-

Posts

3118 -

Joined

-

Last visited

Everything posted by d.p.n.s

-

d.p.n.s 1983 mk5 cortina Ghia..........yip pinthoe

d.p.n.s replied to d.p.n.s's topic in Projects and Build Ups

-

your getting some good power out the old pinto mate.. got talking to a guy i bought my flywheel and starter off and he races a high reving pinto and was talking about the same thing changing bearing for roller..he sent me some pics......said he hasnt broken a type 9 since doing them.

-

ypu have been busy mate... and yes i fight the urge daily to buy more cortinas or just other projects in General.

-

welcome back mate.. still got the cortina?

-

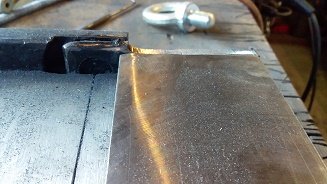

another small area of rust that ended up being a weeeeeeee but more. ran out of flapper discs...so still needs a clean up.

-

d.p.n.s 1983 mk5 cortina Ghia..........yip pinthoe

d.p.n.s replied to d.p.n.s's topic in Projects and Build Ups

well after over 2 years of ownership and passing every wof so far as well as never really letting me down apart from the few times it hasn't wanted to start. there are a few issues with the old girl...after last years hamner meet it picked up a vibration in the drive train.(still looking into that. the motor starts and runs well but it blowing smoke (valve guides are stuffed .(working on that now) so i do have a 205 pinto motor in bits so im going to rebuild that and to factory spec ...no interested in huge cams and twin side drafts ..im happy with the motor in my cortina now so just want the same....its good on gas and can pull a trailer with another car on it fine. so i started cleaning up the old 205 pistons. -

got into some more rust on the passenger side front...got the front edge done and the area around the bonnet hinge mount. (the drivers side was mint so i made a template of that)

-

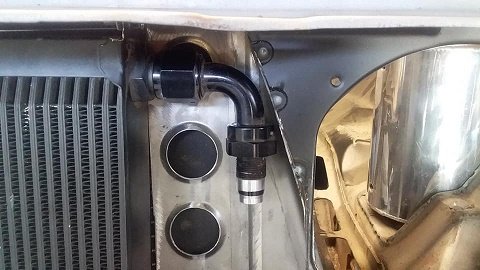

luckily i left enough room for the oil cooler 90. finished up the last of the radiator supports ..(still just silps up under the lip and had 2 brackets on the bottom.) then made the new slam panel...(i had to bolt the bonnet on and drill the pilot hols for the bonnet pins just to see where they would land...before i start)

-

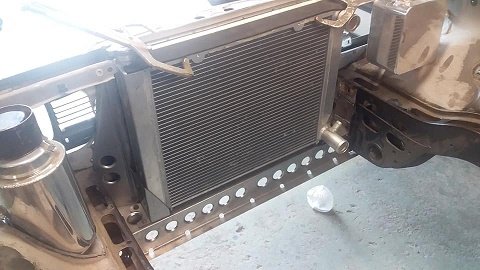

made the bottom radiator brackets.(was going to flod up some alloy tabs and weld them to the rad but i want to be able to get replacement parts off the shelf and bolt them in with out modifying them ) still need to do some trimming on them but they work..i also used adhesive rubber on all the rad sides.

-

well thats the fan,oil cooler and front suppprt panel done. Had to cut more oit of the front.(fuck all between the lights now) Added some strengthening to the panel Even just tacked in the front feels stronger and still more to go. Its a bit tight behind it but i can still get the gan and oil cooler in and out fine. Can still get ghe grill on and a 70mm rad in and still have all the engine bay left.

-

-

didnt even try it Pete. just fucked with it as soon as i seen it out of the box.

-

yup....its shit ...had to hold steel....top plate and fucking do up clamps ....didn't have enough hands

-

your not wrong mate its around 700mm long and the 1st decent bit i wanted to fold was 810 so had to do it at work any way. i would love a sold one around 1.5m but this will do for what i need.

-

for the cross member mate....pretty much the plan. as for the tools....eastwood 8" bead roller .. the folder was the cheapest i could find on trademe (and it was shit..had to modify it to make it bend a decent edge.) think i have some pics and the dimple die was made by one of our members as a side line

-

i bought a few things after xmas mate as up until then i was still bending steel over the edge of my bench and i wanted to see what i can do with half way decent tools...so bought a cheap bead roller ,folder and a 1"dimple die (didnt think i would use much else and not cheap).and a 12ton press.

-

made some ends to cap off the bottom plate....just all tacked in for now.. the i had a look at the fan and oilcooler support panel...just had to make sure i could get the grill on...and be able to remove and replace fan and oil cooler if needed....before i weld the panel fully in..

-

to be honest its the bog and sanding i hate the most...dont mind the rust..love the fab....hate the the fuller sanding shit...love the final paint prep and love the painting.....hate the buffing lol

-

thankd man... I wanted to do all the rust work before i start on fab work... but it has to be done and its a welcome brake from rust

-

-

got some gas so finished the passenger side sill then moved on the the rust in the passenger side wheel well then the passenger outer guard and the passenger rear 1/4 the there is the front....i wanted to do the front lower panel rust..but i realized i needed to make the radiator support parts first and to do that i needed to cut everything thing out i didn't want.

-

-

the passenger side sill....it was smashed in ...i tried with my huge dent puller but decided to cut into it........till the gas run out.

-

cheers mate....

-

started on the passenger underside got a small patch done on the floor got the cap at the end of the sill done. the jack brace looked but looking from the inside it was rusted so i cut it out cleaned it up welded in a new brace and welded back on. and then moved onto the area under the pasenger headlight...i know its not factory shape but with a couple of holes it will drain heaps better