na stuff as well, but isnt the go to on more aggressive stuff -

9 hours ago, WORROY7 said:

kpr said

In most cases with Itb's, just throw away your map sensor and tune in tps vs rpm.

I disagree with this, I am running 45 TWM (Borla 2900 series) and I have a good steady with dynamic range MAP signal this provides the other axis for the BASE table.

I'm just saying you can tune perfectly fine without the map sensor, no need to complicate things.

-

1

1

-

-

The video they done on that itb honda was kinda pointless, as the throttles were too small for it, = vacuum. so they kinda just tuned as normal. does haltech not have a built in baro sensor?

In most cases with Itb's, just throw away your map sensor and tune in tps vs rpm.

-

Its pretty hard to tell by those logs. but yeah run it at say 70% throttle. then 100% and see what the difference is. if 70% is same map reading as 100%, means you have no way to tune the last 30% throttle. so will have a rich/lean situation at 70/100 throttle. As above its pretty easy to tune around with tps when you have it setup right.

-

unsure what you are asking. but if its what mode to tune in; If you run out of vacuum before you get close to 100% throttle just tune fuel map in tps. If you have good vac all the way up to 100% throttle can use map. but likely means your throttles are too small also

i dunno how haltech does it. but when tuning fuel map in tps, should be able to set the fuel model to baro correction or map. and the actual fuel map in tps. if its an aggressive setup with cams etc, use baro. if mild you can usually get away with map, which will make any idle speed stuff or the likes work easier -

100 looks fine to me

most things like all the advance through the middle. the point at high rpm where the cam wants to retard , can vary quite a bit depending on intake and exhaust tuning.

-

1

1

-

-

Also just looking back at your vct/vvti map. seems a bit low. yours should have the 50degree vct pulley. All the ones Ive done like more advance through the middle, pretty much max it out to 50.

-

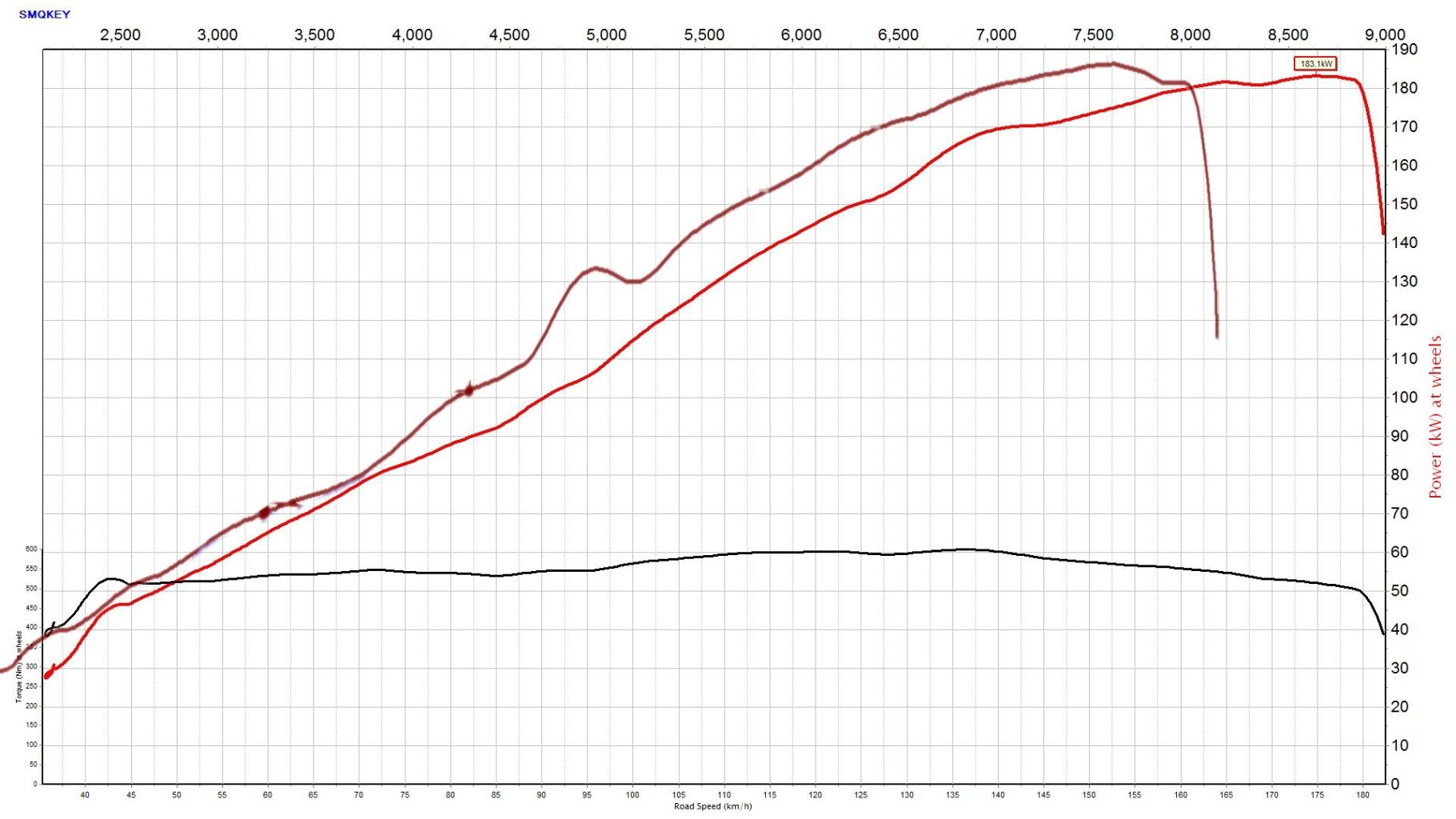

probably not, just come in for a tune. But i sold the intake off the ep3 , to another guy with a k24. k20 head and stage 3 cams, so better head and bigger cams. Done the initial tune on my dyno when it had a skunk2 ultra race? intake. which is the red below, and the ep3 k24 in brown. He lives quite far away, so remote tuned it to get the afr right when he swapped to my inlet manifold. had to add a lot of fuel through the middle and some up top. so probably pretty close to the ep3 power curve now. Don't see why the k20 wouldn't do the same thing. the heads flow good and have plenty of cam from factory, so good gains in getting the bolt ons right.

this is the k20

-

2

2

-

-

probably fine long as the bends arent super aggressive. assuming you are still using the 47mm throttles. probably best to have them on the shorter manifold, then can taper up in diameter sooner

Interestingly i just tuned a k20 on my dyno. had really short intake with big plenum and big short headers. done as expected. made 202hp and weak through the middle.

-

2

2

-

1

1

-

-

one cap cant keep up.

-

yup, I think it runs even better than the other engine on stock cams, which had the inlet advanced a little. its even fixed my weak starter motor. since the cam is pretty retarded at the zero position, it has less dynamic compression and turns over faster haha.

from memory it has from 0 to almost 5mm lift at tdc. the recommended setting for that cam is 2.7mm at tdc-

1

1

-

-

Yeah most "turbo" cams are pretty tame. It definitely starts to hurt the spool up when get to a certain point though. If i put the matching exhaust cam in this, turbo comes on about 1000rpm later. But they are na cams. would be on the big end of turbo cams. It really just has the same effect as an na engine. the bigger you go, the more sensitive engine gets to whats attached to the exhaust side of the engine. get it right and big cams will work down to lower rpm than most people would think. get it wrong and everythings going to come out the wrong end

-

- Popular Post

- Popular Post

Still working through a few things. Also forgot to mention, the new engine still runs super nice with the big inlet cam and vvti. could daily drive it like a factory engine, smooth idle. doesnt stall out easy etc. would be pretty unsuspecting in a street car.

Anyway since has to go in mud and stuff, been making the cambelt covers fit. which took some time, since has oversized pulleys and the 7a block is 15mm taller. made up a 3mm spacer between backing plate and the plastic covers plus a bit to fill the gap. had to nang a hole out for the vvti pulley to stick though. obviously covers arent going to seal off. but should keep most of the junk out

some other stuff that had to do, that actually took pictures of.

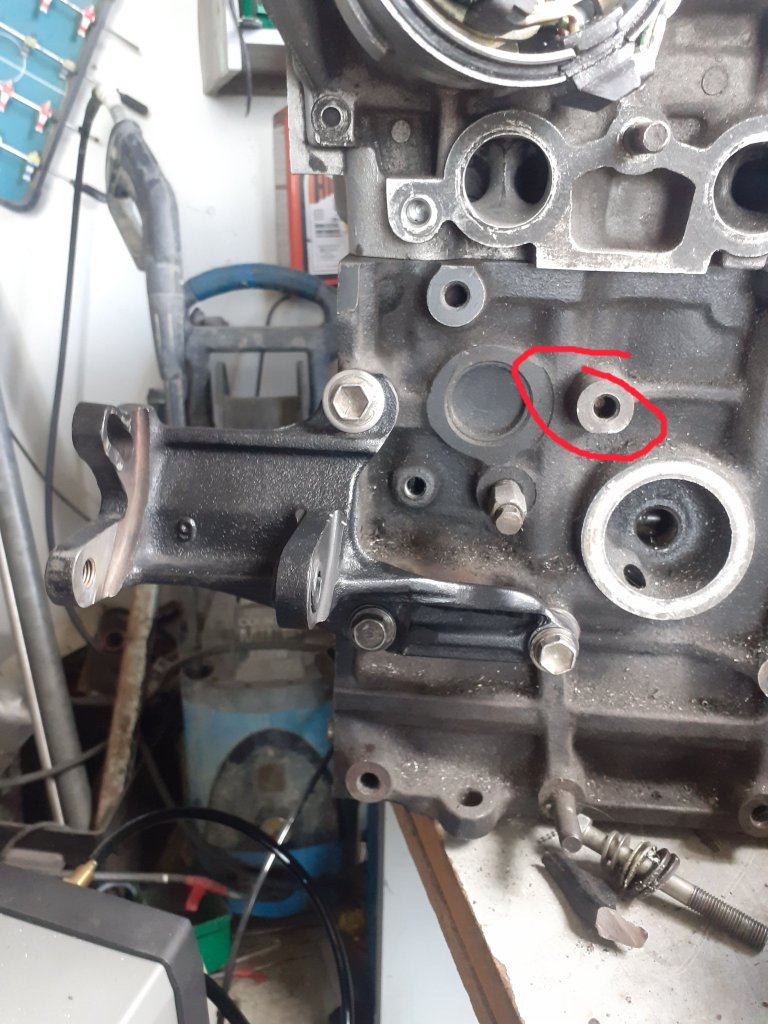

added an external oil drain to back head, between the to trigger sensors. since is bigport head. and this thing is mostly going up a hill when tapped out

7a block is missing a bolt hole which my butchered blacktop ps pump bracket bolts to. so did some illegal welding moves and made it

attach to one of the lower bolt holes. also had some alignment issues making it spit the belt. which think i have solvedcut 15mm out of the exhaust manifold, rather than modifying everything attached to the turbo.

and yeah other stuff.

-

28

28

-

- Popular Post

- Popular Post

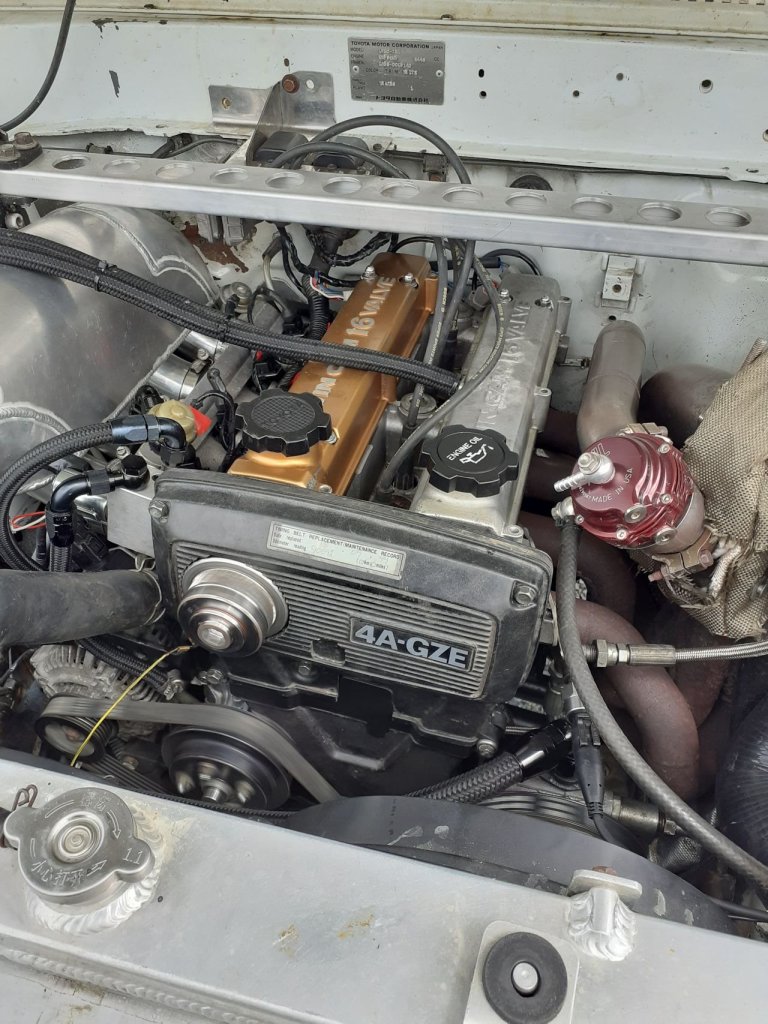

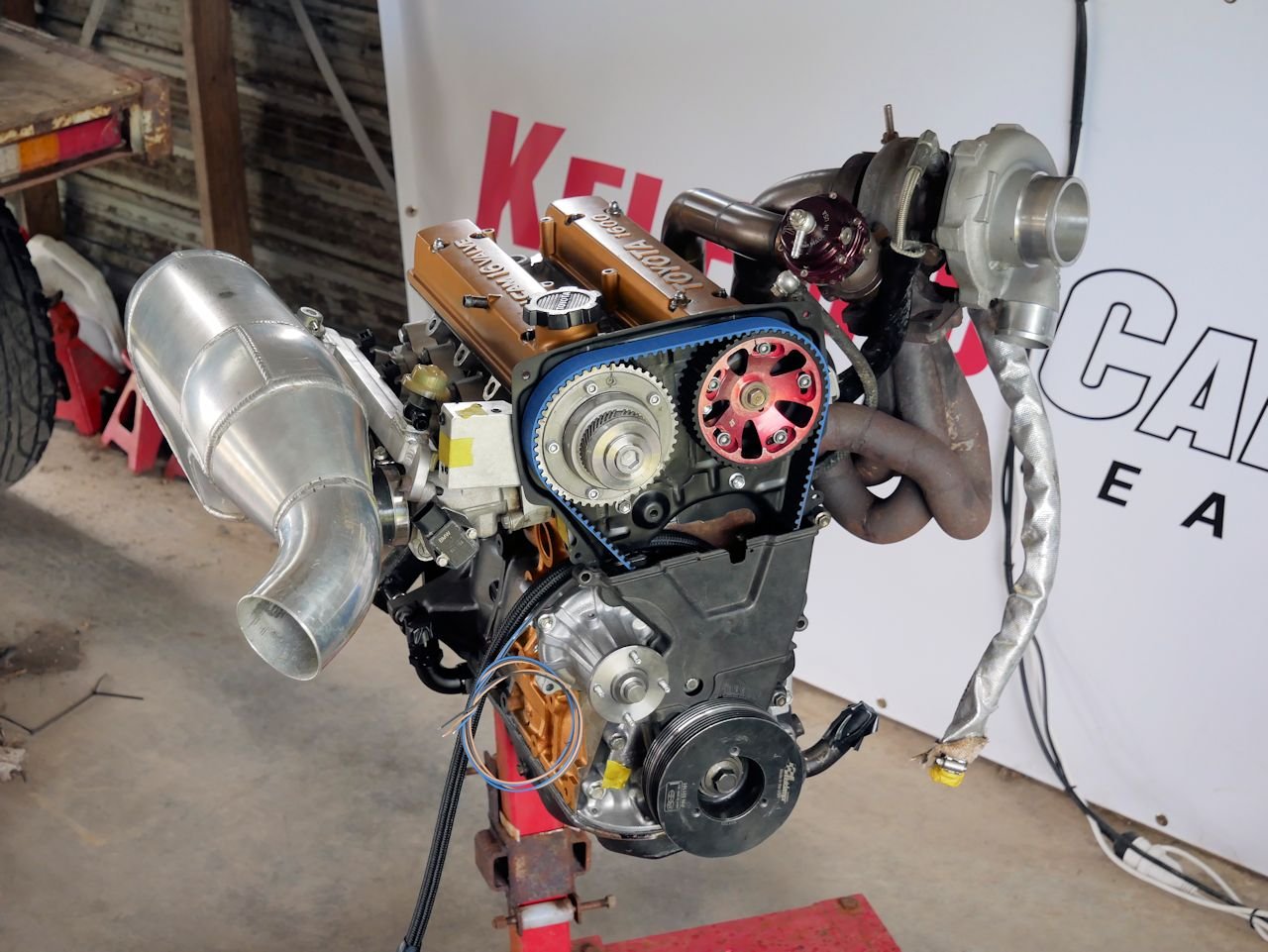

After working on this thing for 2 weeks solid, got it all together and running. Pretty much nothing was a straight bolt together, I think the only thing that went straight on was the plenum to intercooler pipes.

everything else had to be modified in some way. but you get that when no 2 parts on this engine are meant to go together from factoryHad a few little issues once running. but mostly plain sailing

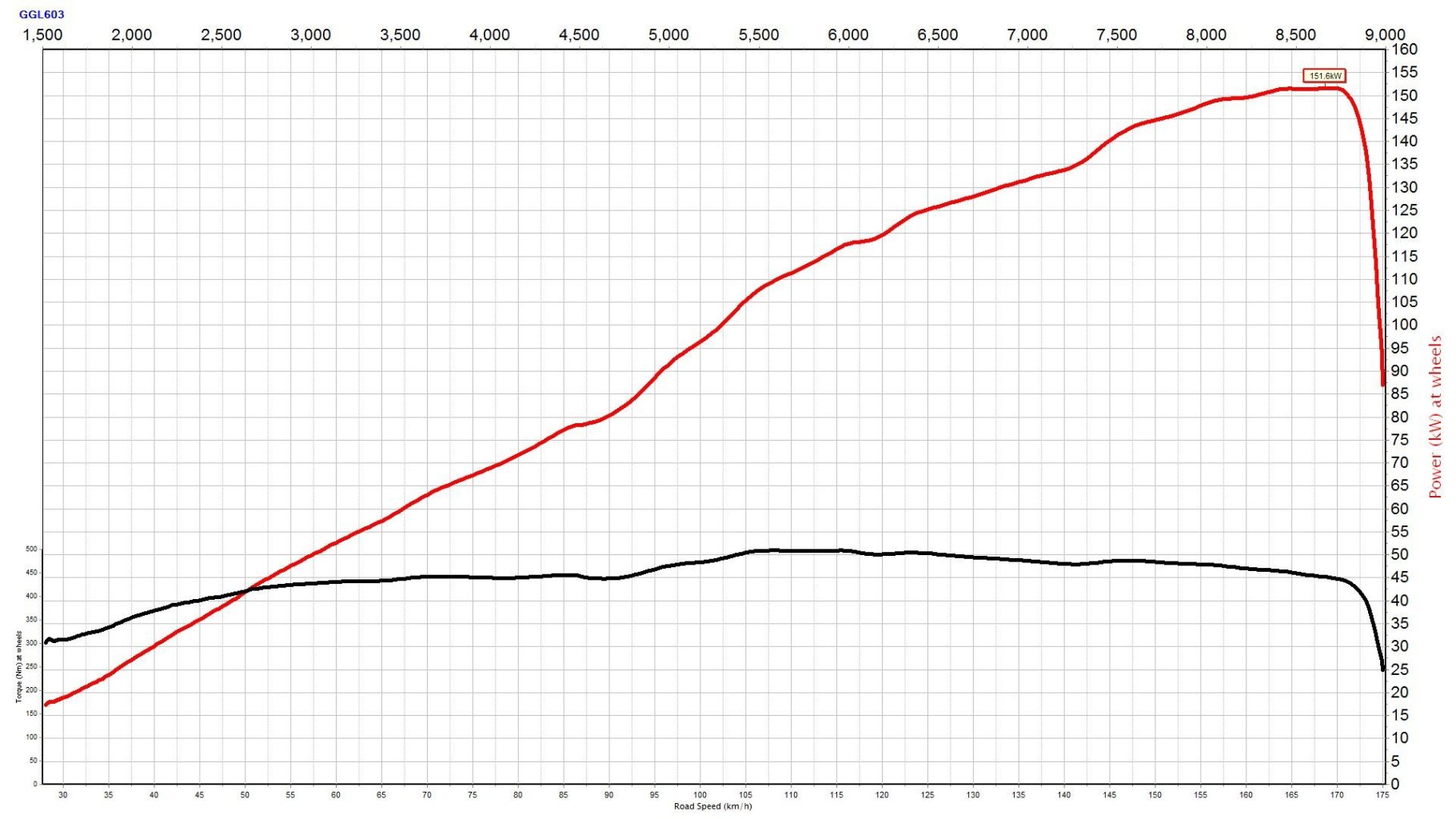

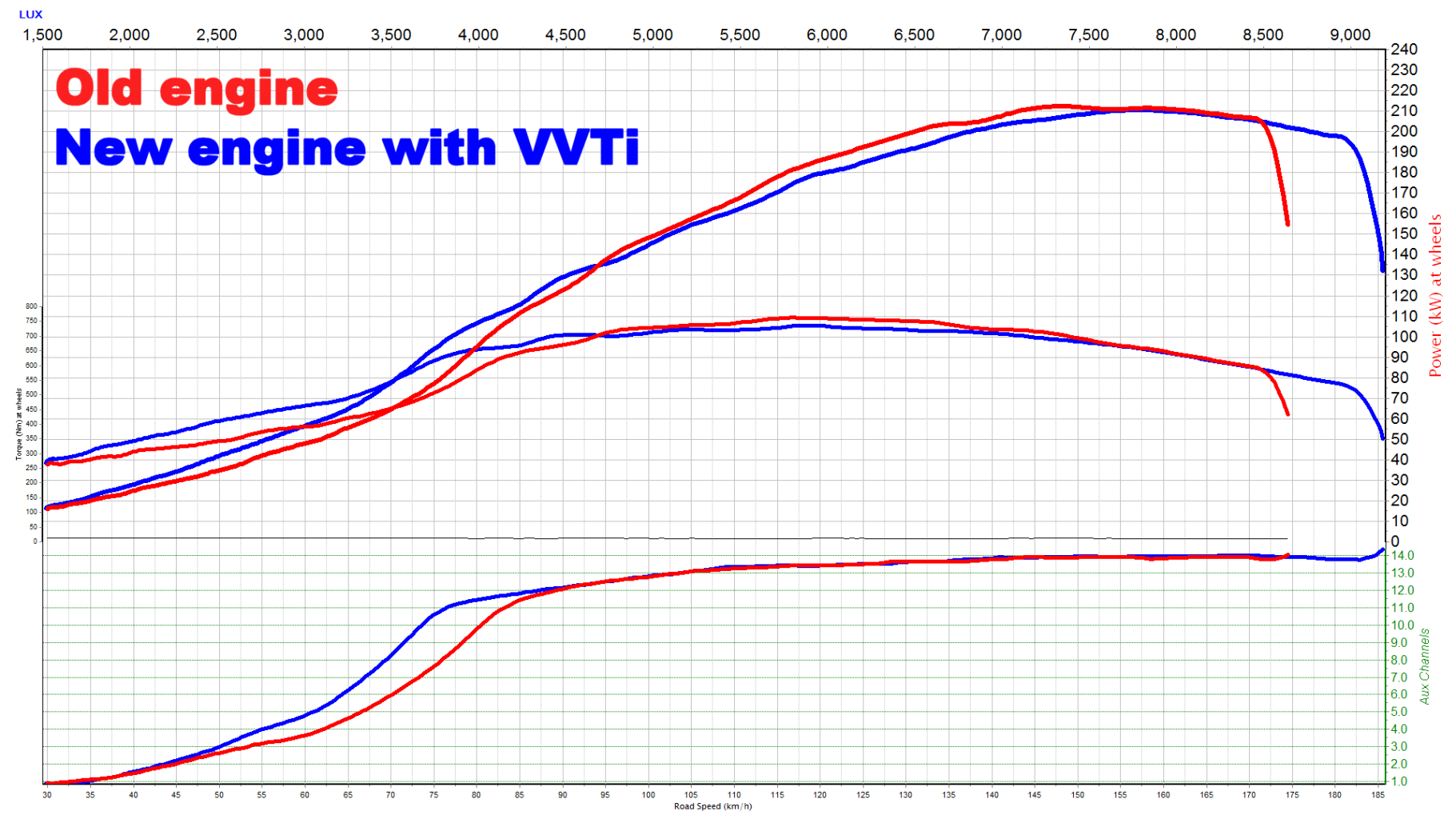

On stock cams the old engine made a little more jam (better head by the looks) but can see the vvti doing its stuff to hold the new one up. with boost coming on decent amount sooner

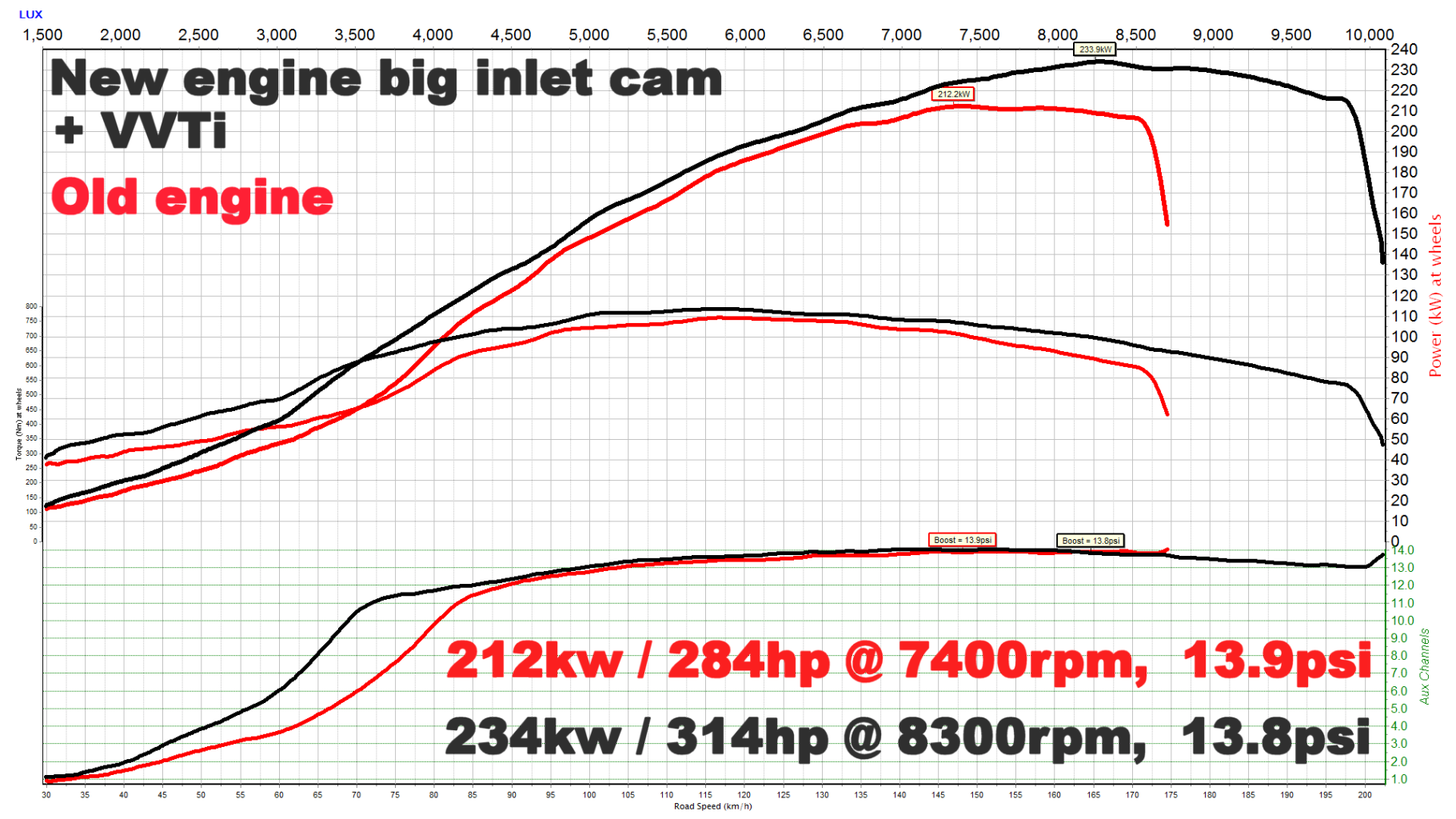

The plan was always to swap to a bigger inlet cam and use the vvti to make it run nice for 4wding stuff. Was going to run with the stock cams for a bit, but had some oil leaks which i was down to the cams to fix. so didnt even make it off the dyno for a test run. Turns out the big inlet cam was the money as expected. is a 284 from 193b set.

Pretty happy with it. It already had plenty of power for what it needed to do. but having more power and revs tagged on each end makes a big difference, especially in high range with the retarded gearing

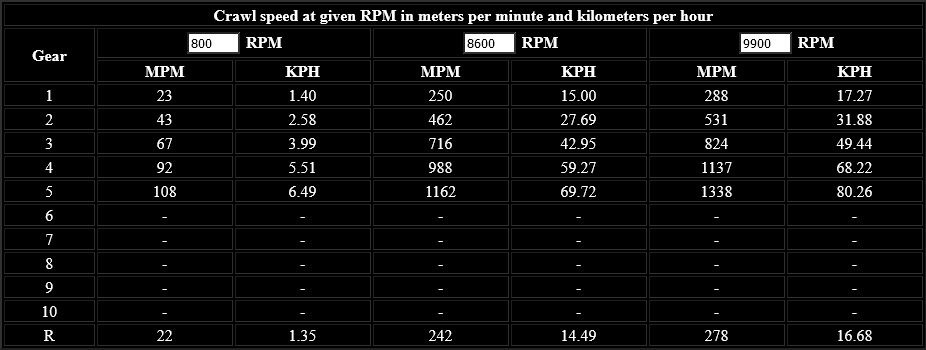

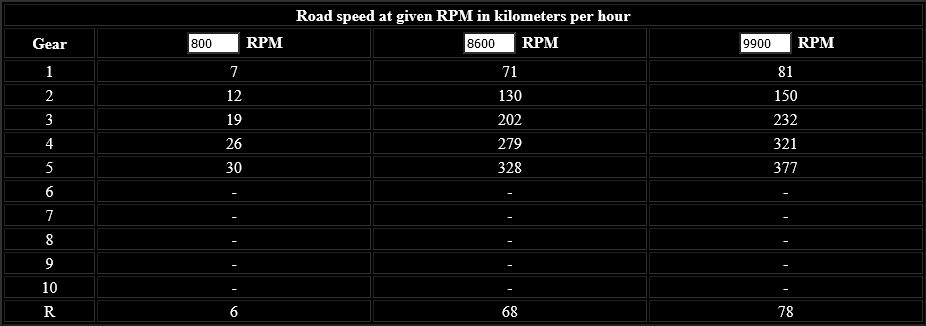

speaking for retarded gear ratio's. this is what 10k rpm, 4.88 diffs, w56, 4.7 crawler gears and 33" tyres gets you

so my main mud bashing gear when you want to get places is 4th, old engine would do 8600rpm. new 9900rpm. so i can pull the same wheel speed

in 4th as in 5th before, which was a bit too tall to get going in. but if you did it would zing. so 4th should be good now...

High range is where it gets really dumb. If skip to the end of the video below i was in high range. chasing down cars driving down the road while in the paddock

more graphs and noises in the vid. skip to the 7min mark at least.

-

32

32

-

1

1

-

1

1

-

- Popular Post

- Popular Post

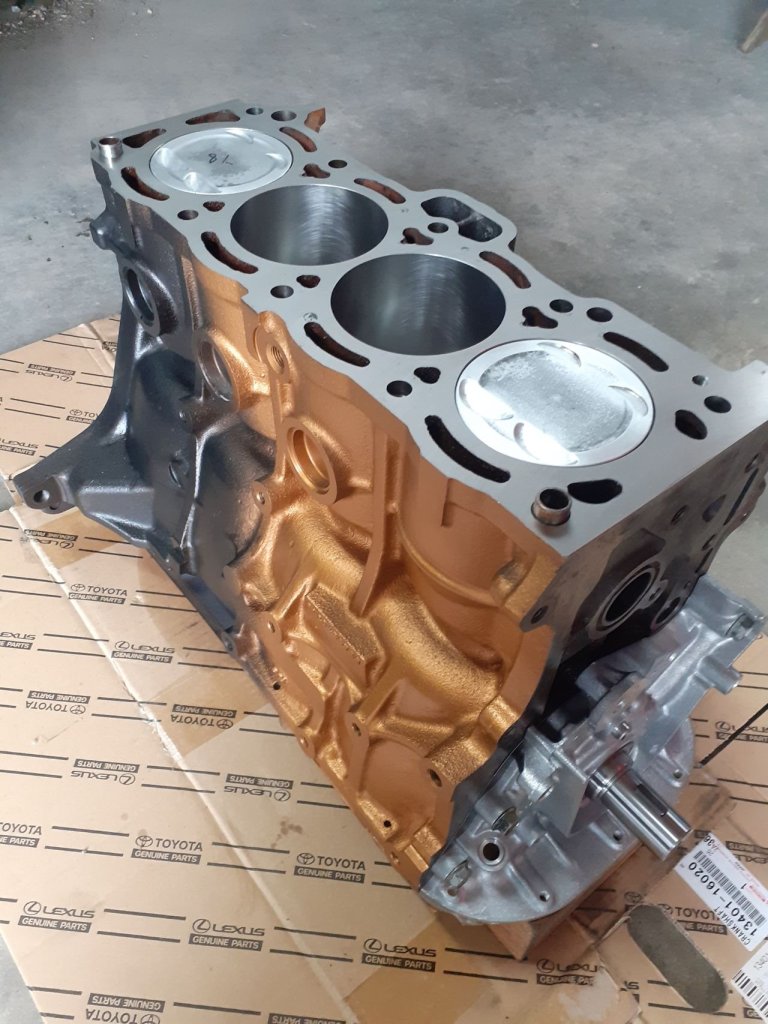

If you follow my youtube, you may have seen the teeboon 7a i tested in the starlet. It wasn't long for this life and ran a big end.

Since 7age's are wet blankets. We come up with a deal, where i would acquire the 7a block and je pistons, leading to the following abortion, which combines these parts with the long rod test engine (frankenturd)So, 7a crank in the bin, bran new 4age crank, custom long rods and the je pistons

First problem was 7a block had been decked .6mm or so, for the 7a with 4age spec pistons. 7a rods sit 4age pistons about .6mm down the bore. so the work around is to nang that amount off the block deck, to get zero deck height, cool. But my custom long rods are made to work with the factory height 7a block. After the block getting a fresh skim, that number was about .8mm.

So skimmed .8mm off the pistons. pretty easy as they have a small dish and only the outer edge needed to come off

The valve cutouts on the je pistons were on the wrong angle and pretty weak, plus they already had ate some valves. since was going to have to do the above butchery anyway,

hit them with the die grinder to get clearance needed. sounds pretty rough, but i would rather buy new pistons then spend money on these old things.weight matched pistons and maxchina rods

Installed with balanced crank, toda oil pump gears and a fresh gold fade

Head is just sitting on the block at this point. But is getting the Turd head with the og vvti setup. Its modified bigport head,

about far as can go on stock valves. from memory it made 120kw on stock cams, and 137kw on 193b cams in na form.

Will just run stock cams to start with at least.

Also made a new trigger setup, that mounts the sensors in the back of the head

The intake cam 3 tooth is for the vvti, I'm just replicating what the jz runs here. Exhaust is single tooth sync/home for engine position.

Will this horrible mess of parts make it to 10k rpm or fly to bits first? place bets now..

tl;dr hilux getting long rod, vvti, turbo

-

21

21

-

4

4

-

20 minutes ago, Roman said:

I'd have thought that whatever the load source, you'd just have slightly different VE numbers at low throttle with it disconnected?

Yeah, doesn't matter that much in most cases. some things and ecu's, the fuel equation is expecting a 1:1

-

1

1

-

-

If its map based tune, run vac to reg. if running itb's and tps tune (alpha n) that doesn't reference map, I would run a flat fuel pressure.

-

1

1

-

-

Back in the day.On an octane limited turbo 1500cc 95 was good for about 15psi boost. 98 20psi. Half avgas half 98 was good for 24psi. Around the 30kw mark for each jump. Pretty sure it was the full lead stuff not 100ll

-

you need argon for tig, co2 wont work

-

2

2

-

1

1

-

1

1

-

-

- Popular Post

- Popular Post

Roman's 4GR V6 Carina discussion thread

in Project Discussion

Posted

na stuff doesnt need that much cooling, especially since your engine is a giant aluminum thing to start with. Also half the time peoples cooling problems, is all the stuff jammed up behind the radiator. if air cant get out, its not going to go through