-

Posts

6759 -

Joined

-

Last visited

-

Days Won

32

Posts posted by Roman

-

-

Aahhh so these injectors might be okay, at least for starters.

I left them all to soak in CRC overnight, then made a up a lead to tap them on/off straight onto a 12v battery, and they all clicked.

So then I setup the injector test mode in the ECU to run them through 10,000 cycles while they were full up with CRC.

Then tested all 6 outputs on my loom and they're all working.

So they might have just been ever so slightly stuck.

They still might be partially blocked or whatever, but I'll flow test them first to make sure they are balanced and that the spray pattern looks okay.

If I can avoid a $500-600 bill for new injectors, that's money this month for stuff like the exhaust which is much better!-

6

6

-

-

4 hours ago, shrike said:

550cc would give you headroom for e85 or are you just looking at running pump gas?

Just pump gas, E85 is just too much hard work.

-

3

3

-

-

Yep just about!

Need to fill gearbox with oil, bolt exhaust manifolds on, replace injectors, make sure the fuel pump still works.

Then coolant is optional for first start, haha. But it's damn close.-

3

3

-

-

At the moment I was just working on the basis that the V10 has 10 cylinders and makes 500hp, so 6 cyl worth of injectors should be 300hp capable no problem.

However has rpm goes up, you need a slightly bigger injector to make the same amount of HP. As your deadtime gobbles up an increasing amount of your available time to spray.

-

2

2

-

-

- Popular Post

- Popular Post

A few hurdles...

Only one side worked for the hoses.

The next size up is 495mm long and sounds like it would work good.

It's over $100 for the hose which is spendy.

But for once in my life I want no joins in the radiator hoses damnit.

So will just do it. (The non fitting side is currently 305mm)

Then I've been making good progress on the wiring, a new roll of DR25 turned up so I finished the injector loom and tested it.

Injector 1 - working fine

injector 2 - working fine

injector 3 - nothing

injector 4 - nothing

injector 5 - nothing

Injector 6 - working fine

I figured I must have derped the wiring somehow, so I pulled my loom back off and test it, traced wires back, blah blah. All seemed okay.

Well, turns out that the wiring wasnt an issue, but the injectors are.

7 out of 10 of the BMW injectors are seized.

BMW life! hahaha.

No big drama, as it's probably a good idea to start with some slightly bigger injectors anyway.

Internet says these factory injectors are somewhere around 248cc which might have been borderline for high rpm, depending on the deadtime.

For interest's sake I will chuck these in Dad's ultrasonic cleaner and see if they unjam at all.

Anyone got some suggestions on a good set of long pintle EV14 injectors? Over 250cc and under... say... 500.

If there's some common 6 cyl car that is pickapartable I'll go grab a set. Needs the long pintle.

-

12

12

-

- Popular Post

- Popular Post

The SW20 radiator turned up, and thankfully it was indeed 755mm wide, not 770. So just needed a small snip up one side to fit.

There isnt actually too much in the way of the fins being shrouded by the front panel, because those side parts are mostly the end tanks. So ended up better than expected, it will mount up to the front panel nicely.

This is the amount of room to the crossmember level:

My next problem was that the radiator outlets are 32mm, but on the motor they are 38mm.

Wellllll, turns out that you can buy flexi hoses with 32mm at one end, 38 at the other. At what looks like good lengths (400 for one side, 300 for the other). So ordered some. Too easy!

I'm glad to not need a join in the hoses this time.

I printed some lower radiator brackets which bolt onto the crossmember similar to the ones I had for the Altezza radiator.

I remember we made the altezza ones out of aluminium, and it seems like it took forever and was a really hard job.

Now with a printer it's just incredibly easier to test print and test fit a few iterations within hardly any time at all.

I've also got all the fuel lines connected, throttles are now mounted on carbon nylon manifolds, throttles are balanced and connected.

My to-do list for getting the motor fired up is rapidly shrinking!-

38

38

-

2

2

-

If you're looking at getting that wagon, probably want to do a rack and pinion conversion as the steering box stuff takes up heaps of space where you'd want to run the exhaust.

Also most likely has leaf spring in rear of that wagon which is a bit gross compared to 4 link.

Also, at the best of times with some $$$ spent these cars handle... not amazing compared to modern stuff.

But with standard suspension etc they just wallow all over the road haha.

Costs a fair bit of $$$ to get them handling and braking a bit better.

With lots of weight in front and not much power would be kind of like wielding a marshmallow sledgehammer.

-

4

4

-

-

-

- Popular Post

- Popular Post

1 hour ago, kpr said:na stuff doesnt need that much cooling, especially since your engine is a giant aluminum thing to start with. Also half the time peoples cooling problems, is all the stuff jammed up behind the radiator. if air cant get out, its not going to go through

Yeah true.

Apart from existing options not fitting, it's also that eventually I want to be able to have an intake something like this.

Both because it looks cool, and works to hide a lot of other sins in my engine bay haha.

-

13

13

-

6 hours ago, GARDRB said:

MR2

Overall size: 770mm x 308mm x 42mm

Core Size: 670mm x 308mm x 42mm

Inlet & Outlet size 32mm

https://www.redlineperformance.co.nz/product/to-suit-toyota-mr2-sw20-radiator/

GT86

Core size: 355mm x 650mm x 42mm.

https://www.fenixcooling.co.nz/collections/performance-radiators/products/toy8877fa42m?variant=41172446480I found an SW20 one that is a little different on dimensions:

Core Size: 675mm *320mm *40mmOverall Size: 755mm *345mm *50mm

Row: 2 Core

If it turns up and is 770mm then I'm in trouble haha. -

52 minutes ago, GARDRB said:

Crazy idea here....

Run what you have, and see what happens. Don't waste energy theorising on what might happen, and over-complicating things. This was the Echo's charm, cheap, cheerful and iterative.

I also know that your name is David and you're incapable of not over-thinking the whole process

Yeah I hear you, and I am focused on getting this from current its current state to a running motor/car ASAP with no fucking around on non essentials. (Can do that iteratively once it's going, like echo. thats the fun part)

As I want to know how well my engine scheme is going to pan out!

So the seemingly easiest way would have been to keep the Altezza radiator that I already had - but the pipe sizes are wrong, and the pipe locations dont really work either.

I was hoping the Mark X setup would just tick off all of these boxes, just have to remake some top and bottom mounts.

But it's actually only as thin as the Altezza radiator (16mm) and the hoses didnt really fit too well since the radiator and engine heights dont match relative positions to factory.

Bottom mounts will be easy, but the top ones tricky because it's tall. But once mounted it's going to be even taller, and I suspect it will hit the bonnet.

So my thinking here is actually to NOT waste my time, rather than to dilly dally with unimportant stuff.

So I'm cutting my losses and ironically going to SW20 parts haha.

To get the motor running I dont need an air intake at all, and I dont need any radiator ducting.

So I'll bang the radiator in there, work out the mounts, work out the pipes, then fill the damn thing up.

This new radiator is 40m thick core as well, so hopefully zero cooling issues if I can get some air to it.

This SW20 radiator was $220 delivered so meets the cheap and cheerful criteria!-

4

4

-

-

Needs to be huge for a car that doesnt go!

And yeah can probably tip it a bit, there's a reasonable amount of room ahead of the motor. -

I've blown up shitloads of Bosch 4.2 and 4.9 sensors, so changed to the 14point7 Spartan controller, with the LSU-ADV sensor.

It lasted the entire lifespan of the echo without blowing up a single sensor, and was running it "hot" on cold starts as well.

(As it's designed to be more compatible with cold starts than 4.2 or 4.9)

Compared to, I think my record with a 4.2 or 4.9 sensor for worst lifespan was that one lasted 3 days.-

2

2

-

1

1

-

-

I think the general idea is that the faster you are going, the less air intake area you need for your radiator size.

A lot of the time attack cars have tiny little holes for the radiator.

Total lower grill entry area is 77542mm2 . Equivalent area to a 315mm circle.

57081mm2 for the upper grill entry. Equivalent area to a 270mm diameter circle.

The front valance sits quite high on this car, but it's really hard to add something to the front to lower it that doesnt look like absolute shit.

I very much do not like this style of front on this era car:

This below though can look cool though but it's hard to get it right, often looks gumby when someone fits one that isnt wide enough or the right shape for the car.

May also be incompatible with my rural driveway haha.

-

1

1

-

-

- Popular Post

- Popular Post

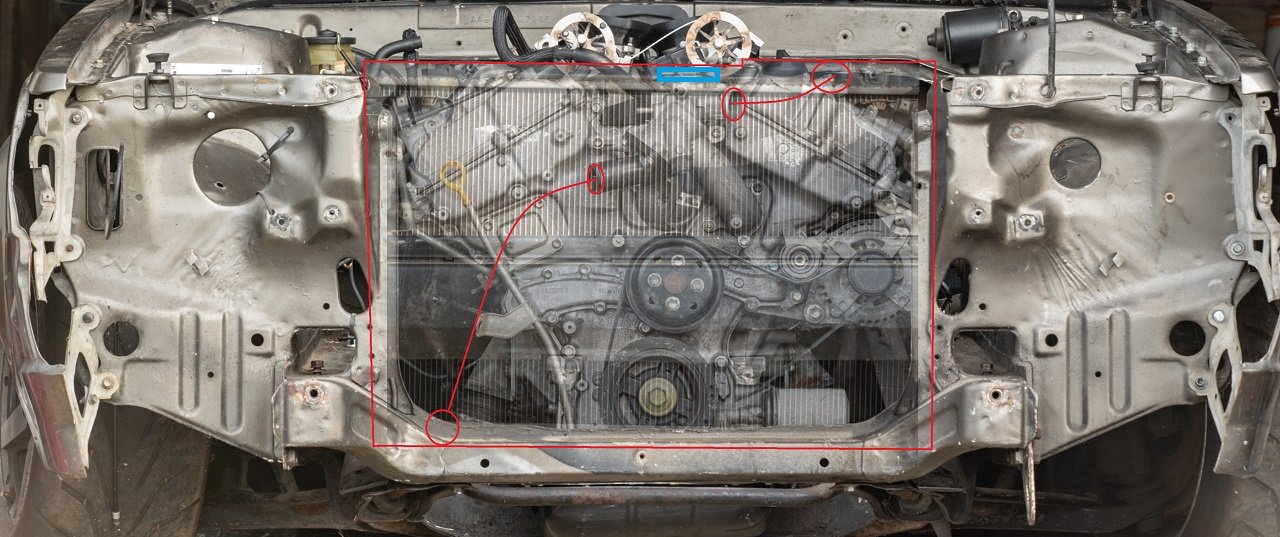

Radiator situation

I've got the Mark X radiator in there currently, and although it made everything nice in a lot of ways in the back of my brain I know it's just not going to work quite right. As the top pipe sits too high.

You can see it sits a little higher than the top crossmember too, and this isnt on any mounts yet. Just sitting hard against the bottom.

The motor's radiator cap (in blue) sits a little lower than the radiator, and the top hose to the radiator flows uphill towards the radiator.

All bad news for ever trying to bleed the air out of this thing.

Another issue is that I'd love to have a front facing intake airbox that goes through to the front grill, like a lot of the BTCC type cars have.

The best option I've found for a low, wide, twin core radiator that doesnt have a radiator cap (and does have an air bleed) is from an SW20 MR2.

Being so much shorter, I can dedicate all of the front grill area for the intake.

And they're a common upgrade item for MR2s, so cheap and plentiful.

The radiator is 5mm wider than my chassis rails, but the end tanks are alloy and on the sides. So will just need a little slice and reweld to fit at the bottom.

If I dedicate the top grill to doort noises, then I dont have a huge amount of frontal area for the radiator coming in from just underneath the bumper.

Possibly need to remove the bonnet catch as well, but I'd prefer to keep it over having bonnet pins or whatever.

This is a rough approximation of how much space I've got for each thing

Red is intake stuff, blue radiator stuff, white is the open area that the radiator can get air through.

So a lot of the radiator area will be fairly useless if hard mounted against the front of the car, as it wont get any air flow. so I'll try mount it as far back as I can towards the engine.

All of this stuff is a bit off topic to my path towards getting the engine fired up, but I've been working on that too.

Last night cut the fuel rails a bit shorter, so there's more room at the back. for the fuel dampers without hitting the body.

Then also had the underside of the rails milled down so the throttle linkages dont hit the rail anymore.

So that's just about all finished once I've retapped the ends and remade the AN lines to suit.-

25

25

-

1

1

-

Recently Dad's car broke the rear door handle, and no inside button. But it turns out he could log in with a canbus scan tool to pop it open.

-

1

1

-

2

2

-

-

TL;DR:

Using a table to look up circle coordinates instead of maths

-

Welcome to

Roman Dave's guide to drawing a circle on a screen when you are mathematically smooth brained

Surely drawing a circle has to be one of the most common and easy things, so there would be heaps of libraries for it?

Yeah there are, but they all use radians which makes absolutely no sense to me.

So instead of figuring out why radians are good I'm going to brute force my way through the problem by not understanding anything.

My LED screen has a resolution of 128x64.

So If I want to draw some circles on it, or having a sweeping needle on a gauge that is circular, or, whatever.

The answer is something to do with Cosine or whatever calculation right?

YEAH PROBABLY.

Instead you can draw a circle in Mspaint that is 64 pixels tall, then count all of the pixels around the perimeter.

So thats the maximum possible number of visible divisions that my circle can have.

Works out to be something like 3.something degrees per division.

So I make a lookup table with 45 values in it (2 degree increments)

then draw a quarter of a circle in fusion 360 and measure the X and Y coordinates as I rotate the line in 2 degree increments.

It turns out that the X axis values are the same as the Y axis values, just starting from the other end.

So I can have a lookup table with only 45 values in it to describe any point in the circle's X and Y coordinates to 2 degrees accuracy"

(Flipping X or Y values depending on which quarter of the circle it needs to be)

//X value = circleLUT [degrees/2]

//Y value = circleLUT [46-degrees/2]

int circleLUT[46] = {0,17,35,52,70,87,104,121,138,155,171,187,203,219,235,250,264,280,293,308,321,334,347,360,372,383,394,405,415,424,433,442,449,457,463,469,476,481,485,489,492,495,497,499,499,500};

-

5

5

-

2

2

-

-

I will use those little slide on linkages that came with the throttles and will weld them to back of the pulleys.

Then have some ability to set the angle when tightening it.

I can also shorten or lengthen the cable. As one end can be unscrewed and moved.

Then if it turns out i still need more fine adjustment. I will add a small tensioner wheel to the cable part way between, that can adjust to effectively tighten the cable.

-

4

4

-

-

- Popular Post

- Popular Post

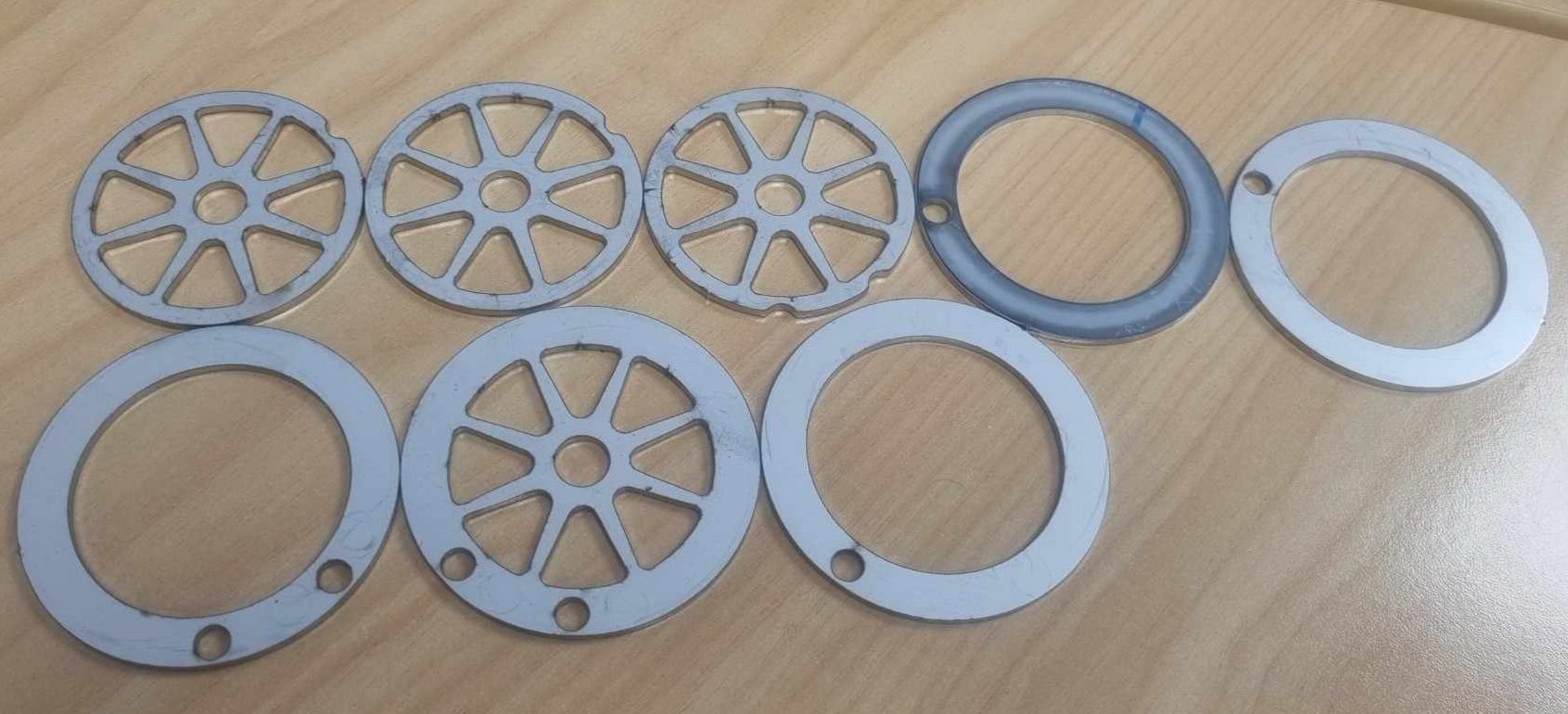

Alright so as of yesterday I'm finally out of mortgage prison!

I finished moving house with heaps of time to spare, I definitely wasnt biffing trailer loads of stuff onto the lawn the night before settlement.

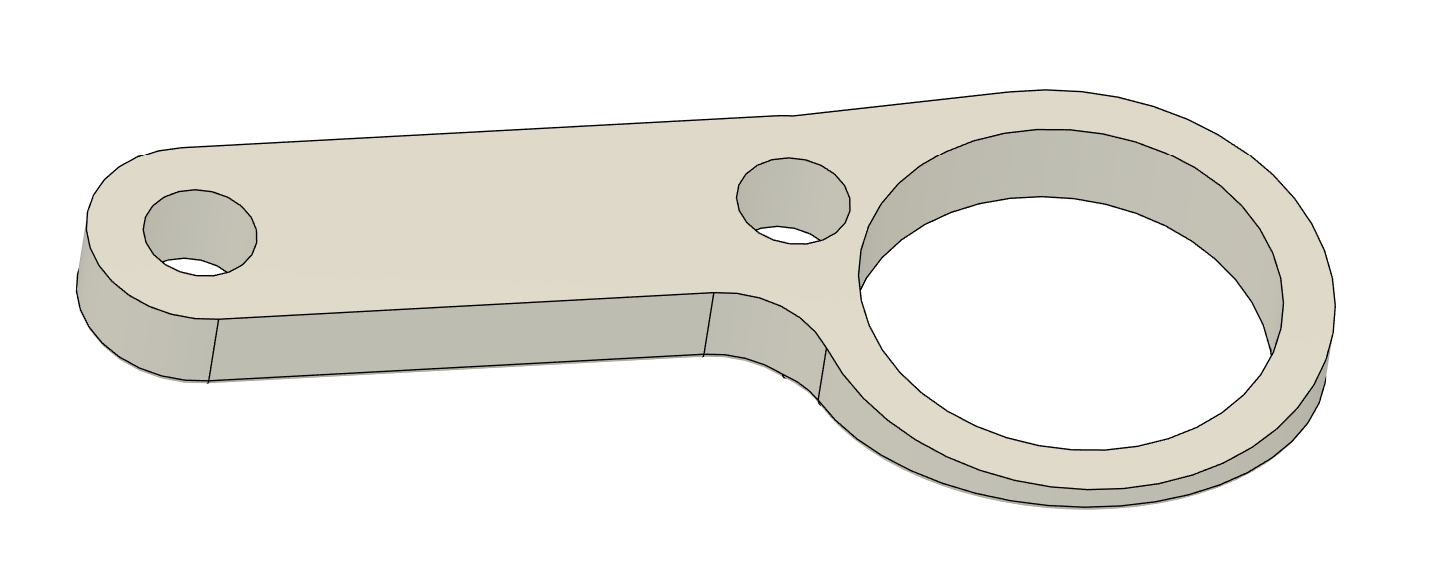

I got some throttle pulleys cut from stainless. I'll put a radius on the inside of the pulley edges and deburr a few spots, but on the whole they came out really nicely. Quite heavy though, probably could have made some parts thinner.

(Everything 2mm stainless)

It's looking like it'll be fiddlier than expected to balance the cable length and pulley positions to get the banks even.

One thing that I didnt take into account is that there is no tolerance for having a cable that is "overlength" as you physically cant slide the protruding end of the cable into the pulley.

However I could probably chop out the relevant section of the pulley to allow this without any issues, as these are still significantly beefier than they need to be.

I need to make some end stops of some sort to stop the throttle rails moving forward or backwards so everything stays aligned correctly.

You may notice that in this photo I've got the linking cable on the wrong way up.

It looks dumb having these on the front of the motor, but down the back is getting very crowded and I've got ants in my pants to get this damn thing fired up.

I got the throttle rails drilled, took about 3 hours to drill 6 holes! We had to grind flats onto the rod to get through the hardening. Otherwise carbide bits didnt even make a dent.

Next jobs are to print a final iteration of the manifold from Nylon, get fuel lines connected up, and keep working on the exhaust. Then I'm preeeeety close to firing it up!

-

49

49

-

1

1

-

1

1

-

100% keen to come do some back breaking labor on some old timey machines in an illegal gold mine

-

7

7

-

-

On 19/02/2024 at 18:36, Snoozin said:

to be fair on Taiwan, a lot of the decent mid-range brands originate there. BC, Fortune Auto, XYZ etc all come out of Taiwan.

Maxpeedingrods is the finest of Chinesium trash.

Also just about every single microchip or processor or whatever in the world comes from Taiwan.

China doesn't want to take it over so they can have cheap coilovers

Also to be faaiiirrrrrr @kpr has used MaxSpeedings... Rods. in his projects with success.

Rods yes, coilovers no.-

2

2

-

-

35 minutes ago, dabuzz said:

interesting, the pulley he used would only produce around 14psi on the street with pump fuel, but with a few more "race" rpm and methanol it saw 21psi out of it, massive for a rootes blower

True, interesting.

This will probably be because theres the same amount of air as before but more of the space being taken up by methanol. So boost goes up. As you run it at a 4:1 ratio or whatever.

(petrol 14.7:1 stoich, meth 6:1)

Maybe also some of the cooling effect of methanol if it was injected before the charger. As roots blower runs crazy hot.

Either way, cant wait to see how this goes with a modern efi setup this time!

-

1

1

-

-

Oh wow, I never knew Tony used the setup after you sold the RX4.

Must have been making some awesome power to run that fast!

What happened to the motor, was it load on the front of the crank made things break or something?

Daves new school holden shambles

in Other Projects

Posted

Ahh yeah thats where I'm stuck at the moment too.

I've got about a dozen new points in the fuel system where it could potentially spray out of, at tank end and engine end.

Need to find the time to clear all of the crap off, and push the whole car out a safe distance from the house. haha.

I'm loving the progress on this!

Shame about the bumper bar, intercooler setup looked cool.