-

Posts

6781 -

Joined

-

Last visited

-

Days Won

32

Everything posted by Roman

-

rods and lower comp pistons. Then same valve springs and cams as mine.

-

Haha nah not from 1300, maybe lucky to get close with 1500cc! I think 264 deg cams being the biggest available for a 1NZ will become a limiting factor. BMW S1000RR is pretty wild, 1 litre engine makes 200hp from factory. Up to 14,000rpm. So good! I've seen a few people swap these motors into small cars overseas but they seem a bit spendy/unobtainable here.

-

While we're discussing other cars. A guy in Hamilton has recently had his turbo 1NZ tuned up. 289hp at the wheels at 18psi. Has an 8700rpm limiter. So easily 200hp per litre from turbo setup (at engine) He's said it's a bit too laggy for his liking though, so is going to try a different turbo. Hopefully manages to keep most of that top end power on the next setup.

-

Okay this makes considerably more sense, than the idea of someone buying a Yaris GS then fitting a silvertop 20v haha!

-

Is there any advantage over all of this instead of just buying a GR Yaris? Apart from cost I'm guessing Is that one 4WD?

-

Right! Okay that makes a lot more sense hahaha.

-

-

Why would anyone put a 20v into a GR Yaris?! Weird. haha I have indeed considered a 2ZZ. But it's a bit beyond my skillset as it requires a whole lot of chopping the front of the car up to make it fit. And motors are comparatively expensive. Pretty sweet results though.

-

Not sure about that, I think that would be even more blasphemous than his 20v content

-

Once I've moved house and sold the old one I'll not be in such dire financial situation. Will just be a while. So if it needs pistons I'll buy them eventually. Goals for the meantime is make it to OS drags, and the Toyota Festival trackday at Hampton. Then whatever else comes up. Then also see how the 1300 setup goes.

-

Interesting! Did not know that. Will take some measurements when I've pulled out one of the more intact pistons haha.

-

Thanks to everyone that pitched in some bucks for a new motor! I closed the page after there was enough to buy one. So thanks an incredible amount. Will have the money through some time next month, so will buy a motor when I can. Hopefully I wont let you all down somehow. I've been doing a bit more nerding with the piston/rod situation. I've been thinking that maybe one day I might be able to CNC a piston from billet, so drew one up with all of the important dimensions as per a standard 1NZ piston. I've made it so that all of the internal piston geometry has no overhangs that you couldnt machine from a vertical tool head. So it looks like it would be possible to machine this in 4 main operations. But I also have absolutely no bloody clue how much extra complication there is in real life to do this. However while doing this, it got me more thinking about how universal pistons and rods potentially are. The only things about a rod that need to be correct are the big end diameter matching your crank, the pin hole matching the piston, and the overall length matching the piston and rod's combined height to top of the block. So the main things I've needed to look for are: 43mm big end, 18mm piston pin, 140.9mm rod length if using standard pistons. The 1NZ has quite a long rod, so although there are some other Toyota engines with a 43mm big end and 18mm pin (4EFTE) they have much shorter rods. Around 130mm or there abouts. Early 4AGE have a 43mm big end as well, but also shorter rods and I think they had a 20mm pin. There were some non Toyota engines that had a 43/18 combo, but rods too short. Since I'm potentially looking to use a bike piston which has a lower compression height (center of the pin to top of piston) I need to find a rod that's a little longer than 140.9mm to make up the difference. The GSX1000R pistons look really nice and light, and they're cheap and normally do 11,000rpm. Buuuutttt the piston top to pin distance is 4.16mm shorter than 1NZ pistons. So to run those with no other changes I'd need a rod around 145mm long. However, despite a caffinated internet binge until 2am. No luck. The only rods that are longer than 1NZ with the correct sized big end that I've found are from a Honda L15A motor. Which is the 1500cc engine out of the Jazz etc. These motors have a smaller bore and an even longer stroke, and have a 149mm rod. (Wow!) and a matching 43mm big end and 18mm pin. MaxSpeeding makes rods for these motors as well. The problem with a 149mm rod is that even with the shorter bike pistons they would stick out the top of the block by about 4mm which is too much to be able to machine off the top safely. However this rod might work for a 2NZ crank in a 1NZ block setup. For some mega revs. The long rod setup, for a 1NZ piston needs a rod which is 152mm long. So that's 3mm difference than what I get with the L15 rod - Meaning if I can find a piston with 3mm larger compression height, it would be bang on. 1NZ compression height is 27.6mm D16 Honda motor is 29.5mm 4EF(T)E is 29.9mm D15B honda 30.7mm So a 1NZ block, 2NZ crank, L15 rod, and a D15 piston would be 0.1mm taller than the original 1NZ piston deck height. Hah! These pistons have a flat top on them, so still might end up with a good compression ratio. So this has been a fairly pointless exercise in terms of finding any better pistons or rods for the 1500 setup. If pistons want to keep flying apart I'll just have to save up some bucks for forged 1NZ pistons. However it would be interesting if this 1300 combo could be chucked together for cheap-ish.

- 1536 replies

-

- 19

-

-

-

Nah. I just need to buy Hayabusa pistons, Hayabusa rods, Hayabusa crank, Hayabusa block and head. Then I'll have the world's fastest 1NZ

-

23.5mm compression height on the bike pistons. Bummer

-

Ahh wow never considered bike pistons! I will have to get out one of the remaining intact 1nz pistons and measure it up haha 1nz piston has a compression height of 27.5mm (top of piston to centre of pin) Ideally find something with a slightly higher number so I could machine the top to get the compression ratio right. If the compression height number is lower, it will drop CR too much. Might be worth buying one of those pistons to have a look though. I'd need to press out the bronze bush in the rod and refit one for a 17mm pin instead of 18mm. Or hone the pistons to suit 18mm pin. But I'm guessing the bike one will be strong enough and probably lighter.

-

Oh yeah so about $1000nzd, not too bad I guess. Maybe closer to 1300 after tax and shipping. But 15:1, sweet I can run it as a diesel too haha! Yeah it looks like Honda D16 motor, Suzuki vitara motor, and 4efte are possible similar options with similar pin and bore size. But people normally put the strong vitara pistons in the d16 motor and make 400hp. But the horsepower load on a cast piston is different to the rpm trying to pull the piston apart.

-

Yeah the lads in Thailand sell forged pistons in whatever CR you request. Up to 15:1 But they're pretty spendy. (Compared to rest of project) heh However my Dad has ordered a 4 axis cnc that will arrive probably in a few months. Pistons and/or rods might be feasible projects eventually. But start with some easier stuff while learning. Could maybe do a cnc port job as well, not as well as a 5 axis but would be cool. But gonna be a learning curve.

-

Daves new school holden shambles. (And finally a Turbo)

Roman replied to Muncie's topic in Other Projects

I've found on proper drag tyres everything feels considerably less abusive on drive train! Wheel hop is the #1 killer I reckon. Big shock loads over and over. Don't get that so bad on squishy drag tyres- 364 replies

-

- 1

-

-

- not as good as a barra

- ecoboost

-

(and 1 more)

Tagged with:

-

Even if i was a casting master, and i know absolutely nothing about it. There would be no benefit if current pistons are at the strength limit of cast material without forging. And there's no way to DIY forging as best I know. Machined from billet might be an option, or see if anyone sells unmachined forged blanks that are close enough. However I'm also not sure how much stronger billet would be.

-

Daves new school holden shambles. (And finally a Turbo)

Roman replied to Muncie's topic in Other Projects

What did that rev to? Being able to rev the piss out of something can make a decent difference haha- 364 replies

-

- 1

-

-

- not as good as a barra

- ecoboost

-

(and 1 more)

Tagged with:

-

Daves new school holden shambles. (And finally a Turbo)

Roman replied to Muncie's topic in Other Projects

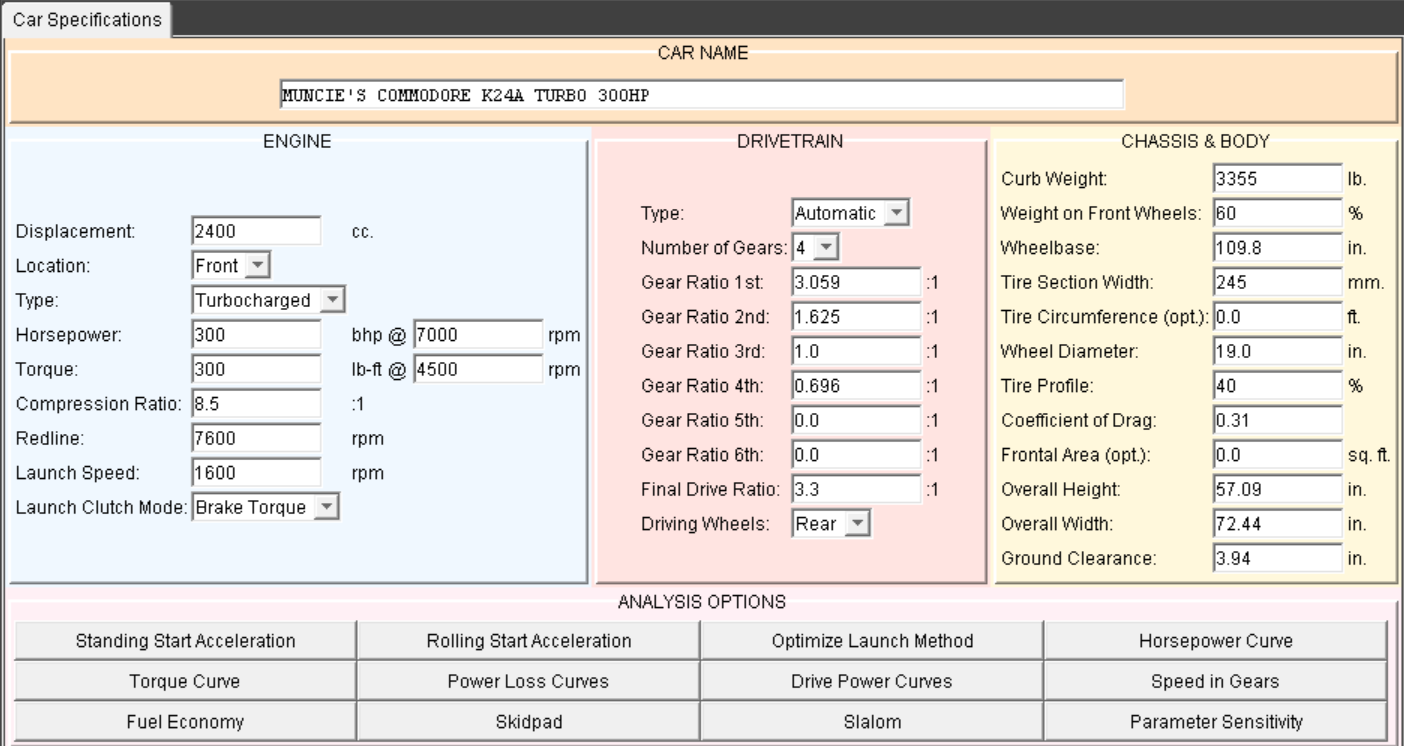

Yeah your car is literally twice as heavy as anything that suits a 1.5 litre engine hahaha. But cos it's a laugh, here we are. Alright so this is all of the above data, no weights changed but just engines swapped. Still auto trans and a 3.3 final drive. NA 1NZFE, since this is the least suitable option I'm assuming it's doorty so 160hp @ 8000rpm with 9000 limiter. Turbo 1NZFE 300hp @ 8000, 9000rpm limit NA K24A is the best standard power version, 204hp 7600 limiter Turbo K24A is 300hp @ 7000rpm 7600 limiter If you want to try any of these numbers a bit different, let me know- 364 replies

-

- 2

-

-

- not as good as a barra

- ecoboost

-

(and 1 more)

Tagged with:

-

Daves new school holden shambles. (And finally a Turbo)

Roman replied to Muncie's topic in Other Projects

If you're planning on using the 4 speed auto it's going to be pretty punishing with that 1st to 2nd gear gap. Also the final drive ratio in the 3.something is going to reaaaalllllyyy kill a smaller motor. Are there any options in the high 3 or low 4 to 1 region for final drive?- 364 replies

-

- not as good as a barra

- ecoboost

-

(and 1 more)

Tagged with:

-

Daves new school holden shambles. (And finally a Turbo)

Roman replied to Muncie's topic in Other Projects

How much do these weigh? Find this information for me, and I'll send you back some dataz on predictions for how each version of the car will run With an NA K24, turbo K24, NA 1NZ, turbo 1NZ- 364 replies

-

- 5

-

-

- not as good as a barra

- ecoboost

-

(and 1 more)

Tagged with:

-

I think you could be right about that. If the piston is trying to fly apart, where the top of the piston is trying to carry on upwards, and the pin is pulling it back down. So the material strength around the pin is the weakness. Then on the exhaust stroke this force is lessened, and when the cylinder is full, on the compression stroke this force is lessened too. The engine didnt fail when it was approaching max rpm, it failed just after a gear shift where throttle got cut to zero. So the worst case scenario would be zero throttle, high vacuum, high rpm on the compression stroke. I'm not sure if these forces are on the same magnitude as each other though. However, I can indeed increase my piston return spring value. I can use e-throttle to set a minimum high rpm throttle value to something like 10% or 20%, and then use a fuel cut and/or pull zillions of ignition timing out to cut power instead. This might bring a host of its own issues, but might be a bodgey solution I guess haha. Flat shifting, interestingly enough, would also help haha. The incredibly clever @Lith made a calculator ages ago that works out forces on pistons/rods. Entering 1NZ stuff. Peak accelleration on the piston at 9000rpm is 4991G! I'm not sure what sort of numbers I was expecting, but thats bloody lots. Then the PEAK piston speed is 41.7 meters per second. Which is 8200 feet per minute. Which is zillions high when 3500fpm is the reccomended mean value.

- 1536 replies

-

- 14

-

-