-

Posts

67 -

Joined

-

Last visited

Everything posted by Themi

-

Ok, finally a bit more progress. Firstly, to address the last video. I believe cylinder 4 was missing in that video contributing to the rasp. It wasn't bad, but I do think it was running as a 3 cylinder. We want it to make it to beach hop next weekend! Likely driving down on the Wednesday, so a warrant will need to happen in the next uh, 10 days?! That will include the first fail, fixing things, and a recheck... So over the last two weekends we did some very boring things, namely: Tidied the last of the wiring in the engine bay Unknowingly damaged some important wires tidying the wiring Realised the car wont start, removed the dash, repaired the wiring Fixed the windscreen washer hosing+pump Added a horn Removed the rear swaybar+links, as all bushings were toast, and I don't think it is a requirement to pass a wof. Replaced all damaged bulbs Replaced the dash Added heater controls Somehow broke the windscreen washer stalk wiring? Fixed a misfire on Cyl4 caused by my bad crimping on the injector wire Tidied up some minor surface rust Took it for a short hoon up and down the road, felt waay better with 4 cylinders instead of 3... Started acting up again at the end, but it could be anything from another botched crimp job to tune. So what we have left to do, we think: Replace right front park light Find out what happened to the windscreen washer stalk Swap wheels to some which have tread left on the tyre (also the current ones are quite flat, just steelies to roll around on) Jerry rig some loom extender for the windows to go up and down? (creature comfort, not mission critical) Install battery tie down and passenger ecu cover/kick panel (on courier) It doesn't feel like much has to get done, but every list of 3 items to repair ends up becoming 14... Picture for fun just to show how small the engine is even in a tiny car. Will it pass wof? Find out next time...

-

New video of it driving from yesterday. New wideband revealed my accel enrichment was very low, managed to clean it up so it accelerates not too badly. Still hesitates when at WOT which I believe is the base map. We also removed the dash and continued the arduous process of tidying up all of the wiring in preparation for a warrant. Video of 1-2 shift: Google Drive

-

More small changes. Probably getting boring but it's progress. Air filter is somewhat back on. I'm going to get a smaller clutch master/reservoir so I don't need the hacked up bit at the back of the filter (it was adjusted to make space). Wires were tidied up on top of the engine, just wrapped in some tesa tape. Does the job, looks way better than the kapton/tefzel rainbow happening before. Although I tell myself this every time I touch it, the car is very close to warrant. Bulbs, horn, tyres, wipers, coolant bleed, finish tidying wiring, alignment, mild road tune, that's about it. Oh and a bonnet, it needs it's bonnet back. I also need to sort out the wideband. It is an innovate lc-2 reading full lean (~22:1) 95% of the time, then 5% of the time it reads somewhere normal (13:1). I'm aware this can be a faulty sensor(unlikely), bad wiring (likely), an exhaust leak (likely) or a misfire (likely). The sensor has been in the exhaust but not plugged in for a while, so it is likely very sooty. I'll need this back for the road tune to get it to a wof place. Pictures are kind of just for fun, not much visually different from last time.

-

A few small updates: - tidied the heater core hoses using a hacked up VS commodore heater hose (nice 90 and 150° bends) - shortened the fuel hoses - plugs, coolant, oil, oil filter... Old oil smelled of petrol and looked dirtier than diesel oil, thinner than water! A lot of unburnt petrol in the oil from test runs, oops - sanded and primed a small amount of surface rust - replaced valve cover with one which had baffles (never replaced baffles on old cover) - tidied up a bit of wiring. Still needs to be wrapped/sleeved/heat shrink. I'm back at uni full time, and have very busy weekends so progress is slow. Still starts, runs, drives. Tidying up the tune today made it run a fair bit better!

-

Ah I've been pretty busy with work and other things (excuses). Currently in need of a battery, but need funds and am trying to save for a daily. Slightly more recent video Driving (no tune)

-

Only if your head gasket is too thin. The engine turns over fine with no head gasket at all but once it's running expansion and momentum makes them touch a bit. It'll still run but not well haha. Oops. The minimum recommended piston to head clearance is 1mm, so a HG that has 1mm or more thickness once compressed is suitable.

-

Anyway here are some misc photos of it making progress in the engine bay. No particular order, I am pretty bad at taking photos. The entire engine and under-dash wiring loom was stripped of loom tape and new wires were run to everything on the engine. Very few photos of this exist, and most of it was re-done as the tesa tape looked horrible. I am using a UA4C ecu from WTMTronics, a derivative of the Speeduino. It works very well and is cheap. Would recommend for anything as long as your tuner is happy to touch it. Anyway, here is the "best" video of it running. The idle screw is unwinding (can be seen spinning at the beginning) which is why it begins to bog towards the end. It is currently sitting in the garage waiting for funds/time/motivation. https://drive.google.com/file/d/11gpFfCK5PV8uKShx7Vq8-_dCq--VkD4v/view?usp=sharing Some theoretical numbers: ZL-VE has 96kW@7000rpm 141Nm@4000rpm with 1.5L and 9.4:1 comp (torque peak is much lower, thanks to the S-VT) B6DE has 90kW@6500rpm 136Nm@5500rpm with 1.6L and 9.4:1 comp My thinking was that higher displacement with the benefits of the ITB's and VVT will pull that peak torque even lower, which is by far my biggest complaint of the 1.6L mx5. Additional responsiveness would be nice. I believe the ZL-VE has a slightly smaller combustion chamber, pulling the new setup to around 9.9:1 as it is, ideally 10.5:1 or 11:1 would be where I leave it if I built a new motor.. Other points: The thermostat for the ZL-VE is at the back of the head, you practically have to conduct a coolant reroute. The ZL-VE has a section in the combustion chamber that is flush with the head surface. As the B6 has a +-0 piston-deck height, you need a head gasket of at least 1mm compressed, no tiny MLS gaskets or pistons will hit the head. The oil feed for the S-VT (Sequential valve timing) does fit with a bit of bending to get around the alternator bracket, in the end I went to GSS and had one made for me with provisions for a honeywell oil pressure sensor. The two additional oil drains in the head had to be blocked (just used freeze plugs). I figured it wont harm anything, yes there is more oil in the head. Lower timing belt pulley/sprocket should be from the ZL-VE as it has less teeth on the cam gears. The reluctor wheel on the cam has 1 tooth on 1 side, and 2 teeth on the other side 180* apart. It uses the same style cam sensor as the engines in the NB MX5. (EDIT: Grinding off the 2-teeth allows a single-tooth cam trigger to be configured with a high-resolution crank trigger wheel) The oil pump is what has the bolt hole for the crank position sensor, if possible get the oil pump from the ZL-VE (should work but not tested) or VVT MX5's as they are designed to put out the additional oil required by the VVT. I had to space my crank sensor and have it offset from its usual position. You will need a different alternator or some other setup for the crank position sensor as the ZL-VE trigger wheel spaces the crank out perfectly for the NA8 alternator but is 4pk unlike the NA6 alternator. Swapping pulleys with some spacer setup might work. The NA8 alternator is unique that it is 4pk style but internally regulated, a requirement as the UA4C does not handle alternator regulation. With regards to particular details, please ask anything that is not covered. Future goals: I have a second head. Going to clean it up the same, send the cams to be re-ground (will need shimming, solid lifter). Get a second B6, get some slightly higher-comp pistons that will still work with this head (need to do the maths on combustion chamber size), rods and the aforementioned BP VVT oil pump. Build this motor outside of the car. Modify some off-the-shelf headers to suit instead of these ugly things. I am a firm believer that I will not need cert for this car. Haven't taken it for a warrant but cannot see why I would, it is the stock block and probably makes similar power to factory. How it looks today: Thanks

- 68 replies

-

- 14

-

-

I'll now talk about the exhaust side and show everyone why you should never let me work on your car. Exhaust: The exhaust ports are not spaced evenly, and does not share pattern with any RWD car so I opted to weld some headers from stainless, more as a learning point than anything. I had some 10mm stainless plate waterjet cut by a friend to match the ports. The 1.25" stainless tube was cheap as chips, and i kid you not the argon + tube + cutoff saw + swearing was cheaper than buying bends to use. Also, it was my first time welding so figured I may as well get some practice in (it is awful, yes, but it was fun). This was the first time the head went into the car, as it is tough to make an exhaust manifold without knowing clearances (turns out there is a lot of space). I plan on replacing these with some high-rise headers later likely from a B6, 4age, 3sge etc., something I can find from a site like cxracing and chop up without worrying too much about wasting a lot of money. Ignition: Next I needed a solution for ignition that was not the factory mazda system, as that uses a coil pack on the back of the block and isn't very good. Opting for the typical Toyota COP's (cheap replicas in the pictures) but then finding out they don't fit in the spark plug wells... I had to get creative. So that is kind of the hardware for headers and spark done. Horrible, yes, but functional.

- 68 replies

-

- 11

-

-

Sorry ~Slideways~ for hijacking the thread - spun off into my own one here about the ZL-VE head. I'll be watching your progress too!

-

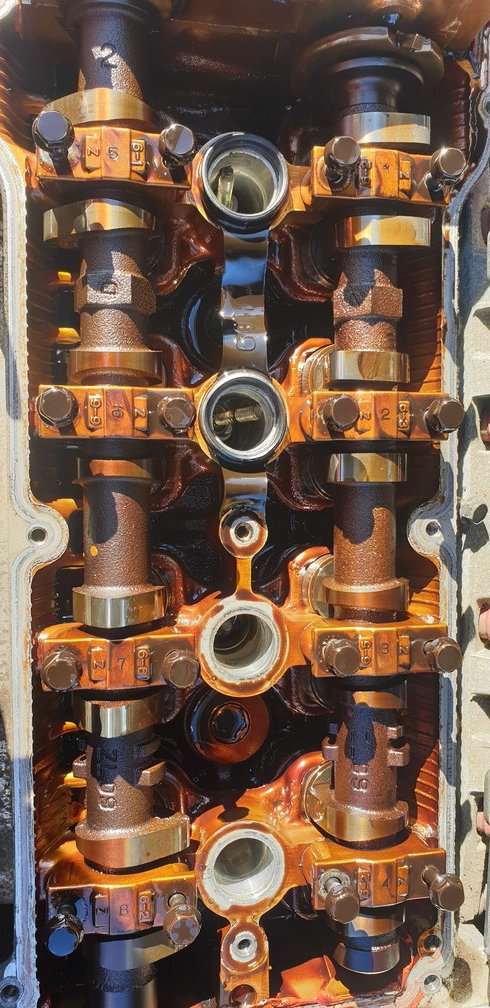

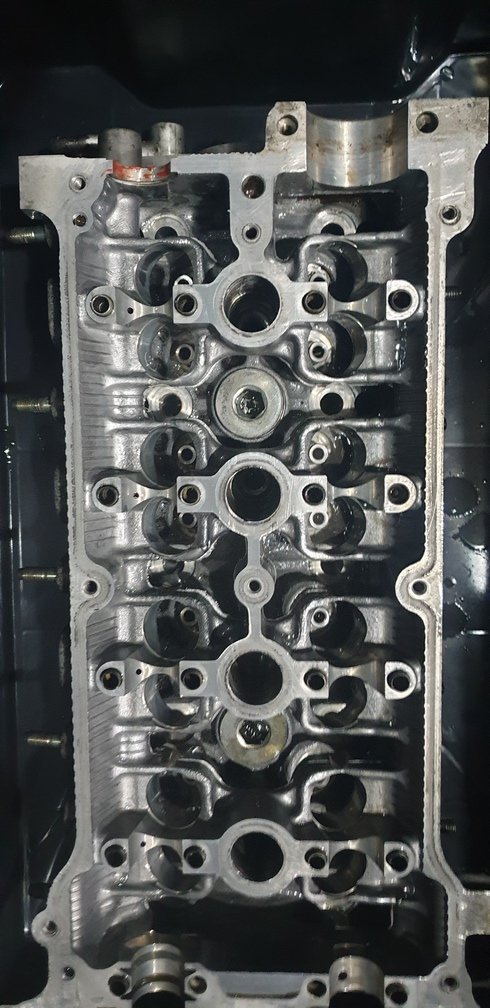

So now that we have the head and it is somewhat clean (actually maybe I did not clean it until later, but still) we need to look at what this head is and why it is being used. The elephant in the room is that the ZL-VE head came FWD only, in a Familia. Specifically around 2001-2003 is what I could find, but there are also the 2.0L Familia's, the 1.6L ZM-DE and the 1.5L ZL-DE. The ZM-DE (Z6) head had been done in the thread linked above (2012). The benefits of the head were larger but steeper port angles, shallower combustion chamber and a few others. I assumed the ZL-VE would have the same steeper port angles and large ports which it did. The lower displacement of the ZL-VE motor was entirely in stroke, but similar compression ratio meant there must be either a difference in pistons or lower combustion chamber volume (both are true). Intake: Here is the ZL-VE intake gasket on the stock B6 head. There was no longitudinally oriented engine with the same intake/exhaust ports. This meant custom intake, custom exhaust and likely more. I hunted around for a little while for some ITB's from a 4age, as in my mind an ITB adapter would be easier than an intake plenum for a singular throttle body. I chopped up a 4age intake manifold with a hacksaw (never again...) and chopped up the stock ZL-VE intake manifold with a mixture of angle grinder and hacksaw. We are on our way to an intake manifold. I used JB-weld to attach them together for testing, and skipping forward a few months ended up tig welding them together. I have a HF DC-TIG welder but no AC-TIG, so aluminium welding cannot happen at home. If you spot JB-weld, it was temporary. If you spot shit welding, thats because I'm a shit welder. Intake manifold complete (ish).

- 68 replies

-

- 11

-

-

-

Idea: I stumbled across the B6/ZM-DE (2012 below) build thread and decided to do some research into the possibilities of head swaps for the 1.6L B6 that came in the car. These were the only mentions I could find now, but I am sure back when I was first investigating the possibilities of the swap there were more. Links, oldest to newest: 2004 (mazda3club.com) 2008 (mazdas247.com) 2008 (trinituner.com) 2011 (forum.miata.net) 2012 (miataturbo.net) Why was this idea so special? Because I could not find anyone who had done it. Also other reasons, which will be revealed later. I chose to get the ZL-VE head, as it seems it will still work but has the benefit of VVT. Also, rough napkin calculations suggested a minor bump in compression. Purchasing and Cleaning: So now that it was an idea I could not get out of my head, the next step was actually attaining one of these heads. PaP it is! Got an absolute steal (unlike my usual trips), I believe I paid $120 for head w/valve cover, intake manifold, injectors, alternator, lower timing pulley and timing covers. Then the most important step: cleaning... In the next post I will discuss the "benefits" of this head/swap.

-

Background: After accidentally hijacking Gavs/~Slideways~ build thread, thought I should make one of my own. Here is my 1991 hunk-o-junk. I purchased the car in Whangarei, was driven up to collect it and took it back to Auckland. Did not check for rust as well as I should have, however ended up getting a gem. The car was always meant to be a daily, but we kind of know how that goes. It lasted about 6 months of minor changes here-and-there. The big issue right from the get go was the plasti-dipped exterior and weird racing strip. It obviously meant the paint would be rough underneath and plasti-dip is a real pain to remove. I've been trying everything possible to remove it, and in the end a good solvent and some elbow grease ended up being the play. Additionally, the car had no power steering and the A/C was NFG, which is an expensive fix due to being r12 not r134a and not technically legal anymore. I did all the fun road-trip things you are supposed to do in a newer car. Engine was running well, gearbox was smooth, clutch was fine (for now). Ended up changing the clutch about 3 months in after being "that guy" merging into a motorway at 60km/h trying to baby the clutch. Around this time I noticed the diff was playing up, and it wasn't. Turned out I have the mazdaspeed 6" clutch-type LSD (as well as mazdaspeed adjustable dampening shocks and mazdaspeed upgraded swaybars). Turns out the car was a good buy after all! Also had a run-in with some shitheads thieves. Fortunately they didnt break anything, just my faith in humanity but it was a good lesson to not leave my car parked outside! Anyway, the positives and negatives: +It ran and drove +Mildly upgraded (kinda old) suspension parts +Clutch-type LSD +Plenty of boot space +Mint soft-top with glass window +Decent interior -Sounds bad -Looks bad -Slow Now that we know whats wrong with it, why don't I go ahead and modify literally everything that doesn't help those three points? Good idea... (Keep in mind I am a student, most of the "Why did you not just pay someone to do it" questions I usually receive can be answered by lack of funds).

-

About 9.9:1 according to my bad maths. Smaller combustion chamber volume on the zl-ve head. The shallower valves also supposedly increase knock-resistance.

-

Really tough to say. ZLVE has 96kW@7000rpm 141Nm@4000rpm with 1.5L and 9.4:1 comp B6DE has 90kW@6500rpm 136Nm@5500rpm with 1.6L and 9.4:1 comp My thinking was that higher displacement with the benefits of the ITB's and VVT will pull that peak torque lower, which is by far my biggest complaint of the 1.6L mx5. Additional responsiveness would be nice. Your gsxr ITB setup will be cool - bike throttles are probably the way to go and those look to be a very good bore size for the engine. I can attest the Speeduino is a good platform with lots of support. Look forward to seeing where that car goes.

-

The head really is tiny, ports are massive and port angle is a bit steeper. I don't want to hijack the thread so I'll leave it at this photo, but it's my favorite one showing just how compact the zlve head is! Not having the front waterneck was big too, as well as no AC and manual rack.

-

Someone sent me a screenshot of your discussion regarding a 1.5l ZL-VE vvt head on the b6 block. Well, I did it and will say it is a lot of hassle. Fun learning process but heaps of work. I've got videos of it running, currently sitting nfg in the garage due to lack of funds/time/motivation. I've got a second head sitting nearby which was going to get new valves, cams sent for regrind etc. If you are actually interested in the process there are so many things I learned along the way which I wish I knew before I started and would be happy to share. It took 4age itb's to replace the intake which faces the wrong way, new exhaust manifold because the stock one points straight down, new cooling setup as it was fwd, all wiring was different, oil feed had to be changed from the one in this picture too. https://drive.google.com/file/d/11gpFfCK5PV8uKShx7Vq8-_dCq--VkD4v/view?usp=sharing Note in the video that the low idle screw was unwinding hence why it starts bogging. It was also not tuned at all. Running it on a Speeduino too, UA4C from WTMtronics.