- Popular Post

-

Posts

37,286 -

Joined

-

Last visited

-

Days Won

346

Content Type

Forums

Downloads

Events

Gallery

Posts posted by Nominal

-

-

Bush lawyer alert!

-

1

1

-

-

Breakpoints in the rules, just like the daft 6 month WOF rule for pre-2000 vehicles.

-

Good luck!

(I did check the entry certification rules and they point to the same link so you should be OK...................)

-

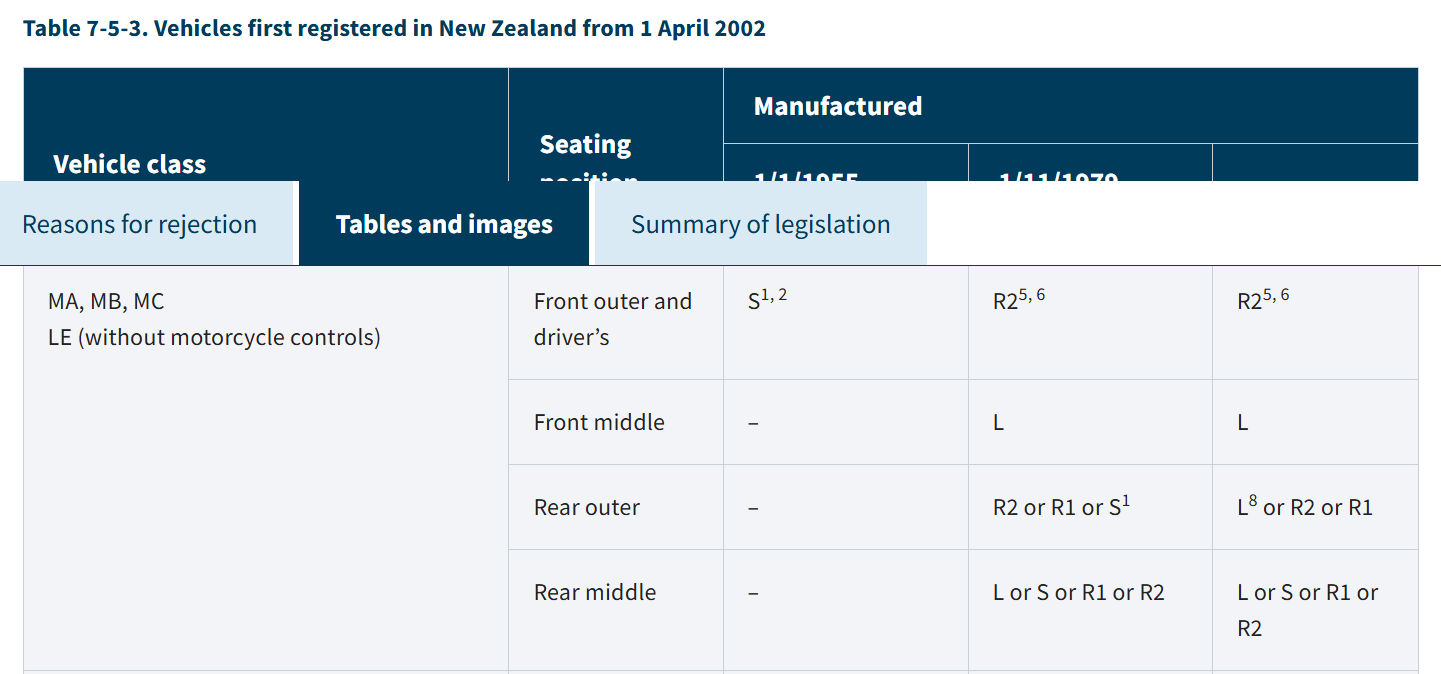

22 minutes ago, anglia4 said:

My Galaxie is advertised from new as being a 10-seat option and I want to register it as such.

Being a 67, it doesn't require rear seat belts, so I'm not fussed about that. But to achieve the 10-seat thing, it has 3 seats across the front bench, but currently only 2 seat belts.

I'm assuming I'll need the third lap belt in the front for my VIN check guys to sign it off as 10 seats. Is it OK to bolt in a lap belt that shares the bolt holes with the other two belts?

I was just going to take out all of the rear belts and use one of them in the front for the inspection so that they all match.

A couple of my old cars have the front middle lap belt done like that.

But you shouldn't need a front middle seatbelt according to the VIRM, just Static (or OEM) on the front outers.

Seatbelts and seatbelt anchorages | Vehicle Inspection Portal

-

1

1

-

-

13 minutes ago, Bling said:

That sucks about the power tripping, not getting in with the charge you're expecting is annoying, been there. The USB issue might be the one DriveEV recondition and sell on their website, you may have already seen it anyway, just mentioning in case not. Handy being able to charge at work, will certainly have dropped the household fuel bill I bet.

Plus not having to stop at Morrinsville Waitomo and fill up in the rain

If only someone would buy the Lexus I'd be happy.

-

2

2

-

-

19 minutes ago, Bling said:

@Nominal how are you finding LEAF life so far?

It's a fine solution for my use case - 100km each way commute. I use about 60% of capacity in the cold mornings, a bit less on the return trip when its warmed, but can charge some at the office.

A couple of times the charger circuit has tripped (at home) so it isn't fully charged. Not sure why that happens, but I've started checking its working OK before bedtime.

USB socket for the Android Auto is flakey so I need to replace that soon.

-

3

3

-

-

The controlled chargers would only be applicable to a proper wired-in smart charger, not the plug-in style.

-

-

2

2

-

1

1

-

-

14 minutes ago, igor said:

Used to? Is ripple control not a thing anymore?

Plenty of retailers offer controlled plans. Don't know if it works everywhere. Probably some are smart meter controlled these days

-

1

1

-

1

1

-

-

Returnless is actually pretty common in OEM these days.

Some link I found from 2014.

-

1

1

-

-

Or the odometer is way out?

-

- Popular Post

- Popular Post

-

You have a bike?

-

I had a gen 2 for a while, cheap but a bit rusty. All good until it died and I sold it

(I don't think it was anything serious, maybe a CAS)

-

-

On 25/06/2025 at 00:34, fletch said:

Delta is the faster more powerful winding. I would set it to that and hook up the drive.

LAG HAST means Make Haste.

Star is slower. HOG HAST is Hurry Up.

Lol.

Plugged it in today and it didn't go bang or let any smoke out so thats good. Even spun the motor in the correct direction. I need to check the oil level in the head before I run it too much.

Thanks for the help!

-

2

2

-

-

If it's dereg then the plate means nothing. Registered owner doesn't equal legal ownership anyway.

All you should need is a receipt from the current owner I think, then work through the entry cert process

-

3 hours ago, a.craw4d said:

https://www.facebook.com/share/1RH1rTCqwT/?mibextid=wwXIfr

Dereg cubic in Christchurch. Anyone keen to go have a look?

Good plate too, if your grandma drives it.

-

2 hours ago, 87creepin said:

Well, everyone who replied on the choice picked the Paj (or bighorns) and you bought the Terrano?

-

5

5

-

3

3

-

-

16 minutes ago, xsspeed said:

im just tryna get a longer deck

I thought you had a Falcon wagon?

Or build a Dynafari?-

1

1

-

-

Steeb always has dudes available.

-

1

1

-

-

11 minutes ago, yoeddynz said:

Yeah even my mum thought ours was too mint so she backed into it

Insurance job for later this year.

Insurance job for later this year.

Better get her a K11 then.

-

Have you been reading the unofficial lvvta page on FB again?

Man that place has some numpties.-

4

4

-

-

What, you mean I can't run 185 radials on my Morris Minor any more????????

-

1

1

-

1

1

-

2L Turbo Piazza Engines

in Tech Talk

Posted

Quality thread dredge @kermet, thanks for fixing the pics