-

Posts

6784 -

Joined

-

Last visited

-

Days Won

32

Posts posted by Roman

-

-

- Popular Post

- Popular Post

38 minutes ago, BlownCorona said:finally got up on a ladder and saw the 4k eh?

-

2

2

-

1

1

-

7

7

-

3 minutes ago, HumberSS said:

Do these k100 throttles on this build solve your height problems?

Nah those are way too small throttle size, and the ones I've got are e-throttle.

The height will be better once the sump is on, and I can measure how much further I can cut down my engine mounts to lower it.

I should probably just print another sump piece for the area under the crossmember, buuuuttttt printer is broken again. damn thing.

Not a drama though as I've got plenty else to carry on with.

Wiring is a big job.-

2

2

-

-

At the moment I am leaning towards the idea of leaving the cap in the standard spot but extending it upwards.

Then I can just jack the back of the car up to help bleed any air out of the radiator I guess.

As much as I hated the electric waterpump in the Echo, it was handy for bleeding the coolant with the motor off.

-

1

1

-

-

- Popular Post

- Popular Post

Some good progress!

I got Kelford valve springs and retainers fitted (with many swear words)

The heads torqued down, cam timing done, (standard cams for now) and front cover gooed in place.

Bellhousing is now fully welded, but I havent swapped this onto the proper box yet.

So back in the hole, then accessories fitted, all covers etc back on, throttles on, coilpacks in.

Then I thought I'd have another try at fitting the Mark X radiator, that I bought from pickapart a while ago.

As it really would make life easy if it works.

Well, it sort of does! Sorry for potato pic.

There's enough height for it to fit without hitting the bonnet, and I could make mounts for it to sit so the factory pipes work okay.

Which would be awesome, as I usually end up with a mish mash of cut and joined pipes on car projects.

But there's one issue. The radiator cap is mounted on the outlet on the engine, not the radiator.

So in factory config, the motor sits higher than the radiator. Mine will be opposite.

As I cant move the radiator any lower, but the engine will sit a little lower than current position.

I'll end up splashing coolant everywhere if I take the radiator cap off, and probably wont bleed all the air out.

So the options are that I could run an inline radiator cap in the top hose near the radiator. (Which will look gumby)

Or otherwise cut the front housing and reweld the cap a little higher up, so it's at the highest point of the cooling system. But the pipe angles might still cause some bleeding issues.

It's damn close to being a good solution, and there are aftermarket Mark X radiators available if it needs more cooling.

So I'd like to run it all like this if I can figure out a good way to make it work.

Next on the list while a few other parts are still in the works, is to start on wiring.

So I'll need to decide where to mount the battery, and then test if it has enough grunt to crank the motor over.

This engine doesnt have variable reluctors for the crank angle sensors, like every previous Toyota engine I've had.

It has 3 wire hall effect.

So this means I can probably get a good rpm signal at a lower rpm than VR sensors.

Which might make start up time and cranking a little easier on the battery.

As the VR sensors seem to need to get up to say 600rpm or there abouts to register a high enough voltage.

One annoying thing though, is these sensors output quite a low voltage.

So to get them working with link ECU, need to wire in some pullup resistors.

But, I've got a solid plan for how it's going to work this time. I'll lead most of the wiring into the vee under the throttles.

I might print a little cable tray for that area, with just small branches coming off rather than a big trunk.

To allow for the inevitable loom meddling I'll be doing later on for whatever reason.-

30

30

-

Yeah but isnt less flow at part throttle why youre there? Haha

Also I saw a cool pic of a sectioned race motor that had a cool barrel setup. I think it was a toyota v8 for something.

-

1

1

-

-

Does freevalve work okay at high rpm though?

-

From what I've seen/read the flow restriction from an open butterfly is essentially negligable if your runners are the right diameter.

I think the only practical benefit of a barrel is that they can be the same (non circular) profile as the port.

I found some pictures of a really interesting intake setup from an Indy Car a while ago.

They had butterfly throttles but mounted way out at the tip of the trumpet.

Then some double barrels from one of the vauxhall BTCC cars.

-

3

3

-

1

1

-

-

A mate told me that's what happened when he ran barrel throttles. Horrible rich on transients if you've been cruising along at part throttle for a while.

As you've got two pinch points for where it is restricting airflow, with the partially open barrel area in the middle. Compared to normal throttle plate where you just have ahead or behind the plate.

So its something like you get a differing amount of vacuum (or airspeed or whatever) in the barrel than either ahead of behind it, so fuel vapour even from port injection ends up condensing in there.

(I'm assuming they were mounted quite close to the head in that case)

In my case this motor has exceptionally long ports, and I want to get both the barrel assembly as close to the flange as possible, and the injector as close as possible too.

In a more ideal situation I'd probably cut down the super long port dividers and mount an injector closer to the valves. As this is all geometry not designed for port injection at all.

-

It's not like you can say "Yeah well it's an old car, so you'd expect a few niggles"

As pretty much that whole list sounds like some fairly recent incompetence.-

2

2

-

-

- Popular Post

- Popular Post

My current intake setup will get the ball rolling, but, I think throttles are probably too small.

The centers are less than ideal and the fuel rail position is uncomfortably close to the bonnet.

But the quality and strength of the print of the manifolds, from the 3rd party print has blown my mind! So good.

One thought I've had is to get 6x tiny ethrottles and control them all individually for lolz.

Otherwise, been thinking. Can you print entire throttle bodies, rather than just adapters?

Well, Not really.

Because the problem is that you need a super thin metal throttle plates.

So that lends itself to being metal or similar only.

But do you know what usually sucks to make out of metal? Barrel throttles.

Barrel throttles might be entirely printable, or partially printable (either just housing or barrel) because there are no thin parts needed.

The thickness of everything is liability from metal but a positive for printing.

There's (I think) going to be less thermal expansion compared to aluminium and so hopefully less chance of throttle sticking.

This would help with my bonnet clearance issue, as I can mount throttles further down towards the head.

My current setup needs to be mounted high-ish, because otherwise the transition is disgusting.

Barrel throttles can be a non circular profile no problem so you can just have them the same shape as the port all the way up.

Anyway, thinking something that looks like this. Bong shaped intake, paying some homage to my West Auckland cultural heritage.

Maybe I could make some trumpets out of 8% woodys cans.

Another problem with barrel throttles is that at part throttle they can end up pooling fuel in the barrel section, then having a hernia on full throttle when it tips it all in.

But I figure you dont actually need both sides of the barrel to seal, and these will be vertical.

So injecting inside the barrel itself and having the rear half more open would probably be sweet.

At part throttle like this:

The barrel shape itself is still quite simple to allow for the injector. But ends up being a decently solid part without any delicate sharp edges anywhere.

(Shape obviously gets more complicated to allow for bearings and TPS etc etc, but you get the idea)

Probably a project for the distant future as I've got my hands well and truly full currently.

But would be pretty cool, have always wanted to try a barrel throttle.

-

32

32

-

1

1

-

- Popular Post

- Popular Post

I yanked the motor back out and put the new bellhousing setup on.

All fits up great and angles are great.

I'll need to cut a hole for the clutch fork, unless I feel like punishing myself with a concentric slave cyl.

Then I'll deliver back to Stu for it to get fully welded.

There's easy clearance for everything, and I've got the motor/box pushed back to a pretty sweet spot.

Easily get 4 cylinders behind the axle line which is cool.

Then next fiddly task is just getting the engine to sit lower, now that I know it's final-ish resting place.

The shifter position has worked out good, maybe a smidge too far forward. But this is with the SQ Engineering relocation bracket, the standard shifter is further back.

I've got a few driveshaft front halves here, one that was previously too long might end up fitting alright now. It's too flogged out to actually use, but will be a handy when getting a new one made up if I've got one the right length.

But, with my new found skills of pooing metal together I can cut and shut something to exactly the right length as a sample, anyway.

-

23

23

-

- Popular Post

- Popular Post

It made my day today when @Stu sent me through some pictures of bellhousing progress!

Firstly the J160 front was milled down to 15mm above flush, to give the correct overall length later.

Then it was noticed that a 75mm tube fit into the input shaft hole nicely.

So then a second round part was machined that fits centrally over the 75mm tube, to the dimensions to centralize the auto bellhousing onto this.

Then all tacked together, ready for a test fit after taking the bits out of the middle. So in the end there was no need for an intermediate plate.

I'll hopefully have time for a test fit in the next few days. But I'm 100% amazed and relieved about how much simpler the job has been thanks to the auto box having that circular mounting setup.

(The job was also easier than expected, because Stu did all the hard bits...)

So thanks again for the assistance and expertise. Very much appreciated.

-

47

47

-

5

5

-

- Popular Post

- Popular Post

I dont know if this is news to anyone else, but today I discovered that cut off discs for aluminium are a thing.

It was actually super easy to cut this off.

RIP 1G J160 bellhousing. You will not be missed.

I've cut it quite high so that it can be milled down accurately.

However, so long as I could centralize the new bellhousing correctly, it might work out alright just to weld it straight together rather than use a plate.

Imagine that the top half has its cut line about another 50mm or something further up, where it tapers in a bit more.

Unfortunately I've got work trips keeping me busy through nearly all of next week so it'll be a while until I can make any further progress.

However, on the whole I'm stoked with how things are progressing currently.

A few of the big remaining jobs are very close to getting ticked off.

Or more specifically, once the sump and bellhousing are sorted. Then I can finish other jobs that are dependent on these being finished. like finalize the engine height/position and make a gearbox crossmember.

It's going to be awesome to have the motor all put back together, and sitting in the right spot.-

38

38

-

Yes there are some factory manual Mark X / IS250, and they use the hilux gearbox/dual mass / etc.

However it's all massively heavy, big, and shifts like crap apparently.

If I were to guess, it would weigh somewhere around 5 million kg more than a J160.-

1

1

-

-

I think I will be able to keep the clutch fork which is good!

As it would become tiring if I had to bleed the slave cylinder every time I blow a motor up.

-

5

5

-

-

- Popular Post

- Popular Post

Alright so one of the reasons I've been dreading dealing with the bellhousing situation, is that usually things are located with 2 or three dowel pins, and then held together with bolts.

The problem is that unless you get the dowel position exactly correct to the centreline of the input shaft, it can end up being way off.

Then you might end up having problems like the gearbox runs real hot, or keeps wearing out bearings or whatever and wont necessarily know why.

So, I think the universe decided I deserved a bit of a win after the adventure of aquiring the box.

Because the Mark X auto box doesnt use dowel pins or anything like that, to locate the bellhousing onto the gearbox...

It just has a giant circle, and a giant round hole that press up against each other. Too good!

So a bit of brain storming with a few mates and taking some measurements, I think I've got a plan.

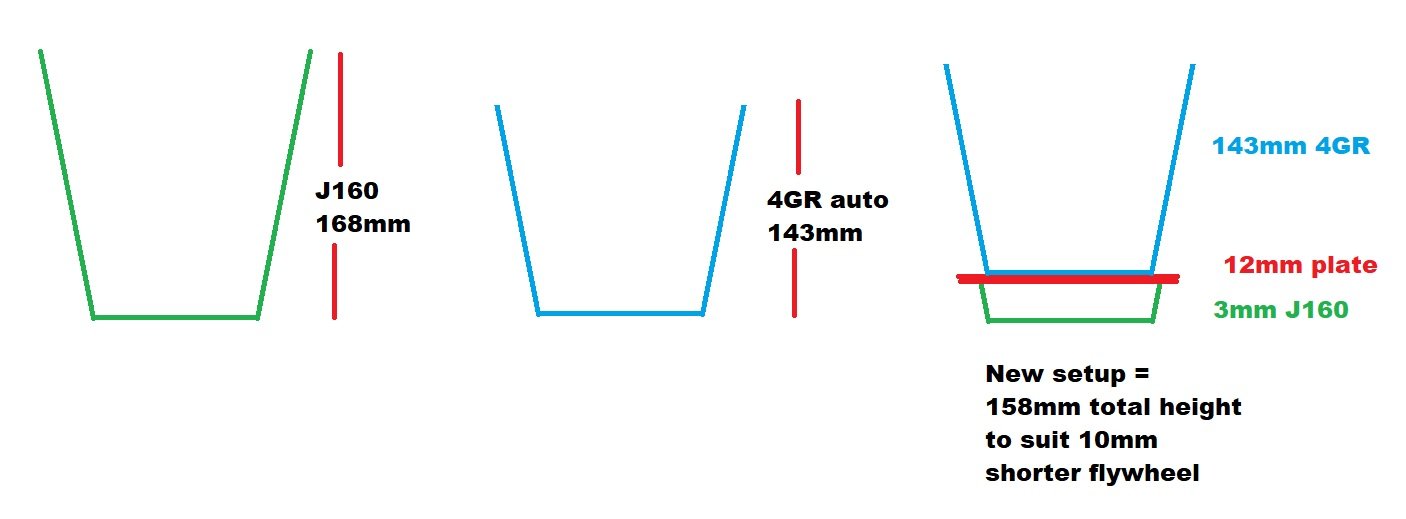

Basically the J160 bellhousing is 25mm longer than the Auto one (hooray)

So I'll basically cut almost the whole thing j160 front off, and weld on a flange/ring that will be easy to position relative to the input shaft hole. As the bellhousing wont be in the way. Then the bellhousing locates on the ring, and bolts up. Sweet!

Also this bellhousing pattern is bloody easy. Both sides are symmetrical and it's really easy to index their positions relative to the round hole.

So something like this will end up welding onto the gearbox.I am thinking could use a second plate in the middle that also slots into the input shaft hole of the gearbox.

So it will be exactly central.

Then once it's welded on, the bellhousing can center itself on the ring, and bolt into the correct place easy as!

The only issue will be that there's no hole for the clutch fork to go through, and will need some bosses welded on for a slave cylinder. EDIT: no, the existing slave cyl holes will work as they are further back. Sweet.

So I'm gonna chop up a bellhousing, print a test piece and then I'll hopefully have @Stu be able to work some magic with machining and welding etc.

Pretty awesome that this looks like it'll work easily, as long term I've always viewed this sort of job as really difficult / above my paygrade.

-

36

36

-

1

1

-

8 minutes ago, Beaver said:

Drop the rest of the gearbox on someones doorstep?

Wow yes

-

6

6

-

2

2

-

-

Silver lining - the auto bellhousing centralizes by just pressing a circle thing onto a circle thing. No randomly placed dowels to try align.

So it might work out well to chop down the j160 bell and weld on a centralized circle plate with matching holes. So the whole auto housing on there.

That messes with clutch fork situation but id prefer peace of mind that its exactly centralized with fewer variables as possible.

Also, Toyota used the "fuck you and your whole family" variant of loctite on the bolts so that was fun. No way i was getting this loose with tools i had.

-

7

7

-

-

2 hours ago, xsspeed said:

whats your plan for bellhousing cuts wise?

I honestly have no idea yet.

Just sort of hoping a good idea emerges when looking at the bits. Haha.

-

2

2

-

-

- Popular Post

- Popular Post

I'll add the alternator belt to my top 20 list of things that are gonna blow up.

Place your bets!-

2

2

-

8

8

-

- Popular Post

- Popular Post

Hey, looks like a great day for Pickapart!

Time to get a bellhousing.

So I using some fairly crappy tools I brought, after smashing a few knuckles and many swear words I got a gearbox separated from an engine.

Luckily I didnt have to undo the torque converter, it just slid off. As that was looking like a whole other nightmare.

I couldnt get the bellhousing off the box, and it's same price for a full box. So I decided I'll just grab the whole thing.

However, my next problem. I'm down near the back of Mangere Pickapart and there are no wheel barrows or carts or anything.

This transmisison is bloody heavy. I can carry J160s okay, but this thing is beefy.

So, I made a little sled out of an engine heat shield and a seat belt.

Instagram vs real life:

Then I dragged it to the car on a piece of carpet.

What a mission haha.

The auto bellhousing is very short, but hopefully the idea of a cut and shut onto J161 front will work okay.

That's enough punishment for one morning though.-

39

39

-

8

8

-

28

28

-

Ahh thanks guys! Thats a very good point ive not considered.

It is quite a long unsupported length.

-

- Popular Post

- Popular Post

I found a belt path that hopefully works decently, with a very simple tensioning setup.

If you undo the top bolt of the alternator and swing it down, it's not tensioned by the idler anymore. Ha! So you can get the belt off.

Hopefully has enough tension on it this way.

The trick to making this work was a smaller diameter idler pulley, that was on clearance sale at repco for 3 bucks.

Which makes it sound like I'm smart so lets not discuss the $6 pulley and the $100+ of wrong sized belts that got me here.

Either way, it's another small task sorted hopefully.

Also! I've been doing scouting missions to pickapart whenever I'm near one of them for work.

I've been waiting for a Mark X to turn up that's got the motor and box out for easy access.

As I'm still looking for a bellhousing.

I found one at Mangere where it's all out on the ground in front of the car.

So will head back with some tools at some point and try wrestle that bellhousing out.

It's tempting to just grab a whole extra motor and box, as they're cheap - Hopefully there will still be a few around when I've got a bit more $$ and space to put things.

-

29

29

-

- Popular Post

- Popular Post

New benchmark for exhaust note goals.

This is 3500cc 2gr motor in the lotus, so tack a few thousand more rpm onto this, and imagine that noise screaming out of an 80s toyota haha.

-

19

19

.jpg.4273c6700fd4a62ae30a21ce3defd3d2.jpg)

.jpg.78557c76caa0e2aa2b522c319d15aad8.jpg)

.jpg.ed28dc38513e105c70ac7c93d56338ea.jpg)

.jpg.84329cae040196a0a03c0bf9987c93b5.jpg)

DIY Fuel injection thread.

in Tech Talk

Posted

14point7.com