-

Posts

7,235 -

Joined

-

Last visited

-

Days Won

39

Content Type

Forums

Downloads

Events

Gallery

Everything posted by Roman

-

-

Big trumpets sticking out the bonnet will be a 1 way ticket to green sticker haha. I should have a new version with bonnet compatible extra length, ready to go by tomorrow night though. These ones are rotated on 45 degree angle in order to try get as much length in as I can. Then about 130 deg of bend or something like that. Hopefully these indicate that they are "too long" as my life is easier if I can fit straight ones. But if they make good power then cant complain! No outer injectors but will try get the runner length right first. Will also try borrow the @Stu Science(tm) tig welder soonish and have a go at splooging together a mild steel exhaust.

-

Yeah thats gonna be tough to try fit, even with some bends. Will see what I can figure out

-

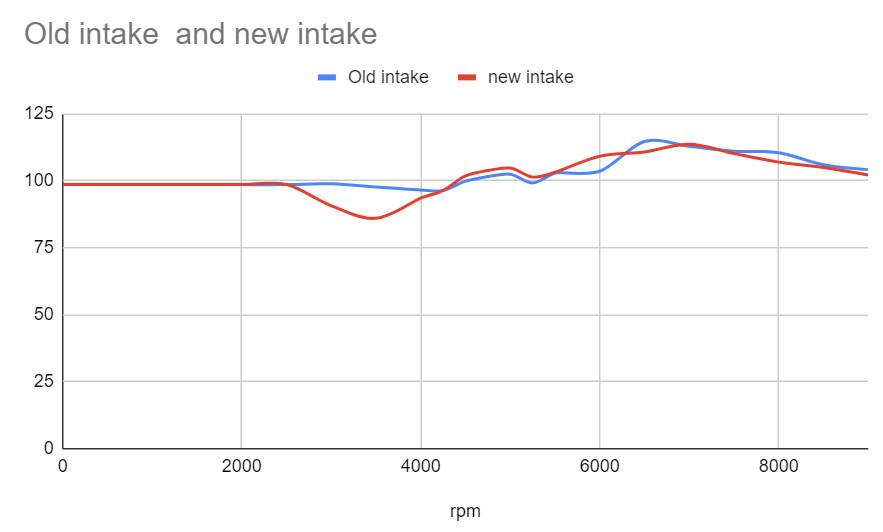

Its now about 360-370mm total length to back of valves. This is before/after. Had quite a taper on other one. Maybe shorter length and wider entrance was about right.

-

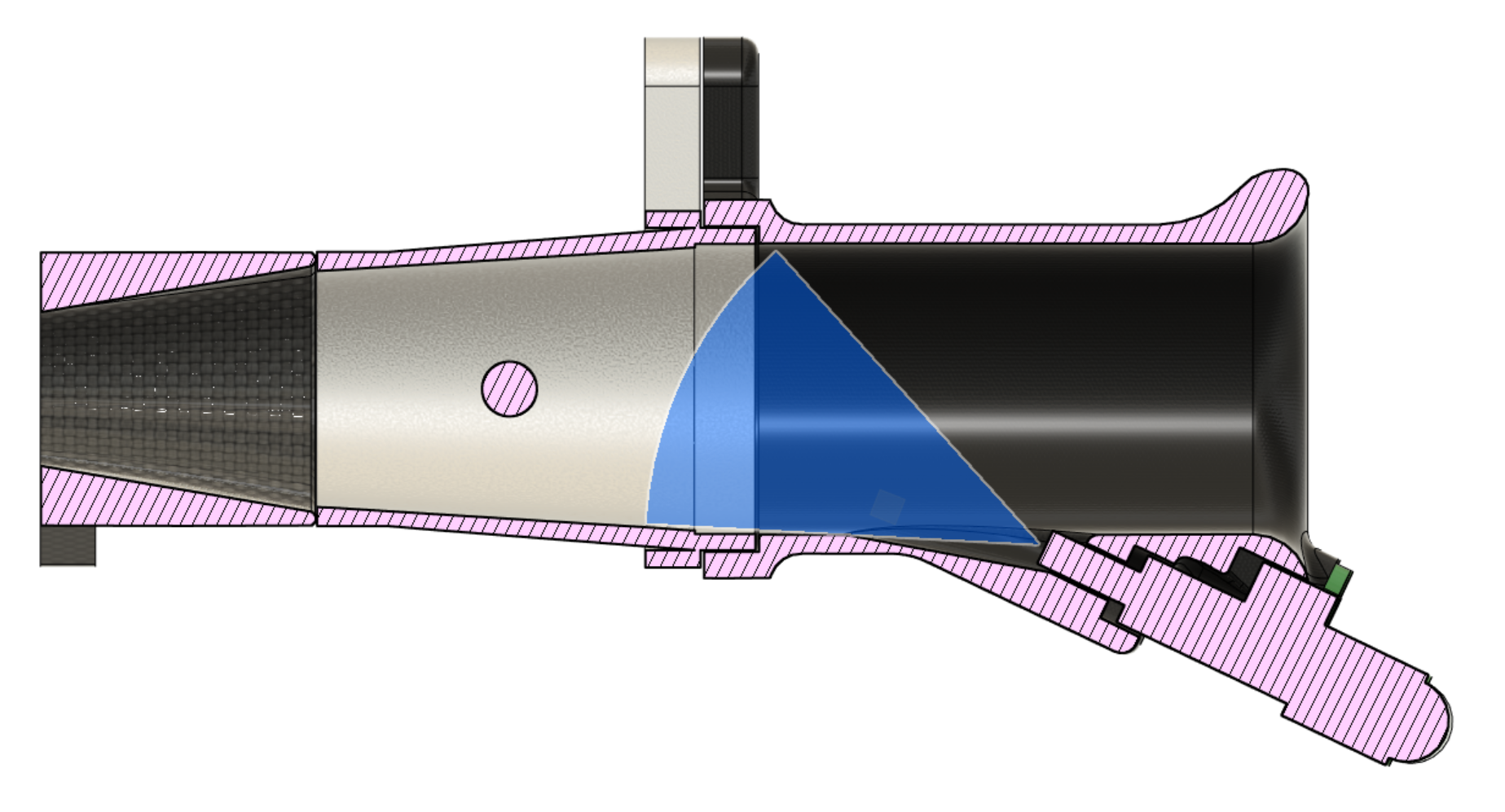

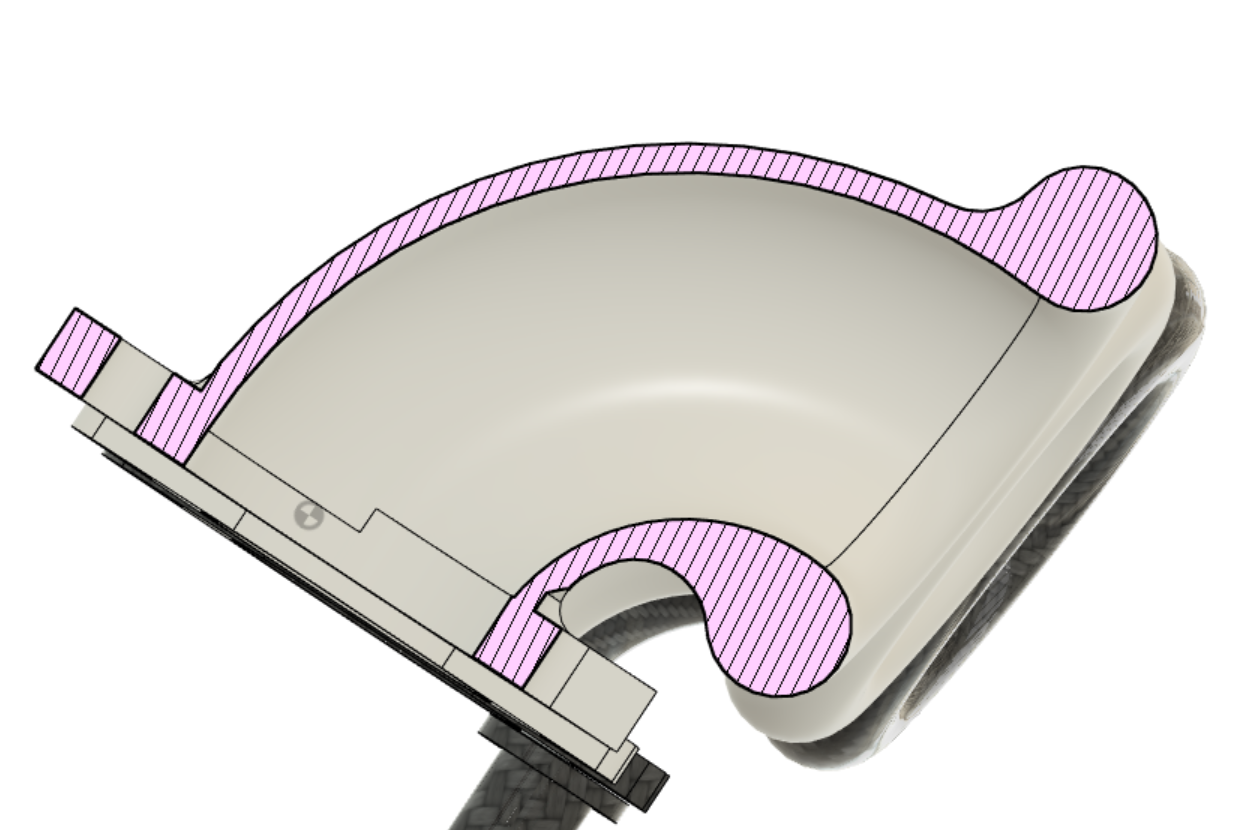

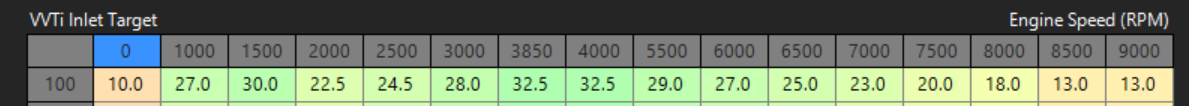

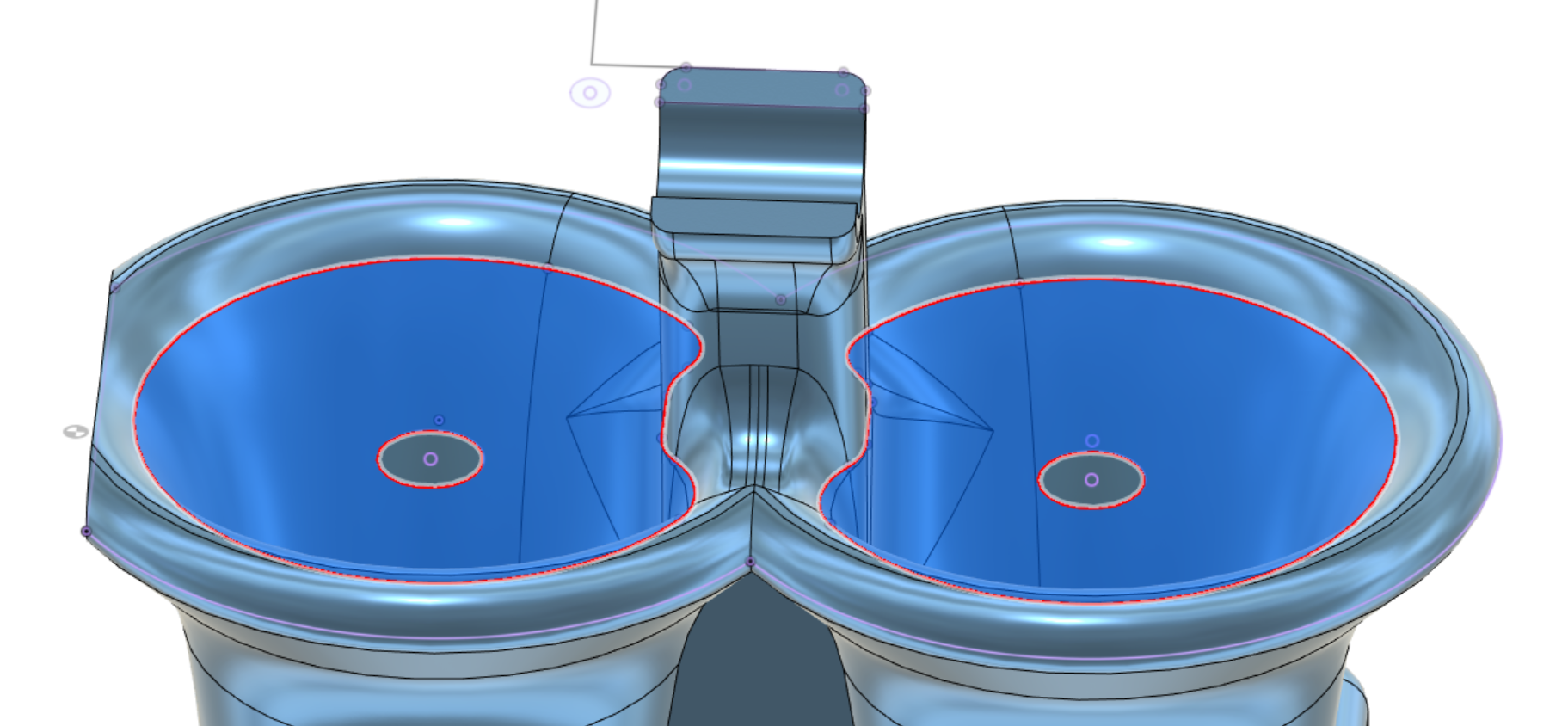

I got a second half printed, still needs a few tweaks for the rail mounting. But before I get too carried away I can at least test how this new intake runner length/shape changes powerband. Just using the inner rail. Interestingly the main difference was that it needed heaps of fuel pulled out around the 3500rpm range. It had a bump around the 6000rpm mark, needing around 5% more fuel to reach target. But then above that it was slight losses in the 1% sort of range. I havent adjusted VVTI to suit any of this, so I might be able to claw back most of the losses, maybe raise some of the good areas too. But it's kinda looking like a slightly shorter intake would work good if I want to bump that 6000rpm peak a little higher. There's definitely no new bumps coming into play at the higher rpm range though, that were previously out of reach. Which is fine by me as this ever so slightly conks the bonnet on one of the runners. It would fit fine if they were just a little shorter. Also make a future airbox solution a little easier too. This is a comparison of the full throttle fuel table changes needed to reach goal air/fuel ratio. This is a cross section of current setup. It would be tempting to just chop some length out of the lower part near the throttles, but then the injectors would end up a bit closer. Ideally want to keep them as far out as I can, to give the concept a fair trial whenever that might eventually happen. Ahh well, back to the drawing board...

-

Toyota Echo Intake version 6 million As per previous waffling I think it will be beneficial from a reflected wave perspective to keep the intake runners more parallel most of the way up... Then also make them a bit longer. So I modelled this up. So this then had the flow on effect of making the fuel rail situation a little tidier as well, as it pokes in from the other side. So just use the regular tabs on the fuel rail for holding it in place. Also keeps more of the perimeter unobstructed, which might be important now tha the cross sectional area at the entrance is greatly reduced. Also now the fuel line and the injector plugs are flipping upside down too, so it will look a lot less messy. First iteration needs some dimensional changes to fit properly but so far so good. It's got about 10mm clearance the the bonnet which is perhaps a little marginal. (because of longer runners) But see how it goes. I still havent figured out how to print the nylon stuff properly yet, might need to wait until I've got some $$ to buy a dehydrator box. But I'll try get the design sorted in PLA for the moment anyway.

-

True, good point! Also something KPR mentioned previously, when he put the injectors in the outer position to test. The inlet then performed like it was slightly longer than it actually was, presumably because of density difference that the waves were travelling through. Just those damn peach cans on the intake dyno test really rattled me aye. haha. I've always had the idea in mind that the primary function of an inlet runner is to maximize mass flow (as in, if steady state mass flow goes up on a flowbench, you're winning) Then from there, you tune for pulses or whatever as a secondary thing. But what I've come to realize is that it seems like you really can just brute force the mass flow issue by going bigger on pipe diameter, and it's very forgiving you dont lose much if anything. The only time it seems to matter that you have a super duper mega efficient bellmouth shape for mass flow, is if your intake is so utterly tiny, that the easiest mass flow improvement would be to simply increase the pipe size. Like race cars that run an intake restrictor, a good bellmouth design can make or break the whole car. However peach cans is a really good example of that they flow "good enough" from a mass flow perspective, just through brute force. Despite seeming absolutely absurd. Yet they still have the right tuned length to bounce some waves back in when the valve is closing. If you've got a pressure wave banging an extra 10kpa at the valves when they shut, it probably doesnt matter if you're losing 2kpa on average from a crappier design. I guess some of these generalizations change again once you start doing 20k rpm and reaching supersonic port speeds or whatever. All interesting stuff.

-

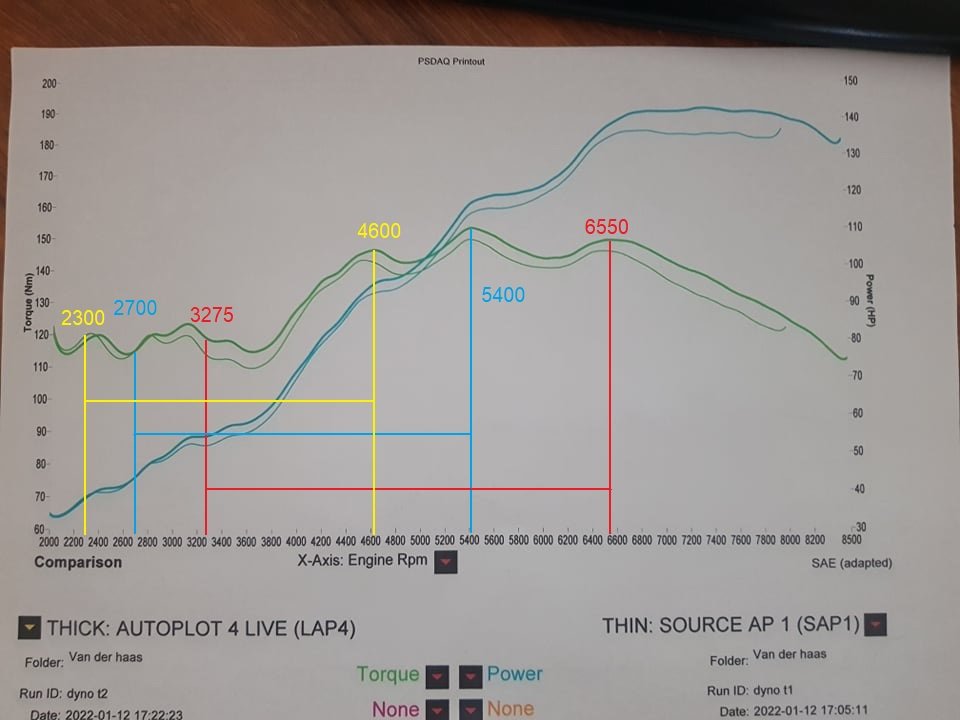

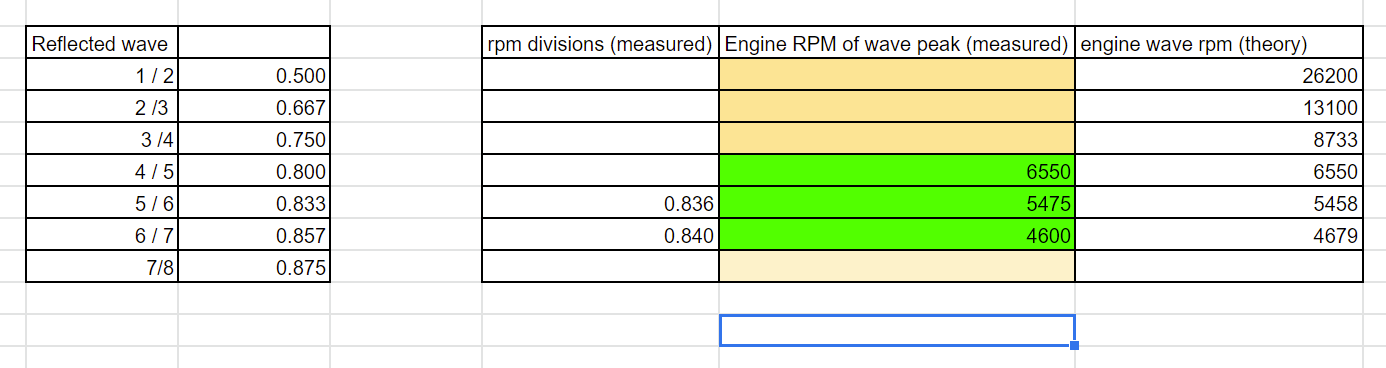

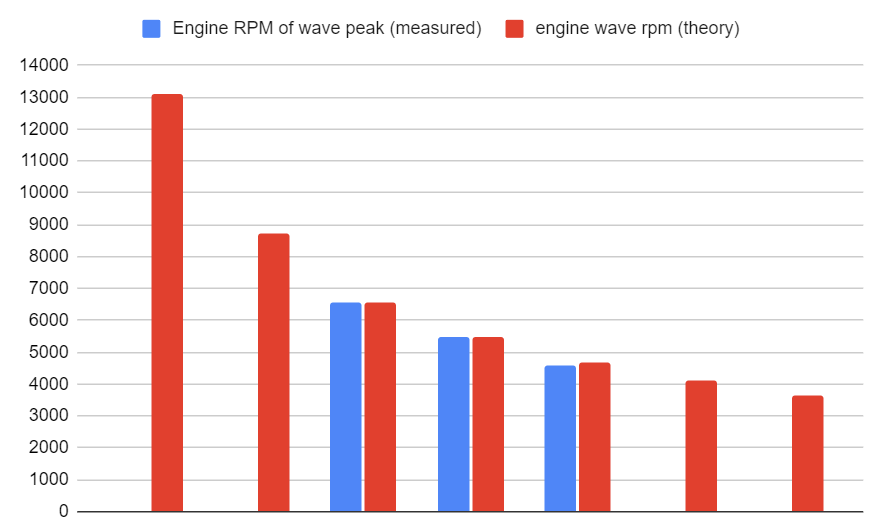

I've also been thinking about what you said about the pressure wave being generated in the cylinder, when there is peak accelleration of the piston. But would this be when it happens, would it be peak accel of the piston, or peak change in volume inside the cylinder Like the first 10 degrees of travel and you might have expansion ratio of 200% (or whatever) But by the time you're half way down the expansion ratio of another 10 degrees crank movement might only be 20% (or whatever) This has all made me think that I've got an 8 channel oscilliscope and it's very easy to hook up a map sensor with a probe dipping into the port. I can setup an output on my ECU to trigger at each TDC event so there's a reference point for the scope. Probably pretty easy to figure out when things are happening and why. If you look at some of the peaks and then see if there's a dip at 50% rpm, it almost lines up as you'd expect... The "not quite" could be because cam timing is different at each point, and just other contributing variables I guess Also a while back I had the thought that you can figure out which reflected waves you are looking at on a dyno plot, by the rpm spacing of them. If you had a first reflected wave, and then a 2nd wave. The 2nd wave would happen at a 2:1 RPM ratio But then 3rd wave and 4th wave, you get a 2:3 ratio between rpm spacing And so on. The point of this is that you can theoretically see the rpm at which the other reflected waves would happen, outside of what's measurable. So maybe if there was a big peak you just werent quite reaching, you could make your intake a little longer to try get to it. or whatever. Another important implication is that if you know which reflected waves you are looking at, then if you assume that it's travelling at the speed of sound, then you know how long the tuned length is. Which will help solve the mystery of whether the wave bounces back for the next engine cycle, or just to the end of the same induction event. In this example if I say one of the peaks is at 6550, and then look at what ratio I need to get next peak at 5400ish 6550 divided by 5400 is 0.836. Which is within ballpark of the 5/6 ratio. Then the next one is close too. So then you can see that the 3/4 ratio wave is apparently happening at around 8700rpm. Which you cant see on the dyno graph as we didnt rev it that high on the day. One thing that will throw a spanner in the works if the wave is first generated at 50% towards BDC or whatever. The first wave will start from that length of the bore, to the tuned end length of the runner. But when that wave reflects back to the head, any subsequent bounces will be bouncing off the back of closed valves which is a shorter tuned length. Then the final tuned length part will be something along lines of your 7/8ths or 3/4 wave distances on your calculator. So there will be an offset for the first wave and last wave but all the middle ones should be the same. However it should be close enough to validate whether the tuned length is the entire cycle or just start/end of induction.

-

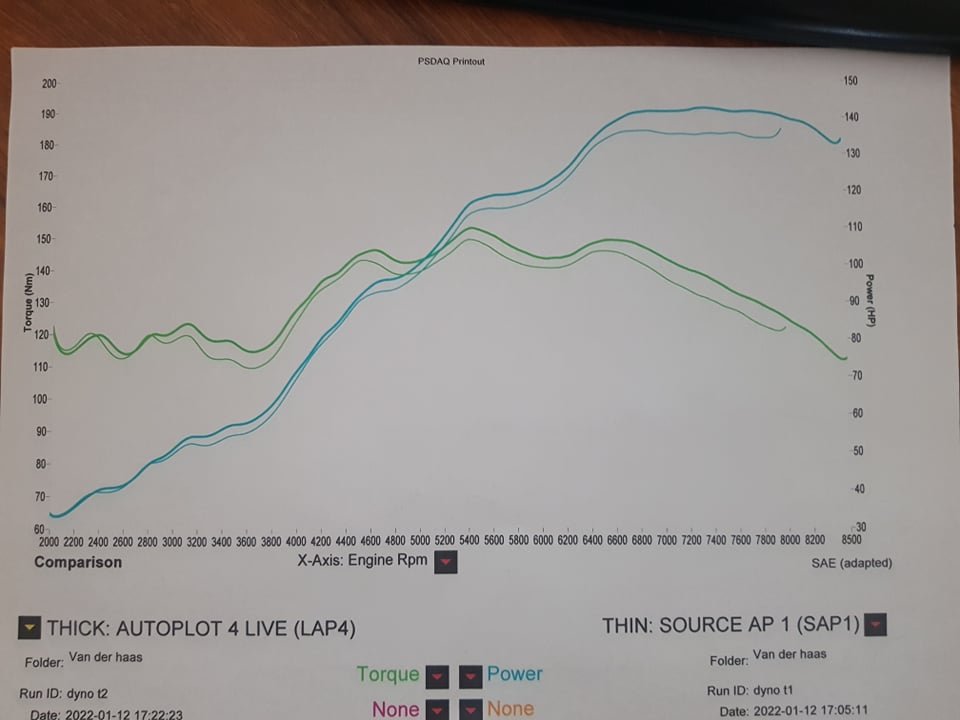

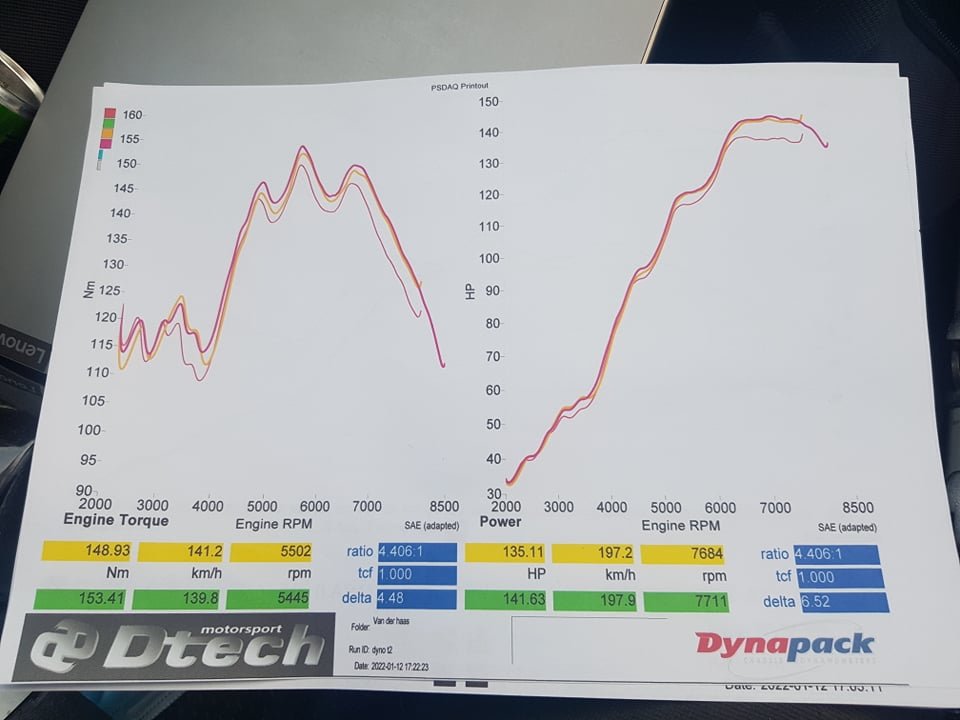

So total intake length from back of valves to the tip of the inlet looks to be around 350mm The trumpets used in this case were curved, but have a fairly linear cross sectional area until right at the end Then here's the dyno plot from this setup. Peaks and troughs are very distinct! This is how many degrees of cam advance it was using through the cycle And a video. It was really interesting to be in the room with bonnet open while car was running, you could feel the pulses from the intake hit your chest. Way more than I would have imagined

-

Using his calculator a little earlier, it looked like 40 degrees of cam movement basically did the equivalent of having adjustable runner length by 200mm or so. Which makes sense, runner length is about catching the pulse in the right spot when the inlet valves are closing. VVTI means you move the catch point rather than the send point. But you still need to have your runner length set to a meaningful range to work across

-

EDIT: nevermind my maths is bad

-

I've been thinking about this some more, apologies if I was initially dismissive etc of your work putting this together. Just venting my dissapointment with reality not often aligning to my own expectations on these topics. However in terms of your calculator, Is there something that you would you like me to do that's helpful for you? I've got a dyno plot of the motor running a known length intake (with bends at the end though) It's got very pronounced dips and peaks in the curve. If you like I can get a fairly accurate overall runner length dimension. But where do you measure to at the head end? Back of closed valve? I dont really have the right tools to find the point relative to TDC of when valves are opening and closing though.

-

"Shorter runners make better higher rpm power" But they've pushed their tuned length to 25,000 on an 7000rpm engine haha.

-

This and people think their random assortment of high dollar aftermarket parts will all magically work in unison to produce the optimal result. Testing testing testing is how you get results

-

Hello! Thanks for the post. Over time ive seen more and more and more of my calcuations and expectations etc unravelling when compared to real life testing. One really interesting thing regarding tuned lengths, which is covered in the video below a bit. I designed some trumpets which had a theoretically ideal bellmouth on them, but, these are too big to fit side by side. So I added a little bit of a curve to stagger them like this. So these didnt actually work out amazingly great, in fact, they were pretty much equalled or beaten by a set of poorly fitting peach cans jammed on the intake. (?!) The interesting part though, was that since I had such a large graduating elliptical shape to the bellmouth. The tuned point at which the wave reflects seemed to be somewhere deeper inside the shape. Not right at the outer end. So they behaved like a much shorter runner than their geometry would suggest. So if I'm using some calculator to tell me how long to make my runners, is this calculator complex enough to take into account how elliptical the entrance is? If not, then its going to spit out the wrong information right from the start. So then you need to do some testing anyway. So why not just do testing anyway? Another issue is that this motor has the crank offset by 14mm towards the intake side, in the block. So the accelleration rate of the piston going down, is different to the piston going up. So the maths for working out peak accel becomes more complex than if it were centered. So without taking this into account, calcs would be wrong again. Also on my previous intake setup, the intake runners had a 90 degree bend in them. If I am working out the tuned length, is this the shortest inside length? Centerline length? Or outside length? How does the speed of sound travel around a bend like this? More brain bending and more complexity to add to a model. Since we're not talking about something deeply theoretical like aligning a space telescope, and empirical testing of different lengths is incredibly easy. Especially in the era of 3d printing. These days I will always prefer to just do some work and test some iterations rather than rely on calculations which cant possibly capture the real life complexities involved. Does the speed of sound travel faster along the inside edge of a curved runner? Honestly I have no idea. But I can make curved runners and see how well they work (or not) It's like, using VVTI to adjust the cam angle. I dont care about, nor can I accurately calculate, all of the theoretical interactions that result in XYZ cam angle giving the best power. But I can move a cam to a particular position, and see that it makes good power. So thats where the cam timing goes. Sounds like a bit of a pea brained approach, but it's actually acknowledging and making peace with how insanely complex all of the contributing variables are. It's nice to delve into some theory but it's just too damn complex to accurately calculate. I think you will find it fascinating to watch basically every single video on the Garage 4AGE youtube channel, hosted by our very own @kpr. It's all amazing stuff, and seeing some real life iterative testing has absolutely crapped all over a lot of my previous expectations. A lot of things that I previously thought would matter a lot, just simply dont. In this video below, he iteratively tests a whole big bloody stack of inlet lengths and shows all of the dyno plots. This might be an interesting data set for your calculator. It's also interesting how much power his 1600cc makes with some incredibly long runners, much longer than most people ever use.

-

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

What I've learned from watching @kprs excellent videos is that leave all of those calculator wielding barrys to their own devices. Because most of the calculations seem to be bullshit and/or too simplistic to be meaningful. For example, in one of the intake runner tests KPR did. If you have a larger flare on the bellmouth, it behaves like a shorter runner than it is. So these people calculating inlet length down to the micron, what assumptions have they made about the intake shape, and where exactly do their length measurements begin and end? Some things you can only truly find all of the relevant variables with some real life testing. Then go through a few iterations of adjustment. Even F1 cars sometimes have big fuck ups because their modelling doesnt work as well as it should, in real life. I reckon just design the intake in such a way that you've got scope to play with some adjustable lengths later on. Then do some real life testing with different lengths. Then just work towards the constraints of available space and some broad general rules for the exhaust. Like you've said you're not chasing every 100th of a horsepower on this, so dont get sucked into a barryhole of pointless calcs that wont work anyway. -

Discuss here about Yoeddynz's little Imp project...

Roman replied to yoeddynz's topic in Project Discussion

The only thing this motor needs is glorious flat six noises. Cant wait to hear this thing sing! -

After about 8 revisions I've made something that fits, doesnt hit the bonnet, seems sufficiently strong on the fuel rail support and blah blah. I've basically run out of other filaments at the moment, so all I had left was a roll of ABS+ that I've not been wanting to use because it stinks when you print it. But it's actually printed quite nice without any warping. But I think it goes a bit soft from exposure to fuel after a few days. So first thing I did is get the motor tuned to be 100% bang on fuel target, using the injectors and fuel rail moved to the "inner" position mounted on vacuum side of the throttles. So when I move the rail and injectors to the outer position, I can look at the comparative lean/rich condition. If it goes lean everywhere, it's probably a bad sign - means I'm losing lots of fuel to reversion or something. I dunno, see what happens? Well, surprisingly, after moving the rail. Is pretty well bang on. Interestingly there are some areas where it's now running rich, rather than lean. Better fuel mixing? The car drives, cruises, and generally behaves just fine. It hasnt felt super soggy on the throttle or anything either, but I have beefed up the accel enrichment a lot. This is a full throttle run, with injectors placed on outer position. You can see the lower rpm area where it runs a bit lean - this is probably where you'd want to use mostly inner injectors instead. Then start phasing the outers in after that. When driving it, the car's felt like it's more eager to get to the redline. Virtual dyno looked to agree, to the tune of about a 5hp bump towards redline. But I think I need to do some more testing before I believe the initial results. Once I've got some less dodgy trumpets printed from a better material, and my ECU fixed. I'll see if I can get back to the dyno and do some proper comparisons.

-

Yeah! Pity it was never finished. Guess it was around the time where the arse fell out of the (4&rotor style) nz drag racing scene.

-

Speaking of such things. Guess what I saw last week. A Quest4 built EP82 drag starlet with a 3SGTE. Car was never finished but the whole front shell came off, but then the whole motor and trans was mounted in such a way you could swap out the whole front. So they could race it in NA and turbo class just by swapping the front. Should have grabbed a picture, it was quite cool.

-

Yeah I guess I can do some dyno testing with bonnet up and then make some decisions from there. Will also print another revised version with injectors lower again. But hopefully get a decent spread of fuel under/over the throttle plate. The BMW airbox turned up today as well. It's super cool with the dual stage trumpets... But also definitely does not fit.

-

I got the 2nd half printed and bodged it all together with a sea of cable ties and shitty wiring. But there are still bonnet clearance issues that I didnt notice earlier, caused by one particular crossmember bit on the bonnet frame. It ends up hitting on the center section that joins the two halves of the outer rails. So not really possible to use these trumpets unless I tip the motor over a bit or something. I'm thinking it might actually work to mount the outer fuel rail onto the radiator crossmember instead. But this means any future plans of fitting an airbox wont work. I could mount the injectors in through the side of the bellmouths instead, from the bottom. This would certainly make it less of a visual abomination, and also mean I can take up more of the space with runner length if needed. But I'd like to see how it goes with a straight shot down the runners, even if just temporarily. Also I wired up the other 4 injector drivers again, but after the previous fix I've still got the same issue. If I put the injector plug on number 4, it holds the injector open. Doing some googling, this is typical behaviour of a failed mosfet. So I'll see if Dad is able to take another look, otherwise I'll send it down to Link for repair. So a bit of a bummer for a few reasons, but will get something sorted. One thing I noticed though, from just giving the car a bit of an idle area tune on the outer injectors only. Even with just idle fuel, the outside of the throttles gets super cold. Like 3-5 degrees kinda thing. Then when you turn the motor off, they slowly come back up to temp again. Interesting! I wonder what it will be like after a full throttle run, maybe this is where the benefit comes from. (if anything) I'm also incredibly surprised at how well it can idle running on just outer injectors as well.

-

New bracket position/shape/etc looks good. Good bonnet clearance. Printing the other half then I'll need to go get another 4 plugs for the bosch injectors and wire up all 8. Then come up with some extra bits to make sure it's all secure and sitting at the correct angle.

-

No idea, but I can do some back to back testing and find that out easy enough. Remember that most of the air comes from around the sides, not from straight ahead. Also the airspeed is (comparatively) incredibly low at the wide point of the bellmouth. Unrelated picture but you get the idea:

-

Version 2 underway. mounted 10mm lower and 5mm further into the runner. Then angling the injector about 5 degrees up I was curious how much the cross sectional area would be affected by having all this extra junk in the way. Taking a cut at what looks like the worst spot, and we've still got cross sectional area equivalent of a 74mm circle per runner. There's still way more bellmouth area than there was with the silvertop throttles.